Development and Application of a Flexible Modeling Approach to Reference Buildings for Energy Analysis

Abstract

:1. Introduction

2. Materials and Methods

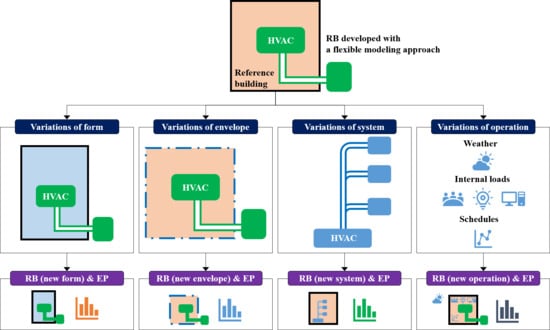

2.1. Research Method and Scope

2.2. Building Energy Simulation: EnergyPlus

2.3. Building Stock

2.4. Autosizing of HVAC System

2.5. Operation

3. Results

3.1. Reference Buildings

3.1.1. Collection of Data from Building Stock

3.1.2. Four Subsets of Reference Buildings

- Form. The parameters necessary for defining geometry and size were acquired through a statistical analysis of the building stock [52]. Five types of form were defined and they are listed in Table 4. The floor plan attributed to the function of the non-residential building was selected as the standard floor plan. As this study aims to develop an RB for energy analysis, conditioned and unconditioned zones in the plan were specified instead of having no specified zones. Hence, representative floor plans of office, sales, and cultural buildings had five zones (four perimeter zones and one core zone), and accommodation and educational buildings representative floor plans were divided into three zones (central corridor, south zone, and north zone).

- Envelope. To define the window-to-wall ratio (WWR), window filling gas, and U-values, statistical data from EAIS [52] were utilized. Envelope characteristics were defined based on the five types of RBs listed in Table 5 and Table 6. For the existing buildings, the gas charged in the gap of the double glazing was air. However, for the target buildings considered in this study, i.e., the latest (2015–2017) buildings, it was found that argon gas with a higher insulation performance than that of air was charged in the gap of the double glazing. Table 2 shows the U-value that is used as the standard during the design of new buildings. For the target new (2015–2017) buildings considered in this study, the U-value of the buildings designed in 2015 had to be designed such that it was lower than the 2013 design standard value, and the U-value of the buildings designed in 2016 and 2017 had to be designed such that it was lower than the 2016 design standard value, as shown in Table 2, depending on the region. Therefore, the U-value must be located between the standard values of 2013 and 2016 for each region shown in Table 2. This is because the U-value calculated in this study was analyzed for the entire country rather than for each region. For example, it can be said that the U-value (0.331) of the exterior walls of the accommodation building, as in Table 6, was reasonably calculated because it is located between the 2016 U-value (0.430) of Jeju and the 2013 U-value (0.270) of central shown in Table 2. In addition, the U-value (0.240) of the exterior walls of the office building was lower than the 2016 standard U-value (0.260) of the central region, which is the most severe condition, indicating that the insulation performance was designed to be much higher than the reasonable level for the latest new buildings. Overall, the U-values in Table 6 are reasonable when compared to the standard values in Table 2. Meanwhile, there are several parameters associated with high uncertainty during the envelope modeling of a building, deriving the best correction results through an optimization technique can be attempted, as Ramos Ruiz and Fernández Bandera [59] did. Our study, however, targeted a number of recently designed (2015–2017) buildings rather than a specific building. In addition, an attempt was made to represent the buildings as per statistical values. Herein, a level of uncertainty was involved because the aim was to develop RBs that can represent the correction of all the buildings rather than for a specific building.

- System. The energy performance can be analyzed, using the RB in two phases. In the first phase, the HVAC system type and the plant equipment are defined. In the second phase, the capacities and flow rates of the HVAC system and plant equipment are defined.

- ①

- First phase: The following three steps were performed to define the HVAC system type and the plant equipment.

- (1)

- Step 1. Statistical analysis based on the data obtained from the EAIS [52]: For the HVAC system type, the office was identified as the central type, while the sales, accommodation, educational, and cultural buildings were all identified as an individual type—electric heat pump (EHP). The core zone of the office was identified as the constant air volume (CAV), while the perimeter zones were identified as the fan coil unit (FCU), thereby making it a hybrid system. Among the central types, the plant equipment in the office was identified as the absorption chiller–heater (ACH) and cooling tower (CT). All buildings other than office buildings were individual system types; no further identification of plant equipment was conducted.

