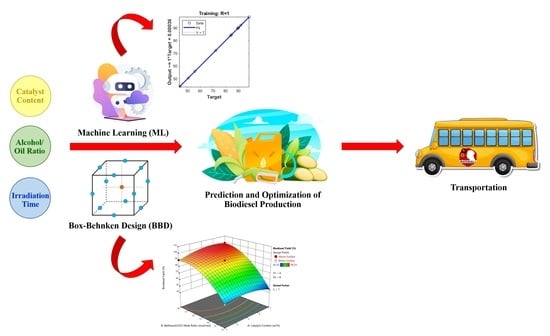

Process Optimization of Biodiesel from Used Cooking Oil in a Microwave Reactor: A Case of Machine Learning and Box–Behnken Design

Abstract

:1. Introduction

2. Methodology for Research

2.1. Materials

2.2. Biodiesel Synthesis from UCO in a Microwave Reactor

2.3. Design of Experiments (DoE) by BBD Modeling

2.4. Improvement of Biodiesel Process by ANN Modeling

3. Results and Discussion

3.1. Modeling and Optimization of Biodiesel Process Using RSM

3.2. Modeling and Regression of Biodiesel Process Using ANN

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bobadilla, M.C.; Lorza, R.L.; García, R.E.; Gómez, F.S.; González, E.P.V. An improvement in biodiesel production from waste cooking oil by applying thought multi-response surface methodology using desirability functions. Energies 2017, 10, 130. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.-H.; Chang, Y.-T.; Lai, M.-C.; Chiou, T.-Y.; Liao, C.-S. Continuous biodiesel production from waste soybean oil using a nano-Fe3O4 microwave catalysis. Processes 2021, 9, 756. [Google Scholar] [CrossRef]

- Gaide, I.; Makareviciene, V.; Sendzikiene, E.; Kazancev, K. Snail shells as a heterogeneous catalyst for biodiesel fuel production. Processes 2023, 11, 260. [Google Scholar] [CrossRef]

- Buasri, A.; Loryuenyong, V. The new green catalysts derived from waste razor and surf clam shells for biodiesel production in a continuous reactor. Green Process. Synth. 2015, 4, 389–397. [Google Scholar] [CrossRef]

- Fatimah, I.; Fadillah, G.; Sagadevan, S.; Oh, W.-C.; Ameta, K.L. Mesoporous silica-based catalysts for biodiesel production: A review. ChemEngineering 2023, 7, 56. [Google Scholar] [CrossRef]

- Razzaq, L.; Abbas, M.M.; Miran, S.; Asghar, S.; Nawaz, S.; Soudagar, M.E.M.; Shaukat, N.; Veza, I.; Khalil, S.; Abdelrahman, A.; et al. Response surface methodology and artificial neural networks-based yield optimization of biodiesel sourced from mixture of palm and cotton seed oil. Sustainability 2022, 14, 6130. [Google Scholar] [CrossRef]

- Mahfouz, A.B.; Ali, A.; Crocker, M.; Ahmed, A.; Nasir, R.; Show, P.L. Neural-network-inspired correlation (N2IC) model for estimating biodiesel conversion in algal biodiesel units. Fermentation 2023, 9, 47. [Google Scholar] [CrossRef]

- Buasri, A.; Sirikoom, P.; Pattane, S.; Buachum, O.; Loryuenyong, V. RSM process optimization of biodiesel production from waste cooking palm oil in the presence of SO3H-PSC catalyst. Eng. Proc. 2023, 37, 73. [Google Scholar]

- Buasri, A.; Rattanapan, T.; Boonrin, C.; Wechayan, C.; Loryuenyong, V. Oyster and Pyramidella shells as heterogeneous catalysts for the microwave-assisted biodiesel production from Jatropha curcas oil. J. Chem. 2015, 2015, 578625. [Google Scholar] [CrossRef] [Green Version]

- Buasri, A.; Lukkanasiri, M.; Nernrimnong, R.; Tonseeya, S.; Rochanakit, K.; Wongvitvichot, W.; Masa-ard, U.; Loryuenyong, V. Rapid transesterification of Jatropha curcas oil to biodiesel using novel catalyst with a microwave heating system. Korean J. Chem. Eng. 2016, 33, 3388–3400. [Google Scholar] [CrossRef]

- Kolakoti, A.; Setiyo, M.; Rochman, M.L. A green heterogeneous catalyst production and characterization for biodiesel production using RSM and ANN approach. Int. J. Renew. Energy Dev. 2022, 11, 703–712. [Google Scholar] [CrossRef]

- El-Khashab, N.A.; Marwa Mohamed Naeem, M.M.; Roushdy, M.H. Optimum biodiesel production using ductile cast iron as a heterogeneous catalyst. ChemEngineering 2022, 6, 40. [Google Scholar] [CrossRef]

