Optical Characterization of Thin Films by Surface Plasmon Resonance Spectroscopy Using an Acousto-Optic Tunable Filter

Abstract

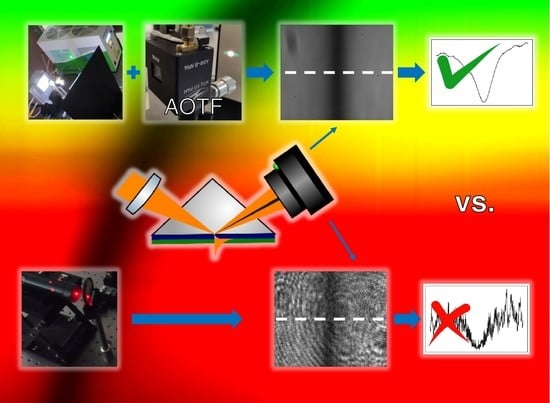

:1. Introduction

2. Materials and Methods

2.1. Optical Setup

2.2. Preparation of Samples

2.3. Experiment

3. Results

4. Discussion

- − chromatism in optical elements, that is, in the AOTF and lenses;

- − misalignments in the setup;

- − inaccuracy in the initial assumptions of the optical model.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Method of Determination of the Thickness of the Deposited Layer Using a Spectrophotometer

References

- Chen, H.-T.; Taylor, A.J.; Yu, N. A Review of Metasurfaces: Physics and Applications. Rep. Prog. Phys. 2016, 79, 076401. [Google Scholar] [CrossRef] [Green Version]

- Shvartsburg, A.B.; Maradudin, A.A. Waves in Gradient Metamaterials; World Scientific: Singapore, 2013; ISBN 978-981-4436-95-3. [Google Scholar]

- Luo, X.; Tsai, D.; Gu, M.; Hong, M. Extraordinary Optical Fields in Nanostructures: From Sub-Diffraction-Limited Optics to Sensing and Energy Conversion. Chem. Soc. Rev. 2019, 48, 2458–2494. [Google Scholar] [CrossRef]

- Malureanu, R.; Lavrinenko, A. Ultra-Thin Films for Plasmonics: A Technology Overview. Nanotechnol. Rev. 2015, 4, 259–275. [Google Scholar] [CrossRef] [Green Version]

- Abelès, F. Surface Electromagnetic Waves Ellipsometry. Surf. Sci. 1976, 56, 237–251. [Google Scholar] [CrossRef]

- Arwin, H.; Poksinski, M.; Johansen, K. Enhancement in Ellipsometric Thin Film Sensitivity near Surface Plasmon Resonance Conditions. Phys. Status Solidi (A) 2008, 205, 817–820. [Google Scholar] [CrossRef]

- Yesudasu, V.; Pradhan, H.S.; Pandya, R.J. Recent Progress in Surface Plasmon Resonance Based Sensors: A Comprehensive Review. Heliyon 2021, 7, e06321. [Google Scholar] [CrossRef] [PubMed]

- Hamza, M.E.; Othman, M.A.; Swillam, M.A. Plasmonic Biosensors: Review. Biology 2022, 11, 621. [Google Scholar] [CrossRef] [PubMed]

- Denizli, A. Plasmonic Sensors and Their Applications, 1st ed.; Wiley-VCH: Weinheim, Germany, 2021; ISBN 3-527-34847-6. [Google Scholar]

- Shukla, N.; Chetri, P.; Boruah, R.; Gogoi, A.; Ahmed, G.A. Surface Plasmon Resonance Biosensors Based on Kretschmann Configuration: Basic Instrumentation and Applications. In Recent Advances in Plasmonic Probes: Theory and Practice; Lecture Notes in Nanoscale Science and Technology; Biswas, R., Mazumder, N., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 191–222. ISBN 978-3-030-99491-4. [Google Scholar]