- (2)

- Step 2. Review of compliance with domestic building equipment regulations [55]: The HVAC system type varies according to the type of building; however, it can also vary among the same type of buildings. In addition, region or policy may contribute to differences; in the case of South Korea, the regulations require thermal energy storage or gas-type HVAC systems to be installed based on the type of building and floor area [55]. This is not necessary when it is not a centralized HVAC system. The possibility of applying the identified equipment in the first step was reviewed in accordance with the regulation. The review analysis determined that the HVAC system type and the plant equipment identified in Step 1 do comply with the domestic regulations and can thus be applied.

- (3)

- Step 3. Comparative analysis between the RB developed in this study and a building from the building stock, which is most similar to the RB: A building comparable in size to that of the RB developed in this study was selected from the EAIS [52]. Afterward, the HVAC system type identified in Steps 1 and 2 was compared with the building’s main equipment for analysis. Essentially, a building that had a floor space closest to the total floor area of the RB was used for comparison. We compared the RB with a real building most similar to it to analyze and determine whether the RB was realistic or not. The result confirmed that the HVAC system type and the plant equipment identified in Steps 1 and 2 are valid, and they are defined as shown in Table 7.

- ②

- Second phase: The capacities and flow rates that correspond to the HVAC system type and the plant equipment determined in the first phase need to be designed. As mentioned earlier, this task was addressed, using the autosizing function in EnergyPlus, and the result thereof is shown in Table 8.

- Operation. The internal loads and schedules used in the dynamic simulation are listed in Table 9. Lighting density was determined by using statistical data from EAIS [52]. South Korean regulations and standards [55,56] and recent reports [57] were used as a reference for infiltration, ventilation, hot water, set-point temperature, and operation schedule. Finally, occupant density, electric equipment density, and schedules used data from the RB of DOE; the data of the building that were most similar in building function and characteristic were used. That is, schedule data for office, sales, accommodation, educational, and cultural buildings correspond to those of large office, retail, large hotel, primary school, and medium office building data in the RB of DOE [8,58]. Figure 4 [8,58] shows the weekday schedules of occupant, lighting, and electric equipment for the five types of buildings, expressed as a ratio between 0 to 1. Here, the educational building schedule refers to weekday schedules while school is in session. In addition, cultural buildings are classified as public buildings in South Korea. Therefore, it was assumed that the schedules of such cultural buildings were identical to those of office buildings for the purpose of comparing the energy performance in Section 4.1.

3.2. Energy Performance of Reference Buildings

4. Discussion

4.1. Review of Energy Performance

4.2. Contributions and Applications

- Objectifying and setting a standard value for researchers and engineers;

- Goal-setting for energy performance improvement and management for non-residential buildings;

- Analyzing technological impacts and economy for energy performance enhancement;

- Assessing the economy and business potential for energy management technology;

- Predicting and improving the government-supported certification system for green buildings;

- Establishing strengthened green-building policy and determining the scope of incentives.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols | |

| Annual energy performance by area (kWh/m2.a) | |

| Annual energy performance (kWh) | |

| Area of conditioned zone (m2) | |

| Subscript | |

| End-use (i.e., cooling, heating, hot water, lighting, ventilation, and electric equipment) of building | |

Acronyms and Abbreviations

| ACH | Absorption chiller–heater |

| BAU | Business as usual |

| CAV | Constant air volume |

| C/T | Cooling tower |

| DB | Database |

| DOE | Department of Energy, USA |

| EAIS | Electronic architectural administration information system |

| ECS | Energy consumption survey |

| EP | Energy performance |

| EHP | Electric heat pump |

| FCU | Fan coil unit |

| GHG | Greenhouse gas |

| GIR | Greenhouse gas inventory and research center of Korea |

| HVAC | Heating, ventilation, and air-conditioning |

| IEA | International Energy Agency |

| KEA | Korea energy agency |

| MOLIT | Ministry of land, infrastructure and transport of Korea |

| MOTIE | Ministry of of trade, industry and energy |

| RB | Reference building |

| RT | Refrigeration tonnage |

| U-value | Thermal transmittance (Thermal insulation performance) |

| WWR | Window to wall ratio |

References

- Jeong, Y.-S. Assessment of Alternative Scenarios for CO2 Reduction Potential in the Residential Building Sector. Sustainability 2017, 9, 394. [Google Scholar] [CrossRef] [Green Version]