- Matei, D.; Doicin, B.; Cursaru, D.; Ezeanu, D.S. Yield optimization using artificial neural networks in biodiesel production from soybean oil. Rev. Chim. 2020, 71, 132–140. [Google Scholar] [CrossRef]

- Thoai, D.N.; Tongurai, C.; Prasertsit, K.; Kumar, A. Predictive capability evaluation of RSM and ANN in modeling and optimization of biodiesel production from palm (Elaeisguineensis) oil. Int. J. Appl. Eng. Res. 2018, 13, 7529–7540. [Google Scholar]

- Milić, P.S.; Rajković, K.M.; Stamenković, O.S.; Veljković, V.B. Kinetic modeling and optimization of maceration and ultrasound-extraction of resinoid from the aerial parts of white lady’s bedstraw (Galium mollugo L.). Ultrason. Sonochem. 2013, 20, 525–534. [Google Scholar] [CrossRef]

- Ayoola, A.A.; Hymore, F.K.; Omonhinmin, C.A.; Babalola, P.O.; Fayomi, O.S.I.; Olawole, O.C.; Olawepo, A.V.; Babalola, A. Response surface methodology and artificial neural network analysis of crude palm kernel oil biodiesel production. Chem. Data Collect. 2020, 28, 100478. [Google Scholar] [CrossRef]

- Farobie, O.; Hasanah, N.; Matsumura, Y. Artificial neural network modeling to predict biodiesel production in supercritical methanol and ethanol using spiral reactor. Procedia Environ. Sci. 2015, 28, 214–223. [Google Scholar] [CrossRef] [Green Version]

- Haryanto, A.; Saputra, T.W.; Telaumbanua, M.; Gita, A.C. Application of artificial neural network to predict biodiesel yield from waste frying oil transesterification. Indones. J. Sci. Technol. 2020, 5, 62–74. [Google Scholar] [CrossRef]

- Hariram, V.; Bose, A.; Seralathan, S. Dataset on optimized biodiesel production from seeds of Vitis vinifera using ANN, RSM and ANFIS. Data Br. 2019, 25, 104298. [Google Scholar] [CrossRef]

- Weldeslase, M.G.; Benti, N.E.; Desta, M.A.; Mekonnen, Y.S. Maximizing biodiesel production from waste cooking oil with lime based zinc doped CaO using response surface methodology. Sci. Rep. 2023, 13, 4430. [Google Scholar] [CrossRef]

- Sarve, A.N.; Varma, M.N.; Sonawane, S.S. Response surface optimization and artificial neural network modeling of biodiesel production from crude mahua (Madhuca indica) oil under supercritical ethanol conditions using CO2 as co-solvent. RSC Adv. 2015, 5, 69702–69713. [Google Scholar] [CrossRef]

- Buasri, A.; Lertnimit, S.; Nisapruksachart, A.; Khunkha, I.; Loryuenyong, V. Box-Behnken design for optimization on esterification of free fatty acids in waste cooking oil using modified smectite clay catalyst. ASEAN J. Chem. Eng. 2023, 23, 40–51. [Google Scholar] [CrossRef]

- Betiku, E.; Odude, V.O.; Ishola, N.B.; Bamimore, A.; Osunleke, A.S.; Okeleye, A.A. Predictive capability evaluation of RSM, ANFIS and ANN: A case of reduction of high free fatty acid of palm kernel oil via esterification process. Energy Convers. Manag. 2016, 124, 219–230. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, J.; Fore, V.; Kumar, A. Performance evaluation of ANFIS, ANN and RSM in biodiesel synthesis from Karanja oil with domestic microwave set up. Multimed. Tools Appl. 2023; in press. [Google Scholar]

- Ezekannagha, C.B.; Ude, C.N.; Onukwuli, O.D. Optimization of the methanolysis of lard oil in the production of biodiesel with response surface methodology. Egypt. J. Pet. 2017, 26, 1001–1011. [Google Scholar] [CrossRef]

- Attari, A.; Abbaszadeh-Mayvan, A.; Taghizadeh-Alisaraei, A. Process optimization of ultrasonic-assisted biodiesel production from waste cooking oil using waste chicken eggshell-derived CaO as a green heterogeneous catalyst. Biomass Bioenerg. 2022, 158, 106357. [Google Scholar] [CrossRef]

- Laskar, I.B.; Deshmukhya, T.; Biswas, A.; Paul, B.; Changmai, B.; Gupta, R.; Chatterjee, S.; Rokhum, S.L. Utilization of biowaste-derived catalysts for biodiesel production: Process optimization using response surface methodology and particle swarm optimization method. Energy Adv. 2022, 1, 287. [Google Scholar] [CrossRef]

