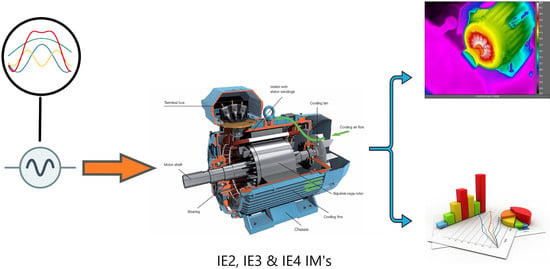

Voltage Harmonic Impacts on Electric Motors: A Comparison between IE2, IE3 and IE4 Induction Motor Classes

Abstract

:1. Introduction

IEC 60034-30-1 and Minimum Energy Performance Standards (MEPS)

2. Improvements in Induction Motors

SCIM’s and LSPMM’s Similarities and Differences

3. Methodology

4. Results and Discussion

4.1. Current Increase Due to Harmonics

4.2. Total Current Harmonic Distortion

4.3. Reactive Power and Power Factor with Voltage Harmonics

4.4. Temperature Increase Due to Harmonics

4.5. Correlation Matrix for Temperature

5. Conclusions

- Second negative sequence harmonic voltage proved to be the most damaging for electric motors, of which the LSPMM shows the worst performance, while the IE3 class motor presented the smallest variations.

- The seventh harmonic also resulted in uniform increases in all motors, however smaller than those found for the second and fifth harmonics of negative sequence.

- The third zero sequence harmonic did not produce considerable variations in electric motors, where the parameters showed variations around their initial values.

- The combination of all harmonics proved to be more damaging than each individual harmonic analyzed, of which the second harmonic had the greatest contribution.

- More efficient motors can result in greater savings in energy and economic terms, mainly in systems with good power quality.

- An analysis of the electricity supply quality at the installation site must be carried out before replacement. Poor power quality reduces electric motor efficiency. Regarding the LSPMM, although in ideal operating conditions, it presented lower current, reactive power and operational temperature, with the presence of harmonics in the supply voltage it presents the worst performance of the three motors analyzed, being more affected by the second harmonic of negative sequence. Another factor to consider is the distortion presented by the LSPMM, which initially already presents values superior to that of the other technologies, and with the presence of harmonics, due to the presence of permanent magnets, higher percentages of THDI are found for this technology. Therefore, in large-scale applications, studies on the quality of the supply before and after installation must be carried out.

- The application type must also be considered. For the LSPMM, it was observed at the moment of starting a difficulty to start with a load, this can be critical mainly for applications with frequent start/stop cycles.

- For future replacements, the economical part is fundamental, the operating time of the old motor in order to verify the payback due to the higher costs of higher efficiency motors. Currently in the Brazilian market, the cost of the IE4 class motor is approximately 1.3 times the cost of the IE3 class motor, while the IE3 class motor is 1.3 times the cost of the IE2 class motor.

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency (IEA) Energy Efficiency 2018—Analysis and Outlooks to 2040—en—OECD. Available online: http://www.oecd.org/publications/energy-efficiency-2018-9789264024304-en.htm (accessed on 15 August 2019).

- U.S. Department of Energy, Energy Efficiency & Renewable Energy Premium Efficiency Motor Selection and Application Guide—A Handbook for Industry. Available online: https://www.energy.gov/eere/amo/downloads/premium-efficiency-motor-selection-and-application-guide-handbook-industry (accessed on 15 August 2019).

- Ferreira, F.J.T.E.; Baoming, G.; Almeida, A.T. de Reliability and Operation of High-Efficiency Induction Motors. IEEE Trans. Ind. Appl. 2016, 52, 4628–4637. [Google Scholar] [CrossRef]

- EM Committee. IEEE Recommended Practice for Monitoring Electric Power Quality. IEEE Std 1995. [Google Scholar] [CrossRef]

- Debruyne, C.; Vandevelde, L.; Desmet, J. Harmonic effects on Induction and Line Start Permanent Magnet Machines. In Proceedings of the International Conference on Energy Efficiency in Motor Driven Systems (EEMODS 2013), Rio de Janeiro, Brazil, 28–30 October 2013. [Google Scholar]

