Influence of the Breed of Sheep on the Characteristics of Zamorano Cheese

New Approaches to Sheep and Goat Milk Cheese: Biochemical, Sensory and Nutritional Characteristics

)

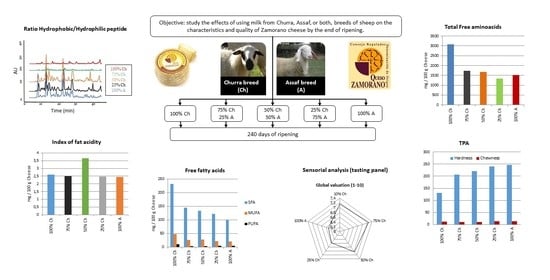

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cheese Making and Sampling

2.2. Peptide Profile Analysis

2.3. Free Amino Acid Content

2.4. Analysis of Lipolysis and Quantification of Free Fatty Acids

2.5. Texture Profile Analysis and Sensory Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Peptide Profile

3.2. Free Amino Acids

3.3. Lipolytic Changes and Quantification of Free Fatty Acids

3.4. Texture Profile Analysis

3.5. Sensory Analysis by Tasting Panel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Commission Regulation (EC) No 1107/96 of 12 June 1996. Registration of Geographical Indications and Designations of Origin under the Procedure Laid down in Article 17 of Council Regulation (EEC) No 2081/92. Off. J. 1996, L 14, 0001–0010.

- Boletín Oficial del Estado. Regulation of 6 May 1993. Regulation of the Denomination of Origin Queso Zamorano and Its Regulatory Council. In State Official Newsletter-Boletín Oficial del Estado (BOE); Boletín Oficial del Estado: Madrid, Spain, 1993; Volume 120, p. 15311. [Google Scholar]

- Commission Implementing Regulation (EU) 2015/625 of 20 April 2015. Approving Non-Minor Amendments to the Specification for a Name Entered in the Register of Protected Designations of Origin and Protected Geographical Indications [Queso Zamorano (PDO)]. Off. J. Eur. Union 2015, L 103/5. Available online: http://data.europa.eu/eli/reg_impl/2015/625/oj (accessed on 11 January 2021).

- Regulation APA 2420. Regulation APA 2420/2003 of August 28, by Which the Official Catalog of Cattle Breeds of Spain is Modified, Contained in the Annex to RD 1682/1997, of 7 November, for Which the Official Catalog of Cattle Breeds of Spain is Updated. State Official Newsletter-Boletín Oficial del Estado (BOE). 5 September 2003, p. 33523. Available online: https://www.boe.es/eli/es/o/2003/08/28/apa2420 (accessed on 11 January 2021).

- De la Fuente, L.F.; Gabiña, D.; Carolino, N.; Ugarte, E. The Awassi and Assaf breeds in Spain and Portugal. In Sheep and Goat Commission. Session 14: Awassi Sheep. In Proceedings of the 57 Annual Meeting of European Association for Animal Production (EAAP), Antalya, Turkey, 17–20 September 2006. Paper S14.2. [Google Scholar]

- Milán, M.J.; Caja, G.; González-González, R.; Fernández-Pérez, A.M.; Such, X. Structure and performance of Awassi and Assaf dairy sheep farms in northwestern Spain. J. Dairy Sci. 2010, 94, 771–784. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stocco, G.; Cipolat-Gotet, C.; Bobbo, T.; Cecchinato, A.; Bittante, G. Breed of cow and herd productivity affect milk composition and modeling of coagulation, curd firming, and syneresis. J. Dairy Sci. 2017, 100, 129–145. [Google Scholar] [CrossRef] [PubMed]

- Vacca, G.M.; Stocco, G.; Dettori, M.L.; Pira, E.; Bittante, G.; Pazzola, M. Milk yield, quality, and coagulation properties of 6 breeds of goats: Environmental and individual variability. J. Dairy Sci. 2018, 101, 7236–7247. [Google Scholar] [CrossRef] [PubMed]

- Ferrandini, E.; Castillo, M.; De Renobales, M.; Virto, M.D.; Garrido, M.D.; Rovira, S.; López, M.B. Influence of lamb rennet paste on the lipolytic and sensory profile of Murcia al Vino cheese. J. Dairy Sci. 2012, 95, 2788–2796. [Google Scholar] [CrossRef] [Green Version]

