1. Introduction

Physical degradation inevitably occurs in engineering systems, which leads to potential risks and hazards. Traditional binary-state reliability models assume that the system is either running perfectly or has completely failed, and is therefore unable to reveal real situations. Multi-state models provide a more realistic depiction, by introducing a finite number of states. Many studies describe the multiple states of the system degradation process and estimate the system reliability based on multi-state models, including the universal generating function technique [

1,

2], the structure function approach [

3], the stochastic process approach [

4,

5], and the Monte-Carlo simulation technique [

6]. The physics-of-failure (PoF) models provide comprehensive interpretation of statistical data based on physics and mechanistic methods. The models serve as good alternatives when the reliable data are limited, by modeling failure mechanisms such as fatigue, aging and wear. In 2002, the PoF-based methods were selected by the IEEE for system reliability prediction [

7]. Recently, increasing attention has been given to PoF-based reliability modeling methods. Sun et al. [

8] analyzed the reliability of the electrolytic capacitor in light-emitting diode drivers using PoF-based methods. Ma et al. [

9] assessed the reliability of a power electronics system by establishing PoF models of components. Zeng et al. [

10] studied the effect of component dependency on system reliability by considering failure collaboration using PoF models. The PoF approaches employ well-developed knowledge and there is no common method to build a PoF model. When information limitation is considered, probabilistic physics-of-failure (PPoF) methods [

11] are proposed to address the related uncertainties.

For a system containing multiple components, system reliability should concern the relationship between various components. To identify the key components that mostly influence the safety and reliability of a system is difficult in practice. Based on different physical arrangements of components, the reliability block diagram, event tree analysis and fault tree analysis [

12] are frequently used to model the statistical effect of components on the entire system. Owing to the dynamic characteristics of systems, dynamic reliability block diagrams [

13], dynamic fault trees [

14] and colored petri nets [

15], combined with Markov chains and Monte-Carlo methods, are proposed [

16,

17]. Since the degrading behavior of a component may have an influence on another component, copulas functions are employed to describe the dependency of the two-degradation process [

18,

19]. Typically, by using such methods, the failure of components is defined individually by a certain threshold. For example, a pump is believed to be failed when the leakage flow reaches a threshold. Practically, with respect to a whole system, it is hard to define an exact failure threshold for each component under different work conditions. For example, the leakage flow of the pump reaches the failure threshold of itself, but the system can still provide enough flow for external loads. The system reliability evaluation based on individual failure threshold may not be a proper method.

To achieve the unified evaluation of a system with diverse components, there are practical difficulties that make it hard to normalize the effect of a single component by different failure mechanisms on the whole system. The systems in the engineering field, in terms of their basic functions, can be divided into a signal transfer system, an energy transfer system, and a mass transfer system. Due to the similar transmission characteristics derived from conservation law, a mass transfer system can be regarded as a special type of energy transfer system. Given input energy, the reliability of an energy transfer system is defined as the probability of providing enough output energy under stated conditions, for a specific period of time. In this paper, we focus on the energy loss during the energy transferring process of energy transfer systems. Energy works as the currency, evaluating performance degradation by different mechanisms of components with different types of energy. A unified indicator of performance degradation, named failure related energy dissipation, is proposed, which can be obtained from PPoF models. Generally, the Markov process assumes that the states transfer time interval is very small and negligible, while the performance degradation of a component is related to time in real application. Considering the state transfer time interval and the different degradation rate between states in the actual degradation process of components, the semi-Markov process [

20,

21] is an effective to way to model the failure behavior and degradation states relationship, which is employed to build the system reliability model. The system reliability is, then, evaluated globally, combining the multi-state model of the system with the PPoF models of the components.

