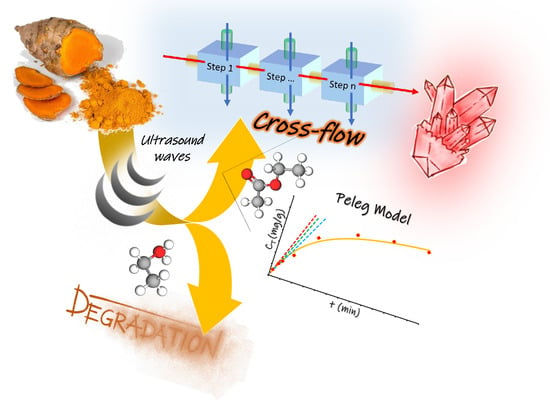

A Cross-Flow Ultrasound-Assisted Extraction of Curcuminoids from Curcuma longa L.: Process Design to Avoid Degradation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Curcuma longa L. Matrix

2.3. Curcuminoid Stability Tests under US

2.4. Ultrasound-Assisted Extraction (UAE)

2.5. Conventional Extraction

2.6. Curcuminoid Determination

2.7. NMR Quali and Quantitative Analyses

2.8. Statistic Treatment

2.9. Kinetic Model

2.10. Crystallization

3. Results

3.1. Curcuminoid Stability Test

3.2. Total Curcuminoid Content Determination

3.3. US-Assisted Extraction

3.3.1. Kinetic Model—Single-Step UAE

3.3.2. Cross-Flow UAE

3.4. Crystallization

4. Discussion

4.1. Curcuminoid Stability Test

4.2. US-Assisted Extraction

4.2.1. Kinetic Model—Single Step UAE

4.2.2. Cross-Flow UAE

4.3. Crystallization

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| t | Curcuminoid Yield ± %SD | Bt a | Linearization | |

|---|---|---|---|---|

| min | % | t/Ct b | ||

| 0 | - | - | - | |

| 2 | 0.057 | ± 0.23 | 0.0285 | 35.0877 |

| 5 | 0.12 | ± 0.21 | 0.024 | 41.6667 |

| 7.5 | 0.144 | ± 0.32 | 0.0192 | 52.0833 |

| 15 | 0.1857 | ± 0.29 | 0.0124 | 80.7754 |

| 30 | 0.231 | ± 0.37 | 0.0077 | 129.8701 |

| 60 | 0.2482 | ± 0.33 | 0.0041 | 241.7405 |

| 90 | 0.2563 | ± 0.24 | 0.0028 | 351.1510 |

| 120 | 0.2588 | ± 0.24 | 0.0022 | 463.6785 |

| t | Curcuminoid Yield ± %SD | Bt a | Linearization | |

|---|---|---|---|---|

| min | % | t/Ct b | ||

| 0 | - | - | - | |

| 2 | 0.1252 | ± 0.33 | 0.0625 | 15.9744 |

| 5 | 0.2188 | ± 0.25 | 0.0438 | 22.8519 |

| 7.5 | 0.2543 | ± 0.26 | 0.0339 | 29.4927 |

| 15 | 0.3501 | ± 0.30 | 0.0233 | 42.8449 |

| 30 | 0.4310 | ± 0.22 | 0.0144 | 69.6056 |

| 60 | 0.4710 | ± 0.31 | 0.0079 | 127.3885 |

| 90 | 0.4718 | ± 0.28 | 0.0052 | 190.7588 |

| 120 | 0.4756 | ± 0.29 | 0.004 | 252.3129 |

References

- Ravindran, P.N. Turmeric—The golden spice of life, In Turmeric: The Genus Curcuma; Ravindran, P.N., Babu, K.N., Sivaraman, K., Eds.; CRC Press: Boca Raton, FL, USA, 2007; Volume 1, pp. 1–14. [Google Scholar]

- Dao, T.T.; Nguyen, P.H.; Won, H.K.; Kim, E.H.; Park, J.; Won, B.Y.; Oh, W.K. Curcuminoids from Curcuma longa and their inhibitory activities on influenza a neuraminidases. Food Chem. 2012, 134, 21–28. [Google Scholar] [CrossRef]

- Nguyen, T.T.H.; Si, J.; Kang, C.; Chung, B.; Chung, D.; Kim, D. Facile preparation of water soluble curcuminoids extracted from turmeric (Curcuma longa L.) powder by using steviol glucosides. Food Chem. 2017, 214, 366–373. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sueth-Santiago, V.; Mendes-Silva, G.P.; Decoté-Ricardo, D.; de Lima, M.E.F. Curcumin, the golden powder from turmeric: Insights into chemical and biological activities. Quim. Nova. 2015, 38, 538–552. [Google Scholar] [CrossRef]