- Thierry, A.; Collins, Y.F.; Mukdsi, M.C.A.; McSweeney, P.L.H.; Wilkinson, M.G.; Spinnler, H.E. Lipolysis and metabolism of fatty acids in cheese. In Cheese: Chemistry, Physics, and Microbiology; McSweeney, P.L.H., Fox, P.F., Cotter, P.D., Everett, D.W., Eds.; Academic Press: Gaithersburg, MD, USA, 2017; Volume 1, pp. 423–444. [Google Scholar]

- Combarros-Fuertes, P.; Fernández, D.; Arenas, R.; Diezhandino, I.; Tornadijo, M.E.; Fresno, J.M. Biogenic amines in Zamorano cheese: Factors involved in their accumulation. J. Sci. Food Agric. 2016, 96, 295–305. [Google Scholar] [CrossRef]

- Fernández-García, E.; Carbonell, M.; Gaya, P.; Nuñez, M. Evolution of the volatile components of ewes raw milk Zamorano cheese. Seasonal variation. Int. Dairy J. 2004, 14, 701–711. [Google Scholar] [CrossRef]

- Fernández, D.; Arenas, R.; Ferrazza, R.E.; Tornadijo, M.E.; Fresno, J.M. Chapter 24. Zamorano Cheese. In Handbook of Animal-Based Fermented Food and Beverage Technology; Hui, Y.H., Özgül Evranuz, E., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 397–416. [Google Scholar]

- Ferrazza, R.E.; Fresno, J.M.; Ribeiro, J.I.; Tornadijo, M.E.; Furtado, M.M. Changes in the microbial flora of Zamorano cheese (P.D.O.) by accelerated ripening process. Food Res. Int. 2004, 37, 149–155. [Google Scholar] [CrossRef]

- Lurueña-Martínez, M.A.; Revilla, I.; Severiano-Pérez, P.; Vivar-Quintana, A.M. The influence of breed on the organoleptic characteristics of Zamorano sheep’s raw milk cheese and its assessment by instrumental analysis. Int. J. Dairy Technol. 2010, 63, 216–223. [Google Scholar] [CrossRef]

- Lau, K.Y.; Barbano, D.M.; Rasmussen, R.R. Influence of Pasteurization of Milk on Protein Breakdown in Cheddar Cheese during Aging. J. Dairy Sci. 1991, 74, 727–740. [Google Scholar] [CrossRef]

- Picón, A.; Gaya, P.; Fernández-García, E.; Rivas-Cañedo, A.; Avila, M.; Núñez, M. Proteolysis, lipolysis, volatile compounds, texture, and flavor of Hispánico cheese made using frozen ewe milk curds pressed for different times. J. Dairy Sci. 2010, 93, 2896–2905. [Google Scholar] [CrossRef]

- Andersen, L.T.; Ardö, Y.; Bredie, W.L.P. Study of taste-active compounds in the water-soluble extract of mature Cheddar cheese. Int. Dairy J. 2010, 20, 528–536. [Google Scholar] [CrossRef]

- Parra, L.; Casal, V.; Gómez, R. Contribution of Lactococcus lactis subsp lactis IFPL 359 and Lactobacillus casei subsp casei IFPL 731 to the Proteolysis of Caprine Curd Slurries. J. Food Sci. 2000, 65, 711–715. [Google Scholar] [CrossRef] [Green Version]

- Alonso, M.L.; Alvarez, A.I.; Zapico, J. Rapid Analysis of Free Amino Acids in Infant Foods. J. Liq. Chromatogr. 1994, 17, 4019–4030. [Google Scholar] [CrossRef]

- ISO. ISO 1740:2004. S Milkfat Products and Butter—Determination of Fat Acidity (Reference Method); International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- De Jong, C.; Badings, H.T. Determination of free fatty acids in milk and cheese procedures for extraction, clean up, and capillary gas chromatographic analysis. J. High Resolut. Chromatogr. 1990, 13, 94–98. [Google Scholar] [CrossRef]

- Arenas, R.; González, L.; Sacristán, N.; Tornadijo, M.E.; Fresno, J.M. Compositional and biochemical changes in Genestoso cheese, a Spanish raw cow’s milk variety, during ripening. J. Sci. Food Agric. 2014, 95, 851–859. [Google Scholar] [CrossRef]

- Bourne, M. Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2002. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 8586:2012. General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Biochemistry of cheese ripening. In Fundamentals of Cheese Science; Springer: New York, NY, USA, 2017; pp. 391–442. [Google Scholar]

