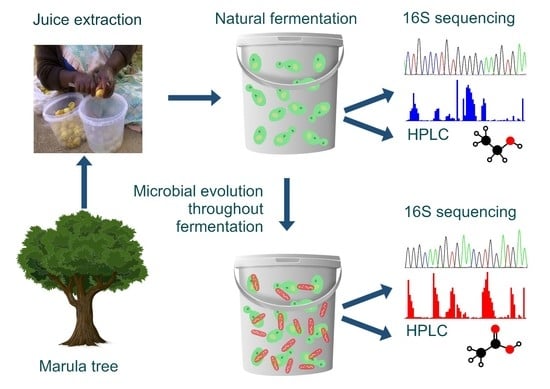

Microbial and Chemical Dynamics during Marula Wine Fermentation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Marula Fruit Juice and Wine Preparations

2.2. Enumeration and Isolation of Bacteria and Yeasts

2.3. Identification by Biotyping of the Bacterial Isolates

2.4. Amplification and Sequencing of rDNA Genes

2.5. Chemical Profiling of Marula Wine Samples

2.6. Statistical Analysis

3. Results

3.1. Marula Fruit and Juice Analysis

3.2. Sugar Utilization during Fermentation

3.3. Microbial Growth during Fermentation

3.4. Yeast Dynamics during Fermentation

3.5. Bacterial Dynamics during Fermentation

3.6. Volatile Compounds Evolution during Fermentation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Wyk, B.E. The potential of South African plants in the development of new food and beverage products. S. Afr. J. Botan. 2011, 77, 857–868. [Google Scholar] [CrossRef]

- Hiwilepo-van Hal, P.; Bille, P.G.; Verkerk, R.; Dekker, M. The effect of temperature and time on the quality of naturally fermented marula (Sclerocarya birrea subsp. caffra) juice. LWT-Food Sci. Technol. 2013, 53, 70–75. [Google Scholar] [CrossRef]

- Komane, B.; Vermaak, I.; Summers, B.; Viljoen, A. Safety and efficacy of Sclerocarya birrea (A.Rich.) Hochst (Marula) oil: A clinical perspective. J. Ethnopharmacol. 2015, 176, 327–335. [Google Scholar] [CrossRef] [PubMed]

- Moganedi, K.; Sibara, M.; Grobler, P.; Goyvaerts, E. An assessment of genetic diversity among marula populations using the amplified fragment length polymorphism (AFLP) technique. Afr. J. Agric. Res. 2011, 6, 790–797. Available online: http://www.academicjournals.org/AJAR (accessed on 5 September 2018).

- Shackleton, S.E.; Shackleton, C.M.; Cunningham, T.; Lombard, C.; Sullivan, C.A.; Netshiluvhi, T.R. Knowledge on Sclerocarya birrea subsp. caffra with emphasis on its importance as a non-timber forest product in South and southern Africa: A Summary. S. Afr. For. J. 2002, 194, 27–41. [Google Scholar] [CrossRef]

- Dube, S.; Shereni, I.; Dlamini, N.R.; Sibanda, T. Extending the shelf life of fresh marula (Sclerocarya birrea) juice by altering its physico-chemical parameters. In Biochemical Testing; Jimenez-Lopez, J.C., Ed.; INTECH Open: London, UK, 2012; pp. 181–196. [Google Scholar] [CrossRef]

- Hiwilepo-van Hal, P.; Bosschaart, C.; van Twisk, C.; Verkerk, R.; Dekker, M. Kinetics of thermal degradation of vitamin C in marula fruit (Sclerocarya birrea subsp. caffra) as compared to other selected tropical fruits. LWT-Food Sci. Technol. 2012, 49, 188–191. [Google Scholar] [CrossRef]

- Simatende, P.; Gadaga, T.H.; Nkambule, S.J.; Siwela, M. Methods of preparation of Swazi traditional fermented foods. J. Eth. Foods 2015, 2, 119–125. [Google Scholar] [CrossRef]