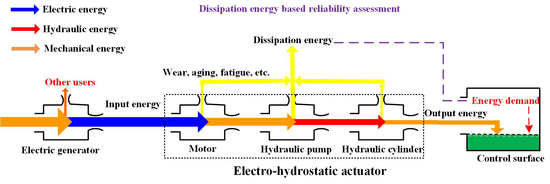

In more electrical aircraft, an electro-hydrostatic actuation system (EHA) replaces some hydraulic actuation systems in the auxiliary surface control system, with convenient electrical transmission and local hydraulic power supply. In EHA, the motor adopts electrical energy and converts it into mechanical energy through electromagnetic energy. The hydraulic pump is driven by the motor to transmit the mechanical energy through hydraulic power. The cylinder accepts the high-pressure oil and drives the piston elongation and contraction. Since the performance of EHA degrades with operational time, its failure process can be regarded as a combination of multiple degenerated levels of motor, hydraulic pump and cylinder. EHA is a typical energy transfer system and taken as an example to illustrate the proposed system-level reliability assessment method.

The rest of the paper is organized as follows: in

Section 2, the energy dissipation is firstly defined, and a multi-state reliability model is established based on energy dissipation. In

Section 3, an illustrative method is proposed showing the parameter estimation process by a PPoF model with Gaussian uncertainties. In

Section 4, the proposed method is conducted in EHA. The PPoF models of hydraulic pump, motor and hydraulic cylinder are established to obtain the failure related energy dissipation and the reliability assessment results are discussed. In

Section 5, some conclusions and remarks are presented.

2. Reliability Model Based on Energy Dissipation

In this paper, we focus on a type of energy transfer system that involves multiple types of energy, such as hydraulic, mechanical and electrical energy. Different types of energy are transferred, stored and transformed by energy transfer components for different desired effects. During the process, degrading behavior such as wear, fatigue and aging inevitably occurs, which results in thermal and volumetric energy loss. Failure-related energy dissipation is introduced to measure the failure behavior of energy transfer system components and characterizes the reliability based on energy dissipation.

2.1. Failure Related Energy Dissipation (FED)

A practical energy transfer system normally contains diversiform energy transfer components, including electrical components, mechanical components, hydraulic components and pneumatic components. Although different components suffer from different types of performance degradation, the similarity is that each of these components transmit energy to implement different functions. For a unified description of the physical degrading process, such components are defined as the energy transmission unit (ETU) in this paper. Assuming that

is the input energy of ETU from an upstream component,

is the output energy to the downstream component and

is the total energy dissipation of ETU that will lead to fault development. A general model of ETU is shown in

Figure 1.

Considering single failure mode, three typical examples of physical degradation are taken to show how to use energy dissipation to describe the failure behavior of ETU.

(a) Wear and tear

According to wear theory [

22], the wear rate between contact surfaces of a friction pair holds the following equation:

where

is the wear coefficient,

is the pressure distribution of the contact surfaces at point

,

is the velocity of relative motion and

are the stress coefficients. Since the wear and tear accumulates with increasing time, the total wear volume

at time

can be described as:

Assuming that the energy cost of a generating unit’s wear volume is constant, the corresponding energy dissipation is proportional to the total wear volume.

(b) Fatigue

Fatigue of materials is generally caused by alternating stresses and will result in cracks. According to the Paris law [

23],

can be used to describe the length of a crack at time

, which is:

where

are constant parameters of materials. Then, the growth rate of the crack can be obtained by:

where

is the stress ratio between minimum stress and maximum stress,

is the stress intensity factor,

is the cracking toughness, the critical value of the stress intensity factor which causes crack extension. If the energy cost of a generating unit’s crack length is constant, the corresponding energy dissipation can be expressed as the proportion of the accumulative damage amount

as:

(c) Aging

It is well known that aging of a plastic material is related to the temperature variance, mechanical force and environmental factors. The Arrhenius model [

24] is commonly chosen to describe the aging behavior:

where

is the coefficient,

is activation energy,

is the gas constant and

is storage temperature. Since the aging process of a plastic material is the accumulation of time and temperature variance, the energy dissipation of aging is proportional to the total amount of aging

which can be described as:

Based on the above failure behavior description, we can conclude that for different degrading processes, the energy dissipation can always be obtained by the time-varying degrading rates, which are related to work stresses with totally different forms. To establish a general reliability model for ETU, we here give a definition as follows:

Definition 1. Energy dissipation. Energy dissipation is the total difference between the input energy and the output energy of an ETU. We should note that the energy dissipation is the joint effect of inherent energy loss and performance degradation.