- Hayaloğlu, A.A.; Tolu, C.; Yasar, K. Influence of goat breeds and starter culture systems on gross composition and proteolysis in Gokceada goat cheese during ripening. Small Rumin. Res. 2013, 113, 231–238. [Google Scholar] [CrossRef]

- Poveda, J.M.; Cabezas, L.; McSweeney, P.L.H. Free amino acid content of Manchego cheese manufactured with different starter cultures and changes throughout ripening. Food Chem. 2004, 84, 213–218. [Google Scholar] [CrossRef]

- Diana, M.; Rafecas, M.; Arco, C.; Quílez, J. Free amino acid profile of Spanish artisanal cheeses: Importance of gamma-aminobutyric acid (GABA) and ornithine content. J. Food Compos. Anal. 2014, 35, 94–100. [Google Scholar] [CrossRef]

- Ferrazza, R.E. Caracterização do Queijo Zamorano dop sob Condições de Maturação Acelerada por Modificações na Temperatura. Ph.D. Thesis, Universidade Federal de Viçosa, Viçosa, Brasil, 2002. [Google Scholar]

- Renes, E.; Ladero, V.; Tornadijo, M.E.; Fresno, J.M. Production of sheep milk cheese with high γ-aminobutyric acid and ornithine concentration and with reduced biogenic amines level using autochthonous lactic acid bacteria strains. Food Microbiol. 2019, 78, 1–10. [Google Scholar] [CrossRef]

- Bovolenta, S.; Romanzin, A.; Corazzin, M.; Spanghero, M.; Aprea, E.; Gasperi, F.; Piasentier, E. Volatile compounds and sensory properties of Montasio cheese made from the milk of Simmental cows grazing on alpine pastures. J. Dairy Sci. 2014, 97, 7373–7385. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, I.M.; Pinho, O.; Sampaio, P. Volatile fraction of DOP “Castelo Branco” cheese: Influence of breed. Food Chem. 2009, 112, 1053–1059. [Google Scholar] [CrossRef]

- Hernández, I.; Barrón, L.J.R.; Virto, M.; Pérez-Elortondo, F.J.; Flanagan, C.; Rozas, U.; Nájer, A.I.; Albisu, M.; Vicente, M.S.; de Renobales, M. Lipolysis, proteolysis and sensory properties of ewe’s raw milk cheese (Idiazábal) made with lipase addition. Food Chem. 2009, 116, 158–166. [Google Scholar] [CrossRef]

- Fernández-Garcia, E.; López-Fandiño, R.; Alonso, L.; Ramos, M. The Use of Lipolytic and Proteolytic Enzymes in the Manufacture of Manchego Type Cheese from Ovine and Bovine Milk. J. Dairy Sci. 1994, 77, 2139–2149. [Google Scholar] [CrossRef]

- Guarrasi, V.; Sannino, C.; Moschetti, M.; Bonanno, A.; Di Grigoli, A.; Settanni, L. The individual contribution of starter and non-starter lactic acid bacteria to the volatile organic compound composition of Caciocavallo Palermitano cheese. Int. J. Food Microbiol. 2017, 259, 35–42. [Google Scholar] [CrossRef]

- Soják, L.; Blaško, J.; Kubinec, R.; Górová, R.; Addová, G.; Ostrovský, I.; Margetín, M. Variation among individuals, breeds, parities and milk fatty acid profile and milk yield of ewes grazed on pasture. Small Rumin. Res. 2013, 109, 173–181. [Google Scholar] [CrossRef]

- Yurchenko, S.; Sats, A.; Tatar, V.; Kaart, T.; Mootse, H.; Jõudu, I. Fatty acid profile of milk from Saanen and Swedish Landrace goats. Food Chem. 2018, 254, 326–332. [Google Scholar] [CrossRef]

- Suárez-Vega, A.; Gutiérrez-Gil, B.; Arranz, J.J. Transcriptome expression analysis of candidate milk genes affecting cheese-related traits in 2 sheep breeds. J. Dairy Sci. 2016, 99, 6381–6390. [Google Scholar] [CrossRef]

- Signorelli, F.; Contarini, G.; Annicchiarico, G.; Napolitano, F.; Orrù, L.; Catillo, G.; Haenlein, G.F.W.; Moioli, B. Breed differences in sheep milk fatty acid profiles: Opportunities for sustainable use of animal genetic resources. Small Rumin. Res. 2008, 78, 24–31. [Google Scholar] [CrossRef]