- de Lima, E.C.; de Carvalho Filho, J.M.; de Sá, J.S. Diagnosis of induction motors operating under distorted and unbalanced voltages. In Proceedings of the 17th International Conference on Harmonics and Quality of Power (ICHQP), Belo Horizonte, Brazil, 16–19 October 2016; pp. 786–791. [Google Scholar]

- Fuchs, E.F.; Roesler, D.J.; Masoum, M.A.S. Are harmonic recommendations according to IEEE and IEC too restrictive? IEEE Trans. Power Deliv. 2004, 19, 1775–1786. [Google Scholar] [CrossRef]

- Munoz, R.A.; Nahmias, C.G. Mechanical vibration of three-phase induction motors fed by nonsinusoidal currents. In Proceedings of the 3rd International Power Electronic Congress, Technical Proceedings, CIEP ’94, Puebla, Mexico, 21–25 August 1994; pp. 166–172. [Google Scholar]

- Song, X.; Hu, J.; Zhu, H.; Zhang, J. Effects of the Slot Harmonics on the Stator Current in an Induction Motor with Bearing Fault. Available online: https://www.hindawi.com/journals/mpe/2017/2640796/ (accessed on 16 June 2020).

- Static Air-Gap Eccentricity Fault Diagnosis Using Rotor Slot Harmonics in Line Neutral Voltage of Three-Phase Squirrel Cage Induction Motor. Available online: https://www.researchgate.net/publication/306417959_Static_air-gap_eccentricity_fault_diagnosis_using_rotor_slot_harmonics_in_line_neutral_voltage_of_three-phase_squirrel_cage_induction_motor (accessed on 15 June 2020).

- Kordestani, M.; Safavi, A.A.; Saif, M. Harmonic Fault Diagnosis in Power Quality System Using Harmonic Wavelet. IFAC-PapersOnLine 2017, 50, 13569–13574. [Google Scholar] [CrossRef]

- Kordestani, M.; Saif, M.; Orchard, M.E.; Razavi-Far, R.; Khorasani, K. Failure Prognosis and Applications—A Survey of Recent Literature. IEEE Trans. Reliab. 2019, 1–21. [Google Scholar] [CrossRef]

- Fault diagnosis and condition monitoring of electrical machines—A Review | Request PDF. Available online: https://www.researchgate.net/publication/224713187_Fault_diagnosis_and_condition_monitoring_of_electrical_machines_-_A_Review (accessed on 16 June 2020).

- Li, W.; Mechefske, C. Induction motor fault detection using vibration and stator current methods. Insight—Non-Destr. Test. Cond. Monit. 2004, 46, 473–478. [Google Scholar] [CrossRef]

- IEC 60034-7:1992 Classification of Types of Constructions and Mounting Arrangements (IM Code). Available online: https://webstore.iec.ch/publication/145 (accessed on 15 August 2019).

- Almeida, A.T.D.; Ferreira, F.J.T.E.; Quintino, A. Technical and economical considerations on super high-efficiency three-phase motors. In Proceedings of the 48th IEEE Industrial Commercial Power Systems Conference, Louisville, KY, USA, 20–24 May 2012; pp. 1–13. [Google Scholar]

- Hassanpour Isfahani, A.; Vaez-Zadeh, S. Line start permanent magnet synchronous motors: Challenges and opportunities. Energy 2009, 34, 1755–1763. [Google Scholar] [CrossRef]

- Kahrisangi, M.G.; Isfahani, A.H.; Vaez-Zadeh, S.; Sebdani, M.R. Line-start permanent magnet synchronous motors versus induction motors: A comparative study. Front. Electr. Electron. Eng. 2012, 7, 459–466. [Google Scholar] [CrossRef]

- Almeida, A.T.d.; Ferreira, F.J.T.E.; Baoming, G. Beyond Induction Motors—Technology Trends to Move Up Efficiency. IEEE Trans. Ind. Appl. 2014, 50, 2103–2114. [Google Scholar] [CrossRef]