Definition 2. Failure related energy dissipation (FED). Failure related energy dissipation is the total energy loss caused by the degradation of an ETU.

If the degradation is the result of more than one degradation mechanism, FED can be expressed as:

where

stands for the FED caused by

degradation mechanism,

is the time-varying works stresses,

is the degrading rate of a certain type of degradation mode and

is the normalized function, which modulates the weight of different energy types.

2.2. Multi-State Reliability Model Based on FED

Considering that the degradation related to FED is time-variant, the random process with state duration can be used to describe the degrading process. The semi-Markov model is a typical statistic process widely used in reliability analysis when the residence time follows arbitrary distribution, which is thereby employed in this paper.

We assume a monotonous degrading process. Based on FED, the degrading process of an ETU can be decomposed into

finite discrete states

as shown in

Figure 2. Assuming that the initial state of ETU is sound at

, which is

, at each time

, the state

satisfies the following:

where

is the maximum energy dissipation, which means the ETU cannot meet the requirement of output energy. If at time

, the state

is

, then there is a fixed transition probability

that at the next time point

, the state will be

, which is:

The sojourn time

in state

may be expressed by a number of specific cycles (for example, the number of minutes, hours, days, or weeks), which is a random variable following any distribution [

25]. Let

be the sojourn time distribution, which is:

where

k is an integer. The semi-Markov kernel can be obtained as:

Then, a semi-Markov model

can be established, where

is the initial state distribution,

is the transition probability matrix composed by

and

is the sojourn time distribution of each state, which can be expressed as:

Based on Definition 2, the reliability of an ETU based on FED can be given as:

and

can be obtained by the recursive method [

26]:

2.3. Reliability Evaluation of Energy Transfer

An energy transfer system with

ETUs transmits different types of energy and each ETU degrades under several possible degrading modes with various degrading paths. Particularly, the degradation of

ETU is influenced by

degrading mechanisms. The failure of the system is when the system cannot provide enough energy to implement a certain function, or the FED of the system exceeds failure threshold of the system

. Then, the reliability of the target system can be obtained by:

where

presents the FED generated by

degrading mechanisms of

ETU.

We should note that the convolutional function in Equation (16), which concerns the energy transfer capacity of the entire system, should be regarded as a global evaluating method. For a system with fixed topology, a traditional method for serial and parallel systems, with individual failure thresholds of each component, such as the block diagram method, can be conducted. In practice, the reliability of the system concerns the performance of the entire system and the threshold of a single component is not easily defined. The influence of the system structure is not explicitly shown by Equation (16). Instead, the work condition of each ETU in the system is influenced by the system structure, which will eventually change the FED and the reliability assessment result.

3. Parameters Estimation Using Probabilistic Physics-of-Failure Models

In

Section 2, a multi-state reliability model of ETU, as well as the energy transfer system is established. The semi-Markov model is employed, which takes advantages of combining statistical reliability data with arbitrary sojourn time distribution. Statistically, all the parameters of the model can be estimated by sufficient data, which is used for reliability evaluation. Since FED is closely related to PPoF models, the parameters are possibly estimated with small sample sizes. In this section, parameters of the proposed model are estimated by mechanism instead of statistics.

