Computational Fluid Dynamics (CFD) as a Tool for Investigating Self-Organized Ascending Bubble-Driven Flow Patterns in Champagne Glasses

Abstract

:1. Introduction

2. Modeling the Glass and Physicochemical Parameters of Champagne

2.1. Modeling the Champagne Glass

2.2. Meshing of the Computational Domain

2.3. Physicochemical Parameters of Champagne and Gas-Phase CO2

3. Numerical Methods and Set-Up

3.1. Liquid-Phase Governing Equations

3.2. Discrete Phase Modeling

3.3. Boundary Conditions

4. Results and Discussion

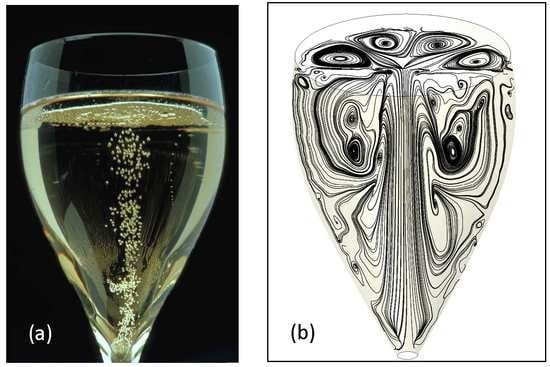

4.1. The Two-Dimensional (2D) Model

4.2. The Three-Dimensional (3D) Model

5. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Liger-Belair, G.; Carvajal-Perez, D.; Cilindre, C.; Facque, J.; Brevot, M.; Litoux-Desrues, F.; Chaperon, V.; Geoffroy, R. Evidence for moderate losses of dissolved CO2 during aging on lees of a champagne prestige cuvee. J. Food Eng. 2018, 233, 40–48. [Google Scholar] [CrossRef]

- Liger-Belair, G.; Bourget, M.; Villaume, S.; Jeandet, P.; Pron, H.; Polidori, G. On the Losses of Dissolved CO2 During Champagne Serving. J. Agric. Food Chem. 2010, 58, 8768–8775. [Google Scholar] [CrossRef] [PubMed]

- Liger-Belair, G.; Parmentier, M.; Cilindre, C. More on the Losses of Dissolved CO2 during Champagne Serving: Toward a Multiparameter Modeling. J. Agric. Food Chem. 2012, 60, 11777–11786. [Google Scholar] [CrossRef] [PubMed]

- Liger-Belair, G.; Bourget, M.; Pron, H.; Polidori, G.; Cilindre, C. Monitoring Gaseous CO2 and Ethanol above Champagne Glasses: Flute versus Coupe, and the Role of Temperature. PLoS ONE 2012, 7, e30628. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liger-Belair, G.; Conreux, A.; Villaume, S.; Cilindre, C. Monitoring the losses of dissolved carbon dioxide from laser-etched champagne glasses. Food Res. Int. 2013, 54, 516–522. [Google Scholar] [CrossRef]

- Liger-Belair, G. How Many Bubbles in Your Glass of Bubbly? J. Phys. Chem. B 2014, 118, 3156–3163. [Google Scholar] [CrossRef] [PubMed]

- Liger-Belair, G. Modeling the losses of dissolved carbon dioxide from laser-etched champagne glasses. J. Phys. Chem. B 2016, 120, 3724–3734. [Google Scholar] [CrossRef]

- Polidori, G.; Jeandet, P.; Liger-Belair, G. Bubbles and Flow Patterns in Champagne. Am. Sci. 2009, 97, 294. [Google Scholar] [CrossRef]

- Cilindre, C.; Conreux, A.; Liger-Belair, G. Simultaneous Monitoring of Gaseous CO2 and Ethanol above Champagne Glasses via Micro-gas Chromatography (μGC). J. Agric. Food Chem. 2011, 59, 7317–7323. [Google Scholar] [CrossRef]

