Minimum Leading Edge Protection Application Length to Combat Rain-Induced Erosion of Wind Turbine Blades

Abstract

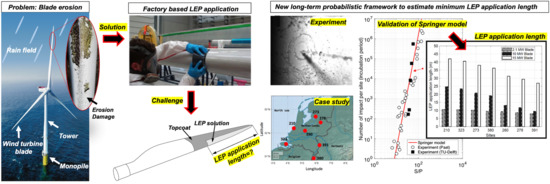

:1. Introduction

1.1. Background

1.2. Challenges

1.3. Scope and Novelty of The Current Work

2. Analysis Procedure

3. Methodology and Details of the Parametric Study

3.1. Methodology

3.1.1. Probabilistic Rainfall Model

| Type of Rainfall | Range of Intensity (mm/h) |

|---|---|

| Dry period | No I recorded |

| Light rainfall (P1) | |

| Moderate rainfall (P2) | |

| Heavy rainfall (P3) | |

| Very heavy/violent rainfall (P4) |

3.1.2. Wind Statistical Model

3.1.3. Wind Turbine Model

3.1.4. Coating Erosion Model

3.1.5. Long-Term Erosion Model

3.2. Parametric Case Studies

4. Experiments: Validation of Springer’s Surface Fatigue Model

4.1. Experimental Procedure

4.2. Validation Methodology

5. Results and Discussion

5.1. Probabilistic Rain Model

5.2. Wind Statistics Model

5.3. Determination of Leading Edge Lifetime and LEP Application Length

6. Conclusions

- 1.

- It was found in the study that for any given WT, the LEL is found to be the lowest at the blade tip, and this value increases rapidly from the tip towards the inner region of the blade in a non-linear fashion. A parameter () was defined that refers to the limiting point along the blade length below which there are no erosion damages expected during the blade’s service life. This parameter calculates the expected eroded blade length, as well as the LEP applications required for the WTB. For the coastal sites, it was found that this parameter is smallest for the 15 MW WT, larger for the 10 MW WT, and even larger for the 2.1 MW WT. However, for the sites further inland, for the 10 MW WT becomes larger than that for the 2.1 MW WT.

- 2.

- The total eroded blade length during the service life due to precipitation was found to be the highest for the 15 MW WT (which ranges between the blade’s radial position 75 m 117 m for all sites) followed by the 10 MW WT (which ranges between 62 m 86.4 m for all sites) and the 2.1 MW WT (which ranges between 33 m 44 m for all sites). Furthermore, the total eroded blade length was found to be the highest for the coastal sites compared to the inland sites.

- 3.

- An experimental investigation was performed to validate Springer’s surface fatigue model for describing the coating incubation time at lab scale. The droplet erosion test results were compared with Springer’s analytical surface fatigue line, which were found to have a close agreement.

- 4.

- It was found in the study that for a given site, the LEP application length requirement increases with increasing power ratings of the WT. For instance, the LEP application length requirements are in the range of 8–11 m for the 2.1 MW blade, 9–25 m for the 10 MW blade, and 27–42 m for the IEA 15 MW turbine. Furthermore, for any given WT, the LEP application length requirement was found to be the highest for the coastal sites and reduced with sites located more inland.

- 5.

- It was found in the study that the LEP application length has the strongest relationship with the hub height, followed by blade length, the power rating of the wind turbine, and finally, with the blade tip speed. A linear regression model was developed to establish the linear equations describing the line of best fit between the LEP application length and turbine-specific parameters. These equations will aid the industry to choose a suitable range of in-factory LEP application lengths, especially for those combinations of turbine parameters for which the analysis was not considered in this paper.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Verma, A.S.; Jiang, Z.; Vedvik, N.P.; Gao, Z.; Ren, Z. Impact assessment of a wind turbine blade root during an offshore mating process. Eng. Struct. 2019, 180, 205–222. [Google Scholar] [CrossRef]

- IRENA. Future of Wind: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects (A Global Energy Transformation Paper); International Renewable Energy Agency: Abu Dhabi, UAE, 2009; Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Oct/IRENA_Future_of_wind_2019.pdf (accessed on 11 September 2020).

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Verma, A.S.; Jiang, Z.; Ren, Z.; Gao, Z.; Vedvik, N.P. Response-Based Assessment of Operational Limits for Mating Blades on Monopile-Type Offshore Wind Turbines. Energies 2019, 12, 1867. [Google Scholar] [CrossRef] [Green Version]

- Verma, A.S.; Jiang, Z.; Gao, Z.; Vedvik, N.P. Effects of a passive tuned mass damper on blade root impacts during the offshore mating process. Mar. Struct. 2020, 72, 102778. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.; Stack, M. Modelling Rain Drop Impact on Offshore Wind Turbine Blades. ASME Turbo Expo 2012. 2012. Available online: https://strathprints.strath.ac.uk/36575/5/Nash_DH_Stack_MM_Pure_Modelling_Rain_Drop_Impact_of_Offshore_Wind_Turbine_Blades_Jun_2012.pdf (accessed on 11 September 2020).