- Famuyibo, A.A.; Duffy, A.; Strachan, P. Developing archetypes for domestic dwellings—An Irish case study. Energy Build. 2012, 50, 150–157. [Google Scholar] [CrossRef] [Green Version]

- Corgnati, S.P.; Fabrizio, E.; Filippi, M.; Monetti, V. Reference buildings for cost optimal analysis: Method of definition and application. Appl. Energy 2013, 102, 983–993. [Google Scholar] [CrossRef]

- Buso, T.; Corgnati, S.P. A customized modelling approach for multi-functional buildings—Application to an Italian Reference Hotel. Appl. Energy 2017, 190, 1302–1315. [Google Scholar] [CrossRef]

- Dino, I.G.; Stouffs, R. Evaluation of reference modeling for building performance assessment. Autom. Constr. 2014, 40, 44–59. [Google Scholar] [CrossRef]

- Moschetti, R.; Mazzarella, L.; Nord, N. An overall methodology to define reference values for building sustainability parameters. Energy Build. 2015, 88, 413–427. [Google Scholar] [CrossRef] [Green Version]

- Stankevicius, V.; Karbauskaite, J.; Monstvilas, E. The development of reference values for energy certification of buildings in Lithuania. Energy Build. 2007, 39, 284–288. [Google Scholar] [CrossRef]

- Deru, M.; Field, K.; Studer, D.; Benne, K.; Griffith, B.; Torcellini, P.; Liu, B.; Halverson, M.; Winiarski, D.; Rosenberg, M.; et al. U.S. Department of Energy Commercial Reference Building Models of the National Building Stock; NREL Report No. TP-5500-46861; National Renewable Energy Laboratory: Golden, CO, USA, 2011; pp. 1–118.

- TABULA Project Team, Typology Approach for Building Stock Energy Assessment—Main Results of the TABULA Project. 2012, p. 43. Available online: https://ec.europa.eu/energy/intelligent/projects/sites/iee-projects/files/projects/documents/tabula_final_report_en.pdf (accessed on 28 February 2020).

- Spiekman, M. Comparison of Energy Performance Requirements Levels: Possibilities and Impossibilities; ASIEPI Proj: Brussel, Belgium, 2010. [Google Scholar]

- EPISCOPE. Monitor Progress towards Climate Targets in European Housing Stocks Main Results of the EPISCOPE Project—Final Project Report—(Deliverable D1.2); Institut Wohnen und Umwelt: Darmstadt, Germany, 2016; ISBN 9783941140561. [Google Scholar]

- Csoknyai, T.; Hrabovszky-Horváth, S.; Georgiev, Z.; Jovanovic-Popovic, M.; Stankovic, B.; Villatoro, O.; Szendrő, G. Building stock characteristics and energy performance of residential buildings in Eastern-European countries. Energy Build. 2016, 132, 39–52. [Google Scholar] [CrossRef]

- Schaefer, A.; Ghisi, E. Method for obtaining reference buildings. Energy Build. 2016, 128, 660–672. [Google Scholar] [CrossRef]

- Bhatnagar, M.; Mathur, J.; Garg, V. Development of reference building models for India. J. Build. Eng. 2019, 21, 267–277. [Google Scholar] [CrossRef]

- Li, J.; Ng, S.T.; Skitmore, M. Review of low-carbon refurbishment solutions for residential buildings with particular reference to multi-story buildings in Hong Kong. Renew Sustain. Energy Rev. 2017, 73, 393–407. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.W.; Kim, Y.M.; Lee, S.H.; Park, W.Y.; Bok, Y.J.; Ha, S.K.; Lee, S.E. Development of Reference Building Energy Models for South Korea. In Proceedings of the 15th IBPSA Conference, San Francisco, CA, USA, 7–9 August 2017; pp. 2693–2700. [Google Scholar]

- Jung, H.K.; Jeong, Y.S. A Study on the Reference Building base on the Building Design Status in Apartments. In Proceedings of the Architectural Institute of Korea 2017 Autumn Annual Conference, Gyeongsangbuk-do, Korea, 10 October 2017; Volume 37, pp. 226–227. [Google Scholar]