- Soryal, K.; Beyene, F.A.; Zeng, S.; Bah, B.; Tesfai, K. Effect of goat breed and milk composition on yield, sensory quality, fatty acid concentration of soft cheese during lactation. Small Rumin. Res. 2005, 58, 275–281. [Google Scholar] [CrossRef]

- Antoniou, K.D.; Petridis, D.; Raphaelides, S.; Ben Omar, Z.; Kesteloot, R. Texture Assessment of French Cheeses. J. Food Sci. 2000, 65, 168–172. [Google Scholar] [CrossRef]

- Guinee, T.P.; Fox, P.F. Salt in Cheese: Physical, Chemical and Biological Aspects. Cheese. In Cheese: Chemistry, Physics and Microbiology, 4th ed.; McSweeney, P.L.H., Fox, P.F., Cotter, P.D., Everett, D.W., Eds.; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2017; pp. 317–375. [Google Scholar] [CrossRef]

- Nazari, S.M.; Mortazavi, A.; Hesari, J.; Yazdi, F.T. Proteolysis and textural properties of low-fat ultrafiltered Feta cheese as influenced by maltodextrin. Int. J. Dairy Technol. 2020, 73, 244–254. [Google Scholar] [CrossRef]

- Martin, B.; Pomiès, D.; Pradel, P.; Verdier-Metz, L.; Rémond, B. Yield and sensory properties of cheese made with milk from Holstein or Montbéliarde cows milked twice or once daily. J. Dairy Sci. 2009, 92, 4730–4737. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fresno, M.; Torres, A.; Capote, J.; Álvarez, S. Effect of breed on physicochemical and sensory characteristics of fresh, semihard and hard goat’s milk cheeses. J. Appl. Anim. Res. 2020, 48, 425–433. [Google Scholar] [CrossRef]

- Mendia, C.; Ibañez, F.C.; Torre, P.; Barcina, Y. Influence of the Season on Proteolysis and Sensory Characteristics of Idiazabal Cheese. J. Dairy Sci. 2000, 83, 1899–1904. [Google Scholar] [CrossRef]

- Stocco, G.; Cipolat-Gotet, C.; Gasparotto, V.; Cecchinato, A.; Bittante, G. Breed of cow and herd productivity affect milk nutrient recovery in curd, and cheese yield, efficiency and daily production. Animal 2017, 12, 434–444. [Google Scholar] [CrossRef] [PubMed]

- Cipolat-Gotet, C.; Cecchinato, A.; Drake, M.A.; Marangon, A.; Martin, B.; Bittante, G. From cow to cheese: Novel phenotypes related to the sensory profile of model cheeses from individual cows. J. Dairy Sci. 2018, 101, 5865–5877. [Google Scholar] [CrossRef] [Green Version]

| Milk | |||||

|---|---|---|---|---|---|

| 100% Ch | 75% Ch:25% A | 50% Ch:50% A | 25% Ch:75% A | 100% A | |

| Zone 1 | 0.34 ± 0.01 c | 0.27 ± 0.01 b | 0.25 ± 0.01 a | 0.24 ± 0.01 a | 0.24 ± 0.01 a |

| Zone 2 | 0.38 ± 0.01 c | 0.36 ± 0.01 b | 0.35 ± 0.01 a,b | 0.33 ± 0.01 a | 0.34 ± 0.01 a,b |

| Zone 3 | 0.28 ± 0.01 b | 0.24 ± 0.01 a | 0.38 ± 0.01 c | 0.43 ± 0.01 d | 0.41 ± 0.01 d |

| Hyphob/Hyphil | 4.00 ± 0.11 a | 5.35 ± 0.15 b | 5.69 ± 0.16 b,c | 5.86 ± 0.16 c | 6.69 ± 0.19 d |

| Milk | |||||

|---|---|---|---|---|---|

| Amino Acids | 100% Ch | 75% Ch:25% A | 50% Ch:50% A | 25% Ch:75% A | 100% A |

| Asp | 40.55 ± 0.86 c | 42.92 ± 0.93 d | 39.85 ± 0.84 c | 30.35 ± 0.58 b | 25.05 ± 0.43 a |