- Esatbeyoglu, T.; Huebbe, P.; Ernst, I.M.; Chin, D.; Wagner, A.E.; Rimbach, G. Curcumin—From molecule to biological function. Angew. Chem. Int. Ed. 2012, 51, 5308–5332. [Google Scholar] [CrossRef] [PubMed]

- Niranjan, A.; Prakash, D. Chemical constituents and biological activities of turmeric (Curcuma longa L.)—A review. J. Food Sci. Technol. 2008, 45, 109–116. [Google Scholar]

- Bessone, F.; Argenziano, M.; Grillo, G.; Ferrara, B.; Pizzimenti, S.; Barrera, G.; Cravotto, G.; Guiot, C.; Stura, I.; Cavalli, R.; et al. Low-dose curcuminoid-loaded in dextran nanobubbles can prevent metastatic spreading in prostate cancer cells. Nanotechnology 2019, 30, 214004–214016. [Google Scholar] [CrossRef] [PubMed]

- Priyadarsini, K.I. The chemistry of curcumin: From extraction to therapeutic agent. Molecules 2014, 19, 20091–20112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Patra, J.K.; Das, G.; Lee, S.; Kang, S.-S.; Shin, H.-S. Selected commercial plants: A review of extraction and isolation of bioactive compounds and their pharmacological market value. Trends Food Sci. Technol. 2018, 82, 89–109. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Fabiano-Tixier, A.-S.; Nutrizio, M.; Jambrak, A.R.; Munekata, P.E.S.; Lorenzo, J.M.; Barba, F.J.; Binello, A.; Cravotto, G. A review of sustainable and intensified techniques for extraction of food and natural products. Green Chem. 2020, 22, 2325–2353. [Google Scholar] [CrossRef] [Green Version]

- Grillo, G.; Boffa, L.; Binello, A.; Mantegna, S.; Cravotto, G.; Chemat, F.; Dizhbite, T.; Lauberte, L.; Telysheva, G. Cocoa bean shell waste valorization; extraction from lab to pilot-scale cavitational reactors. Food Res. Int. 2019, 115, 200–208. [Google Scholar] [CrossRef]

- Berk, Z. Extraction, In Food Process Engineering and Technology, 3rd ed.; Taylor, S.L., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2018; Volume 1, pp. 289–310. [Google Scholar]

- Cacace, J.E.; Mazza, G. Optimization of extraction of anthocyanins from black currants with aqueous ethanol. J. Food Sci. 2003, 68, 240–248. [Google Scholar] [CrossRef]

- Herodez, S.S.; Hadolin, M.; Skerget, M.; Knez, Z. Solvent extraction study of antioxidants from Balm (Melissa officinalis L.) leaves. Food Chem. 2003, 80, 275–282. [Google Scholar] [CrossRef]

- Peleg, M. An empirical model for the description of moisture sorption curves. J. Food Sci. 1988, 54, 1216–1217. [Google Scholar] [CrossRef]

- Bucić-Kojić, A.; Planinić, M.; Tomas, S.; Bilić, M.; Velić, D. Study of solid—Liquid extraction kinetics of total polyphenols from grape seeds. J. Food Eng. 2007, 81, 236–242. [Google Scholar] [CrossRef]

- Shirsath, S.R.; Sable, S.S.; Gaikwad, S.G.; Sonawane, S.H.; Saini, D.R.; Gogate, P.R. Intensification of extraction of curcumin from Curcuma amada using ultrasound assisted approach: Effect of different operating parameters. Ultrason. Sonochem. 2017, 38, 437–445. [Google Scholar] [CrossRef]

- Aguilar, F.; Dusemund, B.; Galtier, P.; Gilbert, J.; Gott, D.M.; Grilli, S.; Gürtler, R.; König, J.; Lambré, C.; Larsen, J.-C.; et al. Scientific opinion on the re-evaluation of curcumin (E 100) as a food additive. EFSA J. 2010, 8, 1–46. [Google Scholar] [CrossRef]

- Revanthy, S.; Elumalai, S.; Benny, M.; Antony, B.J. Isolation, purification and identification of curcuminoids from turmeric (Curcuma longa L.) by column chromatography. Exp. Sci. 2011, 2, 21–25. [Google Scholar]

