Evaluation of Salvage Logging Productivity and Costs in the Sensitive Forests of Bulgaria

Abstract

:1. Introduction

2. Materials and Methods

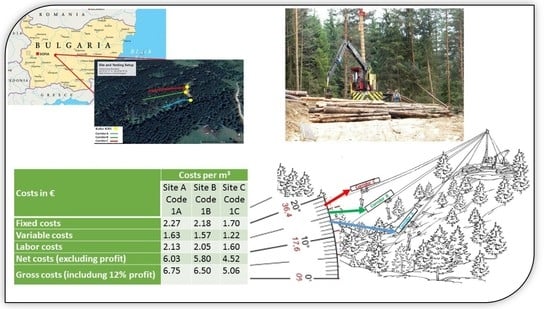

2.1. Description of the Site and Yarding Setup

2.2. Description of the Cable Yarder Unit and Work Team

2.3. Time Study

- Carriage outhaul (CO) begins when the operator is ready to move the empty carriage from the landing out to the stump, and ends when the choker-setter touches the chokers.

- Lateral outhaul (LO) begins at the end of carriage outhaul, and ends when the choker-setter has completed the hooking of the chokers and signals to begin yarding.

- Lateral inhaul (LI) and hook begins at the end of the hook up, and ends when the turn is pulled up to the carriage and the carriage begins to move up the corridor.

- Carriage inhaul (CI) begins at the end of the lateral inhaul, and ends when the load has reached the deck where it can be directly unhooked at the landing.

- Unhook (U) begins at the end of the carriage inhaul, and ends when the chokers have returned to the carriage.

- Delay time (D) includes the rest, personal delays, organizational delays, service, and repair.

2.4. Economic Evaluation

2.5. Data Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| asl | above sea level |

| CI | carriage inhaul time |

| CO | carriage outhaul |

| CO | carriage outhaul time |

| D | delay time |

| DBH | diameter at breast height |

| LO | lateral outhaul time |

| PMH | productive machine hours |

| PTY | processor tower yarder |

| SMH | scheduled machine hour |

| TNET | delay-free cycle time |

| U | unhook time |

References

- Schelhaas, M.J.; Nabuurs, G.J.; Schuck, A. Natural disturbances in the European forests in the 19th and 20th centuries. Glob. Chang. Biol. 2003, 9, 1620–1633. [Google Scholar] [CrossRef]

- Thorn, S.; Bässler, C.; Svoboda, M.; Müller, J. Effects of natural disturbances and salvage logging on biodiversity. Lessons Bohemian For. For. Ecol. Manag. 2017, 388, 113–119. [Google Scholar] [CrossRef]

- Kärhä, K.; Anttonen, T.; Poikela, A.; Palander, T.; Laurén, A.; Peltola, H.; Nuutinen, Y. Evaluation of Salvage Logging Productivity and Costs in Windthrown Norway Spruce-Dominated Forests. Forests 2018, 9, 280. [Google Scholar] [CrossRef] [Green Version]

- Lindenmayer, D.B.; Noss, R.F. Salvage logging, ecosystem processes, and biodiversity conservation. Conserv. Biol. 2006, 20, 946–948. [Google Scholar] [CrossRef]

- Stokes, B.J.; Ashmore, C.; Rawlins, C.L.; Sirois, D.L. Glossary of Terms Used in Timber Harvesting and Forest Engineering; Gen. Tech. Rep. SO-73, New Orleans; USDA Forest Service Southern Forest Experimental Station: Asheville, NC, USA, 1989. [Google Scholar]

- Kramer, K.; Brang, P.; Bachofen, H.; Bugmann, H.; Wohlgemuth, T. Site factors are more important than salvage logging for tree regeneration after wind disturbance in Central European forests. For. Ecol. Manag. 2014, 331, 116–128. [Google Scholar] [CrossRef]

- Cadei, A.; Mologni, O.; Röser, D.; Cavalli, R.; Grigolato, S. Forwarder productivity in salvage logging operations in difficult terrain. Forests 2020, 11, 341. [Google Scholar] [CrossRef] [Green Version]

- Oprea, I. Tehnologia Exploatării Lemnului (Timber Harvesting Technology); Transilvania University Press: Brasov, Romania, 2008; p. 273. ISBN 978-973-598-301-7. [Google Scholar]

- Keeton, W.S. Managing for Late-successional/old-Growth Characteristics in Northern Hardwood-Conifer Forests. For. Ecol. Manag. 2006, 235, 129–142. [Google Scholar] [CrossRef]