- Ferreira, F.J.T.E.; Silva, A.M.; Aguiar, V.P.B.; Pontes, R.S.T.; Quispe, E.C.; Almeida, A.T. de Overview of Retrofitting Options in Induction Motors to Improve Their Efficiency and Reliability. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–12. [Google Scholar]

- Gwoździewicz, M.; Antal, L. Investigation of line start permanent magnet synchronous motor and induction motor properties. Prace Naukowe Instytutu Maszyn, Napędów i Pomiarów Elektrycznych, Politechniki Wrocławskiej. 2010, 64, 13–23. [Google Scholar]

- Debruyne, C.; Derammelaere, S.; Desmet, J.; Vandevelde, L. Comparative study of the influence of harmonic voltage distortion on the efficiency of induction machines versus line start permanent magnet machines. In Proceedings of the IEEE 15th International Conference on Harmonics and Quality of Power, Hong Kong, China, 17–20 June 2012; pp. 342–349. [Google Scholar]

- Aguiar, V.P.B.; Pontes, R.S.T.; Ferreira, F.J.T.E. Technical and Economic Evaluation of Efficiency Improvement after Rewinding in Low-Power Induction Motors: A Brazilian Case. Energies 2018, 11, 1701. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Park, Y.; Liu, H.-C.; Han, P.-W.; Lee, J. Study on Line-Start Permanent Magnet Assistance Synchronous Reluctance Motor for Improving Efficiency and Power Factor. Energies 2020, 13, 384. [Google Scholar] [CrossRef] [Green Version]

- Debruyne, C. Impact of Voltage Distortion on Energy Efficiency of Induction Machines and Line Start Permanent Magnet Machines. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2014. [Google Scholar]

- Tarımer, İ. Investigation of the Effects of Rotor Pole Geometry and Permanent. Elektron. Ir Elektrotechnika 2009, 90, 67–72. [Google Scholar] [CrossRef]

- Miller, T.J.E. Synchronization of Line-Start Permanent-Magnet AC Motors. IEEE Trans. Power Appar. Syst. 1984, PAS-103, 1822–1828. [Google Scholar] [CrossRef]

- Chama, A.; Sorgdrager, A.; Wang, R.-J. Analytical synchronization analysis of line-start permanent magnet synchronous motors. Prog. Electromagn. Res. M 2016, 48, 183–193. [Google Scholar] [CrossRef] [Green Version]

- Design and Analysis of a Hybrid Permanent Magnet Assisted Synchronous Reluctance Motor Considering Magnetic Saliency and PM Usage—IEEE Journals & Magazine. Available online: https://0-ieeexplore-ieee-org.brum.beds.ac.uk/document/8115172 (accessed on 16 May 2020).

- Melfi, M.J.; Rogers, S.D.; Evon, S.; Martin, B. Permanent Magnet Motors for Energy Savings in Industrial Applications. In Proceedings of the 53rd Annual Petroleum and Chemical Industry Conference, Record of Conference Papers—IEEE Industry Applications Society, Philadelphia, PA, USA, 11–13 September, 2006; pp. 1–8. [Google Scholar]

- Takahashi, A.; Kikuchi, S.; Miyata, K.; Binder, A. Asynchronous Torque of Line-Starting Permanent-Magnet Synchronous Motors. IEEE Trans. Energy Convers. 2015, 30, 498–506. [Google Scholar] [CrossRef]

- Vavra, C. Understanding Permanent Magnet Motors. Available online: https://www.controleng.com/articles/understanding-permanent-magnet-motors/ (accessed on 17 May 2020).