| Glu | 357.09 ± 9.82 b | 120.90 ± 3.14 a | 128.15 ± 3.34 a | 119.89 ± 3.11 a | 115.61 ± 2.99 a |

| Asn | 193.64 ± 5.19 e | 53.87 ± 1.52 c | 66.49 ± 1.74 d | 31.19 ± 0.60 a | 40.21 ± 0.85 b |

| Ser | 63.04 ± 1.50 d | 46.63 ± 1.04 c | 38.57 ± 0.81 a,b | 39.39 ± 0.97 b | 36.32 ± 1.03 a |

| Gln+Gly | 709.38 ± 19.78 d | 323.38 ± 9.15 c | 316.09 ± 8.80 c | 217.29 ± 5.58 a | 283.73 ± 7.46 b |

| His | 32.41 ± 0.63 b | 29.12 ± 0.68 a | 29.29 ± 0.55 a | 36.23 ± 0.74 c | 33.32 ± 0.66 b |

| Cit | 7.89 ± 0.34 a | 38.24 ± 1.08 c | 43.67 ± 0.95 d | 20.30 ± 0.29 b | 39.47 ± 0.83 c |

| Tau | 121.44 ± 3.15 d | 52.30 ± 1.20 c | 41.48 ± 0.89 b | 11.53 ± 0.04 a | 12.31 ± 0.07 a |

| Gaba | 26.08 ± 1.87 a | 41.22 ± 0.88 b | 47.92 ± 1.07 c | 49.41 ± 0.41 c | 78.76 ± 1.94 d |

| Arg+Thr | 101.56 ± 2.59 c | 67.61 ± 1.91 a,b | 71.54 ± 1.74 b | 64.98 ± 1.56 a | 64.70 ± 1.55 a |

| Ala | 67.92 ± 1.64 c | 39.63 ± 1.12 b | 42.33 ± 0.91 b | 34.55 ± 0.84 a | 34.25 ± 0.69 a |

| Pro | 26.63 ± 0.47 d | 36.35 ± 1.03 e | 23.70 ± 0.39 c | 20.85 ± 0.31 b | 18.37 ± 0.24 a |

| Tyr | 68.02 ± 1.64 d | 20.53 ± 0.58 c | 21.87 ± 0.34 c | 17.25 ± 0.35 b | 15.04 ± 0.14 a |

| Val | 220.99 ± 5.97 d | 108.28 ± 2.78 b,c | 111.68 ± 2.88 c | 91.23 ± 2.44 a | 101.38 ± 2.58 b |

| Met | 48.56 ± 1.09 d | 19.64 ± 0.27 b,c | 20.55 ± 0.30 c | 18.44 ± 0.38 b | 16.29 ± 0.18 a |

| Cys | ND | 23.71 ± 0.39 b | 22.95 ± 0.37 b | 18.80 ± 0.39 a | 18.78 ± 0.25 a |

| Ile | 42.67 ± 0.92 d | 24.11 ± 0.68 b | 29.33 ± 0.55 c | 17.46 ± 0.35 a | 17.64 ± 0.22 a |

| Leu | 392.25 ± 10.81 d | 274.20 ± 7.47 c | 257.86 ± 7.01 c | 212.19 ± 5.86 a | 237.05 ± 6.42 a |

| Phe | 95.49 ± 2.42 c | 92.21 ± 2.61 c | 57.98 ± 1.36 a | 61.98 ± 1.47 a | 83.76 ± 2.09 b |

| Trp | 118.50 ± 3.07 c | 79.77 ± 1.97 b | 80.66 ± 2.00 b | 68.35 ± 1.79 a | 75.78 ± 1.86 b |

| Orn | 99.33 ± 2.53 c | 67.28 ± 1.62 b | 68.07 ± 1.64 b | 57.86 ± 1.50 | 63.99 ± 1.53 a |

| Lys | 252.06 ± 6.85 d | 138.54 ± 3.64 c | 121.83 ± 3.16 b | 108.12 ± 2.92 a | 103.90 ± 2.94 a |

| Milk | |||||

|---|---|---|---|---|---|

| 100% Ch | 75% Ch:25% A | 50% Ch:50% A | 25% Ch:75% A | 100% A | |

| FAI | 2.61 ± 1.11 a,b | 2.50 ± 0.19 a,b | 3.66 ± 0.08 b | 2.48 ± 1.16 a,b | 2.45 ± 0.70 a |