- Keegan, M.H.; Nash, D.; Stack, M. On erosion issues associated with the leading edge of wind turbine blades. J. Phys. Appl. Phys. 2013, 46, 383001. [Google Scholar] [CrossRef] [Green Version]

- Verma, A.S.; Castro, S.G.; Jiang, Z.; Teuwen, J.J. Numerical investigation of rain droplet impact on offshore wind turbine blades under different rainfall conditions: A parametric study. Compos. Struct. 2020, 241, 112096. [Google Scholar] [CrossRef]

- Fraisse, A.; Bech, J.I.; Borum, K.K.; Fedorov, V.; Johansen, N.F.J.; McGugan, M.; Mishnaevsky, L., Jr.; Kusano, Y. Impact fatigue damage of coated glass fibre reinforced polymer laminate. Renew. Energy 2018, 126, 1102–1112. [Google Scholar] [CrossRef] [Green Version]

- Verma, A.S.; Castro, S.G.; Jiang, Z.; Hu, W.; Teuwen, J.J. Leading edge erosion of wind turbine blades: Effects of blade surface curvature on rain droplet impingement kinematics. J. Physics: Conf. Ser. 2020, 1618, 052003. [Google Scholar]

- Herring, R.; Dyer, K.; Martin, F.; Ward, C. The increasing importance of leading edge erosion and a review of existing protection solutions. Renew. Sustain. Energy Rev. 2019, 115, 109382. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Ni, A. A review on rain erosion protection of wind turbine blades. J. Coatings Technol. Res. 2019, 16, 15–24. [Google Scholar] [CrossRef]

- Papi, F.; Balduzzi, F.; Ferrara, G.; Bianchini, A. Uncertainty Quantification on the Effects of Rain-Induced Erosion on Annual Energy Production and Performance of a Multi-MW Wind Turbine. Renew. Energy 2020, 65, 701–715. [Google Scholar]

- Verma, A.; Jiang, Z.; Ren, Z.; Hu, W.; Teuwen, J. Effects of onshore and offshore environmental parameters on the leading edge erosion of wind turbine blades: A comparative study. J. Offshore Mech. Arct. Eng. 2020, 1–31. [Google Scholar] [CrossRef]

- Picture Taken under Permission from Vattenfall Group. Available online: https://group.vattenfall.com/what-we-do (accessed on 22 September 2020).

- Picture Taken under Permission from TNO. Available online: https://www.tno.nl (accessed on 29 September 2020).

- Picture Taken under Permission from DURALEDGE Project. Available online: http://www.duraledge.dk (accessed on 23 September 2020).

- Rempel, L. Rotor blade leading edge erosion-real life experiences. Wind. Syst. Mag. 2012, 11, 22–24. [Google Scholar]

- weatherguardwind.com. Leading Edge Erosion: A BIG Problem For Wind Turbine Operators. Available online: https://weatherguardwind.com/leading-edge-erosion/ (accessed on 1 December 2020).

- Mishnaevsky, L., Jr. Repair of wind turbine blades: Review of methods and related computational mechanics problems. Renew. Energy 2019, 140, 828–839. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Thomsen, K. Costs of repair of wind turbine blades: Influence of technology aspects. Wind Energy 2020, 27, 2247–2255. [Google Scholar] [CrossRef]

- Hayashi, S.; Takei, T.; Hamamura, K.; Ito, S.; Kanawa, D.; Imanishi, E.; Yamauchi, Y. Moving mechanism for a wind turbine blade inspection and repair robot. In Proceedings of the 2017 IEEE/SICE International Symposium on System Integration (SII), Taipei, Taiwan, 11–14 December 2017; pp. 270–275. [Google Scholar]

- Verma, A.S.; Gao, Z.; Jiang, Z.; Ren, Z.; Vedvik, N.P. Structural Safety Assessment of Marine Operations From a Long-Term Perspective: A Case Study of Offshore Wind Turbine Blade Installation. In Proceedings of the ASME 2019 38th International Conference on Ocean, Offshore and Arctic Engineering, Scotland, UK, 9–14 June 2019. [Google Scholar]

- Austin-Morgan, T. The Value of Leading Edge Protection has Never been Greater Now Wind Power is the Largest Renewable Energy Source in Europe. Available online: https://www.materialsforengineering.co.uk/engineering-materials-features/the-value-of-leading-edge-protection-has-never-been-greater-now-wind-power-is-the-largest-renewable-energy-source-in-europe/182597/ (accessed on 17 November 2020).

