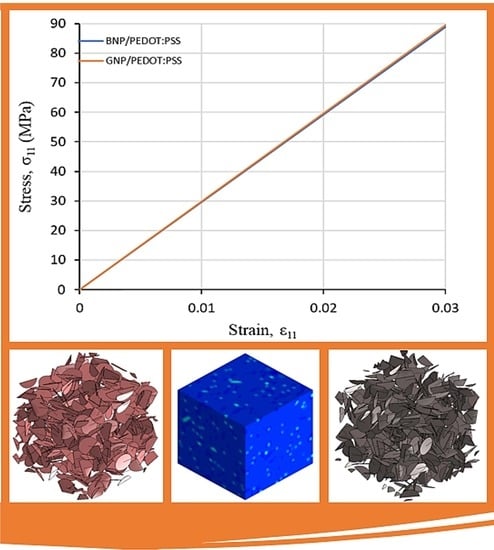

Effect of Borophene and Graphene on the Elastic Modulus of PEDOT:PSS Film—A Finite Element Study

Abstract

:1. Introduction

2. Finite Element Model

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, N.; Lienemann, S.; Petsagkourakis, I.; Mengistie, D.A.; Kee, S.; Ederth, T.; Gueskine, V.; Leclère, P.; Lazzaroni, R.; Crispin, X.; et al. Elastic conducting polymer composites in thermoelectric modules. Nat. Commun. 2020, 11, 1424. [Google Scholar] [CrossRef] [Green Version]

- Fan, X.; Nie, W.; Tsai, H.; Wang, N.; Huang, H.; Cheng, Y.; Wen, R.; Ma, L.; Yan, F.; Xia, Y. PEDOT:PSS for Flexible and Stretchable Electronics: Modifications, Strategies, and Applications. Adv. Sci. 2019, 6, 1900813. [Google Scholar] [CrossRef] [Green Version]

- Díez-Pascual, A.M. Environmentally Friendly Synthesis of Poly(3,4-Ethylenedioxythiophene):Poly(Styrene Sulfonate)/SnO2 Nanocomposites. Polymers 2021, 13, 2445. [Google Scholar] [CrossRef] [PubMed]

- Adekoya, G.J.; Sadiku, R.E.; Ray, S.S. Nanocomposites of PEDOT:PSS with Graphene and its Derivatives for Flexible Electronic Applications: A Review. Macromol. Mater. Eng. 2021, 306, 2000716. [Google Scholar] [CrossRef]

- Lang, U.; Dual, J. Mechanical Properties of the Intrinsically Conductive Polymer Poly(3,4-Ethylenedioxythiophene) Poly(Styrenesulfonate) (PEDOT/PSS). Key Eng. Mater. 2007, 345–346, 1189–1192. [Google Scholar] [CrossRef]

- Qu, J.; Ouyang, L.; Kuo, C.-C.; Martin, D.C. Stiffness, strength and adhesion characterization of electrochemically deposited conjugated polymer films. Acta Biomater. 2016, 31, 114–121. [Google Scholar] [CrossRef] [Green Version]

- Adekoya, G.J.; Adekoya, O.C.; Sadiku, R.E.; Ray, S.S. Structure-property relationship and nascent applications of thermoelectric PEDOT:PSS/carbon composites: A review. Compos. Commun. 2021, 27, 100890. [Google Scholar] [CrossRef]

- Novak, T.G.; Shin, H.; Kim, J.; Kim, K.; Azam, A.; Nguyen, C.V.; Park, S.H.; Song, J.Y.; Jeon, S. Low-Cost Black Phosphorus Nanofillers for Improved Thermoelectric Performance in PEDOT:PSS Composite Films. ACS Appl. Mater. Interfaces 2018, 10, 17957–17962. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, J.A.L.; Capilla, R.P.; Díez-Pascual, A.M. High-Performance PEDOT:PSS/Hexamethylene Diisocyanate-Functionalized Graphene Oxide Nanocomposites: Preparation and Properties. Polymers 2018, 10, 1169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, C.; Yu, H. Modifying the nanostructures of PEDOT:PSS/Ti3C2TX composite hole transport layers for highly efficient polymer solar cells. J. Mater. Chem. C 2020, 8, 4169–4180. [Google Scholar] [CrossRef]

- Li, X.; Liu, C.; Wang, T.; Wang, W.; Wang, X.; Jiang, Q.; Jiang, F.; Xu, J. Preparation of 2D MoSe2/PEDOT:PSS composite and its thermoelectric properties. Mater. Res. Express 2017, 4, 116410. [Google Scholar] [CrossRef]

