Passivity-Based Control of Water Pumping System Using BLDC Motor Drive Fed by Solar PV Array with Battery Storage System

Abstract

:1. Introduction

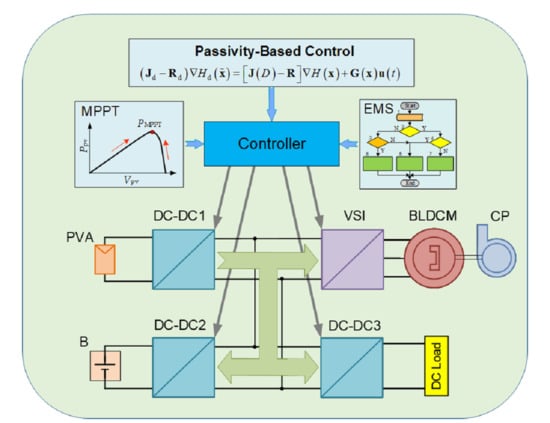

2. System Configuration, Its Modelling and Design

2.1. Proposed System Description

2.2. Mathematical Modelling of Main System Components

2.2.1. PVA Modelling

2.2.2. DC–DC Converter Modelling

2.2.3. Mathematical Model of BLDC Motor

2.2.4. Mathematical Model of Centrifugal Pump

2.3. Justification of System Components Parameters

2.3.1. Development of a Methodology for Parameter Justification

- 1)

- Set the desired value of kload and determine by Equation (14) V*int, which also corresponds to V*dc.

- 2)

- Set the required absolute value of Vdc and determine the absolute value of Vint.max = Vdc/V*dc.

- 3)

- For the specified rated parameters of the centrifugal pump (power PCP and angular velocity ωCP), as well as obtained in paragraph 2 the nominal DC voltage of the inverter VDC.VSI.n = Vint.max, select or design the appropriate BLDCM.

- 4)

- Find the nominal parameters of the PVA: choose the rated voltage from the range of VPVA.n = (0.30–0.35)Vint.max and the rated power of PPVA.n = (1.15–1.20)PCP.

- 5)

- Form the PVA from PV panels of the selected type, determining the required number of panels connected in series in the string and the number of strings connected in parallel.

- 6)

- Find the nominal parameters of the battery: choose the voltage from the range of VBb.n = (0.25–0.35)Vint.max. The required battery capacity depends on factors such as the average annual insolation level and set indexes of water deficiency and power supply probability.

2.3.2. Design of the Studied SWPS

2.3.3. Determination of the Passive Components’ Parameters

- For the boost converter DC–DC1:

- For the buck converter DC–DC3:

- For the bidirectional buck-boost converter DC–DC2:

3. Control Algorithms of Main Subsystems

3.1. MPPT Algorithm

3.2. BLDCM Electronic Commutation

3.3. Development of the EMS

4. Passivity-Based Control System of the Proposed SWPS

4.1. SWPS as Port-Controlled Hamiltonian System

4.2. IDA-PBC Principle

4.3. Control System Synthesis Methodology

4.4. Design of the PBC Systems

4.4.1. PBC1 System

4.4.2. PBC2 System

5. Simulation Results

5.1. Computer Model Description

5.2. Simulation of PBC1 System Operation

5.3. Simulation of PBC2 System Operation

5.4. Switching between PBC1 and PBC2 System Operation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aliyua, M.; Hassana, G.; Saida, S.A.; Siddiquic, M.U.; Alawamid, A.T.; Elamin, I.M. A review of solar-powered water pumping systems. Renew. Sustain. Energy Rev. 2018, 87, 61–76. [Google Scholar] [CrossRef]

- Solomon, Y.; Rao, P.N.; Tadesse, T. A review on solar photovoltaic powered water pumping system for off-grid rural areas for domestic use and irrigation purpose. Int. J. Eng. Res. Technol. (IJERT) 2021, 10, 258–269. [Google Scholar]

