Tiger Nut (Cyperus esculentus) as a Functional Ingredient in Gluten-Free Extruded Snacks

Abstract

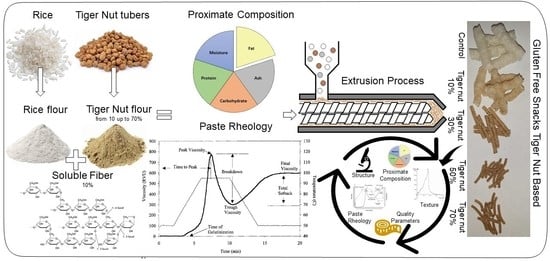

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Tiger Nut Milling and Blends Preparation

2.3. Modified Feeding Device and Extrusion Processing Conditions

2.3.1. Modified Feeding Device

2.3.2. Extrusion Processing Conditions

2.4. Proximate Analysis

2.5. Apparent Viscosity

2.6. Microstructure Analysis

2.7. Final Products Quality Parameters

2.8. Total Soluble Phenolics and Total Antioxidant Capacity of Final Products

2.9. Statistical Analysis

3. Results and Discussion

3.1. Raw Blends Characteristics

3.2. Extruded Products Characteristics

3.3. Total Soluble Phenolics and Total Antioxidant Capacity of Extruded Snacks

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, P.; Arora, A.; Strand, T.A.; Leffler, D.A.; Catassi, C.; Green, P.H.; Kelly, C.P.; Ahuja, V.; Makharia, G.K. Global prevalence of celiac disease: Systematic review and meta-analysis. Clin. Gastroenterol. Hepatol. 2018, 16, 823–836. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diez-Sampedro, A.; Olenick, M.; Maltseva, T.; Flowers, M. A gluten-free diet, not an appropriate choice without a medical diagnosis. J. Nutr. Metab. 2019, 2019, 2438934. [Google Scholar] [CrossRef] [PubMed]

- Kharat, S.; Medina Meza, I.G.; Kowalski, R.; Hosamani, A.; Hiregoudar, S.; Ganjyal, G. Extrusion processing characteristics of whole grain flours of select major millets (Foxtail, Finger, and Pearl). Food Bioprod. Process. 2018, 114. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Sánchez, C.; Cuadrado, C.; Guillamón, E.; Pedrosa, M. The impact of extrusion on the nutritional composition, dietary fiber and in vitro digestibility of gluten-free snacks based on rice, pea and carob flour blends. Food Funct. 2017, 8, 3654–3663. [Google Scholar] [CrossRef]

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Technol. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Flores-Silva, P.C.; Rodriguez-Ambriz, S.L.; Bello-Pérez, L.A. Gluten-free snacks using plantain–chickpea and maize blend: Chemical composition, starch digestibility, and predicted glycemic index. J. Food Sci. 2015, 80, C961–C966. [Google Scholar] [CrossRef]

- Lohani, U.C.; Muthukumarappan, K. Effect of extrusion processing parameters on antioxidant, textural and functional properties of hydrodynamic cavitated corn flour, sorghum flour and apple pomace-based extrudates. J. Food Process. Eng. 2017, 40, e12424. [Google Scholar] [CrossRef]

- Alves, P.L.d.S.; Berrios, J.D.; Pan, J.; Ascheri, J.L.R. Passion fruit shell flour and rice blends processed into fiber-rich expanded extrudates. CyTA J. Food 2018, 16, 901–908. [Google Scholar] [CrossRef] [Green Version]

- Diaz, J.M.R.; Suuronen, J.-P.; Deegan, K.C.; Serimaa, R.; Tuorila, H.; Jouppila, K. Physical and sensory characteristics of corn-based extruded snacks containing amaranth, quinoa and kañiwa flour. LWT Food Sci. Technol. 2015, 64, 1047–1056. [Google Scholar] [CrossRef]

- Gasparre, N.; Rosell, C.M. Role of hydrocolloids in gluten free noodles made with tiger nut flour as non-conventional powder. Food Hydrocoll. 2019, 97, 105194. [Google Scholar] [CrossRef]