- Leakey, R.R.B. Potential for novel food products from agroforestry trees. Food Chem. 1999, 66, 1–14. [Google Scholar] [CrossRef]

- Mokgolodi, N.C.; Ding, Y.; Setshogo, M.P.; Ma, C.; Liu, Y. The importance of an indigenous tree of Southern African communities with specific reference to its domestication and commercialization: A case of the marula tree. For. Stud. China 2011, 13, 36–44. [Google Scholar] [CrossRef]

- Okagbue, R.; Siwela, M. Yeasts and related microorganisms isolated from ripe marula fruits (Sclerocarya caffra) in Zimbabwe. S. Afr. J. Sci. 2002, 98, 551–552. Available online: https://hdl.handle.net/10520/EJC97428 (accessed on 9 August 2018).

- Dlamini, N.R.; Dube, S. Studies on the physico-chemical, nutritional and microbiological changes during the traditional preparation of marula wine in Gwanda, Zimbabwe. Nutr. Food Sci. 2008, 38, 61–69. [Google Scholar] [CrossRef]

- Mpofu, A.; Kock, J.L.F.; Pretorious, E.E.; Pohl, C.H.; Zvauya, R. Identification of yeast isolated from mukumbi, a Zimbabwean traditional wine. J. Sus. Dev. Afr. 2008, 10, 88–102. [Google Scholar]

- Prins, W.A.; Botha, M.; Botes, M.; de Kwaadsteniet, M.; Endo, A.; Dicks, L.M.T. Lactobacillus plantarum 24, isolated from the marula fruit (Sclerocarya birrea), has probiotic properties and harbours genes encoding the production of three bacteriocins. Curr. Microbiol. 2010, 61, 584–589. [Google Scholar] [CrossRef]

- Sambrook, J.; Rusell, D.W. Rapid isolation of yeast, DNA. In Molecular Cloning, a Laboratory Manual; Sambrook, J., Rusell, D.W., Eds.; Cold Harbor Laboratory Press: New York, NY, USA, 2001; pp. 631–632. [Google Scholar]

- Neumann, B.; Pospiech, A.; Schairer, H. Rapid isolation of genomic DNA from gram-negative bacteria. Trends Genet. 1992, 8, 332–333. [Google Scholar] [CrossRef]

- White, T.J.; Bruns, T.; Lee, S.; Taylor, J. Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In PCR Protocols: A Guide to Methods and Applications; Innis, M.A., Gelfand, D.H., Sninsky, J.J., Eds.; Academic Press Incorporated: New York, NY, USA, 1990; pp. 315–322. [Google Scholar]

- Fundira, M. Optimization of Fermentation Processes for the Production of Indigenous Fruit Wines (Marula). Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2001. [Google Scholar]

- Weinert, I.A.G.; van Wyk, P.J.; Holtzhausen, L.C. Marula. In Fruits of Tropical and Subtropical Origin: Composition, Properties and Uses; Nagy, S., Shaw, P.E., Wardowski, W.F., Eds.; Florida Science Source, Inc.: Lake Alfred, FL, USA, 1990; pp. 88–113. [Google Scholar]

- Berthels, N.; Cordero-Otero, R.; Bauer, F.; Thevelein, J.; Pretorius, I. Discrepancy in glucose and fructose utilization during fermentation by Saccharomyces cerevisiae wine yeast strains. FEMS Yeast Res. 2004, 4, 683–689. [Google Scholar] [CrossRef]

- Jolly, N.P.; Augustyn, O.P.H.; Pretorius, I.S. The effect of non-Saccharomyces yeasts on fermentation and wine quality. S. Afri. J. Enol. Vitic. 2003, 24, 55–62. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y. Dynamic study of yeast species and Saccharomyces cerevisiae strains during the spontaneous fermentations of Muscat blac in Jingayang, China. Food Microbiol. 2013, 33, 172–177. [Google Scholar] [CrossRef]

- Fleet, G.H. Yeast interactions and wine flavour. Int. J. Food Microbiol. 2003, 86, 11–22. [Google Scholar] [CrossRef]