| C2:0 | 2.71 ± 0.04 d | 2.61 ± 0.04 c | 2.58 ± 0.03 c | 2.45 ± 0.03 b | 2.31 ± 0.03 a |

| C4:0 | 10.50 ± 0.26 b,c | 11.04 ± 0.27 c | 10.02 ± 0.25 b,c | 9.59 ± 0.23 b | 8.52 ± 0.20 a |

| C6:0 | 28.16 ± 0.76 d | 18.78 ± 0.49 b,c | 19.77 ± 0.52 c | 17.42 ± 0.45 b | 15.64 ± 0.40 a |

| C8:0 | 10.23 ± 0.25 c | 4.85 ± 0.10 b | 4.89 ± 0.10 b | 4.08 ± 0.08 a | 3.75 ± 0.07 a |

| C10:0 | 33.28 ± 0.90 d | 18.25 ± 0.48 c | 16.74 ± 0.44 b | 15.56 ± 0.40 b | 13.85 ± 0.35 a |

| C10:1 | 0.50 ± 0.02 a | 0.58 ± 0.02 c | 0.53 ± 0.02 b,c | 0.97 ± 0.01 d | 1.39 ± 0.00 e |

| C12:0 | 20.11 ± 0.53 d | 10.34 ± 0.25 c | 8.20 ± 0.19 b | 7.51 ± 0.17 b | 5.49 ± 0.12 a |

| C14:0 | 39.80 ± 1.09 d | 20.10 ± 0.53 c | 20.55 ± 0.54 c | 17.54 ± 0.46 b | 14.80 ± 0.38 a |

| C14:1 | 0.77 ± 0.02 e | 0.62 ± 0.02 d | 0.53 ± 0.02 c | 0.39 ± 0.03 b | 0.00 ± 0.00 a |

| C15:0 | 2.91 ± 0.04 d | 1.47 ± 0.00 b | 1.67 ± 0.01 c | 1.45 ± 0.00 b | 0.72 ± 0.02 a |

| C16:0 | 59.07 ± 1.39 e | 38.05 ± 1.04 d | 32.29 ± 0.88 c | 28.59 ± 0.77 b | 21.24 ± 0.56 a |

| C16:1 | 0.65 ± 0.02 a | 0.89 ± 0.01 b | 1.14 ± 0.01 d | 1.05 ± 0.01 c | 2.69 ± 0.04 e |

| C18:0 | 25.74 ± 0.69 d | 19.36 ± 0.51 c | 16.72 ± 0.43 b | 18.18 ± 0.48 c | 11.98 ± 0.30 a |

| C18:1 | 46.23 ± 1.27 d | 24.66 ± 0.66 c | 24.88 ± 0.67 c | 19.28 ± 0.51 b | 15.69 ± 0.41 a |

| C18:2 | 8.22 ± 0.19 d | 2.95 ± 0.05 b | 2.57 ± 0.03 a | 3.23 ± 0.05 c | 3.33 ± 0.06 c |

| C18:3 | 0.98 ± 0.01 d | 0.31 ± 0.03 b,c | 0.16 ± 0.03 a | 0.34 ± 0.03 c | 0.25 ± 0.03 b |

| C18:2 Conjugated | 0.82 ± 0.02 d | 0.39 ± 0.03 a,b | 0.35 ± 0.03 a | 0.43 ± 0.03 b | 0.61 ± 0.02 c |

| SFA | 232.50 ± 17.38 c | 144.86 ± 10.65 b | 133.42 ± 9.39 b | 122.38 ± 8.45 b | 98.29 ± 6.55 a |

| MUFA | 48.16 ± 21.11 b | 26.74 ± 11.10 a | 27.08 ± 11.18 a | 21.70 ± 8.56 a | 19.76 ± 6.51 a |

| PUFA | 10.02 ± 3.78 b | 3.65 ± 1.35 a | 3.08 ± 1.20 a | 4.00 ± 1.47 a | 4.19 ± 1.51 a |

| Milk | |||||

|---|---|---|---|---|---|

| 100% Ch | 75% Ch:25% A | 50% Ch:50% A | 25% Ch:75% A | 100% A | |

| Fracturability | 53.97 ± 4.91 a | 68.64 ± 4.68 b | 71.35 ± 3.04 b | 76.65 ± 2.05 b | 103.53 ± 9.21 c |

