Behind Subcontractor Risk: A Multiple Case Study Analysis of Mining and Natural Resources Fatalities

Abstract

:1. Introduction

1.1. Reasons for Subcontractor Risk

1.2. Approaches to Reduce Subcontractor Risk

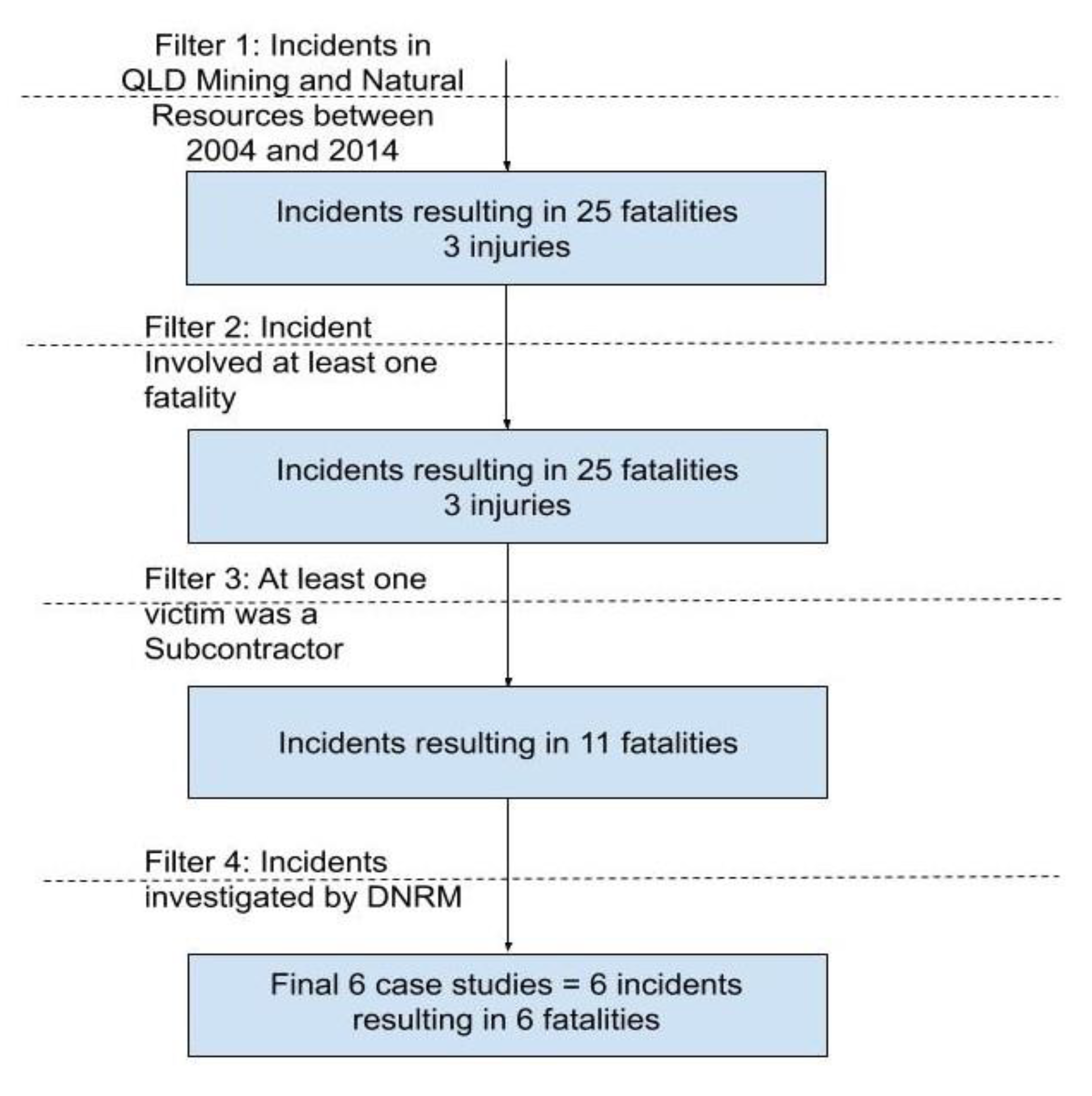

2. Materials and Methods

- The incident occurred between 2004 and 2014;

- The incident involved at least one fatality;