- Aarniovuori, L.; Niemelä, M.; Pyrhönen, J.; Cao, W.; Agamloh, E.B. Loss Components and Performance of Modern Induction Motors. In Proceedings of the 13th International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1253–1259. [Google Scholar]

- Jonathan, M.T.; Ortiz de Matos, E.; Soares, T.M.; Tostes, M.E.d.L.; Paye, J.C. Fifth & Seventh Harmonic Effects on the Performance of IE2, IE3 & IE4 Induction Motor Classes. In Proceedings of the 13th Latin-American Congress on Electricity Generation and Transmission—CLAGTEE 2019, Santiago, Chile, 20–23 October 2019; p. 6. [Google Scholar]

- Jonathan, M.T.; Soares, T.M.; Tostes, M.E.d.L.; Ortiz de Matos, E.; Moreira, C.E. Impactos do 5o Harmônico na Temperatura de Motores Elétricos Classes IE2, IE3 e IE4. In Proceedings of the Brazilian Conference on Electric Quality (CBQEE), São Paulo, Brazil, 22–25 October 2019; p. 6. [Google Scholar]

- Mirzamani, H.O.; Choobari, A.L. Study of harmonics effects on performance of induction motors. In Proceedings of the 4th WSEAS international conference on Applications of electrical engineering, World Scientific and Engineering Academy and Society (WSEAS), Prague, Czech Republic, 11–13 March 2005; pp. 389–394. [Google Scholar]

- Bonnett, A.H. The impact that voltage and frequency variations have on AC induction motor performance and life in accordance with NEMA MG-1 standards. In Proceedings of the Conference Record of 1999 Annual Pulp and Paper Industry Technical Conference (Cat. No.99CH36338), Seattle, WA, USA, 21–25 June 1999; pp. 16–26. [Google Scholar]

- Almeida, A.T.d.; Ferreira, F.J.T.E.; Fong, J.A.C. Standards for Super-Premium Efficiency class for electric motors. In Proceedings of the Conference Record 2009 IEEE Industrial Commercial Power Systems Technical Conference, Calgary, AB, Canada, 3–7 May 2009; pp. 1–8. [Google Scholar]

- Beleiu, H.G.; Maier, V.; Pavel, S.G.; Birou, I.; Pică, C.S.; Dărab, P.C. Harmonics Consequences on Drive Systems with Induction Motor. Appl. Sci. 2020, 10, 1528. [Google Scholar] [CrossRef] [Green Version]

- Debruyne, C.; Desmet, J.; Derammelaere, S.; Vandevelde, L. Derating factors for direct online induction machines when supplied with voltage harmonics: A critical view. In Proceedings of the 2011 IEEE International Electric Machines Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011; pp. 1048–1052. [Google Scholar]

- Duarte, S.X.; Kagan, N. A Power-Quality Index to Assess the Impact of Voltage Harmonic Distortions and Unbalance to Three-Phase Induction Motors. IEEE Trans. Power Deliv. 2010, 25, 1846–1854. [Google Scholar] [CrossRef]

- Neves, A.B.F.; de Mendonça, M.V.B.; de Leles Ferreira Filho, A.; Rosa, G.Z. Effects of voltage unbalance and harmonic distortion on the torque and efficiency of a Three-Phase Induction Motor. In Proceedings of the 17th International Conference on Harmonics and Quality of Power (ICHQP), Belo Horizonte, Brazil, 16–19 October 2016; pp. 943–948. [Google Scholar]

- Zawilak, T.; Zawilak, J. Minimization of higher harmonics in line-start permanent magnet synchronous motor. Pr. Nauk. Inst. Masz. Napędów Pomiarów Elektr. Politech. Wroc. Stud. Mater. 2009, 63, 107–115. [Google Scholar]

- 519-2014—IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems. Available online: https://0-standards-ieee-org.brum.beds.ac.uk/standard/519-2014.html (accessed on 15 May 2020).

- Elistratova, V. Optimal Design of Line-Start Permanent Magnet Synchronous Motors of High Efficiency. 2015. Available online: https://tel.archives-ouvertes.fr/tel-01308575/ (accessed on 15 May 2019).