- ELLE’, P. ELLE™ Puts an End to Leading Edge Erosion, Downtime and Costly Repairs to Your Blades. Available online: https://www.polytech.com/products-solutions/elle-leading-edge-protection/ (accessed on 17 November 2020).

- Gerdes, J. How a ‘Swim Cap’ Could Extend the Life of Wind Turbine Blades. Available online: https://www.greentechmedia.com/articles/read/swim-cap-extend-the-life-of-wind-turbine-blades (accessed on 17 November 2020).

- ELLE’, P. Polytech ELLE™ Puts an End to Leading Edge Erosion, Downtime and Costly Repairs to Your Blades. Available online: https://www.polytech.com/media/1339/polytech-elle-factory-solution.pdf (accessed on 11 September 2020).

- De Vries’, E. SGRE Brings Leading-Edge Protection as Retrofit. Available online: https://www.windpowermonthly.com/article/1663378/sgre-brings-leading-edge-protection-retrofit (accessed on 17 November 2020).

- Moorthikal, D. Putting Belzona’s Leading Edge Protection Coating to the Test. Available online: https://blog.belzona.com/belzona-1341-leading-edge-protection/ (accessed on 17 November 2020).

- Cortés, E.; Sánchez, F.; O’Carroll, A.; Madramany, B.; Hardiman, M.; Young, T.M. On the material characterisation of wind turbine blade coatings: The effect of interphase coating–laminate adhesion on rain erosion performance. Materials 2017, 10, 1146. [Google Scholar] [CrossRef] [Green Version]

- DNVGL. DNVGL Standard DNVGL-RP-0171 Testing of Rotor Blade Erosion Protection Systems. Available online: https://rules.dnvgl.com/docs/pdf/DNVGL/RP/2018-02/DNVGL-RP-0171.pdf (accessed on 17 November 2020).

- Amirzadeh, B.; Louhghalam, A.; Raessi, M.; Tootkaboni, M. A computational framework for the analysis of rain-induced erosion in wind turbine blades, part I: Stochastic rain texture model and drop impact simulations. J. Wind. Eng. Ind. Aerodyn. 2017, 163, 33–43. [Google Scholar] [CrossRef] [Green Version]

- Verma, A.S.; Jiang, Z.; Marco, C.; Verhoef, H.; van der Mijle Meijer, H.; Castro, S.G.; Teuwen, J.J. A probabilistic rainfall model to estimate the leading-edge lifetime of wind turbine blade coating system. Renew. Energy 2020. under review. [Google Scholar]

- Giguère, P.; Selig, M.S. Aerodynamic effects of leading-edge tape on airfoils at low Reynolds numbers. Wind. Energy Int. J. Prog. Appl. Wind. Power Convers. Technol. 1999, 2, 125–136. [Google Scholar]

- Sareen, A.; Sapre, C.A.; Selig, M.S. Effects of leading-edge protection tape on wind turbine blade performance. Wind. Eng. 2012, 36, 525–534. [Google Scholar] [CrossRef]

- Kyle, R.; Wang, F.; Forbes, B. The effect of a leading edge erosion shield on the aerodynamic performance of a wind turbine blade. Wind Energy 2020, 23, 953–966. [Google Scholar] [CrossRef]

- Performance Composite Delivery Service. Leading Edge Erosion. Available online: http://www.thebladedoctors.com/projects/153-leading-edge-protection.html (accessed on 11 December 2020).

- Verma, A.S.; Jiang, Z.; Ren, Z.; Marco, C.; Verhoef, H.; van der Mijle Meijer, H.; Castro, S.G.; Teuwen, J.J. A probabilistic long-term framework for site-specific erosion analysis of wind turbine blades: A case study of 31 Dutch sites. Wind Energy 2021. in production. [Google Scholar]

- Herring, R.; Dyer, K.; Howkins, P.; Ward, C. Characterisation of the Offshore Precipitation Environment to Help Combat Leading Edge Erosion of Wind Turbine Blades. Wind. Energy Sci. Discuss. 2020, 5, 1399–1409. [Google Scholar] [CrossRef]

- 61400-3, I. Wind Turbines, Part 3: Design Requirements for Offshore Wind Turbines. 2009. Available online: http://www.ishare5.com/dodownload.action?key=1358&f=IEC+61400-3+Wind+turbines+-+Part+3++Design+requirements+for+offshore+wind+turbines.pdf&r=2.23MB&rid=10423239 (accessed on 11 December 2020).