- Nägeli, C.; Jakob, M.; Catenazzi, G.; Ostermeyer, Y. Towards agent-based building stock modeling: Bottom-up modeling of long-term stock dynamics affecting the energy and climate impact of building stocks. Energy Build. 2020, 211. [Google Scholar] [CrossRef]

- Xikai, M.; Lixiong, W.; Jiwei, L.; Xiaoli, Q.; Tongyao, W. Comparison of regression models for estimation of carbon emissions during building’s lifecycle using designing factors: A case study of residential buildings in Tianjin, China. Energy Build. 2019, 204, 109519. [Google Scholar] [CrossRef]

- Mata, É.; Medina, B.G.; Sasic, K.A.; Johnsson, F. Modelling opportunities and costs associated with energy conservation in the Spanish building stock. Energy Build. 2015, 88, 347–360. [Google Scholar] [CrossRef]

- Brandão De Vasconcelos, A.; Pinheiro, M.D.; Manso, A.; Cabaço, A. EPBD cost-optimal methodology: Application to the thermal rehabilitation of the building envelope of a Portuguese residential reference building. Energy Build. 2016, 111, 12–25. [Google Scholar] [CrossRef]

- Krarti, M.; Aldubyan, M.; Williams, E. Residential building stock model for evaluating energy retrofit programs in Saudi Arabia. Energy 2020, 195, 116980. [Google Scholar] [CrossRef]

- Ye, Y.; Hinkelman, K.; Zhang, J.; Zuo, W.; Wang, G. A methodology to create prototypical building energy models for existing buildings: A case study on U.S. religious worship buildings. Energy Build. 2019, 194, 351–365. [Google Scholar] [CrossRef]

- Brandão de Vasconcelos, A.; Cabaço, A.; Pinheiro, M.D.; Manso, A. The impact of building orientation and discount rates on a Portuguese reference building refurbishment decision. Energy Policy 2016, 91, 329–340. [Google Scholar] [CrossRef]

- Brandão de Vasconcelos, A.; Pinheiro, M.D.; Manso, A.; Cabaço, A. A Portuguese approach to define reference buildings for cost-optimal methodologies. Appl. Energy 2015, 140, 316–328. [Google Scholar] [CrossRef]

- European Commission Guidelines accompanying Commission Delegated Regulation (EU) No 244/2012 of 16 January 2012 supplementing Directive 2010/31/EU of the European Parliament and of the Council. Off. J. Eur. Union 2012, 55, 1–28. [CrossRef]

- Pieri, S.P.; Tzouvadakis, I.; Santamouris, M. Identifying energy consumption patterns in the Attica hotel sector using cluster analysis techniques with the aim of reducing hotels’ CO2 footprint. Energy Build. 2015, 94, 252–262. [Google Scholar] [CrossRef]

- Gao, X.; Malkawi, A. A new methodology for building energy performance benchmarking: An approach based on intelligent clustering algorithm. Energy Build. 2014, 84, 607–616. [Google Scholar] [CrossRef]

- Santamouris, M.; Mihalakakou, G.; Patargias, P.; Gaitani, N.; Sfakianaki, K.; Papaglastra, M.; Pavlou, C.; Doukas, P.; Primikiri, E.; Geros, V.; et al. Using intelligent clustering techniques to classify the energy performance of school buildings. Energy Build. 2007, 39, 45–51. [Google Scholar] [CrossRef]

- Farrou, I.; Kolotroni, M.; Santamouris, M. A method for energy classification of hotels: A case-study of Greece. Energy Build. 2012, 55, 553–562. [Google Scholar] [CrossRef]

- Filogamo, L.; Peri, G.; Rizzo, G.; Giaccone, A. On the classification of large residential building stocks by sample typologies for energy planning purposes. Appl. Energy 2014, 135, 825–835. [Google Scholar] [CrossRef]

- EnergyPlus. Available online: https://energyplus.net/ (accessed on 28 February 2020).

- The European Parliament and the Council of the European Union. Directive 2010/31/EU of the European parliament and of council of 19 May 2010 on the energy performance of buildings (recast). Off. J. Eur. Union 2010, 18, 2010. [Google Scholar]

- Seo, D.; Noh, B.; Ihm, B. A Research on Prototypical Apartment House Definition for Detailed Building Energy Simulation. J. Reg. Assoc. Archit. Inst. Korea 2014, 16, 285–296. [Google Scholar]

- Korean Government. Amendment of 2030 National GHG Emissions Reduction Roadmap; Korean Government: Sejong, Korea, 2018.

