Integration of BIM and Procedural Modeling Tools for Road Design

Abstract

:1. Introduction

2. Procedural Modeling of a Road Infrastructure

- Italian geometric Standard [29], which defines the criteria for the design of the functional aspects and geometric elements of roads, in relation to their classification according to the Highway Code;

- Road Pavements Catalogue [30], which offers a range of road structure solutions of various types and valid for the typical traffic and environmental conditions;

- Regulations for the implementation of the Highway Code [31], taken as reference for horizontal road markings.

2.1. Use Case: Road Infrastructure Design in OpenSCAD

2.2. Use Case: Road Infrastructure Design in Rhinoceros and Grasshopper

- GHPython Script, to weave the values provided in the road pavement catalogue model through a series of statements written in the Python programming language. Indeed, the thickness of each layer of road pavement, namely Surface, Binder, Base and Subbase Thickness, is identified. Firstly, the category of the road structure is chosen, that can be flexible, semi-rigid, rigid unreinforced or rigid with continuous reinforcement. Secondly the Resilient Module and the Average Daily Traffic expected in the infrastructure are selected.

- Number Slider, in the form of Integer or Floating point for Number of Lanes, Total Length and Cross Inclination;

- Value List, which provides a list of individual values to choose from, adopted for the inputs of Lane Width, Divider Width, Left Quay Width, Right Quay Width, Broken White Width, Broken White Length, Broken White Gap, Edge White Width, Barrier Width, Barrier Height and White Stripe Thickness.

3. Results

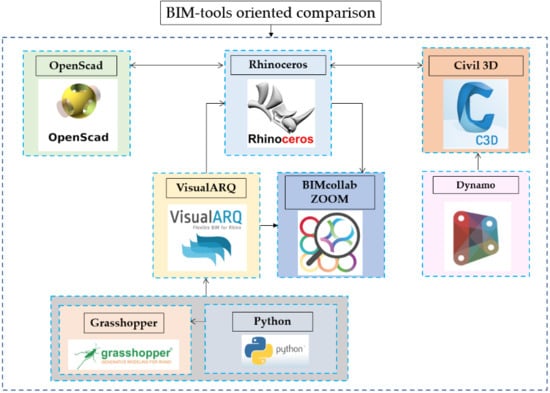

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ng, S.T.; Xu, F.J.; Yang, Y.; Lu, M. A master data management solution to unlock the value of big infrastructure data for smart, sustainable and resilient city planning. Procedia Eng. 2017, 196, 939–947. [Google Scholar] [CrossRef]

- Mgbere, C.; Knyshenko, V.A.; Bakirova, A.B. Building information modeling. A management tool for Smart City. In Proceedings of the 2018 IEEE 13th International Scientific and Technical Conference on Computer Sciences and Information Technologies (CSIT), Lviv, Ukraine, 11–14 September 2018; Article number 8526634. pp. 177–182. [Google Scholar]

- Kupriyanovsky, V.; Alenkov, V.; Sokolov, I.; Zazhigalkin, A.; Klimov, A.; Stepanenko, A.; Sinyagov, S.; Namiot, D. Smart infrastructure, physical and information assets, Smart Cities, BIM, GIS, and IoT. Int. J. Open Inf. Technol. 2017, 5, 55–86. [Google Scholar]

- Geospatial World. Available online: https://www.geospatialworld.net/blogs/bim-smart-cities/ (accessed on 4 March 2020).

- Hassnain, R.; Waqas, T.; Seungsoo, L.; Jongwon, S. Flexible Earthwork BIM Module Framework for Road Project. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction (ISARC 2017), Taipei, Taiwan, 28 June–1 July 2017; pp. 410–451. [Google Scholar]

- Bradley, A.; Li, H.; Lark, R.; Dunn, S. BIM for infrastructure: An overall review and constructor perspective. Automat. Constr. 2016, 71, 139–152. [Google Scholar] [CrossRef]

- Pasetto, M.; Giordano, A.; Borin, P.; Giacomello, G. Integrated railway design using Infrastructure-Building Information Modeling. The case study of the port of Venice. Transp. Res. Procedia 2020, 45, 850–857. [Google Scholar] [CrossRef]

- Singer, D.; Borrmann, A. A Novel Knowledge-Based Engineering Approach for Infrastructure Design. In Proceedings of the Fourth International Conference on Soft Computing Technology in Civil, Structural and Environmental Engineering, Prague, Czech Republic, 1–4 September 2015. [Google Scholar]

- Chong, H.Y.; Lopez, R.; Wang, J.; Wang, X.; Zhao, Z. Comparative Analysis on the Adoption and Use of BIM in Road Infrastructure Projects. J. Manag. Eng. 2016, 32, 05016021. [Google Scholar] [CrossRef]

- Dell’Acqua, G.; Guerra De Olivera, S.; Biancardo, S.A. Railway-BIM: Analytical review, data standard and overall perspective. Ingegneria Ferroviaria 2018, 11, 901–923. [Google Scholar]

- Abbondati, F.; Biancardo, S.A.; Palazzo, S.; Capaldo, F.S.; Viscione, N. I-BIM for Airport Infrastructures. Transp. Res. Proc. 2019, 45, 596–603. [Google Scholar] [CrossRef]

- AEC Excellence Awards 2017. Foster + Partners and FR-EE Take off with BIM AEC. Available online: https://www.autodesk.com/solutions/bim/hub/aec-excellence-2017/infrastructure/first-place (accessed on 31 March 2020).