- Codina-Torrella, I.; Guamis, B.; Trujillo, A.J. Characterization and comparison of tiger nuts (Cyperus esculentus L.) from different geographical origin: Physico-chemical characteristics and protein fractionation. Ind. Crop. Prod. 2015, 65, 406–414. [Google Scholar] [CrossRef]

- Aguilar, N.; Albanell, E.; Miñarro, B.; Capellas, M. Chickpea and tiger nut flours as alternatives to emulsifier and shortening in gluten-free bread. LWT Food Sci. Technol. 2015, 62, 225–232. [Google Scholar] [CrossRef]

- Demirkesen, I.; Sumnu, G.; Sahin, S. Quality of gluten-free bread formulations baked in different ovens. Food Bioprocess Technol. 2013, 6, 746–753. [Google Scholar] [CrossRef]

- Ahmed, Z.; Hussein, A. Exploring the suitability of incorporating tiger nut flour as novel ingredient in gluten-free biscuit. Pol. J. Food Nutr. Sci. 2014, 64, 27–33. [Google Scholar] [CrossRef] [Green Version]

- Kareem, S.T.; Adebowale, A.-R.A.; Sobukola, O.P.; Adebisi, M.A.; Obadina, O.A.; Kajihausa, O.E.; Adegunwa, M.O.; Sanni, L.O.; Keith, T. Some quality attributes of high quality cassava-tigernut composite flour and its extruded snacks. J. Culin. Sci. Technol. 2015, 13, 242–262. [Google Scholar] [CrossRef]

- Martín-Esparza, M.; Raigón, M.; Raga, A.; Albors, A. High fibre tiger nut pasta and xanthan gum: Cooking quality, microstructure, physico-chemical properties and consumer acceptance. Food Sci. Biotechnol. 2018, 27, 1075–1084. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, Z.S.; Abozed, S.S.; Negm, M. Nutritional value and sensory profile of gluten-free tiger nut enriched biscuit. World J. Dairy Food Sci. 2014, 9, 127–134. [Google Scholar]

- Robin, F.; Schuchmann, H.P.; Palzer, S. Dietary fiber in extruded cereals: Limitations and opportunities. Trends Food Sci. Technol. 2012, 28, 23–32. [Google Scholar] [CrossRef]

- Moscicki, L.; van Zuilichem, D.J. Extrusion-cooking and related technique. In Extrusion-Cooking Techniques: Applications, Theory and Sustainability; Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 1–24. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis of the Association of Official Analytical Chemists; Association of Official Analytical Chemists: Rockville, MD, USA, 2020. [Google Scholar]

- Berrios, J.D.J.; Wood, D.F.; Whitehand, L.; Pan, J. Sodium bicarbonate and the microstructure, expansion and color of extruded black beans. J. Food Process. Preserv. 2004, 28, 321–335. [Google Scholar] [CrossRef]

- Patil, R.; Berrios, J.D.J.; Tang, d.J.; Swanson, B. Evaluation of methods for expansion properties of legume extrudates. Appl. Eng. Agric. 2007, 23, 777–783. [Google Scholar] [CrossRef]

- Nayak, B.; Berrios, J.D.J.; Powers, J.R.; Tang, J. Effect of extrusion on the antioxidant capacity and color attributes of expanded extrudates prepared from purple potato and yellow pea flour mixes. J. Food Sci. 2011, 76, C874–C883. [Google Scholar] [CrossRef] [PubMed]

- Patel, P.; Ellis, K.; Sunkara, R.; Shackelford, L.; Ogutu, S.; Walker, L.T.; Herring, J.; Verghese, M. Development of a functional food product using guavas. Food Nutr. Sci. 2016, 7, 927–937. [Google Scholar] [CrossRef] [Green Version]

- Adegunwa, M.; Adelekan, E.; Adebowale, A.; Bakare, H.; Alamu, E. Evaluation of nutritional and functional properties of plantain (Musa paradisiaca L.) and tigernut (Cyperus esculentus L.) flour blends for food formulations. Cogent Chem. 2017, 3, 1383707. [Google Scholar] [CrossRef]

- Yanniotis, S.; Petraki, A.; Soumpasi, E. Effect of pectin and wheat fibers on quality attributes of extruded cornstarch. J. Food Eng. 2007, 80, 594–599. [Google Scholar] [CrossRef]