| Hardness | 192.99 ± 6.21 a | 205.71 ± 16.15 a,b | 220.49 ± 6.52 b,c | 239.54 ± 0.23 c | 246.15 ± 6.17 c |

| Adhesiveness | −6.53 ± 1.34 | −6.25 ± 3.62 | −3.73 ± 2.66 | −4.99 ± 0.21 | −4.83 ± 1.15 |

| Cohesiveness | 0.14 ± 0.01 | 0.12 ± 0.02 | 0.13 ± 0.01 | 0.14 ± 0.01 | 0.14 ± 0.02 |

| Springiness | 0.47 ± 0.01 | 0.42 ± 0.05 | 0.38 ± 0.07 | 0.40 ± 0.08 | 0.47 ± 0.00 |

| Gumminess | 26.10 ± 0.14 a,b | 24.64 ± 1.98 a | 27.98 ± 0.33 b | 31.61 ± 1.68 c | 28.99 ± 0.47 b |

| Chewiness | 12.31 ± 0.33 a,b | 10.39 ± 2.04 a | 10.69 ± 2.03 a | 12.49 ± 2.01 a,b | 13.21 ± 0.32 b |

| Milk | |||||

|---|---|---|---|---|---|

| 100% Ch | 75% Ch:25% A | 50% Ch:50% A | 25% Ch:75% A | 100% A | |

| APPAREANCE | |||||

| Color intensity | 3.71 ± 0.68 | 3.38 ±0.34 | 3.63 ± 0.65 | 3.63 ± 0.65 | 3.88 ± 0.51 |

| Holes size | 3.71 ± 0.68 | 3.25 ± 0.61 | 3.00 ± 0.40 | 3.13 ± 0.78 | 4.13 ± 1.00 |

| Holes number | 3.69 ± 0.47 | 3.47 ± 0.72 | 3.01 ± 0.57 | 3.23 ± 0.68 | 3.97 ± 0.89 |

| ODOR | |||||

| Lactic | 4.12 ± 0.64 | 4.36 ± 0.40 | 4.23 ± 0.37 | 4.01 ± 0.62 | 4.24 ± 0.01 |

| Fresh and clean | 3.98 ± 0.54 | 4.23 ± 0.37 | 4.23 ± 0.37 | 3.88 ± 0.12 | 4.13 ± 0.12 |

| Flowers/fruits | 4.12 ± 0.35 | 3.99 ± 0.13 | 3.87 ± 0.29 | 4.01 ± 0.62 | 4.13 ± 0.13 |

| Grassy | 3.98 ± 0.54 | 4.13 ± 0.13 | 3.73 ± 0.40 | 3.74 ± 0.04 | 4.01 ± 0.62 |

| Dry fruits | 3.84 ± 0.36 | 4.01 ± 0.62 | 3.99 ± 0.13 | 4.01 ± 0.62 | 4.01 ± 0.62 |

| Vanilla | 4.14 ± 0.09 | 3.88 ± 0.12 | 3.99 ± 0.13 | 3.88 ± 0.12 | 4.01 ± 0.62 |

| Wax | 3.99 ± 0.20 | 4.01 ± 0.62 | 3.99 ± 0.13 | 4.01 ± 0.62 | 4.01 ± 0.62 |

| TEXTURE | |||||

| Elasticity | 4.26 ± 0.78 | 3.62 ± 0.15 | 3.61 ± 0.40 | 3.61 ± 0.45 | 3.48 ± 0.58 |

| Crumbliness | 4.27 ± 0.48 | 3.88 ± 0.12 | 3.11 ± 0.43 | 3.23 ± 0.49 | 3.36 ± 0.59 |

| Adhesiveness | 4.25 ± 1.19 b | 4.12 ± 0.02 b | 3.23 ± 0.02 a | 3.37 ± 0.32 a | 3.23 ± 0.42 a |

| Grainy | 2.85 ± 0.74 a | 2.87 ± 0.18 a | 3.71 ± 0.07 a,b | 3.48 ± 0.41 a,b | 3.99 ± 0.28 b |

| Solubility | 4.27 ± 0.44 c | 3.98 ± 0.42 b,c | 3.23 ± 0.49 a | 3.72 ± 0.69 a,b | 3.36 ± 0.49 a |

| Hardness | 3.49 ± 0.06 a | 3.62 ± 0.13 a | 4.01 ± 0.62 a,b | 3.88 ± 0.12 a | 4.13 ± 0.19 b |