- At least one victim was a subcontractor employee; and

- There was a completed investigation by DNRM with the full report available

2.1. Theories Related to the Analysis

2.1.1. Institutional Safety Mechanisms

2.1.2. Labels of Work

2.1.3. Transfer of Information between Layers of the Contracting System

3. Case Studies

3.1. Case Study 1

3.2. Case Study 2

3.3. Case Study 3

3.4. Case Study 4

3.5. Case Study 5

3.6. Case Study 6

4. Analysis

4.1. Institutional Safety Mechanisms Do Not Cope with Variability Introduced by Subcontractors

4.1.1. Variations in Time Spent on Site

4.1.2. Multiple Jobs on Multiple Sites

4.1.3. Different Rules at Different Times on Different Sites

4.2. Expertise in Work Does Not Translate to Expertise in Safety

4.2.1. Financial Constraints, Multitasking and Expertise

4.2.2. General vs. Site-Specific Expertise

4.2.3. Verifying Expertise

4.3. Communication Does Not Flow to the Subcontractor from the Layers above Them

4.3.1. Filtration of Regulatory Information

4.3.2. Layers of Complexity

4.4. Safety Work Is Viewed Differently by Subcontractor Staff When Compared to Principal Contractors’/Operators’

4.4.1. Core Tasks and Non-Core Tasks

4.4.2. Short Term and Long-Term Goals

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Valluru, C.T.; Dekker, S.; Rae, A. How and why do subcontractors experience different safety on high-risk work sites? Cogn. Technol. Work 2017, 19, 785–794. [Google Scholar] [CrossRef] [Green Version]

- Gochfeld, M.; Mohr, S. Protecting Contract Workers: Case Study of the US Department of Energy’s Nuclear and Chemical Waste Management. Am. J. Public Health 2007, 97, 1607–1613. [Google Scholar] [CrossRef] [PubMed]

- Kalleberg, A.L. Nonstandard Employment Relations: Part-time, Temporary and Contract Work. Annu. Rev. Sociol. 2000, 26, 341–365. [Google Scholar] [CrossRef] [Green Version]

- Burgess, J.; Campbell, I. The Nature and Dimensions of Precarious Employment in Australia. Labour Ind. A J. Soc. Econ. Relat. Work 1998, 8, 5–21. [Google Scholar] [CrossRef]

- Rodgers, J.; Rodgers, J. Precarious Jobs in Labour Market Regulation: The Growth of Atypical Employment in Western Europe; International Institute for Labour Studies: Geneva, Switzerland, 1989. [Google Scholar]

- Vosko, L.F.; Zukewich, N.; Cranford, C. Precarious jobs: A new typology of employment. Perspect. Labour Income Ott. 2003, 15, 16–26. [Google Scholar]

- Polivka, A.E.; Nardone, T. On the Definition of Contingent Work The Quality of Jobs. Mon. Labor Rev. 1989, 112, 9–16. [Google Scholar]

- Quinlan, M.; Bohle, P. Contingent work and occupational safety. In The Psychology of Workplace Safety; Barling, J., Frone, M.R., Eds.; American Psychological Association: Washington, DC, USA, 2004; pp. 81–105. [Google Scholar]

- Cummings, K.J.; Kreiss, K. Contingent Workers and Contingent Health: Risks of a Modern Economy. JAMA 2008, 299, 448–450. [Google Scholar] [CrossRef]

- Foley, M. Factors underlying observed injury rate differences between temporary workers and permanent peers. Am. J. Ind. Med. 2017, 60, 841–851. [Google Scholar] [CrossRef]

- Gibson-Light, M. Classification Struggles in Semi-Formal and Precarious Work: Lessons from Inmate Labor and Cultural Production. In Precarious Work; Emerald Publishing Limited: Bingley, UK, 2017; Volume 31, pp. 61–89. [Google Scholar] [CrossRef]

- Kalleberg, A.L.; Vallas, S.P. Probing Precarious Work: Theory, Research, and Politics. In Precarious Work; Emerald Publishing Limited: Bingley, UK, 2017; Volume 31, pp. 1–30. [Google Scholar] [CrossRef] [Green Version]

- Kheni, N.A.; Dainty, A.; Gibb, A. Health and safety management practices of small subcontractors. In Proceedings of the 21st Annual ARCOM Conference, University of London, Association of Researchers in Construction Management, London, UK, 7–9 September 2005. [Google Scholar]