- Khoa, D.Q.; Hieu, N.N.; Hoi, B.D. Enhanced anisotropic electrical conductivity of perturbed monolayer β12-borophene. Phys. Chem. Chem. Phys. 2020, 22, 286–294. [Google Scholar] [CrossRef]

- Vázquez de Parga, A.L.; Calleja, F.; Norris, A. Electronic Structure of Organic Films on Graphene, in Encyclopedia of Interfacial Chemistry; Wandelt, K., Ed.; Elsevier: Oxford, UK, 2018; pp. 45–49. [Google Scholar]

- Dasari, B.; Naher, S. Graphene Materials for Batteries, in Encyclopedia of Smart Materials; Olabi, A.-G., Ed.; Elsevier: Oxford, UK, 2022; pp. 69–84. [Google Scholar]

- Banerjee, S.; Lee, J.H.; Kuila, T.; Kim, N.H. 7-Synthesis of Graphene-Based Polymeric Nanocomposites, in Fillers and Reinforcements for Advanced Nanocomposites; Dong, Y., Umer, R., Lau, A.K.-T., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 133–155. [Google Scholar]

- Khasim, S.; Badi, N.; Pasha, A.; Al-Ghamdi, S.A.; Dhananjaya, N.; Pratibha, S. Fabrication and Testing of Ultra-Long Life Anode Material Using PEDOT-PSS/Graphene Nanoplatelet Composite for Flexible Li-ion Batteries. Int. J. Electrochem. Sci. 2021, 16, 210227. [Google Scholar] [CrossRef]

- Ayodhya, D.; Veerabhadram, G. A brief review on synthesis, properties and lithium-ion battery applications of borophene. FlatChem 2020, 19, 100150. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Y.; Penev, E.S.; Yakobson, B.I. Elasticity, Flexibility, and Ideal Strength of Borophenes. Adv. Funct. Mater. 2017, 27, 1605059. [Google Scholar] [CrossRef] [Green Version]

- Arabha, S.; Akbarzadeh, A.; Rajabpour, A. Engineered porous borophene with tunable anisotropic properties. Compos. Part B Eng. 2020, 200, 108260. [Google Scholar] [CrossRef]

- Ali, D.; Sen, S. Finite element analysis of the effect of boron nitride nanotubes in beta tricalcium phosphate and hydroxyapatite elastic modulus using the RVE model. Compos. Part B Eng. 2016, 90, 336–340. [Google Scholar] [CrossRef]

- Chandra, Y.; Adhikari, S.; Flores, E.S.; Figiel, L. Advances in finite element modelling of graphene and associated nanostructures. Mater. Sci. Eng. R Rep. 2020, 140, 100544. [Google Scholar] [CrossRef]

- Xiao, W.; Zhai, X.; Ma, P.; Fan, T.; Li, X. Numerical study on the thermal behavior of graphene nanoplatelets/epoxy composites. Results Phys. 2018, 9, 673–679. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Jamali, J. A new form of a Halpin–Tsai micromechanical model for characterizing the mechanical properties of carbon nanotube-reinforced polymer nanocomposites. Bull. Mater. Sci. 2019, 42, 117. [Google Scholar] [CrossRef] [Green Version]

- e-Xstream. Digimat—A Nonlinear Multi-Scale Material Modeling Platform. In Mscsoftware; Hexagon, Ed.; e-Xstream: Luxembourg, 2017. [Google Scholar]

- Amirmaleki, M.; Samei, J.; Green, D.E.; van Riemsdijk, I.; Stewart, L. 3D micromechanical modeling of dual phase steels using the representative volume element method. Mech. Mater. 2016, 101, 27–39. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Ryzińska, G.; Biglar, M.; Gromada, M. Modelling of multilayer actuator layers by homogenisation technique using Digimat software. Ceram. Int. 2017, 43, 3259–3266. [Google Scholar] [CrossRef]

- Lenz, A.; Kariis, H.; Pohl, A.; Persson, P.; Ojamäe, L. The electronic structure and reflectivity of PEDOT:PSS from density functional theory. Chem. Phys. 2011, 384, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Kyaw, A.K.K.; Yemata, T.A.; Wang, X.; Lim, S.L.; Chin, W.S.; Hippalgaonkar, K.; Xu, J. Enhanced Thermoelectric Performance of PEDOT:PSS Films by Sequential Post-Treatment with Formamide. Macromol. Mater. Eng. 2018, 303, 1700429. [Google Scholar] [CrossRef]