- Díaz, C.; Molina, A.M.; Nähring, J.; Fischer, R. Characterization and dynamic behaviour of wild yeast during spontaneous fermentation in steel tanks and amphorae. Biomed. Res. Int. 2013, 2013, 540465. [Google Scholar] [CrossRef]

- Laureys, D.; De Vuyst, L. Microbial species diversity, community dynamics, and metabolite kinetics of water kefir fermentation. Appl. Environ. Microbiol. 2014, 80, 2564–2572. [Google Scholar] [CrossRef]

- Bartowsky, E.J.; Henschke, P.A. Acetic acid bacteria spoilage of bottled red wine—A review. Int. J. Food Microbiol. 2008, 125, 60–70. [Google Scholar] [CrossRef]

- De Ley, J.; Gillis, M.; Swings, J.; Family, V.I. Acetobacteraceae. In Bergey’s Manual of Systematic Bacteriology; Krieg, N.R., Holt, J.G., Eds.; Williams & Wilkins: Baltimore, MD, USA, 1984; pp. 267–278. [Google Scholar]

- Berbegal, C.; Peña, N.; Russo, P.; Grieco, F.; Pardo, I.; Ferrer, S.; Spano, G.; Capozzi, V. Technological properties of Lactobacillus plantarum strains isolated from grape must fermentation. Food Microbiol. 2016, 57, 187–194. [Google Scholar] [CrossRef]

- Pinto, L.; Malfeito-Ferreira, M.; Quintieri, L.; Silva, A.C.; Baruzzi, F. Growth and metabolite production of a grape sour rot yeast-bacterium consortium on different carbon sources. Int. J. Food Microbiol. 2019, 296, 65–74. [Google Scholar] [CrossRef]

- Xiangyu, Q.; Linlin, Y.; Weiying, W.; Riming, Y.; Zhibin, Z.; Huilin, Y.; Du, Z.; Bo, Z. Comparative Evaluation of Microbiota Dynamics and Metabolites Correlation between Spontaneous and Inoculated Fermentations of Nanfeng Tangerine Wine. Front. Microbiol. 2021, 12, 649978. [Google Scholar] [CrossRef]

- Amoa-Awua, W.K.; Sampson, E.; Tano-Debrah, K. Growth of yeasts, lactic and acetic acid bacteria in palm wine during tapping and fermentation from felled oil palm (Elaeis guineensis) in Ghana. J. Appl. Microbiol. 2007, 102, 599–606. [Google Scholar] [CrossRef]

- Atter, A.; Obiri-Danso, K.; Amoa-Awua, W.K. Microbiological and chemical processes associated with the production of burukutu a traditional fermented beer in Ghana. Int. Food Res. J. 2014, 21, 1769–1776. Available online: https://www.researchgate.net/publication/287292436 (accessed on 13 February 2018).

- Wilson, P.; David, T.; Sam, B. Microbial and chemical changes occuring during production of traditional Rwandese banana beer urwagwa. J. Ferm. Technol. 2012, 1, 104. [Google Scholar] [CrossRef]

- Jerpersen, L. Occurrence and taxonomic characteristics of strains of Saccharomyces cerevisiae predominant in African indigenous fermented foods and beverages. FEMS Yeast Res. 2003, 3, 191–200. [Google Scholar] [CrossRef]

- Gamero, A.; Quintilla, R.; Groenewald, M.; Alkema, W.; Boekhout, T.; Hazelwood, L. High-throughput of a large collection of non-conventional yeasts reveals their potential for aroma formation in food fermentation. Food Microbiol. 2016, 60, 147–159. [Google Scholar] [CrossRef]

- Rojas, V.; Gil, J.; Pinaga, F.; Manzanares, P. Studies on acetate ester production by non-Saccharomyces wine yeast. Int. J. Food Microbiol. 2001, 70, 283–289. [Google Scholar] [CrossRef]