- Guy, R. Extrusion Cooking: Technologies and Applications; Woodhead Publishing: Cambridge, UK, 2001. [Google Scholar]

- Moraru, C.; Kokini, J. Nucleation and expansion during extrusion and microwave heating of cereal foods. Compr. Rev. Food Sci. F 2006, 2, 147–165. [Google Scholar] [CrossRef]

- Bisharat, G.; Oikonomopoulou, V.; Panagiotou, N.; Krokida, M.; Maroulis, Z. Effect of extrusion conditions on the structural properties of corn extrudates enriched with dehydrated vegetables. Food Res. Int. 2013, 53, 1–14. [Google Scholar] [CrossRef]

- Ilo, S.; Schoenlechner, R.; Berghofe, E. Role of lipids in the extrusion cooking processes. Grasas Aceites 2000, 51. [Google Scholar] [CrossRef] [Green Version]

- Bravo-Nunez, A.; Garzon, R.; Rosell, C.M.; Gomez, M. Evaluation of Starch-Protein Interactions as a Function of pH. Foods 2019, 8, 155. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, C.W.P.; Takeiti, C.Y.; Freitas, D.D.G.C.; Ascheri, J.L.R. Use of sesame oil cake (Sesamum indicum L.) on corn expanded extrudates. Food Res. Int. 2012, 45, 434–443. [Google Scholar]

- Lazou, A.; Krokida, M. Structural and textural characterization of corn–lentil extruded snacks. J. Food Eng. 2010, 100, 392–408. [Google Scholar] [CrossRef]

- Mohamad Mazlan, M.; Talib, R.A.; Mail, N.F.; Taip, F.S.; Chin, N.L.; Sulaiman, R.; Shukri, R.; Mohd Nor, M.Z. Effects of extrusion variables on corn-mango peel extrudates properties, torque and moisture loss. Int. J. Food Prop. 2019, 22, 54–70. [Google Scholar] [CrossRef] [Green Version]

- Yağcı, S.; Göğüş, F. Response surface methodology for evaluation of physical and functional properties of extruded snack foods developed from food-by-products. J. Food Eng. 2008, 86, 122–132. [Google Scholar] [CrossRef]

- Duarte, G.; Carvalho, C.; Ascheri, J. Effect of soybean hull, screw speed and temperature on expanded maize extrudates. Braz. J. Food Technol. 2009, 12, 205–212. [Google Scholar] [CrossRef]

- Berrios, J.D.J.; Cámara, M.; Torija, M.E.; Alonso, M. Effect of extrusion cooking and sodium bicarbonate addition on the carbohydrate composition of black bean flours. J. Food Process. Preserv. 2002, 26, 113–128. [Google Scholar] [CrossRef]

- Cervantes-Ramirez, J.E.; Cabrera-Ramirez, A.H.; Morales-Sanchez, E.; Rodriguez-Garcia, M.E.; Reyes-Vega, M.D.; Ramirez-Jimenez, A.K.; Contreras-Jimenez, B.L.; Gaytan-Martinez, M. Amylose-lipid complex formation from extruded maize starch mixed with fatty acids. Carbohydr. Polym. 2020, 246, 10. [Google Scholar] [CrossRef] [PubMed]

- Thachil, M.T.; Chouksey, M.K.; Gudipati, V. Amylose-lipid complex formation during extrusion cooking: Effect of added lipid type and amylose level on corn-based puffed snacks. Int. J. Food Sci. Technol. 2014, 49, 309–316. [Google Scholar] [CrossRef]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional aspects of Food extrusion: A review. Int. J. Food Sci. Technol. 2007, 42, 916–929. [Google Scholar] [CrossRef]

- Melini, V.; Melini, F. Gluten-Free Diet: Gaps and Needs for a Healthier Diet. Nutrients 2019, 11, 170. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Zapata, E.; Fernández-López, J.; Angel Pérez-Alvarez, J. Tiger nut (Cyperus esculentus) commercialization: Health aspects, composition, properties, and food applications. Compr. Rev. Food Sci. F 2012, 11, 366–377. [Google Scholar] [CrossRef]