The work stress of ETU can be load, pressure, flow, temperature and velocity and external environment may also influence the system, which results in different forms of degrading rates. Without loss of generality, we consider a time-varying incremental process to represent the physical degradation. The degrading rate is assumed to follow a Gaussian distribution, which is commonly utilized to describe the growth of cracks [

27] and abrasive wear [

28]. We should note that the degrading rate, which is based on a specific PPoF model, can be in arbitrary form. The increment of FED within a small-time duration should also follow a Gaussian distribution, which can be written as

. Based on the specific degradation mechanism,

degradation state can be divided by deterministic FED

. Then, the FED at time

can be derived as:

and the sojourn time of

ith state can be expressed as:

where

and

are related to the specific form of

and

, respectively. Particularly, if the incremental process is a standard wiener process,

and

, otherwise,

and

can be obtained by the Monte-Carlo method. The probability density function of

can be written as:

Considering the state transition model shown in

Figure 3, the state keeps in the current state or transits to the next state. Assuming that at

the state arrives at

, given arbitrary time interval

, the state transition probability can be written as:

and

. The discrete sojourn time distribution can be written as:

Generally, with a deterministic PPoF model, the probability density function of τi can be derived. For different state transition models, the state transition probability and discrete sojourn time distribution follow a deterministic form. Then, the semi-Markov kernel can be obtained by Equation (12) and the reliability of ETU can be calculated by Equation (14).

4. Application in Electro-Hydrostatic Actuation System

The electro-hydrostatic actuation system (EHA) is a typical energy transfer system which drives external load by transferring electrical power to hydraulic power. In more electrical aircraft, EHA is used to drive control surfaces such as the aileron, elevator and rudder. Since EHA is used as the backup system, its failure may result in the aircraft going out of control. An EHA is composed of a high-speed motor, hydraulic pump and hydraulic cylinder, which are regarded as ETUs in this paper. The high-speed motor drives the rotation of the hydraulic pump, which provides high hydraulic pressure to drive the motion of the cylinder. The structure of EHA is shown in

Figure 4.

An EHA fails when it cannot provide enough energy to drive the external load. The insufficiency of energy is the result of degradation on each ETU. The degradation of the motor will lead to a low input rotation speed and torque of the pump. The leakage of the pump results in lower driving pressure of the cylinder, and the degradation of the cylinder directly affects the output force of the system. For the pump, we consider three degradation mechanisms, which are leakage caused by abrasion between the piston and the plunger chamber, leakage caused by abrasion between the cylinder barrel and the valve plate, and leakage caused by abrasion between the slipper and swash plate. For the motor, we view decreasing output torque as wear between the bearing rings and bearing ball. For the cylinder, we consider the leakage caused by wear of seals. We should note that the degradation mechanisms considered in this paper may cover the major energy loss caused by wear, but are far from complete, due to the limitation of the authors’ knowledge. It is mainly used to illustrate the proposed method and some of the assumptions are different from practice. PPoF models for ETUs are firstly built in

Section 4.1,

Section 4.2,

Section 4.3, and the proposed method is conducted to analyze the reliability of the system in

Section 4.4.

4.1. Probabilistic Physics-of-Failure Model for Hydraulic Pump Degradation

In an aviation EHA, the axial piston pump is used to transfer energy from the electrical motor to the hydraulic cylinder. According to the statistic survey, the main failure of the piston pump is wearing and tearing of friction pairs, as shown in

Figure 5. Since the degradation of the piston pump failure goes through the stages of lubrication, boundary lubrication and friction wear, its failure mechanism-based model needs describe all of the above process. When wear produces abrasive particles between the friction pairs of the piston pump, the increased wear leads to leakage between the friction pairs. At this moment, it is difficult to provide the required flow rate to the downstream component. There are three friction pairs in the piston pump, which are the valve-plate–cylinder-barrel, the slipper–swash plate and the piston–plunger chamber. Their wear and tear cause more than 95% leakage during the pump running [

29] in real application.

Here we select the valve-plate–cylinder-barrel to indicate how to establish the failure mechanism-based model considering the degradation process. Because the piston pump goes through the lubrication, boundary lubrication and wear process during the degradation, the pressure distribution and the oil film distribution vary with the time, and thus the leakage flow can be calculated when the dimensional parameters of the valve plate

,

,

and

are fixed by [

28]:

where

is the angle distribution of the pistons,

is the suction pressure,

is the discharge pressure,

is the dynamic viscosity and

is the average clearance between the cylinder barrel and the valve plate. During the working process of the pump, the surfaces of the cylinder-barrel–valve-plate are not directly contacted, so that the surfaces are separated by a thin lubricating oil film. When there is no contaminant, the thickness of the lubricating oil film is equal to the clearance between the cylinder barrel and the valve plate. The abrasion will lead to a larger average clearance and the degradation rate of leakage can be obtained by

.