- Dhawane, S.H.; Kumar, T.; Halder, G. Central composite design approach towards optimization of flamboyant pods derived steam activated carbon for its use as heterogeneous catalyst in transesterification of Hevea brasiliensis oil. Energy Convers. Manag. 2015, 100, 277–287. [Google Scholar] [CrossRef]

- Mostafaei, M.; Ghobadian, B.; Barzegar, M.; Banakar, A. Optimization of ultrasonic assisted continuous production of biodiesel using response surface methodology. Ultrason. Sonochem. 2015, 27, 54–61. [Google Scholar] [CrossRef]

- Ansori, A.; Mahfud, M. Box-Behnken design for optimization on biodiesel production from palm oil and methyl acetate using ultrasound assisted interesterification method. Period. Polytech. Chem. Eng. 2022, 66, 30–42. [Google Scholar]

- Sai Bharadwaj, A.V.S.L.; Singh, M.; Niju, S.; Meera Sheriffa Begum, K.M.; Anantharaman, N. Biodiesel production from rubber seed oil using calcium oxide derived from eggshell as catalyst—Optimization and modeling studies. Green Process. Synth. 2019, 8, 430–442. [Google Scholar] [CrossRef]

- Kumar, S.; Aggrawal, M.; Kumar, N.; Deswal, V. Optimisation and prediction of Karanja oil transesterification with domestic microwave by RSM and ANN. Int. J. Ambient Energy 2022, 43, 3744–3751. [Google Scholar] [CrossRef]

- Samuel, O.D.; Okwu, M.O.; Tartibu, L.K.; Giwa, S.O.; Sharifpur, M.; Jagun, Z.O.O. Modelling of Nicotiana tabacum L. oil biodiesel production: Comparison of ANN and ANFIS. Front. Energy Res. 2021, 8, 612165. [Google Scholar] [CrossRef]

- Adizue, U.L.; Nwanya, S.C.; Ozor, P.A. Artificial neural network application to a process time planning problem for palm oil production. Eng. Appl. Sci. Res. 2020, 47, 161–169. [Google Scholar]

- Huang, J.; Wang, J.; Huang, Z.; Liu, T.; Li, H. Photothermal technique-enabled ambient production of microalgae biodiesel: Mechanism and life cycle assessment. Bioresour. Technol. 2023, 369, 128390. [Google Scholar] [CrossRef]

- Matei, P.L.; Busuioc, C.; Ionescu, N.; Stoica-Guzun, A.; Chira, N.-A. Cnicus benedictus oil as a raw material for biodiesel: Extraction optimization and biodiesel Yield. Sustainability 2021, 13, 13193. [Google Scholar] [CrossRef]

- Farobie, O.; Hasanah, N. Artificial neural network approach to predict biodiesel production in supercritical tert-butyl methyl ether. Indones. J. Sci. Technol. 2016, 1, 23–36. [Google Scholar] [CrossRef] [Green Version]

- Akinfalabi, S.-I.; Rashid, U.; Yunus, R.; Taufiq-Yap, Y.H. Synthesis of biodiesel from palm fatty acid distillate using sulfonated palm seed cake catalyst. Renew. Energ. 2017, 111, 611–619. [Google Scholar] [CrossRef]

- Akinfalabi, S.-I.; Rashid, U.; Shean, T.Y.C.; Nehdi, I.A.; Sbihi, H.M.; Gewik, M.M. Esterification of palm fatty acid distillate for biodiesel production catalyzed by synthesized kenaf seed cake-based sulfonated catalyst. Catalysts 2019, 9, 482. [Google Scholar] [CrossRef] [Green Version]

- Buasri, A.; Loryuenyong, V. Continuous production of biodiesel from rubber seed oil using a packed bed reactor with BaCl2 impregnated CaO as catalyst. Bull. Chem. React. Eng. Catal. 2018, 13, 320–330. [Google Scholar] [CrossRef]

| Process Variables | Symbol | Units | Levels | ||

|---|---|---|---|---|---|

| Low −1 | Mid 0 | High +1 | |||

| Catalyst content | A | wt.% | 3.0 | 5.0 | 7.0 |

| Methanol/UCO mole ratio | B | mol/mol | 12:1 | 15:1 | 18:1 |

| Irradiation time | C | Min | 5.0 | 7.0 | 9.0 |

| Property | Value/Comment |

|---|---|

| Training algorithm | Levenberg-Marquardt (LM) or trainlm |

| Back-propagation (BP) | |

| Learning | Supervised |

| Input layer | No transfer function is used |

| Hidden layer | TANSIG transfer function |

| Output layer | PURELIN transfer function |

| Number of best iterations/epoch | 5 |

| Number of input neurons | 3 |

| Number of hidden neurons | 10 |

| Number of output neurons | 1 |

| Run | A Catalyst Content (wt.%) | B Methanol/UCO Mole Ratio (mol/mol) | C Irradiation Time (min) | Experimental Biodiesel Yield (%) | Predicted Biodiesel Yield (%) |