- McVittie, D.; Banikin, H.; Brocklebank, W. The effects of firm size on injury frequency in construction. Saf. Sci. 1997, 27, 19–23. [Google Scholar] [CrossRef]

- Loosemore, M.; Andonakis, N. Barriers to implementing OHS reforms—The experiences of small subcontractors in the Australian Construction Industry. Int. J. Proj. Manag. 2007, 25, 579–588. [Google Scholar] [CrossRef]

- Wong, J.Y.Y.; Gray, J.; Sadiqi, Z. Barriers to good occupational health and safety (OHS) practices by small construction firms. J. Constr. Manag. 2015, 30, 55–66. [Google Scholar]

- Milch, V.; Laumann, K. Interorganizational complexity and organizational accident risk: A literature review. Saf. Sci. 2016, 82, 9–17. [Google Scholar] [CrossRef]

- Oedewald, P.; Gotcheva, N. Safety culture and subcontractor network governance in a complex safety critical project. Reliab. Eng. Syst. Saf. 2015, 141, 106–114. [Google Scholar] [CrossRef]

- Bust, P.D.; Gibb, A.G.F.; Pink, S. Managing construction health and safety: Migrant workers and communicating safety messages. Saf. Sci. 2008, 46, 585–602. [Google Scholar] [CrossRef] [Green Version]

- MacKenzie, R. Subcontracting and the reregulation of the employment relationship: A case study from the telecommunications industry. Work Employ. Soc. 2000, 14, 707–726. [Google Scholar] [CrossRef]

- Lingard, H.; Holmes, N. Understandings of occupational health and safety risk control in small business construction firms: Barriers to implementing technological controls. Constr. Manag. Econ. 2001, 19, 217–226. [Google Scholar] [CrossRef]

- Goldenhar, L.M.; Moran, S.K.; Colligan, M. Health and safety training in a sample of open-shop construction companies. J. Saf. Res. 2001, 32, 237–252. [Google Scholar] [CrossRef]

- Luzzia, R.; Maida, L.; Martinettib, A.; Patruccob, M. Information, formation and training for the maintenance operations: The lesson learned from fatal accidents. Chem. Eng. 2013, 32, 229–334. [Google Scholar]

- Benavides, F.G.; Benach, J.; Muntaner, C.; Delclos, G.L.; Catot, N.; Amable, M. Associations between temporary employment and occupational injury: What are the mechanisms? Occup. Environ. Med. 2006, 63, 416–421. [Google Scholar] [CrossRef]

- Johnstone, R.; Stewart, A. Swimming against the Tide: Australian Labor Regulation and the Fissured Workplace. Comp. Lab. L. Policy J. 2015, 37, 55–90. [Google Scholar]

- Vosko, L.F. Precarious Employment: Towards an Improved Understanding of Labour Market Insecurity; McGill-Queen’s University Press: Montreal, QC, Canada; Kingston, CA, USA, 2006; Volume 2006. [Google Scholar]

- Akintan, O.A.; Morledge, R. Improving the collaboration between main contractors and subcontractors within traditional construction procurement. J. Constr. Eng. 2013, 2013, 281236. [Google Scholar] [CrossRef]

- Blackford, J. Can Safety Be Bought in Mining Contracts? The Cobra Effect. Acquire Procurement Services. Available online: http://acquireprocure.com/procurement-insights/can-safety-be-bought-in-mining-services-contracts-beware-the-cobra-effect/ (accessed on 26 October 2016).

- Ivensky, V. Safety Risk Management of Subcontractors: What is a standard of care? Prof. Saf. 2008, 53, 43–46. [Google Scholar]

- Smith, G.W. Contractor Safety Management; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Thomas, H.R.; Flynn, C.J. Fundamental Principles of Subcontractor Management. Pract. Period. Struct. Des. Constr. 2011, 16, 106–111. [Google Scholar] [CrossRef]

- Hartmann, A.; Ling, F.Y.Y.; Tan, J.S.H. Relative Importance of Subcontractor Selection Criteria: Evidence from Singapore. J. Constr. Eng. Manag. 2009, 135, 826–832. [Google Scholar] [CrossRef] [Green Version]

- Wells, J.; Hawkins, J. Promoting Construction Health and Safety through Procurement: A Briefing Note for Developing Countries; Engineers Against Poverty: London, UK, 2014. [Google Scholar]

- Young, B.; Seidu, R.D.; Nganga, D.; Robinson, H.; Ebohon, J.O. Driving Construction Health and Safety Through Procurement Strategy; Association of Researchers in Construction Safety, Health, and Well-being (ARCOSH): Cape Town, South Africa; Available online: https://openresearch.lsbu.ac.uk/item/8664x (accessed on 3 June 2019).