- Islam, H.; Mekhilef, S.; Shah, N.B.M.; Soon, T.K.; Seyedmahmousian, M.; Horan, B.; Stojcevski, A. Performance evaluation of maximum power point tracking approaches and photovoltaic systems. Energies 2018, 11, 365. [Google Scholar] [CrossRef] [Green Version]

- Harsh, K.; Pandey, K.; Kumar, R.; Jangir, A.K. BLDC motor driven water pump fed by solar photovoltaic array using boost converter. Int. J. Eng. Res. Technol. (IJERT) 2020, 9, 635–639. [Google Scholar]

- Kumar, R.; Singh, B.; Chandra, A.; Al-Haddad, K. Solar PV array fed water pumping using BLDC motor drive with boost-buck converter. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015. [Google Scholar]

- Kumar, R.; Singh, B. Solar PV array fed water pumping system using SEPIC converter based BLDC motor drive. In Proceedings of the 2014 Eighteenth National Power Systems Conference (NPSC), Guwahati, India, 18–20 December 2014; pp. 1–5. [Google Scholar]

- Kumar, R.; Singh, B. BLDC Motor-Driven Solar PV array-fed water pumping system employing Zeta converter. IEEE Trans. Ind. Appl. 2016, 52, 2315–2322. [Google Scholar] [CrossRef]

- Durgaprasad, R.; Guruvulunaidu, P.; Prasad, C. Solar PV array-fed water pumping system using zeta converter based closed-loop control of BLDC motor drive. Int. J. Eng. Res. Technol. (IJERT) 2018, 7, 389–397. [Google Scholar]

- Sharma, V.; Hossain, M.J.; Nawazish Ali, S.M.; Kashif, M. A photovoltaic-fed Z-source inverter motor drive with fault-tolerant capability for rural irrigation. Energies 2020, 13, 4630. [Google Scholar] [CrossRef]

- Darcy Gnana Jegha, A.; Subathra, M.S.P.; Kumar, N.M.; Ghosh, A. Optimally tuned interleaved Luo converter for PV array fed BLDC motor driven centrifugal pumps using whale optimization algorithm—A resilient solution for powering agricultural loads. Electronics 2020, 9, 1–24. [Google Scholar]

- Singh, B.; Kumar, R. Solar photovoltaic array fed water pump driven by brushless DC motor using Landsman converter. IET Renew. Power Gener. 2016, 10, 474–484. [Google Scholar] [CrossRef]

- Lakshmiprabha, K.E.; Govindaraju, C. An integrated isolated inverter fed BLDC motor for photovoltaic agric pumping systems. Microprocess. Microsyst. 2020, 79, 103276. [Google Scholar] [CrossRef]

- Mujawar, S.; Tamboli, T.; Patel, D.; Kute, S. Solar panel fed BLDC motor for water pumping. Int. Res. J. Eng. Technol. (IRJET) 2020, 7, 5987–5994. [Google Scholar]

- Kumar Mishra, A.; Singh, B. Control of SRM drive for photovoltaic powered water pumping system. IET Electr. Power Appl. 2017, 11, 1055–1066. [Google Scholar] [CrossRef]

- Ronanki, D.; Parthiban, P. PV-battery powered direct torque controlled switched reluctance motor drive. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012; pp. 1–4. [Google Scholar]

- Singh, B.; Mishra, A.K.; Kumar, R. Solar powered water pumping system employing switched reluctance motor drive. IEEE Trans. Ind. Appl. 2016, 52, 3949–3957. [Google Scholar] [CrossRef]

- Khiareddine, A.; Salah, C.B.; Mimouni, M.F. Power management of a photovoltaic/battery pumping system in agricultural experiment station. Sol. Energy 2015, 112, 319–338. [Google Scholar] [CrossRef]

- Zahab, E.E.A.; Zaki, A.M.; El-sotouhy, M.M. Design and control of a standalone PV water pumping system. J. Electr. Syst. Inf. Technol. 2017, 4, 322–337. [Google Scholar] [CrossRef] [Green Version]