- AEC Excellence Awards 2018. Improving Design & Approvals for a Monorail. Available online: https://www.autodesk.com/solutions/bim/hub/aec-excellence-2018/infrastructure/finalists/taejongdae-monorail (accessed on 31 March 2020).

- Recognizing AEC Brilliance. Available online: https://excellenceawards.autodesk.com/ (accessed on 31 March 2020).

- Tschuchnigg, F.; Lederhilger, C. BIM in Geotechnics—Application to Road and Railway Construction. In Proceedings of the International Conference on Information technology in Geo-Engineering, Guimarães, Portugal, 29 September–2 October 2019; pp. 471–482. [Google Scholar]

- Khan, N.; Ali, A.K.; Skibniewski, M.J.; Lee, D.J.; Park, C. Excavation Safety Modeling Approach Using BIM and VPL. Adv. Civ. Eng. 2019, 2019, 1515808. [Google Scholar] [CrossRef] [Green Version]

- Shaaban, K.; Nadeem, A. Professionals’ perception towards using building information modelling (BIM) in the highway and infrastructure projects. Int. J. Eng. Manag. Econ. 2015, 5, 273. [Google Scholar] [CrossRef]

- Georgoula, V. Development of an Autodesk Revit Add- in for the Parametric Modeling of Bridge Abutments for BIM in Infrastructure. Master’s Thesis, Technical University of Munich, Munich, Germany, 2019. Available online: https://publications.cms.bgu.tum.de/theses/2019_Georgoula_Vilgertshofer.pdf (accessed on 31 March 2020).

- Slobodchikov, R.; Bakke, K.L.; Svennevig, P.R.; O’Born, R. Implementing climate impacts in road infrastructure in the design phase by combining BIM with LCA. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Graz, Austria, 11–14 September 2019; Volume 323. [Google Scholar]

- Tang, F.; Ma, T.; Zhang, J.; Guan, Y.; Chen, L. Integrating three-dimensional road design and pavement structure analysis based on BIM. Autom. Constr. 2020, 113, 103152. [Google Scholar] [CrossRef]

- Amer, A.H.; Hasan, O. Level of detail (LOD) specifications, standards and file-format challenges in infrastructure projects for BIM level three. WIT Trans. Built Environ. 2017, 169, 143–154. [Google Scholar]

- Liu, B.; Cai, T.; Xiao, S.; Fu, H.; Chu, W. Research on application of BIM technology in municipal road construction. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Graz, Austria, 11–14 September 2019; Volume 330. [Google Scholar]

- Chen, L.; Shi, P.; Tang, Q.; Liu, W.; Wu, Q. Development and application of a specification-compliant highway tunnel facility management system based on BIM. Tunn. Undergr. Space Technol. 2020, 97, 103262. [Google Scholar] [CrossRef]

- Costin, A.; Adibfar, A.; Hu, H.; Chen, S.S. Building Information Modeling (BIM) for transportation infrastructure—Literature review, applications, challenges, and recommendations. Automat. Constr. 2018, 94, 257–281. [Google Scholar] [CrossRef]

- Floros, G.S.; Boyes, G.; Owens, D.; Ellul, C. Developing IFC for infrastructure: A case study of three highway entities. In Proceedings of the ISPRS Annals of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Singapore, 24–27 September 2019. [Google Scholar]

- Ozturk, G.B. Interoperability in building information modeling for AECO/FM industry. Automat. Constr. 2020, 113, 103122. [Google Scholar] [CrossRef]

- Al Sayed, K.; Bew, M.; Penn, A.; Palmer, D.; Broyd, T. Modelling dependency networks to inform data structures in BIM and smart cities. In Proceedings of the 10th International Space Syntax Symposium, London, UK, 13–17 July 2015. [Google Scholar]

- Vilgertshofer, S.; Borrmann, A. Using graph rewriting methods for the semi-automatic generation of parametric infrastructure models. Adv. Eng. Inf. 2017, 33, 502–515. [Google Scholar] [CrossRef]

- Ministero delle Infrastrutture e dei Trasporti. Decreto Ministeriale 5 novembre 2001, n. 6792 (S.O. n.5 alla G.U. n.3. del 4.1.02). Norme Funzionali e Geometriche per la Costruzione delle Strade. Available online: http://www.mit.gov.it/mit/mop_all.php?p_id=1983 (accessed on 4 March 2020).

- Consiglio Nazionale delle Ricerche. Catalogo delle Pavimentazioni Stradali; Consiglio Nazionale delle Ricerche: Roma, Italy, 1995. [Google Scholar]

- Decreto del Presidente della Repubblica. Regolamento di Esecuzione e di Attuazione del Nuovo Codice della Strada, 16 Dicembre 1992, n. 495. Available online: https://www.gazzettaufficiale.it/eli/id/1992/12/28/092G0531/sg (accessed on 4 March 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biancardo, S.A.; Capano, A.; de Oliveira, S.G.; Tibaut, A. Integration of BIM and Procedural Modeling Tools for Road Design. Infrastructures 2020, 5, 37. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures5040037

Biancardo SA, Capano A, de Oliveira SG, Tibaut A. Integration of BIM and Procedural Modeling Tools for Road Design. Infrastructures. 2020; 5(4):37. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures5040037

Chicago/Turabian StyleBiancardo, Salvatore Antonio, Alessandra Capano, Sara Guerra de Oliveira, and Andrej Tibaut. 2020. "Integration of BIM and Procedural Modeling Tools for Road Design" Infrastructures 5, no. 4: 37. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures5040037