- Adebowale, A.; Kareem, S.; Sobukola, O.; Adebisi, M.; Obadina, A.; Kajihausa, O.; Adegunwa, M.; Sanni, L.; Keith, T. Mineral and antinutrient content of high quality cassava-tigernut composite flour extruded snack. J. Food Process. Preserv. 2017, 41, e13125. [Google Scholar] [CrossRef] [Green Version]

- Roselló-Soto, E.; Garcia, C.; Carpin, A.; Barba, F.; Munekata, P.; Lorenzo, J.M.; Remize, F. Nutritional and microbiological quality of tiger nut tubers (Cyperus esculentus), derived plant-based and lactic fermented beverages. Fermentation 2018, 5, 3. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Raw Blends | ||||

|---|---|---|---|---|---|

| Control R | R1 | R2 | R3 | R4 | |

| Proximate Composition | |||||

| Moisture (g/100 g) | 11.76 ± 0.12 e | 11.52 ± 0.06 d | 10.66 ± 0.09 c | 9.58 ± 0.08 b | 8.72 ± 0.04 a |

| Protein (g/100 g) | 5.02 ± 0.07 a | 5.34 ± 0.08 b | 5.71 ± 0.12 c | 6.08 ± 0.10 d | 6.30 ± 0.03 e |

| Fat (g/100 g) | 0.28 ± 0.01 a | 3.46 ± 0.08 b | 9.06 ± 0.00 c | 15.08 ± 0.06 d | 20.45 ± 0.19 e |

| Ash (g/100 g) | 0.36 ± 0.01 a | 0.51 ± 0.00 b | 0.80 ± 0.00 c | 1.15 ± 0.03 d | 1.46 ± 0.02 e |

| Carbohydrates (g/100 g) | 82.58 | 79.17 | 73.77 | 68.11 | 63.07 |

| Apparent Viscosity | |||||

| Onset temperature (°C) | 70.3 ± 0.9 a | 70.9 ± 0.8 a | 71.9 ± 0.4 a | 75.1 ± 1.3 b | 78.2 ± 1.1 b |

| Peak Time (min) | 5.7 ± 0.0 a | 5.8 ± 0.1 a | 5.8 ± 0.0 a | 5.8 ± 0.1 a | 7.1 ± 0.0 b |

| Peak viscosity (mPa·s) | 3980 ± 70 e | 3040 ± 60 d | 1630 ± 20 c | 710 ± 10 b | 290 ± 0 a |

| Trough viscosity (mPa·s) | 2130 ± 30 e | 1750 ± 100 d | 1080 ± 10 c | 630 ± 0 b | 280 ± 0 a |

| Breakdown (mPa·s) | 1850 ± 40 e | 1300 ± 40 d | 550 ± 10 c | 90 ± 10 b | 10 ± 0 a |

| Final viscosity (mPa·s) | 3140 ± 190 d | 2900 ± 100 d | 2100 ± 0 c | 1400 ± 20 b | 770 ± 10 a |

| Total Setback (mPa·s) | 1010 ± 220 bc | 1160 ± 0 bc | 1030 ± 10 c | 780 ± 10 b | 480 ± 10 a |

| Parameters | Extruded Samples | ||||

|---|---|---|---|---|---|

| Control E | E1 | E2 | E3 | E4 | |

| Apparent Viscosity | |||||

| Onset temperature (°C) | 50.5 ± 0.0 a | 50.4 ± 0.1 a | 70.4 ± 0.5 b | 79.9 ± 2.5 c | 87.2 ± 0.6 d |

| Peak Time (min) | 2.2 ± 0.0 a | 4.2 ± 0.2 b | 6.5 ± 0.2 c | 6.2 ± 0.0 c | 7.15 ± 0.1 d |

| Peak viscosity (mPa·s) | 100 ± 10 a | 150 ± 0 b | 300 ± 0 d | 510 ± 10 e | 210 ± 0 c |

| Trough viscosity (mPa·s) | 50 ± 0 a | 100 ± 0 b | 290 ± 0 d | 480 ± 10 e | 210 ± 0 c |