- Benzaouia, M.; Bekkay, H.; Rabhi, A.; Mellit, A.; Anas, B.; Migan-Dubois, A. Energy management strategy for an optimum control of a standalone photovoltaic-batteries water pumping system for agriculture applications. In Proceedings of the 2nd International Conference on Electronic Engineering and Renewable Energy Systems, ICEERE 2020, Saidia, Morocco, 13–15 April 2020; Springer: Singapore, 2020; pp. 855–868. [Google Scholar]

- Madichetty, S.; Pullaguram, D.; Mishra, S. A standalone BLDC based solar air cooler with MPP tracking for improved efficiency. CSEE J. Power Energy Syst. 2019, 5, 111–119. [Google Scholar]

- Sarada, S.; Ganesh, C.; Aparna, K. Brushless DC (BLDC) motor drive for solar photovoltaic (SPV) array fed water pumping system by using fuzzy logic controller. Int. J. Electr. Eng. 2017, 10, 289–305. [Google Scholar]

- Shchur, I.; Biletskyi, Y. Passivity-based control of hybrid energy storage system with common battery and modular multilevel DC-DC converter-based supercapacitor packs. In Proceedings of the 20th IEEE International Conference Computational Problems of Electrical Engineering (CPEE), Lviv-Slavske, Ukraine, 15–18 September 2019; pp. 1–6. [Google Scholar]

- Shchur, I.; Biletskyi, Y. Battery current limitation in passivity-based controlled battery/supercapacitor hybrid energy storage system. In Proceedings of the 38th IEEE International Conference on Electronics and Nanotechnology (ELNANO-2018), Kyiv, Ukraine, 24–26 April 2018; pp. 504–510. [Google Scholar]

- Shchur, I.; Biletskyi, Y. Robust passivity-based controllers for fast output voltage regulated, non-ideal DC-DC boost converter in Hamiltonian representation. In Proceedings of the IEEE 3rd International Conference Intelligent Energy and Power Systems (IEPS-2018), Kharkiv, Ukraine, 10–14 September 2018; pp. 310–315. [Google Scholar]

- Becherif, M.; Ayad, M.Y.; Henni, A.; Aboubou, A. Hybridization of solar panel and batteries for street lighting by passivity based control. In Proceedings of the 2010 IEEE International Energy Conference, Manama, Bahrain, 18–22 December 2010; pp. 664–669. [Google Scholar]

- Benmouna, A.; Becherif, M.; Depature, C.; Boulon, L.; Depernet, D. Experimental study of energy management of FC/SC hybrid system using the Passivity Based Control. Int. J. Hydrog. Energ. 2018, 43, 11583–11592. [Google Scholar] [CrossRef]

- Benmouna, A.; Becherif, M.; Depernet, C.; Ebrahim, M.A. Novel energy management technique for hybrid electric vehicle via interconnection and damping assignment passivity based control. Renew. Energy 2018, 119, 116–128. [Google Scholar] [CrossRef]

- Ortega, R.; van der Schaft, A.; Mareels, I.; Maschke, B. Putting energy back in control. IEEE Control Syst. Mag. 2001, 21, 18–33. [Google Scholar]

- Ortega, R.; van der Schaft, A.; Escobar, G.; Maschke, B. Interconnection and damping assignment passivity-based control of port-controlled Hamiltonian systems. Automatica 2002, 38, 585–596. [Google Scholar] [CrossRef] [Green Version]

- Sira-Ramires, H.; Peres-Moreno, R.A.; Ortega, R.; Garcia-Esteban, M. Passivity-based controllers for the stabilization of DC-to-DC power converters. Automatica 1997, 33, 499–512. [Google Scholar] [CrossRef]

- Mozaffari Niapour, S.A.; Shokri Garjan, G.H.; Shafiei, M.; Feyzi, M.R.; Danyali, S.; Bahrami Kouhshahi, M. Review of permanent-magnet brushless DC motor basic drives based on analysis and simulation study. Int. Rev. Electr. Eng. 2014, 9, 930–957. [Google Scholar] [CrossRef] [Green Version]

- Documentation on PV Module 1Soltech 1CTH-350-WH. Available online: http://www.solarhub.com/product-catalog/pv-modules/24996-1STH-350-WH-1Soltech (accessed on 11 August 2021).