- Springer, G.S.; Baxil, C. A model for rain erosion of homogeneous materials. In Erosion, Wear, and Interfaces with Corrosion; ASTM International: Conshohocken, PA, USA, 1974. [Google Scholar]

- Atlas, D.; Srivastava, R.; Sekhon, R.S. Doppler radar characteristics of precipitation at vertical incidence. Rev. Geophys. 1973, 11, 1–35. [Google Scholar] [CrossRef]

- Papadakis, M.; Wong, S.C.; Rachman, A.; Hung, K.E.; Vu, G.T.; Bidwell, C.S. Large and Small Droplet Impingement Data on Airfoils and Two Simulated Ice Shapes. 2007. Available online: https://ntrs.nasa.gov/api/citations/20070034950/downloads/20070034950.pdf (accessed on 11 December 2020).

- Keegan, M.H.; Nash, D.; Stack, M. Wind Turbine Blade Leading Edge Erosion: An Investigation of Rain Droplet and Hailstone Impact Induced Damage Mechanisms. Ph.D. Thesis, University of Strathclyde, Glasgow, Scotland, 2014. [Google Scholar]

- Class Instrumentation Ltd. Class Instrumentation Ltd Ultrasonic Sound Velocity Table. Available online: http://www.classltd.com/sound_velocity_table.html (accessed on 3 May 2018).

- 3M Wind Blade Protection Coating W4600 Technical Data Sheet and Application Guide. 2014. Available online: https://multimedia.3m.com/mws/media/978868O/3m-wind-blade-coating-w4600-app-guide-and-technical (accessed on 9 November 2020).

| Station Number | Site Name | Longitude (East) | Latitude (North) | Altitude (m) |

|---|---|---|---|---|

| 210 | Valkenburg | 4.430 | 52.171 | −0.200 |

| 260 | De Bilt | 5.180 | 52.100 | 1.900 |

| 273 | Marknesse | 5.888 | 52.703 | −3.300 |

| 278 | Heino | 6.259 | 52.435 | 3.600 |

| 323 | Wilhelminadorp | 3.884 | 51.527 | 1.400 |

| 380 | Maastricht | 5.762 | 50.906 | 114.300 |

| 391 | Arcen | 6.197 | 51.498 | 19.500 |

| Turbine Specs | 2.1 MW | DTU 10 MW | IEA 15 MW |

|---|---|---|---|

| Blade length | 44 m | 86.4 m | 117 m |

| Hub height | 80 m | 119 m | 150 m |

| Max. tip speed | 75 m/s | 90 m/s | 95 m/s |

| Cut-in wind speed | 4 m/s | 4 m/s | 3 m/s |

| Rated wind speed | 14 m/s | 11.4 m/s | 10.59 m/s |

| Cut-off wind speed | 25 m/s | 25 m/s | 25 m/s |

| St.No. | (%) | (%) | (%) | (%) | (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 210 | 1.83 | 8.25 | 10.34 | 1.42 | 0.100 | 0.0009 | 11.86 | −0.16 | 0.86 |

| 260 | 1.96 | 5.77 | 10.60 | 1.27 | 0.090 | 0.0012 | 11.96 | −0.25 | 0.87 |

| 273 | 1.93 | 7.06 | 10.70 | 1.18 | 0.102 | 0.0021 | 11.98 | −0.27 | 0.85 |

| 278 | 1.82 | 5.43 | 10.36 | 1.07 | 0.094 | 0.0004 | 11.52 | −0.32 | 0.85 |

| 323 | 1.94 | 7.91 | 10.17 | 1.23 | 0.081 | 0.0010 | 11.48 | −0.24 | 0.83 |

| 380 | 1.90 | 6.97 | 9.90 | 1.02 | 0.094 | 0.0012 | 11.02 | −0.35 | 0.92 |

| 391 | 1.85 | 5.32 | 9.49 | 0.99 | 0.086 | 0.0008 | 10.56 | −0.32 | 0.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verma, A.S.; Noi, S.D.; Ren, Z.; Jiang, Z.; Teuwen, J.J.E. Minimum Leading Edge Protection Application Length to Combat Rain-Induced Erosion of Wind Turbine Blades. Energies 2021, 14, 1629. https://0-doi-org.brum.beds.ac.uk/10.3390/en14061629

Verma AS, Noi SD, Ren Z, Jiang Z, Teuwen JJE. Minimum Leading Edge Protection Application Length to Combat Rain-Induced Erosion of Wind Turbine Blades. Energies. 2021; 14(6):1629. https://0-doi-org.brum.beds.ac.uk/10.3390/en14061629

Chicago/Turabian StyleVerma, Amrit Shankar, Sandro Di Noi, Zhengru Ren, Zhiyu Jiang, and Julie J. E. Teuwen. 2021. "Minimum Leading Edge Protection Application Length to Combat Rain-Induced Erosion of Wind Turbine Blades" Energies 14, no. 6: 1629. https://0-doi-org.brum.beds.ac.uk/10.3390/en14061629