- Elmarakbi, A.; Azoti, W.; Serry, M. Multiscale modelling of hybrid glass fibres reinforced graphene platelets polyamide PA6 matrix composites for crashworthiness applications. Appl. Mater. Today 2017, 6, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Mannix, A.J.; Zhou, X.-F.; Kiraly, B.; Wood, J.D.; Alducin, D.; Myers, B.D.; Liu, X.; Fisher, B.L.; Santiago, U.; Guest, J.R.; et al. Synthesis of borophenes: Anisotropic, two-dimensional boron polymorphs. Science 2015, 350, 1513. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385. [Google Scholar] [CrossRef] [PubMed]

- Greco, F.; Zucca, A.; Taccola, S.; Menciassi, A.; Fujie, T.; Haniuda, H.; Takeoka, S.; Dario, P.; Mattoli, V. Ultra-thin conductive free-standing PEDOT/PSS nanofilms. Soft Matter 2011, 7, 10642–10650. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.; Jang, Y.; Oh, J.; Jung, J. A silver-nanoparticle-embedded activated-carbon–PEDOT:PSS composite conductor for enhancing electrical conductivity of a gas sensor module. Dig. J. Nanomater. Biostruct. 2018, 13, 527–534. [Google Scholar]

| Properties | PEDOT:PSS | BNP | GNP |

|---|---|---|---|

| Density (g/cm3) | 1.01–1.72 [27,28] | 2.53 | 2.2 [29] |

| Young’s modulus (GPa) | 0.5–2.7 [5,6,7] | X = 1372.40 Y = 586.20 [19,30] | 1000 [31] |

| Shear Modulus (GPa) | - | 287.35 | - |

| Poisson ratio | 0.33 [32] | X = −0.04 Y = −0.02 [19,30] | 0.22 [29] |

| Particle size (nm) | 30 nm [33] | - | - |

| Thickness | - | 0.27–0.31 nm | ~0.34 nm [31] |

| Aspect ratio | - | 0.01 | 0.000333 [29] 0.01 (in this work) |

| Volume fraction | - | 4% | 4% |

| Mechanical Parameter | Dimension (nm) | Moduli (GPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume Fraction (%) | Aspect Ratio | Diameter | Thickness | E1 (MPa) | E2 (MPa) | E3 (MPa) | v12 | v13 | v23 | G12 (MPa) | G13 (MPa) | G23 (MPa) | |

| BNP/PEDOT:PSS | 4 | 0.01 | 29.00 | 0.29 | 2962.24 | 2961.66 | 2957.15 | 0.32 | 0.32 | 0.32 | 1093.12 | 1090.50 | 1096.23 |

| GNP/PEDOT:PSS | 4 | 0.01 | 29.00 | 0.29 | 2984.52 | 2961.30 | 2981.71 | 0.32 | 0.32 | 0.32 | 1105.77 | 1104.08 | 1103.23 |

| Composites | FE (MPa) | H-T Model (MPa) |

|---|---|---|

| BNP/PEDOT:PSS | 2960.35 | 2952.59 |

| GNP/PEDOT:PSS | 2975.84 | 2952.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adekoya, G.J.; Adekoya, O.C.; Sadiku, E.R.; Hamam, Y.; Ray, S.S. Effect of Borophene and Graphene on the Elastic Modulus of PEDOT:PSS Film—A Finite Element Study. Condens. Matter 2022, 7, 22. https://0-doi-org.brum.beds.ac.uk/10.3390/condmat7010022

Adekoya GJ, Adekoya OC, Sadiku ER, Hamam Y, Ray SS. Effect of Borophene and Graphene on the Elastic Modulus of PEDOT:PSS Film—A Finite Element Study. Condensed Matter. 2022; 7(1):22. https://0-doi-org.brum.beds.ac.uk/10.3390/condmat7010022

Chicago/Turabian StyleAdekoya, Gbolahan Joseph, Oluwasegun Chijioke Adekoya, Emmanuel Rotimi Sadiku, Yskandar Hamam, and Suprakas Sinha Ray. 2022. "Effect of Borophene and Graphene on the Elastic Modulus of PEDOT:PSS Film—A Finite Element Study" Condensed Matter 7, no. 1: 22. https://0-doi-org.brum.beds.ac.uk/10.3390/condmat7010022