- Documentation on BYD Battery-BOX LV LOW VOLTAGE BATTERY STORAGE. Available online: https://www.solahart.com.au/media/5374/ih0113_byd_battery-box-l-35-140_june-2019.pdf (accessed on 16 August 2021).

- Muhammad, H.R. Power Electronics Handbook: Devices, Circuits, and Applications Handbook, 3rd ed.; Academic Press: London, UK, 2011; p. 1389. [Google Scholar]

- Wu, T.; Cheng, Z.; Zhang, J.; He, Z. A PCH strong tracking control strategy for power coordinated allocation of Li-SC HESS. Microelectron. Reliab. 2018, 88–90, 1261–1267. [Google Scholar] [CrossRef]

- Shchur, I.; Biletskyi, Y. Improved structure of passivity-based control of battery-supercapacitor hybrid energy storage system. Appl. Asp. Inf. Technol. 2020, 3, 232–245. [Google Scholar]

| Parameters | Value |

|---|---|

| Rated DC voltage (V) | 380 |

| Rated power (kW) | 2.7 |

| Rated angular velocity (rpm) | 3000 |

| Number of pole pairs | 2 |

| Rated torque (Nm) | 8.6 |

| Maximum torque (Nm) | 21 |

| Efficiency (%) | 90 |

| Phase winding resistance (Ω) | 1.25 |

| Winding inductance (mH) | 3.5 |

| PM flux (Wb) | 0.271 |

| Parameter | Value |

|---|---|

| Maximum power (W) | 350 |

| Open circuit voltage (V) | 51.5 |

| Short-circuit current (A) | 9.4 |

| Voltage at MMP (V) | 43 |

| Current at MPP (A) | 8.13 |

| Shunt resistance (ohms) | 47.97 |

| Series resistance (ohms) | 0.2283 |

| Open circuit voltage temperature coefficient (%/°C) | −0.36 |

| Short-circuit current temperature coefficient (%/°C) | 0.09 |

| DC–DC1 | DC–DC2 | DC–DC3 |

|---|---|---|

| L1 = 1.6 mH | L2 = 4.5 mH | L3 = 6.8 mH |

| C1 = 600 μF | C2 = 10 μF | C3 = 20 μF |

| Θ, deg | Hall Signals | Switching States | |||||||

|---|---|---|---|---|---|---|---|---|---|

| h3 | h2 | h1 | S1 | S2 | S3 | S4 | S5 | S6 | |

| NA | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 0–60 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 |

| 60–120 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 |

| 120–180 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 |

| 180–240 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 |

| 240–300 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| 300–360 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 |

| NA | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shchur, I.; Lis, M.; Biletskyi, Y. Passivity-Based Control of Water Pumping System Using BLDC Motor Drive Fed by Solar PV Array with Battery Storage System. Energies 2021, 14, 8184. https://0-doi-org.brum.beds.ac.uk/10.3390/en14238184

Shchur I, Lis M, Biletskyi Y. Passivity-Based Control of Water Pumping System Using BLDC Motor Drive Fed by Solar PV Array with Battery Storage System. Energies. 2021; 14(23):8184. https://0-doi-org.brum.beds.ac.uk/10.3390/en14238184

Chicago/Turabian StyleShchur, Ihor, Marek Lis, and Yurii Biletskyi. 2021. "Passivity-Based Control of Water Pumping System Using BLDC Motor Drive Fed by Solar PV Array with Battery Storage System" Energies 14, no. 23: 8184. https://0-doi-org.brum.beds.ac.uk/10.3390/en14238184