| Creaminess | 4.13 ± 0.12 c | 3.88 ± 0.12 c | 3.49 ± 0.14 b | 3.50 ± 0.10 b | 3.13 ± 0.08 a |

| Rugosity | 3.99 ± 0.20 | 3.98 ± 0.42 | 3.23 ± 0.42 | 3.60 ± 0.91 | 3.12 ± 0.08 |

| Dryness | 3.41 ± 0.39 | 3.87 ± 0.12 | 3.22 ± 0.89 | 3.48 ± 0.45 | 3.12 ± 0.18 |

| TASTE | |||||

| Salty | 3.74 ± 0.14 a | 3.74 ± 0.13 a | 3.74 ± 0.13 a | 4.12 ± 0.11 b | 3.99 ± 0.07 a,b |

| Fresh milk | 4.11 ± 0.71 | 3.88 ± 0.12 | 3.37 ± 0.32 | 3.74 ± 0.04 | 3.61 ± 0.45 |

| Acid | 3.27 ± 0.49 | 3.37 ± 0.32 | 2.99 ± 0.08 | 3.61 ± 0.45 | 3.48 ± 0.41 |

| Hot spicy | 3.97 ± 0.95 | 4.11 ± 0.45 | 3.62 ± 0.30 | 3.99 ± 0.13 | 3.74 ± 0.30 |

| Sweet | 3.54 ± 0.75 | 3.86 ± 0.43 | 3.62 ± 0.05 | 4.11 ± 0.37 | 3.87 ± 0.13 |

| Bitter | 2.98 ± 0.41 | 2.99 ± 0.34 | 2.74 ± 0.18 | 3.37 ± 0.16 | 3.23 ± 0.49 |

| Aftertaste and persistence | 4.35 ± 0.16 b | 4.14 ± 0.43 a,b | 3.74 ± 0.14 a,b | 3.36 ± 0.49 a | 3.43 ± 0.51 a |

| OVERALL EVALUATION | |||||

| Overall score | 7.16 ± 0.62 | 7.25 ± 0.48 | 7.04 ± 0.05 | 6.58 ± 0.33 | 6.50 ± 0.51 |

| Milk | |||||

|---|---|---|---|---|---|

| 100% Ch | 75% Ch:25% A | 50% Ch:50% A | 25% Ch:75% A | 100% A | |

| Aspect | 5.45 ± 0.35 a,b | 5.20 ± 0.36 a,b | 5.58 ± 0.24 b | 4.95 ± 0.57 a | 5.25 ± 0.24 a,b |

| Odor | 6.03 ± 0.37 | 5.80 ± 0.16 | 6.03 ± 0.34 | 5.85 ± 0.24 | 5.65 ± 0.34 |

| Taste | 7.20 ± 0.23 | 6.75 ± 0.51 | 6.85 ± 0.42 | 6.80 ± 0.48 | 6.60 ± 0.62 |

| Texture and trigeminal sensations | 5.33 ± 0.22 a,b | 5.00 ± 0.16 a | 5.53 ± 0.38 b | 5.38 ± 0.15 a,b | 5.40 ± 0.34 a,b |

| Overall score | 6.33 ± 0.46 | 6.45 ± 0.62 | 6.00 ± 0.45 | 6.15 ± 0.47 | 6.03 ± 0.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, D.; Combarros-Fuertes, P.; Renes, E.; Abarquero, D.; Fresno, J.M.; Tornadijo, M.E. Influence of the Breed of Sheep on the Characteristics of Zamorano Cheese. Dairy 2021, 2, 242-255. https://0-doi-org.brum.beds.ac.uk/10.3390/dairy2020021

Fernández D, Combarros-Fuertes P, Renes E, Abarquero D, Fresno JM, Tornadijo ME. Influence of the Breed of Sheep on the Characteristics of Zamorano Cheese. Dairy. 2021; 2(2):242-255. https://0-doi-org.brum.beds.ac.uk/10.3390/dairy2020021

Chicago/Turabian StyleFernández, Domingo, Patricia Combarros-Fuertes, Erica Renes, Daniel Abarquero, José María Fresno, and María Eugenia Tornadijo. 2021. "Influence of the Breed of Sheep on the Characteristics of Zamorano Cheese" Dairy 2, no. 2: 242-255. https://0-doi-org.brum.beds.ac.uk/10.3390/dairy2020021