- Moriaux, A.-L.; Vallon, R.; Parvitte, B.; Zeninari, V.; Liger-Belair, G.; Cilindre, C. Monitoring gas-phase CO2 in the headspace of champagne glasses through combined diode laser spectrometry and micro-gas chromatography analysis. Food Chem. 2018, 264, 255–262. [Google Scholar] [CrossRef]

- Liger-Belair, G.; Religieux, J.-B.; Fohanno, S.; Vialatte, M.-A.; Jeandet, P.; Polidori, G. Visualization of Mixing Flow Phenomena in Champagne Glasses under Various Glass-Shape and Engravement Conditions. J. Agric. Food Chem. 2007, 55, 882–888. [Google Scholar] [CrossRef] [PubMed]

- Liger-Belair, G.; Beaumont, F.; Vialatte, M.-A.; Jégou, S.; Jeandet, P.; Polidori, G. Use of laser tomography techniques to determine the kinetics and stability of the mixing flow patterns found in champagne glasses:Likely impact on champagne tasting. Anal. Chim. Acta 2008, 621, 30–37. [Google Scholar] [CrossRef]

- Polidori, G.; Beaumont, F.; Jeandet, P.; Liger-Belair, G. Ring vortex scenario in engraved champagne glasses. J. Vis. 2009, 12, 275–282. [Google Scholar] [CrossRef]

- Liger-Belair, G.; Cilindre, C.; Beaumont, F.; Jeandet, P.; Polidori, G. Evidence for ascending bubble driven flow patterns in champagne glasses, and their impact on gaseous CO2 and ethanol release under standard tasting conditions. Bubble Sci. Eng. Technol. 2012, 4, 35–48. [Google Scholar] [CrossRef]

- Beaumont, F.; Liger-Belair, G.; Polidori, G. Flow analysis from PIV in engraved champagne tasting glasses: Flute versus coupe. Exp. Fluids 2015, 56, 170. [Google Scholar] [CrossRef]

- Beaumont, F.; Liger-Belair, G.; Polidori, G. Instabilities and topological behavior of the flow inside champagne glasses. J. Flow Visual. Image Proces. 2015, 22, 97–115. [Google Scholar] [CrossRef]

- Beaumont, F.; Liger-Belair, G.; Polidori, G. Unsteady evolution of the two-phase flow in sparkling wine tasting and the subsequent role of glass shape. Exp. Fluids 2019, 60, 111. [Google Scholar] [CrossRef]

- Beaumont, F.; Liger-Belair, G.; Bailly, Y.; Polidori, G. A synchronized particle image velocimetry and infrared thermography technique applied to convective mass transfer in champagne glasses. Exp. Fluids 2016, 57, 85. [Google Scholar] [CrossRef]

- Beaumont, F.; Popa, C.V.; Liger-Belair, G.; Polidori, G. Temperature Dependence of Ascending Bubble-Driven Flow Patterns Found in Champagne Glasses as Determined through Numerical Modeling. Adv. Mech. Eng. 2013, 5, 156430. [Google Scholar] [CrossRef] [Green Version]

- Beaumont, F.; Popa, C.; Liger-Belair, G.; Polidori, G. Numerical modelling of bubble-driven flow patterns in champagne glasses. Int. J. Numer. Method. H. 2014, 24, 563–578. [Google Scholar] [CrossRef]

- Beaumont, F.; Liger-Belair, G.; Polidori, G. Three-dimensional modeling of complex swirling flows in champagne glasses: CFD and flow visualization. Acta Mech. 2018, 230, 213–224. [Google Scholar] [CrossRef]

- Benilov, E.S.; Cummins, C.; Lee, W. Why do bubbles in Guinness sink? Am. J. Phys. 2013, 81, 88–91. [Google Scholar] [CrossRef] [Green Version]