- Miller, C.J.; Packham, G.A.; Thomas, B.C. Harmonization between main contractors and subcontractors: A prerequisite for lean construction? J. Constr. Res. 2002, 3, 67–82. [Google Scholar] [CrossRef]

- Dainty, A.R.; Millett, S.J.; Briscoe, G.H. New perspectives on construction supply chain integration. Supply Chain Manag. Int. J. 2001, 6, 163–173. [Google Scholar] [CrossRef]

- Braun, V.; Clarke, V. What can “thematic analysis” offer health and wellbeing researchers? Int. J. Qual. Stud. Health Well-Being 2014, 9, 26152. [Google Scholar] [CrossRef] [Green Version]

- Yin, R.K. Case Study Research and Applications: Design and Methods; Sage Publications: New York, NY, USA, 2017. [Google Scholar]

- Demichela, M.; Monai, L.; Patrucco, M. The Deep Analysis of the Accidents as an Essential Prevention Tool: A Post-Event Investigation Protocol for the Analyst. In Ingegneria Forense: Metodologie, Protocolli e Casi di Studio; Flaccovio Dario: Palermo, Italy, 2011; pp. 231–246. (In Italian) [Google Scholar]

- Martinetti, A.; van Dongen, L.A.M.; Romano, R. Beyond Accidents: A Back-Analysis on Conveyor Belt Injury for a Better Design for Maintenance Operations. Am. J. Appl. Sci. 2017, 14, 1–12. [Google Scholar] [CrossRef]

- Dubois, A.; Gadde, L.-E. Systematic combining: An abductive approach to case research. J. Bus. Res. 2002, 55, 553–560. [Google Scholar] [CrossRef]

- Nowell, L.S.; Norris, J.M.; White, D.E.; Moules, N.J. Thematic Analysis: Striving to Meet the Trustworthiness Criteria. Int. J. Qual. Methods 2017, 16, 1609406917733847. [Google Scholar] [CrossRef]

- Patterson, J. Human Error in Mining: A Multivariable Analysis of Mining Accidents/Incidents in Queensland, Australia and the United States of America Using the Human Factors Analysis and Classification System Framework. Master’s Thesis, Clemson University, Clemson, SC, USA, December 2009. [Google Scholar]

- Bahn, S. Moving from contractor to owner operator: Impact on safety culture—A case study. Empl. Relat. 2012, 35, 157–172. [Google Scholar] [CrossRef]

- Hinze, J.; Gambatese, J. Factors That Influence Safety Performance of Specialty Contractors. J. Constr. Eng. Manag. 2003, 129, 159–164. [Google Scholar] [CrossRef] [Green Version]

- Collinson, D.L. ‘Surviving the Rigs’: Safety and Surveillance on North Sea Oil Installations. Organ. Stud. 1999, 20, 579–600. [Google Scholar] [CrossRef]

- Papadopoulos, G.; Georgiadou, P.; Papazoglou, C.; Michaliou, K. Occupational and public health and safety in a changing work environment: An integrated approach for risk assessment and prevention. Saf. Sci. 2010, 48, 943–949. [Google Scholar] [CrossRef]

- Quinlan, M. The ‘pre-invention’of precarious employment: The changing world of work in context. Econ. Labour Relat. Rev. 2012, 23, 3–24. [Google Scholar]

- Lewchuk, W.; Clarke, M.; de Wolff, A. Working without commitments: Precarious employment and health. Work Employ. Soc. 2008, 22, 387–406. [Google Scholar] [CrossRef]

- Beard, K.M.; Edwards, J.R. Employees at Risk: Contingent Work and the Psychological Experience of Contingent Workers. J. Organ. Behav. 1995, 2, 109. [Google Scholar]

- Virtanen, M.; Kivimäki, M.; Joensuu, M.; Virtanen, P.; Elovainio, M.; Vahtera, J. Temporary employment and health: A review. Int. J. Epidemiol. 2005, 34, 610–622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lingard, H.; Rowlinson, S.M. Occupational Health and Safety in Construction Project Management; Spon Press: New York, NY, USA, 2005. [Google Scholar]