Based on the definition of FED, the fluid energy of the leakage can be roughly regarded as the dissipation energy of the degradation caused by the abrasion between cylinder barrel and valve plate when the thermal effect is ignored. Assuming that the pump is working under pressure

, the corresponding FED can be calculated as:

We consider a three-body abrasive wear process to illustrate a possible way to obtain the degradation rate. A relevant research study [

30] shows that the degree of wear caused by particles is mainly affected by the size of debris particles and the distance between the two surfaces. As is shown in

Figure 6a, the scratch of valve plate is probably caused by the invasion of a debris particle. The measurement data of the abrasion length is shown in

Figure 6b.

Based on the research by Dwyer-Joyce [

31], assuming that the debris particles follow Gaussian distribution, the increment of the average clearance can be expressed as

, and:

where

is the nominal contact area,

is the rotating speed of pump,

is the relative hardness of the two contact surfaces,

and

are the parameters of debris loss rate, and the expression of

and

which are related to the dimensional parameters of pump and distributions of debris particles is shown in

Appendix A. We should note that such a model neglects the energy cost of material fracture, frictional sliding and the flow loss caused by the invasion of debris, which takes a low percentage.

Similarly, the FED caused by the other two degradation mechanisms can be obtained. According to the study by Wang [

28], the leakage caused by the friction pair of piston and plunger chamber can be calculated by

where

is the eccentricity ratio,

is the relative velocity of the two contact surfaces,

is the diameter of the piston,

is the piston length and

is the average clearance of the two surfaces. The increasing leakage

can be obtained when the average clearance of the two surfaces changes. The leakage caused by the friction pair of slipper and swash plate can be calculated by:

where

is the pressure in the slipper center hole,

and

are the dimensional parameters shown in

Figure 5, and

is the average clearance of the two surfaces. Then the FED of the pump by the three degradation mechanisms can be obtained by:

4.2. Probabilistic Physics-of-Failure Model for Motor Degradation

The motor drives the rotation pump by converting electrical energy into mechanical energy. The degradation of the motor is mainly reflected by the decreasing of output torque and speed. Based on different control methods, the motor can maintain its output by increasing input energy when degradation occurs, which results in lower efficiency. The degradation may be caused by the magnetic components or mechanical components. In this part, we only consider the decreasing output torque by wear between the bearing rings and bearing balls of an angular contact ball bearing (ACBB).

With the operation of the motor, a degrading ACBB will generate additional friction torque. This part of torque can be regarded as the reduction of rated output torque. According to the characteristics of internal friction in ACBB, the additional friction torque is mainly caused by the elastic hysteresis between ball and the rings, the fluid dynamic pressure and the effect of differential sliding. The study result by Deng et al. [

32] is employed to illustrate how to establish the relation between FED and PPoF models of decreasing output torque by wear between the bearing rings and bearing balls, considering two-body wear between balls and rings. On the basis of dynamic analysis [

33], the hysteresis energy through a loading cycle for the

(total number of balls is

) ball can be written as:

where

is the elastic hysteresis coefficient,

is the rotating speed,

is the revolution speed of the ball,

is the contact load between each ball and the ring,

and

are the Poisson’s ratio of balls and rings,

and

are the elastic modulus of balls and rings,

is the ellipticity of contact ellipse, which is shown in

Figure 7,

is the distance from the ball to the rotary shaft,

is the sum of curvatures,

is complete elliptic integral of the first kind on the contact ellipse,

is the complete elliptic integral of the second kind on the contact ellipse and the superscript

and

represent the inner ring (cone) and outer ring (cup), respectively. The torque reduction by the hysteresis energy can be calculated as:

The energy cost by fluid dynamic pressure can be calculated by:

where

is the oil film thickness,

is the viscosity of oil,

is the fluid dynamic pressure,

is the relative velocity of the ball and inner ring and

is the relative velocity of the ball and outer ring. The torque reduction by fluid dynamic pressure can be calculated as:

The energy cost by the effect of differential sliding can be calculated by:

where

is the friction coefficient between balls and rings,

is the differential sliding velocity,

is the contact ellipse area. The torque reduction by the effect of differential sliding can be calculated as:

The total reductive torque can be calculated as:

and the corresponding FED can be given as:

where

is the rotating speed of the motor.