|---|---|---|---|---|---|

| 1 | 5 | 15 | 7 | 90 | 89.68 |

| 2 | 5 | 12 | 5 | 43 | 42.25 |

| 3 | 5 | 15 | 7 | 90 | 89.68 |

| 4 | 5 | 15 | 7 | 90 | 89.68 |

| 5 | 5 | 15 | 7 | 90 | 89.68 |

| 6 | 3 | 12 | 7 | 51 | 50.82 |

| 7 | 7 | 12 | 7 | 44 | 45.34 |

| 8 | 5 | 12 | 9 | 56 | 55.56 |

| 9 | 5 | 15 | 7 | 90 | 89.68 |

| 10 | 5 | 15 | 7 | 90 | 89.68 |

| 11 | 3 | 18 | 7 | 90 | 89.01 |

| 12 | 5 | 15 | 7 | 90 | 89.68 |

| 13 | 3 | 15 | 9 | 84 | 84.11 |

| 14 | 7 | 15 | 5 | 77 | 77.31 |

| 15 | 7 | 15 | 9 | 85 | 83.78 |

| 16 | 5 | 18 | 9 | 96 | 96.62 |

| 17 | 7 | 18 | 7 | 99 | 98.39 |

| 18 | 5 | 15 | 7 | 90 | 89.68 |

| 19 | 5 | 18 | 5 | 92 | 92.44 |

| 20 | 3 | 15 | 5 | 72 | 73.08 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 5758.98 | 9 | 639.89 | 909.89 | <0.0001 |

| A—Catalyst content | 7.61 | 1 | 7.61 | 10.81 | 0.0082 |

| B—Methanol/UCO mole ratio | 4162.83 | 1 | 4162.83 | 5919.32 | <0.0001 |

| C—Irradiation time | 153.04 | 1 | 153.04 | 217.61 | <0.0001 |

| AB | 55.20 | 1 | 55.20 | 78.50 | <0.0001 |

| AC | 5.20 | 1 | 5.20 | 7.39 | 0.0216 |

| BC | 20.84 | 1 | 20.84 | 29.63 | 0.0003 |

| A2 | 136.63 | 1 | 136.63 | 194.27 | <0.0001 |

| B2 | 811.00 | 1 | 811.00 | 1153.20 | <0.0001 |

| C2 | 98.39 | 1 | 98.39 | 139.91 | <0.0001 |

| Residual | 7.03 | 10 | 0.7033 | ||

| Lack of fit | 7.01 | 3 | 2.34 | 681.75 | <0.0001 |

| Pure error | 0.0240 | 7 | 0.0034 | ||

| Cor. total | 5766.02 | 19 |

| Model | A Catalyst Content (wt.%) | B Methanol/UCO Mole Ratio (mol/mol) | C Irradiation Time (min) | Predicted Biodiesel Yield (%) | Validation Biodiesel Yield (%) |

|---|---|---|---|---|---|

| BBD | 4.94 | 16.76 | 8.13 | 98.62 | 98 |

| ANN | 7 | 18 | 7 | 98.53 | 98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buasri, A.; Sirikoom, P.; Pattane, S.; Buachum, O.; Loryuenyong, V. Process Optimization of Biodiesel from Used Cooking Oil in a Microwave Reactor: A Case of Machine Learning and Box–Behnken Design. ChemEngineering 2023, 7, 65. https://0-doi-org.brum.beds.ac.uk/10.3390/chemengineering7040065

Buasri A, Sirikoom P, Pattane S, Buachum O, Loryuenyong V. Process Optimization of Biodiesel from Used Cooking Oil in a Microwave Reactor: A Case of Machine Learning and Box–Behnken Design. ChemEngineering. 2023; 7(4):65. https://0-doi-org.brum.beds.ac.uk/10.3390/chemengineering7040065

Chicago/Turabian StyleBuasri, Achanai, Phensuda Sirikoom, Sirinan Pattane, Orapharn Buachum, and Vorrada Loryuenyong. 2023. "Process Optimization of Biodiesel from Used Cooking Oil in a Microwave Reactor: A Case of Machine Learning and Box–Behnken Design" ChemEngineering 7, no. 4: 65. https://0-doi-org.brum.beds.ac.uk/10.3390/chemengineering7040065