- Watamura, T.; Iwatsubo, F.; Sugiyama, K.; Yamamoto, K.; Yotsumoto, Y.; Shiono, T. Bubble cascade in Guinness beer is caused by gravity current instability. Sci. Rep. 2019, 9, 5718. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liger-Belair, G.; Parmentier, M.; Jeandet, P. Modeling the Kinetics of Bubble Nucleation in Champagne and Carbonated Beverages. J. Phys. Chem. B 2006, 110, 21145–21151. [Google Scholar] [CrossRef]

- Perret, A.; Bonhommeau, D.; Liger-Belair, G.; Cours, T.; Alijah, A. CO2 Diffusion in Champagne Wines: A Molecular Dynamics Study. J. Phys. Chem. B 2014, 118, 1839–1847. [Google Scholar] [CrossRef]

- Bonhommeau, D.; Perret, A.; Nuzillard, J.-M.; Cilindre, C.; Cours, T.; Alijah, A.; Liger-Belair, G. Unveiling the Interplay Between Diffusing CO2 and Ethanol Molecules in Champagne Wines by Classical Molecular Dynamics and 13C NMR Spectroscopy. J. Phys. Chem. Lett. 2014, 5, 4232–4237. [Google Scholar] [CrossRef]

- Shams, E.; Finn, J.R.; Apte, S. A numerical scheme for Euler-Lagrange simulation of bubbly flows in complex systems. Int. J. Numer. Methods Fluids 2010, 67, 1865–1898. [Google Scholar] [CrossRef]

- Groll, R.; Tropea, C.; Jakirlic, S. Comparative study of Euler/Euler and Euler/Lagrange approaches simulating evaporation in a turbulent gas-liquid flow. Int. J. Numer. Methods Fluids 2009, 59, 873–906. [Google Scholar] [CrossRef]

- Park, I.R.; Kim, K.S.; Kim, J.; Van, S.H. A volume-of-fluid method for incompressible free surface flows. Int. J. Numer. Methods Fluids 2009, 61, 1331–1362. [Google Scholar] [CrossRef]

- Annaland, M.V.S.; Deen, N.G.; Kuipers, J. Numerical simulation of gas bubbles behaviour using a three-dimensional volume of fluid method. Chem. Eng. Sci. 2005, 60, 2999–3011. [Google Scholar] [CrossRef]

- Rabha, S.S.; Buwa, V.V. Volume-of-fluid (VOF) simulations of rise of single/multiple bubbles in sheared liquids. Chem. Eng. Sci. 2010, 65, 527–537. [Google Scholar] [CrossRef]

- Nikseresht, A.H.; Alishahi, M.M.; Emdad, H. Complete flow field computation around an ACV (air-cushion vehicle) using 3D VOF with Lagrangian propagation in computational domain. Comput. Struct. 2008, 86, 627–641. [Google Scholar] [CrossRef]

- Asnaashari, A.; Akhtari, A.A.; Dehghani, A.A.; Bonakdari, H. Experimental and numerical investigation of the flow field in the gradual transition of rectangular to trapezoidal open channels. Eng. Appl. Comput. Fluid Mech. 2016, 10, 272–282. [Google Scholar] [CrossRef] [Green Version]

- Abbaspour, A.; Kia, S.H. Numerical investigation of turbulent open channel flow with semi-cylindrical rough beds. KSCE J. Civ. Eng. 2014, 18, 2252–2260. [Google Scholar] [CrossRef]

- Shi, S.-P.; Zitney, S.E.; Shahnam, M.; Syamlal, M.; Rogers, W.A. Modelling coal gasification with CFD and discrete phase method. J. Energy Inst. 2006, 79, 217–221. [Google Scholar] [CrossRef]

- Herrmann, E.; Lihavainen, H.; Hyvärinen, A.-P.; Riipinen, I.; Wilck, M.; Stratmann, F.; Kulmala, M. Nucleation Simulations Using the Fluid Dynamics Software FLUENT with the Fine Particle Model FPM. J. Phys. Chem. A 2006, 110, 12448–12455. [Google Scholar] [CrossRef]