We consider a two-body wear between the ball and rings. Particularly, we assume that the wear performs uniformly on the balls, and that the balls remain isotropous during the wear. The two-body wear leads to a reduction on the radius of the balls. Since the two-body wear is a stochastic process, which is influenced by rough contact surfaces and the environment, the wear rate, which depicts the radius change of the ball, is assumed to follow a certain distribution.

The change of the sum of curvatures

can then be obtained by:

where

is the radius of the ball,

is the radius of inner ring and

is the radius of outer ring. Based on Hertz theory, the parameter of the contact ellipse can be calculated by:

where

is the contact pressure,

and

are related to the dimensional parameters of the bearing. We should note that such a model neglects the deformation of rings, the wear of rings and the energy cost during the wear process.

4.3. Probabilistic Physics-of-Failure Model for Hydraulic Cylinder Degradation

The hydraulic cylinder, working as the actuator in EHA, outputs the terminal energy to external loads. The degradation of the hydraulic cylinder leads to the decreasing of output force. The dynamic seals move with the piston of the cylinder, as shown in

Figure 8. A vital degradation mode is the internal leakage, caused by the wear of dynamic seals, which makes the pressure difference between the high-pressure chamber and the low-pressure chamber decrease. The internal leakage will, then, cause the reduction of output force.

We consider the internal leakage caused by the wear of dynamic seals. The total internal leakage of the cylinder can be calculated by [

34]:

where

is the clearance between the seal and the cylinder barrel,

is the contact width of seal and cylinder along axial direction,

is the contact length of seal and cylinder,

is the kinematic viscosity and

is the percolation channel shape correction coefficient.

By introducing Archard’s equation, the clearance between the seal and the cylinder barrel can be calculated by:

where

is the wear efficient,

is the hardness of seal,

is the contact pressure between the seal and the cylinder barrel. The details to obtain

is derived in

Appendix B. The FED can be obtained by:

Since the wear process is influenced by topology of the rough contact surfaces, the contact pressure between the seal and the piston is assumed to follow a certain distribution.

4.4. Reliability Evaluation of Electro-Hydrostatic Actuation System

The target scenario is to use a certain type of EHA [

35] to drive a control surface of an aircraft independently. The rated output power of the EHA is 10 kW, the rated hydraulic pressure is 28 MPa and the rated motor rotation speed is 12,000 r/min. According to the energy requirement listed in [

36,

37], the minimum power requirement for an aileron during a regular flight is approximate 8 kW. Assuming that the rated efficient of the EHA is 90%, the FED threshold of the system is estimated at 2.2 kW.

The details of the uncertainty for the considered scenario is shown in

Table 1, which has been configured by the author, according to [

32,

34,

38]. The degradation rate of each variable has been normalized to each minute. For an intuitive degradation process, a Monte-Carlo simulation is conducted. The degradation process of each ETU is illustrated by 1000 samples under the proposed uncertainty configuration. As shown in

Figure 9, 90% confidence interval of all the 1000 samples at each time point is calculated, and the FED corresponding to the specific failure mechanism is shown with the degradation process of each ETU.

If the system is evaluated by the criterion that the system fails when the FED of the system reaches 2.2 kW, then the reliability of the system can be obtained by the proposed method. To compare with the traditional evaluating method, the criterion of which is defined by failure thresholds of individual components, the individual failure thresholds are defined as

,

and

, respectively. In traditional methods, in fact, the failure data and failure thresholds are obtained by reliability test. Hereby, traditional thresholds of given components are referred to, and configured by, the author. The traditional reliability of the serial system can thus be obtained by:

where

is the torque reduction of motor,

is the leakage of pump and

is the leakage of cylinder.