| Breakdown (mPa·s) | 50 ± 0 e | 40 ± 0 d | 10 ± 0 b | 20 ± 0 c | 0 ± 0 a |

| Final viscosity (mPa·s) | 80 ± 0 a | 170 ± 0 b | 680 ± 0 d | 1160 ± 10 e | 580 ± 0 c |

| Total Setback (mPa·s) | 30 ± 0 a | 70 ± 0 b | 390 ± 0 d | 670 ± 0 e | 370 ± 0 c |

| Quality Parameters | |||||

| Diameter (mm) | 10.19 ± 0.28 d | 9.27 ± 0.27 c | 3.46 ± 0.12 b | 2.53 ± 0.03 a | 2.51 ± 0.03 a |

| Expansion ratio | 16.63 ± 0.92 d | 13.78 ± 0.81 c | 1.92 ± 0.14 b | 1.02 ± 0.02 a | 1.01 ± 0.02 a |

| Bulk density (g/cm³) | 0.19 ± 0.02 a | 0.21 ± 0.01 a | 0.62 ± 0.01 b | 0.69 ± 0.02 c | 0.65 ± 0.02 b |

| True density (g/cm³) | 1.52 ± 0.01 d | 1.54 ± 0.01 e | 1.50 ± 0.01 c | 1.44 ± 0.01 b | 1.35 ± 0.00 a |

| Total Pore volume (cm³/g) | 0.34 ± 0.01 d | 0.35 ± 0.00 e | 0.33 ± 0.01 c | 0.30 ± 0.01 b | 0.26 ± 0.00 a |

| Firmness (g) | 712 ± 146 c | 922 ± 261 d | 242 ± 52 a | 367 ± 39 b | 313 ± 73 ab |

| Work of Shear (g·s) | 11 ± 3 b | 19 ± 6 c | 2 ± 1 a | 4 ± 1 a | 4 ± 1 a |

| Proximate Composition | |||||

| Moisture (g/100 g) | 6.67 ± 0.07 b | 6.12 ± 0.04 a | 6.14 ± 0.06 a | 6.20 ± 0.05 a | 6.24 ± 0.02 a |

| Protein (g/100 g) | 4.65 ± 0.13 a | 4.87 ± 0.07 b | 5.25 ± 0.09 c | 5.57 ± 0.06 d | 5.83 ± 0.04 e |

| Fat (g/100 g) | 0.05 ± 0.01 a | 1.47 ± 0.01 b | 6.62 ± 0.02 c | 14.11 ± 0.04 d | 19.32 ± 0.14 e |

| Ash (g/100 g) | 0.36 ± 0.00 a | 0.67 ± 0.02 b | 0.93 ± 0.01 c | 1.22 ± 0.02 d | 1.52 ± 0.01 e |

| Carbohydrates (g/100 g) | 88.26 | 86.87 | 81.07 | 72.90 | 67.09 |

| Total Soluble Phenolics Gallic acid Equivalent (µg/mg) | 10 ± 0.00 a | 110 ± 0.00 b | 240 ± 0.01 c | 550 ± 0.02 d | 720 ± 0.03 e |

| Antioxidant Capacity Trolox Equivalent (µg/g) | 533 ± 17 a | 596 ± 15 b | 730 ± 10 c | 852 ± 10 d | 937 ± 9 e |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gasparre, N.; Pan, J.; da Silva Alves, P.L.; Rosell, C.M.; De J. Berrios, J. Tiger Nut (Cyperus esculentus) as a Functional Ingredient in Gluten-Free Extruded Snacks. Foods 2020, 9, 1770. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9121770

Gasparre N, Pan J, da Silva Alves PL, Rosell CM, De J. Berrios J. Tiger Nut (Cyperus esculentus) as a Functional Ingredient in Gluten-Free Extruded Snacks. Foods. 2020; 9(12):1770. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9121770

Chicago/Turabian StyleGasparre, Nicola, James Pan, Priscila Leal da Silva Alves, Cristina M. Rosell, and Jose De J. Berrios. 2020. "Tiger Nut (Cyperus esculentus) as a Functional Ingredient in Gluten-Free Extruded Snacks" Foods 9, no. 12: 1770. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9121770