- Ferreira, F.; Cistelecan, M.V.; de Almeida, A. Voltage Unbalance Impact on the Performance of Line-Start Permanent-Magnet Synchronous Motors. In Proceedings of the 6th International Conference EEMODS, Nantes, France, 14–17 September 2009. [Google Scholar]

- Kalluf, F.; Pompermaier, C.; da Luz, M.V.F.; Sadowski, N. Braking torque analysis of the single phase line-start permanent magnet synchronous motor. XIX Int. Conf. Electr. Mach.—ICEM 2010 2010. [Google Scholar] [CrossRef]

- Kumar, A.; Srivastava, A. Performance Comparison of Two Different Rotor Topologies of Line Start Permanent Magnet Synchronous Motors. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5. [Google Scholar]

- Liu, M.; Han, Z.; Pei, Y.; Shi, P. Optimization of permanent magnet motor air-gap flux density based on the non-uniform air gap. In Proceedings of the 2013 International Conference on Mechatronic Sciences, Electric Engineering and Computer (MEC), Shenyang, China, 20–22 December 2013; pp. 3422–3426. [Google Scholar]

- Sorgdrager, A.; Wang, R.-J.; Grobler, A.J. Transient Performance Optimisation of Line-Start Permanent Magnet Synchronous Motors Using Taguchi Regression Rate Method. 2017. Available online: https://www.researchgate.net/publication/313221998_Transient_performance_optimisation_of_line-start_permanent_magnet_synchronous_motors_using_Taguchi_regression_rate_method (accessed on 15 May 2019).

- Zeng, X.; Quan, L.; Zhu, X.; Xu, L.; Liu, F. Investigation of an Asymmetrical Rotor Hybrid Permanent Magnet Motor for Approaching Maximum Output Torque. IEEE Trans. Appl. Supercond. 2019, 29, 1–4. [Google Scholar] [CrossRef]

- Ferreira, F.J.T.E.; de Almeida, A.T.; Carvalho, J.F.S.; Cistelecan, M.V. Experiments to observe the impact of power quality and voltage-source inverters on the temperature of three-phase cage induction motors using an infra-red camera. In Proceedings of the 2009 IEEE International Electric Machines and Drives Conference, Miami, FL, USA, 3–6 May 2009; pp. 1311–1318. [Google Scholar]

- IEC 60034-30-1:2014 Rotating electrical machines—Part 30-1: Efficiency classes of line operated AC motors (IE code). Available online: https://webstore.iec.ch/publication/136 (accessed on 15 August 2019).

- U4E, United for Efficiency Accelerating the Global Adoption of Energy-Efficient Electric Motors and Motor Systems. Available online: https://united4efficiency.org/resources/accelerating-global-adoption-energy-efficient-electric-motors-motor-systems/ (accessed on 15 August 2019).

- Anibal, A.; Rob, B.; Conrad, U.B.; Martin, D.; William, H. Motor MEPS Guide, 1st ed.; Copyright: Authors (2009); Zurich, Switzerland, February 2009. [Google Scholar]

- Peter, I.; Scutaru, G.; Nistor, C.G. Manufacturing of asynchronous motors with squirrel cage rotor, included in the premium efficiency category IE3, at S.C. Electroprecizia Electrical-Motors S.R.L. Săcele. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Bran, Romania, 22–24 May 2014; pp. 421–425. [Google Scholar]

- Parasiliti, F.; Bertoldi, P. (Eds.) Energy Efficiency in Motor Driven Systems; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 978-3-540-00666-4. [Google Scholar]

- Hughes, A.; Drury, B. Electric Motors and Drives—4th Edition. Available online: https://0-www-elsevier-com.brum.beds.ac.uk/books/electric-motors-and-drives/hughes/978-0-08-098332-5 (accessed on 15 August 2019).

- SKF Energy Efficient Deep Groove Ball Bearings. Available online: https://www.skf.com/br/industry-solutions/electric-motors/electric-motors-for-consumer-goods/applications/brush-motors/skf-energy-efficient-deep-groove-ball-bearing/index.html (accessed on 15 August 2019).

- Kim, D.-J.; Choi, J.-H.; Chun, Y.-D.; Koo, D.-H.; Han, P.-W. The Study of the Stray Load Loss and Mechanical Loss of Three Phase Induction Motor considering Experimental Results. J. Electr. Eng. Technol. 2014, 9. [Google Scholar] [CrossRef] [Green Version]

- Behbahanifard, H.; Sadoughi, A. Line Start Permanent Magnet Synchronous Motor Performance and Design; a Review. J. World Elec. Eng. Tech. 2015, 4, 58–66. [Google Scholar]

- Ferreira, F.J.T.E.; Leprettre, B.; Almeida, A.T. de Comparison of Protection Requirements in IE2-, IE3-, and IE4-Class Motors. IEEE Trans. Ind. Appl. 2016, 52, 3603–3610. [Google Scholar] [CrossRef]

- Minitab 18 Statistical Software (2010). [Computer software]. State College, PA: Minitab, Inc. (www.minitab.com). Available online: https://www.minitab.com/es-mx/ (accessed on 15 August 2019).