- Ukrainczyk, M.; Hodnett, B.K.; Rasmuson, A.C. Process parameters in the purification of curcumin by cooling crystallization. Org. Process Res. Dev. 2016, 20, 1593–1602. [Google Scholar] [CrossRef]

- Joshi, P.; Jain, S.; Sharma, V. Turmeric (Curcuma longa) a natural source of edible yellow colour. Int. J. Food Sci. Technol. 2009, 44, 2402–2406. [Google Scholar] [CrossRef]

- Thorat, A.A.; Dalvi, S.V. Particle formation pathways and polymorphism of curcumin induced by ultrasound and additives during liquid antisolvent precipitation. CrystEngComm 2014, 16, 11102–11114. [Google Scholar] [CrossRef] [Green Version]

- Kuhnen, S.; Bernardi Ogliari, J.; Dias, P.F.; da Santos, M.S.; Ferreira, A.N.G.; Bonham, C.C.; Maraschin, M. Metabolic fingerprint of brazilian maize landraces silk (stigma/styles) using NMR spectroscopy and chemometric methods. J. Agric. Food Chem. 2010, 58, 2194–2200. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.-O.; Shin, Y.-S.; Hyun, S.-H.; Cho, S.; Bang, K.-H.; Lee, D.; Choi, H.-K. NMR-based metabolic profiling and differentiation of ginseng roots according to cultivation ages. J. Pharm. Biomed. Anal. 2012, 58, 19–26. [Google Scholar] [CrossRef] [PubMed]

- Gad, H.A.; Bouzabata, A. Application of chemometrics in quality control of Turmeric (Curcuma longa) based on Ultra-violet, Fourier transform-infrared and 1H NMR spectroscopy. Food Chem. 2017, 237, 857–864. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Konecke, S.; Wegiel, L.A.; Taylor, L.S.; Edga, K.J. Both solubility and chemical stability of curcumin are enhanced by solid dispersion in cellulose derivative matrices. Carbohydr. Polym. 2013, 98, 1108–1116. [Google Scholar] [CrossRef]

- Gordon, O.N.; Luis, P.B.; Sintim, H.O.; Schneider, C. Unraveling curcumin degradation: Autoxidation proceeds through spiroepoxide and vinylether intermediates en route to the main bicyclopentadione. J. Biol. Chem. 2015, 290, 4817–4828. [Google Scholar] [CrossRef] [Green Version]

- Schneider, C.; Gordon, O.N.; Edwards, R.L.; Luis, P.B. Degradation of curcumin: From mechanism to biological implications. J. Agric. Food Chem. 2015, 63, 7606–7614. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khurana, A.; Ho, C.T. High performance liquid chromatographic analysis of curcuminoids and their photo-oxidative decomposition compounds in Curcuma longa L. J. Liq. Chromatogr. 1988, 11, 2295–2304. [Google Scholar] [CrossRef]

- Peram, M.R.; Jalalpure, S.S.; Palkar, M.B.; Diwan, P.V. Stability studies of pure and mixture form of curcuminoids by reverse phase-HPLC method under various experimental stress conditions. Food Sci. Biotechnol. 2017, 26, 591–602. [Google Scholar] [CrossRef]

- Price, L.C.; Buescher, R.W. Kinetics of alkaline degradation of the food pigments curcumin and curcuminoids. J. Food Sci. 1997, 62, 267–269. [Google Scholar] [CrossRef]

- Didenko, Y.T.; Suslick, K.S. The energy efficiency of formation of photons, radicals and ions during single-bubble cavitation. Nature 2002, 418, 394–407. [Google Scholar] [CrossRef]

- Riesz, P.; Kondo, T. Free radical formation induced by ultrasound and its biological implications. Free Radic. Biol. Med. 1992, 13, 247–270. [Google Scholar] [CrossRef]

- Riesz, P.; BerdahI, D.; Christman, C.L. Free radical generation by ultrasound in aqueous and nonaqueous solutions. Environ. Heal. Perspect. 1985, 64, 233–252. [Google Scholar] [CrossRef] [PubMed]

- Riesz, P.; BerdahI, D.; Christman, C.L. Dissolved gas and ultrasonic cavitation—A review. Ultrason. Sonochem. 2013, 20, 1–11. [Google Scholar] [CrossRef]