- Liger-Belair, G. Effervescence in champagne and sparkling wines: From grape harvest to bubble rise. Eur. Phys. J. Spec. Top. 2017, 226, 3–116. [Google Scholar] [CrossRef]

- Shafer, N.E.; Zare, R.N. Through a Beer Glass Darkly. Phys. Today 1991, 44, 48–52. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Z. Fizzics of Bubble Growth in Beer and Champagne. Elements 2008, 4, 47–49. [Google Scholar] [CrossRef]

- Liger-Belair, G.; Jeandet, P. More on the Surface State of Expanding Champagne Bubbles Rising at Intermediate Reynolds and High Peclet Numbers. Langmuir 2003, 19, 801–808. [Google Scholar] [CrossRef]

- Duineveld, P. Bouncing and Coalescence of Bubble Pairs Rising at High Reynolds Number in Pure Water or Aqueous Surfactant Solutions. Flow Turbul. Combust. 1997, 58, 409–439. [Google Scholar] [CrossRef]

- Liger-Belair, G. Nucléation, ascension et éclatement d’une bulle de champagne. Ann. Phys. 2006, 31, 1–133. [Google Scholar] [CrossRef]

- Liu, B.; Manica, R.; Liu, Q.; Klaseboer, E.; Xu, Z. Coalescence or Bounce? How Surfactant Adsorption in Milliseconds Affects Bubble Collision. J. Phys. Chem. Lett. 2019, 10, 5662–5666. [Google Scholar] [CrossRef]

- Lai, Q.; Luo, Z.; Hou, Q.; Zhang, T.; Wang, X.; Zou, Z. Numerical Study of Inclusion Removal in Steel Continuous Casting Mold Considering Interactions Between Bubbles and Inclusions. ISIJ Int. 2018, 58, 2062–2070. [Google Scholar] [CrossRef] [Green Version]

- Beaumont, F.; Liger-Belair, G.; Polidori, G. Unveiling self-organized two-dimensional (2D) convective cells in champagne glasses. J. Food Eng. 2016, 188, 58–65. [Google Scholar] [CrossRef]

- Petit, L.; Gondret, P. Redressement d’un écoulement alternatif. J. Phys. II 1992, 2, 2115–2144. [Google Scholar] [CrossRef]

- Riley, N.; Trinh, E.H. Steady streaming in an oscillatory inviscid flow. Phys. Fluids 2001, 13, 1956–1960. [Google Scholar] [CrossRef]

- An, H.; Cheng, L.; Zhao, M. Steady streaming around a circular cylinder in an oscillatory flow. Ocean Eng. 2009, 36, 1089–1097. [Google Scholar] [CrossRef]

| Champagne | Gas-Phase CO2 | |

|---|---|---|

|

Density ρ (kg m−3) | 9.98 × 102 | 1.79 |

|

Dynamic viscosity η (kg m−1 s−1) | 1.56 × 10−3 | 1.37 × 10−5 |

|

Surface tension γ (mN m−1) | 46.8 | / |

| Dissolved CO2 concentration [CO2]ini (g L−1) | 7.4 | / |

|

CO2 diffusion coefficient D (m2 s−1) | ≈1.4 × 10−9 | / |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beaumont, F.; Liger-Belair, G.; Polidori, G. Computational Fluid Dynamics (CFD) as a Tool for Investigating Self-Organized Ascending Bubble-Driven Flow Patterns in Champagne Glasses. Foods 2020, 9, 972. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9080972

Beaumont F, Liger-Belair G, Polidori G. Computational Fluid Dynamics (CFD) as a Tool for Investigating Self-Organized Ascending Bubble-Driven Flow Patterns in Champagne Glasses. Foods. 2020; 9(8):972. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9080972

Chicago/Turabian StyleBeaumont, Fabien, Gérard Liger-Belair, and Guillaume Polidori. 2020. "Computational Fluid Dynamics (CFD) as a Tool for Investigating Self-Organized Ascending Bubble-Driven Flow Patterns in Champagne Glasses" Foods 9, no. 8: 972. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9080972