- Pretorius, V.; Rohmer, E.; Rapp, A.; Holtzhausen, L.C.; Mandery, H. Volatile flavour components of marula juice. Z. Lebensmittel. Fors. 1985, 181, 458–461. [Google Scholar] [CrossRef]

- Belda, I.; Ruiz, J.; Esteban-Fernández, A.; Navascués, E.; Marquina, D.; Santos, A.; Moreno-Arribas, M.V. Microbial contribution to wine aroma and its extended use for wine quality improvement. Molecules 2017, 22, 189. [Google Scholar] [CrossRef]

- Shale, K.; Mukamugema, K.J.; Lues, R.J.; Venter, P.; Mokoena, K.K. Characterization of selected volatile organic compounds in Rwandan indigenous beer urwagwa by dynamic headspace gas chromatography-mass spectometry. Afr. J. Biotechnol. 2013, 12, 2990–2996. [Google Scholar] [CrossRef]

- Torija, M.J.; Mateo, E.; Guillamón, J.M.; Mas, A. Identification and quantification of acetic acid bacteria in wine and vinegar by TaqMan–MGB probes. Food Microbiol. 2010, 27, 257–265. [Google Scholar] [CrossRef]

- Tucker, G.A. Introduction. In Biochemistry of Fruit Ripening; Seymour, G.B., Taylor, J.E., Tucker, G.A., Eds.; Chapman & Hall: London, UK, 1993; pp. 1–55. [Google Scholar]

- Lago, L.O.; Welke, J.E. Carbonyl compounds in wine: Factors related to presence and toxic effects. Food Technol. 2019, 49, e20190349. [Google Scholar] [CrossRef]

- Bueno, M.; Marrufo-Curtido, A.; Carrascon, V.; Fernandez-Zurbano, P.; Escudero, A.; Ferreira, V. Formation and accumulation of acetaldehyde and Strecker aldehydes during red wine oxidation. Front. Chem. 2018, 6, 20. [Google Scholar] [CrossRef] [PubMed]

- Cordente, A.G.; Espinase Nandorfy, D.; Solomon, M.; Schulkin, A.; Kolouchova, R.; Francis, I.L.; Schmidt, S.A. Aromatic higher alcohols in wine: Implication on aroma and palate attributes during chardonnay aging. Molecules 2021, 26, 4979. [Google Scholar] [CrossRef]

- Romano, P.; Fiore, C.; Paraggio, M.; Caruso, M.; Capece, A. Function of yeast species and strains in wine flavour. Int. J. Food Microbiol. 2003, 86, 169–180. [Google Scholar] [CrossRef]

- Badura, J.; van Wyk, N.; Brezina, S.; Pretorius, I.S.; Rauhut, D.; Wendland, J.; von Wallbrunn, C. Development of Genetic Modification Tools for Hanseniaspora uvarum. Int. J. Mol. Sci. 2021, 22, 1943. [Google Scholar] [CrossRef]

- Han, G.; Webb, M.R.; Waterhouse, A.L. Acetyladehyde reactions during wine bottle storage. Food Chem. 2019, 290, 208–215. [Google Scholar] [CrossRef]

- Guth, H. Quantification and sensory studies of character impact odorants of different white wine varieties. J. Agric. Food Chem. 1997, 45, 3027–3032. [Google Scholar] [CrossRef]

- Ferreira, V.; Lopéz, R.; Cacho, J.F. Quantification determination of the odorants of young red wines from different grape varieties. J. Sci. Food Agric. 2000, 80, 1659–1667. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phiri, A.; La Grange, D.; Moganedi, K. Microbial and Chemical Dynamics during Marula Wine Fermentation. Beverages 2022, 8, 50. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages8030050

Phiri A, La Grange D, Moganedi K. Microbial and Chemical Dynamics during Marula Wine Fermentation. Beverages. 2022; 8(3):50. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages8030050

Chicago/Turabian StylePhiri, Archie, Daniel La Grange, and Kgabo Moganedi. 2022. "Microbial and Chemical Dynamics during Marula Wine Fermentation" Beverages 8, no. 3: 50. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages8030050