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a new-generation building energy simulation program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- U.S. Department of Energy. EnergyPlus Version 8.9 Documentation, Engineering Reference; U.S. Department of Energy: Washington, DC, USA, 2018.

- Picco, M.; Lollini, R.; Marengo, M. Towards energy performance evaluation in early stage building design: A simplification methodology for commercial building models. Energy Build. 2014, 76, 497–505. [Google Scholar] [CrossRef]

- Hygh, J.S.; DeCarolis, J.F.; Hill, D.B.; Ranji Ranjithan, S. Multivariate regression as an energy assessment tool in early building design. Build. Environ. 2012, 57, 165–175. [Google Scholar] [CrossRef]

- Kamal, R.; Moloney, F.; Wickramaratne, C.; Narasimhan, A.; Goswami, D.Y. Strategic control and cost optimization of thermal energy storage in buildings using EnergyPlus. Appl. Energy 2019, 246, 77–90. [Google Scholar] [CrossRef]

- Cetin, K.S.; Fathollahzadeh, M.H.; Kunwar, N.; Do, H.; Tabares-Velasco, P.C. Development and validation of an HVAC on/off controller in EnergyPlus for energy simulation of residential and small commercial buildings. Energy Build. 2019, 183, 467–483. [Google Scholar] [CrossRef]

- Dahanayake, K.W.D.K.C.; Chow, C.L. Studying the potential of energy saving through vertical greenery systems: Using EnergyPlus simulation program. Energy Build. 2017, 138, 47–59. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Lu, L.; Ma, T.; Yang, H. Assessment of energy performance of semi-transparent PV insulating glass units using a validated simulation model. Energy 2016, 112, 538–548. [Google Scholar] [CrossRef]

- Zhang, R.; Hong, T. Modeling of HVAC operational faults in building performance simulation. Appl. Energy 2017, 202, 178–188. [Google Scholar] [CrossRef]

- Mun, S.H.; Kwak, Y.; Huh, J.H. A case-centered behavior analysis and operation prediction of AC use in residential buildings. Energy Build. 2019, 188–189, 137–148. [Google Scholar] [CrossRef]

- OpenStudio. Available online: https://www.openstudio.net/ (accessed on 28 February 2020).

- Sketchup. Available online: https://www.sketchup.com/ (accessed on 28 February 2020).

- Ministry of Land, Infrastructure and Transport (MOLIT). Green Buildings Construction Support Act; Korean Government: Sejong, Korea, 2019.

- Ministry of Land, Infrastructure and Transport (MOLIT). The Building Energy Saving Design Standards; Korean Government: Sejong, Korea, 2017.

- International Energy Agency (IEA). Energy Policies of IEA Countries: Republic of Korea 2012 Review; International Energy Agency: Paris, France, 2012. [Google Scholar]

- Ministry of Land, Infrastructure and Transport (MOLIT). Zero-Energy Building, Beyond Architecture, into the City! START Now; Korean Government: Sejong, Korea, 2019.

- Electronic Architectural Administration Information System (EAIS). Available online: https://www.eais.go.kr/ (accessed on 28 February 2020).

- U.S. Department of Energy. EnergyPlus Version 8.9 Documentation, Input Output Reference; U.S. Department of Energy: Washington, DC, USA, 2018.

- Ministry of Land, Infrastructure and Transport (MOLIT). Building Act; Korean Government: Sejong, Korea, 2019.

- Ministry of Land, Infrastructure and Transport (MOLIT). Rules on the Building Equipment Standards, etc.; Korean Government: Sejong, Korea, 2017.

- Korea Energy Agency (KEA). Building Energy Efficiency Rating Certification Scheme Operation Rules; Korea Energy Agency: Ulsan, Korea, 2016.

- Greenhouse Gas Inventory and Research Center (GIR). Establishment of Standard Model DB for GHG Reduction Potential Model Analysis in Buildings (I); Greenhouse Gas Inventory and Research Center: Seoul, Korea, 2016. [Google Scholar]

- DOE, Commercial Reference Building. Available online: http://www.energy.gov/eere/buildings/commercial-reference-buildings/ (accessed on 28 February 2020).