- Vinogradov, E.A.; Leskova, T.A. Polaritons in Thin Films on Metal Surfaces. Phys. Rep. 1990, 194, 273–280. [Google Scholar] [CrossRef]

- Gu, G.; Lu, X.; Kemsri, T.; Zhang, Y. Surface Plasmonics and Its Applications in Infrared Sensing. In Nanoplasmonics—Fundamentals and Applications; Barbillon, G., Ed.; InTech: Rang-Du-Fliers, France, 2017; ISBN 978-953-51-3277-6. [Google Scholar]

- Bogomolov, G.D.; Jeong, U.Y.; Zhizhin, G.N.; Nikitin, A.K.; Zavyalov, V.V.; Kazakevich, G.M.; Lee, B.C. Generation of Surface Electromagnetic Waves in Terahertz Spectral Range by Free-Electron Laser Radiation and Their Refractive Index Determination. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2005, 543, 96–101. [Google Scholar] [CrossRef]

- Gerasimov, V.; Knyazev, B.; Nikitin, A.; Khasanov, I.; Lemzyakov, A.; Kameshkov, O.; Osintseva, N.; Kukotenko, V.; Pavelyev, V. Novel Experiments on THz Plasmonics Using Novosibirsk Free Electron Laser. In Synchrotron and Free Electron Laser Radiation: Generation and Application (SFR-2022); Book of Abstracts; BINP: Novosibrsk, Russia, 2022; p. 40. [Google Scholar]

- Filion-Côté, S.; Tabrizian, M.; Kirk, A.G. Real-Time Measurement of Complex Refractive Indices with Surface Plasmon Resonance. Sens. Actuators B Chem. 2017, 245, 747–752. [Google Scholar] [CrossRef]

- Harris, S.E.; Wallace, R.W. Acousto-Optic Tunable Filter*. J. Opt. Soc. Am. JOSA 1969, 59, 744–747. [Google Scholar] [CrossRef]

- Tran, C.D. Principles and Analytical Applications of Acousto-Optic Tunable Filters, an Overview. Talanta 1997, 45, 237–248. [Google Scholar] [CrossRef]

- Tsepulin, V.G.; Tolstoguzov, V.L.; Perchik, A.V.; Karasik, V.E.; Arefiev, A.P. Тhickness Distribution Measurement of Multilayer Film Structures by Spectral Reflectometry Methods. Instrum. Metrol. Inf. Meas. Instrum. Syst. 2016, 3, 3–12. [Google Scholar] [CrossRef] [Green Version]

- Machikhin, A.S.; Pozhar, V.E.; Viskovatykh, A.V.; Burmak, L.I. Acousto-Optical Tunable Filter for Combined Wideband, Spectral, and Optical Coherence Microscopy. Appl. Opt. AO 2015, 54, 7508–7513. [Google Scholar] [CrossRef]

- Machikhin, A.S.; Khokhlov, D.D.; Batshev, V.I.; Pozhar, V.E. An Acousto-Optic Endoscopic Module for Nondestructive Testing. Bull. Russ. Acad. Sci. Phys. 2018, 82, 1403–1405. [Google Scholar] [CrossRef]

- Machikhin, A.; Batshev, V.; Pozhar, V.; Naumov, A.; Gorevoy, A. Acousto-Optic Tunable Spectral Filtration of Stereoscopic Images. Opt. Lett. OL 2018, 43, 1087–1090. [Google Scholar] [CrossRef]

- Zajtsev, A.K.; Kludzin, V.V.; Kochin, L.B.; Polosin, L.L.; Sokolov, V.K. Characteristics of Acousto-Optic Tunable Filter for Colorimetry. In Proceedings of the 3rd International Conference on Optical Information Processing, Moscow, Russia, 28–31 May 1999; SPIE: Washington, DC, USA, 1999; pp. 54–59. [Google Scholar] [CrossRef]