- Toma, M.; Vinatoru, M.; Paniwnyk, L.; Mason, T.J. Investigation of the effects of ultrasound on vegetal tissues during solvent extraction. Ultrason. Sonochem. 2001, 8, 137–142. [Google Scholar] [CrossRef]

| Irradiation (min) | EtOH | EtOAc | ||||

|---|---|---|---|---|---|---|

| Curcumin conc. ± %SD (mg/mL) | Degradation (%) | Curcumin conc. ± %SD (mg/mL) | Degradation (%) | |||

| 0 | 4.21 | ± 0.42 | - | 4.21 | ± 0.39 | - |

| 30 | 3.70 | ± 0.61 | 12.11 | 3.89 | ± 0.46 | 7.60 |

| 60 | 3.35 | ± 0.54 | 20.43 | 3.73 | ± 0.65 | 11.40 |

| 90 | 3.17 | ± 0.73 | 24.70 | 3.52 | ± 0.63 | 16.39 |

| 120 | 2.96 | ± 0.68 | 29.69 | 3.48 | ± 0.70 | 17.34 |

| Irradiation (min) | Closed Vessel | |

|---|---|---|

| Degradation | ± SD | |

| (%) | ||

| 30 | 4.00 | ± 0.58 |

| 60 | 8.54 | ± 0.72 |

| 90 | 10.72 | ± 1.14 |

| 120 | 11.27 | ± 1.48 |

| Irradiation | EtOH | EtOAc | ||||

|---|---|---|---|---|---|---|

| Curcuminoid conc. ± %SD | Degradation | Curcuminoid conc. ± %SD | Degradation | |||

| (min) | (mg/mL) | (%) | (mg/mL) | (%) | ||

| 0 | 3.83 | ± 0.39 | - | 4.79 | ± 0.51 | - |

| 30 | 3.71 | ± 0.61 | 3.13 | 4.74 | ± 0.70 | 1.05 |

| 60 | 3.54 | ± 0.57 | 7.57 | 4.61 | ± 0.38 | 3.76 |

| 90 | 3.16 | ± 0.49 | 17.49 | 4.48 | ± 0.57 | 6.47 |

| 120 | 3.08 | ± 0.67 | 19.58 | 4.25 | ± 0.44 | 11.27 |

| US Technology | Dry Extract | Curcuminoid conc. ± %SD | |

|---|---|---|---|

| (%) | (%) | ||

| Cup-horn a | 19.19 | 72.07 | ± 0.22 |

| Horn b | 16.31 | 68.43 | ± 0.38 |

| Horn c | 18.17 | 72.68 | ± 0.29 |

| Step | 6 mm Matrix | 2 mm Matrix | ||||||

|---|---|---|---|---|---|---|---|---|

| Dry Extract | Curcuminoid Yield ± %SD | Yield Increase | Dry Extract | Curcuminoid Yield ± %SD | Yield Increase | |||

| % | % | % | % | % | % | |||

| 1 | 5.44 | 23.10 | ± 0.37 | - | 11.19 | 43.10 | ± 0.22 | - |

| 2 | 12.24 | 51.97 | ± 0.33 | 28.87 | 22.56 | 88.54 | ± 0.19 | 45.44 |

| 3 | 18.17 | 72.68 | ± 0.29 | 20.71 | 23.77 | 92.10 | ± 0.30 | 3.56 |

| 4 | 20.12 | 80.04 | ± 0.31 | 7.36 | - | - | - | - |

| Step | 6 mm Curcuminoid Yield | 2 mm Curcuminoid Yield | ||

|---|---|---|---|---|

| Model | Experimental | Model | Experimental | |

| % | % | % | % | |

| 1 | 22.92 | 23.10 | 41.06 | 43.10 |

| 2 | 40.59 | 51.97 | 65.26 | 88.54 |

| 3 | 54.20 | 72.68 | 79.52 | 92.10 |

| 4 | 64.70 | 80.04 | 87.93 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Binello, A.; Grillo, G.; Barge, A.; Allegrini, P.; Ciceri, D.; Cravotto, G. A Cross-Flow Ultrasound-Assisted Extraction of Curcuminoids from Curcuma longa L.: Process Design to Avoid Degradation. Foods 2020, 9, 743. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9060743

Binello A, Grillo G, Barge A, Allegrini P, Ciceri D, Cravotto G. A Cross-Flow Ultrasound-Assisted Extraction of Curcuminoids from Curcuma longa L.: Process Design to Avoid Degradation. Foods. 2020; 9(6):743. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9060743

Chicago/Turabian StyleBinello, Arianna, Giorgio Grillo, Alessandro Barge, Pietro Allegrini, Daniele Ciceri, and Giancarlo Cravotto. 2020. "A Cross-Flow Ultrasound-Assisted Extraction of Curcuminoids from Curcuma longa L.: Process Design to Avoid Degradation" Foods 9, no. 6: 743. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9060743