- Ramos Ruiz, G.; Fernández Bandera, C. Analysis of uncertainty indices used for building envelope calibration. Appl. Energy 2017, 185, 82–94. [Google Scholar] [CrossRef]

- Eguaras-Martínez, M.; Vidaurre-Arbizu, M.; Martín-Gómez, C. Simulation and evaluation of building information modeling in a real pilot site. Appl. Energy 2014, 114, 475–484. [Google Scholar] [CrossRef] [Green Version]

- OneBuilding. Available online: http://climate.onebuilding.org/WMO_Region_2_Asia/KOR_South_Korea/index.html/ (accessed on 28 February 2020).

- Ministry of Trade, Industry and Energy (MOTIE). 2017 Energy Consumption Survey; Korean Government: Sejong, Korea, 2018.

- Krawczyk, D.A. Theoretical and real effect of the school’s thermal modernization—A case study. Energy Build. 2014, 81, 30–37. [Google Scholar] [CrossRef]

- Ali, H.; Hashlamun, R. Envelope retrofitting strategies for public school buildings in Jordan. J. Build. Eng. 2019, 25, 100819. [Google Scholar] [CrossRef]

- Kwak, Y.; Kang, J.A.; Huh, J.H.; Kim, T.H.; Jeong, Y.S. An analysis of the effectiveness of greenhouse gas reduction policy for office building design in South Korea. Sustainability 2019, 11, 7172. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; McCuskey Shepley, M.; Choi, J. Exploring the effects of a building retrofit to improve energy performance and sustainability: A case study of Korean public buildings. J. Build. Eng. 2019, 25. [Google Scholar] [CrossRef]

- Dascalaki, E.; Santamouris, M. On the potential of retrofitting scenarios for offices. Build. Environ. 2002, 37, 557–567. [Google Scholar] [CrossRef]

- Song, X.; Ye, C.; Li, H.; Wang, X.; Ma, W. Field study on energy economic assessment of office buildings envelope retrofitting in southern China. Sustain. Cities Soc. 2017, 28, 154–161. [Google Scholar] [CrossRef]

- Dimoudi, A.; Kostarela, P. Energy monitoring and conservation potential in school buildings in the C′ climatic zone of Greece. Renew. Energy 2009, 34, 289–296. [Google Scholar] [CrossRef]

- Liu, Q.; Ren, J. Research on the Building Energy Efficiency Design Strategy of Chinese Universities Based on Green Performance Analysis. Energy Build. 2020, 224, 110242. [Google Scholar] [CrossRef]

- Chung, M.H.; Rhee, E.K. Potential opportunities for energy conservation in existing buildings on university campus: A field survey in Korea. Energy Build. 2014, 78, 176–182. [Google Scholar] [CrossRef]

- Nagpal, S.; Hanson, J.; Reinhart, C. A framework for using calibrated campus-wide building energy models for continuous planning and greenhouse gas emissions reduction tracking. Appl. Energy 2019, 241, 82–97. [Google Scholar] [CrossRef]

- Shorrock, L.D.; Dunster, J.E. The physically-based model BREHOMES and its use in deriving scenarios for the energy use and carbon dioxide emissions of the UK housing stock. Energy Policy 1997, 25, 1027–1037. [Google Scholar] [CrossRef]

- Chaudhary, G.; New, J.; Sanyal, J.; Im, P.; O’Neill, Z.; Garg, V. Evaluation of “Autotune” calibration against manual calibration of building energy models. Appl. Energy 2016, 182, 115–134. [Google Scholar] [CrossRef] [Green Version]

- Jeong, Y.S.; Jung, H.K.; Jang, H.K.; Yu, K.H. A Study on the Reference Building based on the Building Design Trends for Non-residential Buildings. J. Korean Sol. Energy Soc. 2014, 34, 1–11. [Google Scholar] [CrossRef]

| Research Goals | Research | Building Types | Countries |

|---|---|---|---|

| Energy analysis and efficiency evaluation | Deru et al. [8] | 1 residential building; 15 non-residential buildings | US |

| TABULA Project Team [9] Spiekman [10] EPISCOPE [11] | Residential building | Europe | |

| Csoknyai et al. [12] | Residential building | Eastern-European countries (Bulgaria, Serbia, Hungary, and Czech Republic) | |

| Schaefer and Ghisi [13] | Residential building | Brazil | |

| Bhatnagar et al. [14] | Non-residential building (office) | India | |

| Li et al. [15] | Residential building | Hong Kong | |

| Promoting national policy and technological development, GHG emission mitigation | Kim et al. [16] | 2 residential buildings; 8 non-residential buildings | South Korea |