- Balakshy, V.I. Application of Acousto-Optic Interaction for Holographic Conversion of Light Fields. Opt. Laser Technol. 1996, 28, 109–117. [Google Scholar] [CrossRef]

- Polschikova, O.; Machikhin, A.; Gorevoy, A.; Stoykova, E. Single-Shot Multiwavelength Digital Holography Using Bragg Diffraction of Light by Several Ultrasound Waves. J. Opt. Soc. Am. A JOSAA 2022, 39, A79–A85. [Google Scholar] [CrossRef] [PubMed]

- Pozhar, V.; Machihin, A. Image Aberrations Caused by Light Diffraction via Ultrasonic Waves in Uniaxial Crystals. Appl. Opt. 2012, 51, 4513–4519. [Google Scholar] [CrossRef]

- Batshev, V.; Machikhin, A.; Gorevoy, A.; Martynov, G.; Khokhlov, D.; Boritko, S.; Pozhar, V.; Lomonov, V. Spectral Imaging Experiments with Various Optical Schemes Based on the Same AOTF. Materials 2021, 14, 2984. [Google Scholar] [CrossRef]

- Voloshinov, V.B.; Parygin, V.N.; Molchanov, V.Y. Tunable Acousto-Optic Filters and Their Applications in Laser Technology, Optical Communication, and Processing of Images. In Proceedings of the Laser Optics 2000: Control of Laser Beam Characteristics and Nonlinear Methods for Wavefront Control, Petersburg, Russia, 26–30 June 2000; SPIE: Washington, DC, USA, 2001; Volume 4353, pp. 17–22. [Google Scholar] [CrossRef]

- Machikhin, A.S.; Sharikova, M.O.; Lyashenko, A.I.; Kozlov, A.B.; Pozhar, V.E.; Lomonov, V.A.; Stoikova, E. Attenuation of the Intensities of Spectral Components of a Multiwavelength Pulsed Laser System by Means of the Bragg Diffraction of Radiation by Several Acoustic Waves. Quantum. Electron. 2022, 52, 454. [Google Scholar] [CrossRef]

- Gottlieb, M.S. Acousto-Optic Tunable Filters. In Design and Fabrication of Acousto-Optic Devices; CRC Press: Boca Raton, FL, USA, 1994; ISBN 978-1-00-321022-1. [Google Scholar]

- Voloshinov, V.B.; Yushkov, K.B.; Linde, B.B.J. Improvement in Performance of a TeO2 Acousto-Optic Imaging Spectrometer. J. Opt. A Pure Appl. Opt. 2007, 9, 341. [Google Scholar] [CrossRef] [Green Version]

- Antonov, S.N. Acousto-Optic Deflector with a High Diffraction Efficiency and Wide Angular Scanning Range. Acoust. Phys. 2018, 64, 432–436. [Google Scholar] [CrossRef]

- Sopko, I.M.; Ignatyeva, D.O.; Knyazev, G.A.; Belotelov, V.I. Efficient Acousto-Optical Light Modulation at the Mid-Infrared Spectral Range by Planar Semiconductor Structures Supporting Guided Modes. Phys. Rev. Appl. 2020, 13, 034076. [Google Scholar] [CrossRef] [Green Version]

- Mil’kov, M.G.; Volnyanskii, M.D.; Antonenko, A.M.; Voloshinov, V.B. Acoustic Properties of Biaxial Crystal of Double Lead Molybdate Pb2MoO5. Acoust. Phys. 2012, 58, 172–179. [Google Scholar] [CrossRef]

- Kupreychik, M.I.; Balakshy, V.I. Peculiarities of Acousto-Optic Interaction in Biaxial Crystal of Alpha-Iodic Acid. Appl. Opt. AO 2018, 57, 5549–5555. [Google Scholar] [CrossRef]

- Dürr, W. Acousto-Optic Interaction in Gases and Liquid Bases in the Far Infrared. Int. J. Infrared Milli. Waves 1986, 7, 1537–1558. [Google Scholar] [CrossRef]