- Bentley, T.; Tappin, D.; Legg, S. An exploratory analysis of falls in New Zealand small business residential construction. J. Occup. Health Saf. Aust. N. Z. 2004, 20, 539–545. [Google Scholar]

- Bahn, S. Workplace hazard identification and management: The case of an underground mining operation. Saf. Sci. 2013, 57, 129–137. [Google Scholar] [CrossRef]

- Bahn, S.; Barratt-Pugh, L. Evaluation of the mandatory construction induction training program in Western Australia: Unanticipated consequences. Eval. Program Plan. 2012, 35, 337–343. [Google Scholar] [CrossRef] [PubMed]

- Kaskutas, V.; Jaegers, L.; Dale, A.M.; Evanoff, B. Toolbox talks: Insights for improvement. Prof. Saf. 2016, 61, 33–37. [Google Scholar]

- Olson, R.; Varga, A.; Cannon, A.; Jones, J.; Gilbert-Jones, I.; Zoller, E. Toolbox talks to prevent construction fatalities: Empirical development and evaluation. Saf. Sci. 2016, 86, 122–131. [Google Scholar] [CrossRef]

- ICAO. Safety Management Manual (SMM), 3rd ed.; International Civil Aviation Organization: Montreal, QC, Canada, 2013; Available online: https://www.skybrary.aero/bookshelf/books/644.pdf (accessed on 21 May 2020).

- Rowlinson, S.M. Construction Safety Management Systems, 1st ed.; Spon Press: London, UK, 2004. [Google Scholar]

- Choudhry, R.M.; Dongping, F.; Ahmed, S.M. Safety Management in Construction: Best Practices in Hong Kong. J. Prof. Issues Eng. Educ. Pract. 2008, 134, 20–32. [Google Scholar] [CrossRef]

- Gallagher, C.; Underhill, E.; Rimmer, M. Occupational Health and Safety Management Systems: A Review of Their Effectiveness in Securing Healthy and Safe Workplaces [Review]; National Occupational Health and Safety Commission: Sydney, Australia, 2001; pp. 1–82. Available online: https://www.safeworkaustralia.gov.au/system/files/documents/1702/ohsmanagementsystems_reviewofeffectiveness_nohsc_2001_archivepdf.pdf (accessed on 13 May 2020).

- Masi, D.; Cagno, E.; Micheli, G.J. Developing, implementing and evaluating OSH interventions in SMEs: A pilot, exploratory study. Int. J. Occup. Saf. Ergon. 2014, 20, 385–405. [Google Scholar] [CrossRef] [PubMed]

- Segarra Cañamares, M.; Villena Escribano, B.M.; González García, M.N.; Romero Barriuso, A.; Rodríguez Sáiz, A. Occupational risk-prevention diagnosis: A study of construction SMEs in Spain. Saf. Sci. 2017, 92, 104–115. [Google Scholar] [CrossRef]

- Quinlan, M.; Johnstone, R.; McNamara, M. Australian Health and Safety Inspectors’ Perceptions and Actions in Relation to Changed Work Arrangements. J. Ind. Relat. 2009, 51, 557–573. [Google Scholar] [CrossRef]

- Boiral, O.; Ebrahimi, M.; Kuyken, K.; Talbot, D. Greening remote SMEs: The case of small regional airports. J. Bus. Ethics 2019, 154, 813–827. [Google Scholar] [CrossRef]

- Spence, L.J. Does size matter? The state of the art in small business ethics. Bus. Ethics A Eur. Rev. 1999, 8, 163–174. [Google Scholar] [CrossRef]

- Wadick, P. Safety culture among subcontractors in the domestic housing construction industry. Struct. Surv. 2010, 28, 108–120. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valluru, C.T.; Rae, A.; Dekker, S. Behind Subcontractor Risk: A Multiple Case Study Analysis of Mining and Natural Resources Fatalities. Safety 2020, 6, 40. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6030040

Valluru CT, Rae A, Dekker S. Behind Subcontractor Risk: A Multiple Case Study Analysis of Mining and Natural Resources Fatalities. Safety. 2020; 6(3):40. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6030040

Chicago/Turabian StyleValluru, Charan Teja, Andrew Rae, and Sidney Dekker. 2020. "Behind Subcontractor Risk: A Multiple Case Study Analysis of Mining and Natural Resources Fatalities" Safety 6, no. 3: 40. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6030040