| Jung and Jeong [17] | Apartment (Multifamily dwelling) | South Korea | |

| Quantitative assessment of energy demand and GHG emissions | Nägeli et al. [18] | Residential building | Switzerland |

| Estimate carbon emissions | Xikai et al. [19] | Residential building | China |

| Assessment the potential of energy conservation measures and GHG emissions | Mata et al. [20] | 6 building types (single-family dwellings, multifamily dwellings, commercial, culture and leisure, offices, and other services), | Spain |

| Building envelope optimization | Brandão et al. [21] | Residential building | Portugal |

| Evaluating energy retrofit | Krarti et al. [22] | Residential building | Saudi Arabia |

| Building energy saving potentials | Ye et al. [23] | Non-residential building (religious worship building) | US |

| Support to policies | Buso and Corgnati [4] | Non-residential building (hotel) | Italy |

| Brandão et al. [24] | Residential building | Portugal | |

| Cost optimal analysis | Corgnati et al. [3] | Non-residential building (office) | Italy |

| Brandão et al. [25] | Residential building | Portugal |

| Enforcement Date | Region | Thermal Insulation of Building Envelope (W/m2·K) | |||

|---|---|---|---|---|---|

| Exterior Wall | Roof | Lowest Floor | Window | ||

| Oct. 2013 | Central | 0.270 | 0.180 | 0.410 | 2.100 |

| Southern | 0.340 | 0.220 | 0.470 | 2.400 | |

| Jeju | 0.440 | 0.280 | 0.550 | 3.000 | |

| Jan. 2016 | Central | 0.260 | 0.150 | 0.300 | 1.500 |

| Southern | 0.320 | 0.180 | 0.350 | 1.800 | |

| Jeju | 0.430 | 0.250 | 0.470 | 2.400 | |

| Component | Autosizing Parameters |

|---|---|

| Design capacity | Cooling capacity |

| Heating capacity | |

| Design water flow rate | Chilled water |

| Condenser water | |

| Hot water | |

| Design air flow rate | Supply air |

| Cooling tower |

| Elements | Office | Sales | Accommodation | Educational | Cultural | |

|---|---|---|---|---|---|---|

| Total floor area (m2) | 30,842 | 13,060 | 13,440 | 24,185 | 9120 | |

| Number of floors | Ground | 12 | 4 | 8 | 4 | 2 |

| Basement | 2 | 1 | 2 | 1 | 2 | |

| Floor height (m) | 3.9 | 4.6 | 3.3 | 3.6 | 5.0 | |

| Aspect ratio (building length/building width) | 2.43:1 | 1.96:1 | 2.67:1 | 3.85:1 | 2.90:1 | |

| Elements | Office | Sales | Accommodation | Educational | Cultural |

|---|---|---|---|---|---|

| Window-to-wall ratio (%) | 26.83 | 17.72 | 19.97 | 28.82 | 20.05 |

| Window filling gas | Argon | Argon | Argon | Argon | Argon |

| Elements | Office | Sales | Accommodation | Educational | Cultural |

|---|---|---|---|---|---|

| (W/m2·K) | |||||

| Exterior walls | 0.240 | 0.259 | 0.331 | 0.262 | 0.274 |

| Roof | 0.138 | 0.147 | 0.170 | 0.175 | 0.144 |

| Lowest floor | 0.193 | 0.204 | 0.259 | 0.323 | 0.200 |

| Windows | 1.403 | 1.752 | 1.612 | 1.825 | 1.333 |

| Elements | Office | Sales | Accommodation | Educational | Cultural |

|---|---|---|---|---|---|

| HVAC system type | Central | Individual | Individual | Individual | Individual |

| (CAV+FCU) | (EHP) | (EHP) | (EHP) | (EHP) | |

| Plant equipment | ACH+CT | - | - | - | - |

| Component | Parameters of HVAC System | Office | Sales | Accommodation | Educational | Cultural |

|---|---|---|---|---|---|---|

| Design Capacity | Cooling capacity (kW) 1 | 3157 | 926 | 869 | 1142 | 839 |

| Heating capacity (kW) 1 | 906 | 609 | 3320 | 322 | ||

| Design Water Flow Rate | Chilled water (m3/s) | 0.149 | - | - | - | - |

| Condenser water (m3/s) | 0.296 | - | - | - | - | |

| Hot water (m3/s) | 0.026 | - | - | - | - | |

| Design Air Flow Rate | Supply air (m3/s) 1 | 148.67 | 51.78 | 52.52 | 45.98 | 53.83 |