- Heumann, C. Introduction to Statistics and Data Analysis with Exercises, Solutions and Applications in R. Available online: https://0-link-springer-com.brum.beds.ac.uk/content/pdf/10.1007/978-3-319-46162-5.pdf (accessed on 15 May 2020).

- Costa, G.G.d.O. Probabilidades e Estatísticas Inferencial: Teoria e Prática, 2nd ed.; EDITORA ATLAS S.A.: Sao Paulo, Brazil, 2018; ISBN 85-224-6660-2. [Google Scholar]

- Spearman’s Rank-Order Correlation—A Guide to when to Use it, what it does and What the Assumptions are. Available online: https://statistics.laerd.com/statistical-guides/spearmans-rank-order-correlation-statistical-guide.php (accessed on 16 June 2020).

- Minitab. A comparison of the Pearson and Spearman correlation methods. Minitab 18 Support. Available online: https://support.minitab.com/en-us/minitab-express/1/help-and-how-to/modeling-statistics/regression/supporting-topics/basics/a-comparison-of-the-pearson-and-spearman-correlation-methods/ (accessed on 29 June 2020).

| Paper Main Subject | Relevant Literature |

|---|---|

| Induction motors comparison | [2,3,16,18,19,20,22,25,34,35,37,38] |

| Harmonics impacts on induction motors | [5,6,22,34,35,36,39,40,41,42,43,44] |

| Harmonics presence and diagnosis in power systems | [11,12,44] |

| Fault diagnosis in induction motors | [10,13,14] |

| Economic substitution studies | [16,23] |

| Line start permanent magnet motor (LSPMM) | [5,17,18,21,22,24,25,26,27,28,31,32,43,45,46,47,48,49,50,51] |

| Temperature increase due to harmonics | [3,5,34,35,36,52] |

| IM Class | IE2 | IE3 | IE4 |

|---|---|---|---|

| Technology | SCIM | SCIM | LSPMM |

| Power | 1 Hp | 1 Hp | 1 Hp |

| Voltage | 220/380 V | 220/380 V | 220/380 V |

| Speed (rpm) | 1730 | 1725 | 1800 |

| Torque (Nm) | 4.12 | 4.13 | 3.96 |

| Current (A) | 2.98/1.73 | 2.91/1.68 | 3.08/1.78 |

| Efficiency (%) | 82.6 | 82.6 | 87.4 |

| Power Factor | 0.80 | 0.82 | 0.73 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muñoz Tabora, J.; de Lima Tostes, M.E.; Ortiz de Matos, E.; Mota Soares, T.; Bezerra, U.H. Voltage Harmonic Impacts on Electric Motors: A Comparison between IE2, IE3 and IE4 Induction Motor Classes. Energies 2020, 13, 3333. https://0-doi-org.brum.beds.ac.uk/10.3390/en13133333

Muñoz Tabora J, de Lima Tostes ME, Ortiz de Matos E, Mota Soares T, Bezerra UH. Voltage Harmonic Impacts on Electric Motors: A Comparison between IE2, IE3 and IE4 Induction Motor Classes. Energies. 2020; 13(13):3333. https://0-doi-org.brum.beds.ac.uk/10.3390/en13133333

Chicago/Turabian StyleMuñoz Tabora, Jonathan, Maria Emília de Lima Tostes, Edson Ortiz de Matos, Thiago Mota Soares, and Ubiratan Holanda Bezerra. 2020. "Voltage Harmonic Impacts on Electric Motors: A Comparison between IE2, IE3 and IE4 Induction Motor Classes" Energies 13, no. 13: 3333. https://0-doi-org.brum.beds.ac.uk/10.3390/en13133333