A total of 3 groups of comparisons are conducted to show the difference between traditional reliability assessment methods using individual failure thresholds, and the proposed system-level method. For the first group, the summation of equivalent FED of each individual failure threshold is set to be larger than the system threshold 2.2 kW. For the second group, the summation of the equivalent FED of each individual failure threshold is set to be around the system threshold. For the third group, the summation FED of each individual failure threshold is set to be less than the system threshold. The detailed simulation data are listed in

Table 2.

With different individual failure thresholds, the reliability evaluated by the individual failure thresholds are shown in

Figure 10. We can see that in

Figure 10a, when the summation of equivalent FED of each individual threshold is larger than the system FED threshold, the reliability evaluated by the traditional method has a greater margin than the proposed method, which is in accordance with the fact that larger thresholds mean more tolerance of degradation. In

Figure 10c, when the summation of the equivalent FED of each individual threshold is less than the system FED threshold, then the reliability evaluated by the traditional method has a smaller margin than the proposed method. For group 2, the traditional method has less tolerance of degradation than the proposed method, which can be explained by the fact that, although the pump has already met the presupposed threshold, for the system, it can still be used. On this basis, the proposed method is less rigorous than the traditional method, when the summation of equivalent FED equals the system FED threshold.

From the figures, we can also see that the reliability evaluated by the traditional method sharply decreases when the summation of the equivalent FED is relatively small. This is related to the uncertainty configuration. Since under a smaller threshold of failure, the reliability is more likely to be influenced by the components with fewer uncertainties, in the PPoF models established in the above sections, the modeling uncertainty of the motor is weakened by the assumption of the uniform wear process, which leads to the dominance of the motor when the summation of equivalent FED is relatively small.

As a global criterion, the reliability evaluated by the system failure threshold can help ascertain the traditional thresholds of individual components. In fact, the ascertaining traditional thresholds of individual components is a dynamic process. By setting the thresholds of the pump and the cylinder fixed at

L/min and

L/min, the traditional reliability can be calculated by changing the threshold of the motor. As shown in

Figure 11, the red surface is the reliability evaluated by the proposed method, which is only dependent on time, meanwhile, the other surface, which presents the traditional reliability, depends on both time and the individual failure threshold of the motor. The intersecting curve of the two surfaces can be used to ascertain the failure thresholds of the motor, with fixed thresholds of the pump and the cylinder. By using such a method, it can effectively avoid the scenario where, despite the motor already meeting the presupposed threshold, the system continues to provide enough output, which will prolong the service life and will provide potential economic benefits.

5. Conclusions

A system-level reliability assessment method for the energy transfer system is proposed in this paper to solve the practical difficulty of a unified description of the system degradation state, caused by different physical degradation mechanisms. FED is an additive variable to quantitatively evaluate the effect of component degradation on the entire system. PPoF models of different mechanisms can be used to obtain the corresponding FED. By using FED, the system reliability can be defined from the perspective of the system, instead of using a set of individual failure thresholds of components. An application in EHA shows that the proposed method is effective for describing system reliability and the method can help ascertain the component failure threshold when the system threshold is confirmed.

It is worth noting that, although in this paper wear processes of different EHA components are modeled and FED is obtained, the other degradation mechanisms such as electrical, magnetic and chemical mechanisms could also be modeled, and the corresponding FED can be obtained in a similar way. Since there is no common method to build the PPoF models, sufficient knowledge of studied degradation mechanisms is required to establish the relation between uncertainties and system dynamics. In this paper, we consider some uncertainties which are modeled as certain distributions and make assumptions to avoid some uncertainties, but there are still uncertainties that are not recognized by the authors. With the development of knowledge, there will be more and more uncertainties being transformed to certainties. For unknown degradation mechanisms, the statistical reliability data can be used to describe the state transition model of the degrading process, alternatively.