- Batshev, V.I.; Machikhin, A.S.; Kozlov, A.B.; Boritko, S.V.; Sharikova, M.O.; Karandin, A.V.; Pozhar, V.E.; Lomonov, V.A. Tunable Acousto-Optic Filter for the 450–900 and 900–1700 Nm Spectral Range. J. Commun. Technol. Electron. 2020, 65, 800–805. [Google Scholar] [CrossRef]

- Voloshinov, V.B.; Mironov, O.V. Wide-aperture acoustooptical filter for the middle IR. Opt. I Spektrosk. 1990, 68, 452–457. [Google Scholar]

- Voloshinov, V.B.; Gupta, N.; Kulakova, L.A.; Khorkin, V.S.; Melekh, B.T.; Knyazev, G.A. Investigation of Acousto-Optic Properties of Tellurium-Based Glasses for Infrared Applications. J. Opt. 2016, 18, 025402. [Google Scholar] [CrossRef]

- Nikitin, P.; Voloshinov, V.; Knyazev, B.; Scheglov, M. Observation of Acousto-Optic Diffraction of Terahertz Radiation in Liquefied Sulfur Hexafluoride at Room Temperature. IEEE Trans. Terahertz Sci. Technol. 2019, 10, 44–50. [Google Scholar] [CrossRef]

- Vogel, T.; Dodel, G. Acousto-Optic Modulation in the Far-Infrared. Infrared Phys. 1985, 25, 315–318. [Google Scholar] [CrossRef]

- Voloshinov, V.B.; Mishin, D.D. Spectral Resolution Control of Acousto-Optical Cells Operating with Collimated and Divergent Beams. In Proceedings of the International Conference on Optical Information Processing, Saint Petersburg, Russia, 2–7 August 1993; SPIE: Washington, DC, USA, 1994; Volume 2051, pp. 378–385. [Google Scholar] [CrossRef]

- Schasfoort, R.B.M. (Ed.) Handbook of Surface Plasmon Resonance; Royal Society of Chemistry: Cambridge, UK, 2017; pp. P001–P004. ISBN 978-1-78262-730-2. [Google Scholar]

- Tian, Y.; Zhao, L.; Song, D.; Liu, X.; Cao, Y.; Peng, Z.; Liu, Z.; Zhang, H. Acousto-Optic Tunable Filter—Based Surface Plasmon Resonance Biosensor for Determination of Human Factor B. Anal. Chim. Acta 2004, 511, 97–104. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, Y.; Song, D.; Liu, X.; Bi, S.; Zhou, X.; Cao, Y.; Zhang, H. Acousto-Optic Tunable Filter-Surface Plasmon Resonance Immunosensor for Fibronectin. Anal. Chim. Acta 2005, 551, 98–104. [Google Scholar] [CrossRef]

- Luo, Z.; Huang, Y. Sensitivity Enhancement of Surface Plasmon Resonance Sensor Based on Wavelength and Angular Combined Modulations. Optik 2018, 168, 271–277. [Google Scholar] [CrossRef]

- Anisimov, A.V.; Khasanov, I.S. Algorithm for Optical Characterization of Dielectric Gradient Index Nanofilm by Surface Plasmon Resonance Spectroscopy. J. Phys. Conf. Ser. 2021, 2091, 012067. [Google Scholar] [CrossRef]

- Nikitin, P.A.; Gerasimov, V.V.; Khasanov, I.S. Temperature Effects in an Acousto-Optic Modulator of Terahertz Radiation Based on Liquefied SF6 Gas. Materials 2021, 14, 5519. [Google Scholar] [CrossRef]

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface Plasmon Subwavelength Optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.W. Optical Constants of the Noble Metals. Phys. Rev. B 1972, 6, 4370–4379. [Google Scholar] [CrossRef]