| Cooling tower (m3/s) | 172.73 | - | - | - | - |

| Component | Elements | Office | Sales | Accommodation | Educational | Cultural |

|---|---|---|---|---|---|---|

| Internal loads | Occupants (m2/person) | 18.58 | 6.19 | 26.01 | 4.00 | 18.58 |

| Lighting (W/m2) | 7.13 | 8.95 | 5.68 | 6.91 | 6.27 | |

| Electric equipment (W/m2) | 10.76 | 3.23 | 14.30 | 4.00 | 10.76 | |

| Others | Infiltration (Air change per hour) | 0.90 | 0.80 | 0.90 | 0.80 | 0.90 |

| Ventilation (m3/person.h) | 29.0 | 29.0 | 29.0 | 36.0 | 29.0 | |

| Hot water (Wh/m2d) | 30.0 | 30.0 | 30.0 | 30 | 30.0 | |

| Set-point temperatures | Cooling (°C) | 26.0 | 26.0 | 26.0 | 26.0 | 26.0 |

| Heating (°C) | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 | |

| Operation schedules | Cooling (day/mon.) | 1st January–31st December | 1st January–31st December. | 1st January–31st December | 1st January–31st December 1 | 1st January–31st December |

| Heating (day/mon.) | 1st January–31st December | 1st January–31st December | 1st January–31st December | 1st January–31st December 1 | 1st January–31st December |

| End-Use | Energy Performance (kWh/m2.a) | ||||

|---|---|---|---|---|---|

| Office | Sales | Accommodation | Educational | Cultural | |

| Cooling | 47.5 | 15.9 | 13.0 | 6.9 | 13.7 |

| Heating | 45.8 | 38.0 | 54.5 | 12.6 | 39.5 |

| Hot water | 15.7 | 10.7 | 43.9 | 2.9 | 16.9 |

| Lighting | 22.9 | 32.9 | 20.3 | 25.7 | 20.5 |

| Ventilation | 13.9 | 12.7 | 19.1 | 3.3 | 12.5 |

| Electric equipment 1 | 43.7 | 11.9 | 36.5 | 12.9 | 25.5 |

| Total | 189.5 | 122.1 | 187.3 | 64.3 | 128.6 |

| Buildings | Research | Retrofit | Energy Savings |

|---|---|---|---|

| Office | Dascalaki and Santamouris [67] | Improve exterior building envelope | 40–60% |

| Use energy saving lighting | |||

| Enhance HVAC system | |||

| Song et al. [68] | Improve exterior building envelope | 16.47% | |

| Lee et al. [66] | Improve exterior building envelope | 31% | |

| Kwak et al. [65] | Improve exterior building envelope | 13% | |

| School | Krawczyk [63] | Improve exterior building envelope | 33% |

| Dimoudi and Kostarela [69] | Improve insulation and air tightness | 28.75% | |

| Ali and Hashlamun [64] | Improve exterior building envelope | 54% | |

| Campus | Liu and Ren [70] | Improve exterior building envelope | 47.4% |

| Chung and Rhee [71] | Improve exterior building envelope | 10–22% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwak, Y.; Kang, J.; Mun, S.-H.; Jeong, Y.-S.; Huh, J.-H. Development and Application of a Flexible Modeling Approach to Reference Buildings for Energy Analysis. Energies 2020, 13, 5815. https://0-doi-org.brum.beds.ac.uk/10.3390/en13215815

Kwak Y, Kang J, Mun S-H, Jeong Y-S, Huh J-H. Development and Application of a Flexible Modeling Approach to Reference Buildings for Energy Analysis. Energies. 2020; 13(21):5815. https://0-doi-org.brum.beds.ac.uk/10.3390/en13215815

Chicago/Turabian StyleKwak, Younghoon, Jeonga Kang, Sun-Hye Mun, Young-Sun Jeong, and Jung-Ho Huh. 2020. "Development and Application of a Flexible Modeling Approach to Reference Buildings for Energy Analysis" Energies 13, no. 21: 5815. https://0-doi-org.brum.beds.ac.uk/10.3390/en13215815