- Byrnes, S.J. Multilayer Optical Calculations. arXiv 2020, arXiv:1603.02720. [Google Scholar]

- Mackay, T.G.; Lakhtakia, A. The Transfer-Matrix Method in Electromagnetics and Optics. Synth. Lect. Electromagn. 2020, 1, 1–126. [Google Scholar] [CrossRef]

- McPeak, K.M.; Jayanti, S.V.; Kress, S.J.P.; Meyer, S.; Iotti, S.; Rossinelli, A.; Norris, D.J. Plasmonic Films Can Easily Be Better: Rules and Recipes. ACS Photonics 2015, 2, 326–333. [Google Scholar] [CrossRef]

- Hunderi, O. Optics of Rough Surfaces, Discontinuous Films and Heterogeneous Materials. Surf. Sci. 1980, 96, 1–31. [Google Scholar] [CrossRef]

- Schlesinger, Z.; Sievers, A.J. Broadband Surface Electromagnetic Wave Spectroscopy. Surf. Sci. 1981, 102, L29–L34. [Google Scholar] [CrossRef]

- Johansen, K.; Arwin, H.; Lundström, I.; Liedberg, B. Imaging Surface Plasmon Resonance Sensor Based on Multiple Wavelengths: Sensitivity Considerations. Rev. Sci. Instrum. 2000, 71, 3530–3538. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Zhang, B.; Wang, G.; Zhou, Q.; Hu, H. Application of Graded-Index Thin Film in Laser Attack and Defense Equipment. J. Phys. Conf. Ser. 2020, 1507, 102037. [Google Scholar] [CrossRef]

- Azarov, I.A.; Kuper, K.E.; Lemzyakov, A.G.; Porosev, V.V.; Shklyaev, A.A. Scintillator Surface Modification by Glancing Angle Deposition of Thin ZrO2 Films. J. Inst. 2022, 17, T05013. [Google Scholar] [CrossRef]

- Stenzel, O.; Ohlídal, M. Optical Characterization of Thin Solid Films, 1st ed.; Springer series in surface sciences 64; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-75324-9. [Google Scholar]

- Harris, P.M.; Cox, M.G. On a Monte Carlo Method for Measurement Uncertainty Evaluation and Its Implementation. Metrologia 2014, 51, S176. [Google Scholar] [CrossRef]

| Method | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

|---|---|---|---|---|

| Spectrophotometry | 0 | 13.0 ± 3.0 | 17.1 ± 4.2 | 30.0 ± 5.2 |

| SPR spectroscopy | 0 | 8.7 ± 1.5 | 12.0 ± 1.4 | 25.9 ± 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khasanov, I.S.; Knyazev, B.A.; Lobastov, S.A.; Anisimov, A.V.; Nikitin, P.A.; Kameshkov, O.E. Optical Characterization of Thin Films by Surface Plasmon Resonance Spectroscopy Using an Acousto-Optic Tunable Filter. Materials 2023, 16, 1820. https://0-doi-org.brum.beds.ac.uk/10.3390/ma16051820

Khasanov IS, Knyazev BA, Lobastov SA, Anisimov AV, Nikitin PA, Kameshkov OE. Optical Characterization of Thin Films by Surface Plasmon Resonance Spectroscopy Using an Acousto-Optic Tunable Filter. Materials. 2023; 16(5):1820. https://0-doi-org.brum.beds.ac.uk/10.3390/ma16051820

Chicago/Turabian StyleKhasanov, Ildus Sh., Boris A. Knyazev, Sergey A. Lobastov, Alexander V. Anisimov, Pavel A. Nikitin, and Oleg E. Kameshkov. 2023. "Optical Characterization of Thin Films by Surface Plasmon Resonance Spectroscopy Using an Acousto-Optic Tunable Filter" Materials 16, no. 5: 1820. https://0-doi-org.brum.beds.ac.uk/10.3390/ma16051820