- Keeton, W.; Chernyavskyy, M.; Gratzer, G.; Main-Knorn, M.; Shpylchak, M.; Bihun, Y. Structural Characteristics and Aboveground Biomass of old-growth spruce–fir Stands in the Eastern Carpathian Mountains, Ukraine. Plant Biosyst. 2010, 144, 148–159. [Google Scholar] [CrossRef]

- Lehnert, L.W.; Bässler, C.; Brandl, R.; Burton, P.J.; Müller, J. Conservation Value of Forests Attacked by Bark Beetles: Highest Number of Indicator Species is found in Early Successional Stages. J. Nat. Conserv. 2013, 21, 97–104. [Google Scholar] [CrossRef]

- Lindenmayer, D.B.; Burton, P.J.; Franklin, J.F. Salvage Logging and Its Ecological Consequences; Island Press: Washington, DC, USA, 2012. [Google Scholar]

- Wermelinger, B.; Moretti, M.; Duelli, P.; Lachat, T.; Pezzatti, G.B.; Obrist, M.K. Impact of windthrow and salvage-logging on taxonomic and functional diversity of forest arthropods. For. Ecol. Manag. 2017, 391, 9–18. [Google Scholar] [CrossRef]

- Jonášová, M.; Prach, K. The Influence of Bark Beetles Outbreak vs. Salvage Logging on Ground Layer Vegetation in Central European Mountain Spruce Forests. Biol. Conserv. 2008, 141, 1525–1535. [Google Scholar] [CrossRef]

- Michalová, Z.; Morrissey, R.C.; Wohlgemuth, T.; Bače, R.; Fleischer, P.; Svoboda, M. Salvage-Logging after Windstorm Leads to Structural and Functional Homogenization of Understory Layer and Delayed Spruce Tree Recovery in Tatra Mts., Slovakia. Forests 2017, 8, 88. [Google Scholar]

- European Commission. Council Directive 92/43/EEC on the conservation of natural habitats and of wild fauna and flora. Off. J. Eur. Union 1992, 206, 7–50. [Google Scholar]

- European Commission. NATURA 2000 Viewer User Guide. 2020. Available online: https://natura2000.eea.europa.eu/# (accessed on 30 November 2020).

- Krejcí, F.; Vacek, S.; Bílek, L.; Mikeska, M.; Hejcmanová, P.; Vacek, Z. The effects of climatic conditions and forest site types on disintegration rates in Picea abies occurring at the Modrava Peat Bogs in the Šumava National Park. Dendrobiology 2013, 70, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Vacek, S.; Moucha, P.; Bílek, L.; Mikeska, M.; Remeš, J.; Simon, J.; Hynek, V.; Šrùtka, P.; Schwarz, O.; Mánek, J.; et al. Management of Forest Ecosystems in the Protected Areas of the Czech Republic; Ministry of the Environment of the Czech Republic: Prague, Czech Republic, 2012.

- Remeš, J.; Pulkrab, K.; Bílek, L.; Podrázský, V. Economic and production effect of tree species change as a result of adaptation to climate change. Forests 2020, 11, 431. [Google Scholar] [CrossRef] [Green Version]

- Šimůnek, V.; Vacek, Z.; Vacek, S. Solar Cycles in Salvage Logging: National Data from the Czech Republic Confirm Significant Correlation. Forests 2020, 11, 973. [Google Scholar] [CrossRef]

- Vacek, S.; Vacek, Z.; Bílek, L.; Hejcmanová, P.; Štícha, V.; Remeš, J. The dynamics and structure of dead wood in natural spruce-beech forest stand—A 40 year case study in the Krkonoše national park. Dendrobiology 2015, 73, 21–32. [Google Scholar] [CrossRef]

- Bîrda, M.; Borz, S.A. A comparison between tractor based and skyline based mechanized systems for timber logging. Bull. Transilv. Univ. Bras. Ser. II For. Wood Ind. Agric. Food Eng. 2012, 5, 19–24. [Google Scholar]

- Proto, A.R.; Skoupy, A.; Macrì, G.; Zimbalatti, G. Time consumption and productivity of a medium size mobile tower yarder in downhill and uphill configurations: A case study in Czech Republic. J. Agric. Eng. 2016, 47, 216–221. [Google Scholar] [CrossRef] [Green Version]

- Visser, R.J.M.; Stampfer, K. Cable extraction of harvester felled thinnings an Austrian case study. J. Eng. 1998, 1, 39–46. [Google Scholar]

- Huyler, N.K.; LeDoux, C.B. Cycle-Time Equation for the Koller K300 Cable Yarder Operating on Steep Slopes in the Northeast; Research Paper NE-705; US Department of Agriculture, Forest Service, Northeastern Forest Experiment Station: Radnor, PA, USA, 1997; p. 4.

- Messingerova, V. Analysis of Basic Parameters for Optimal Utilization of the Forestry Cable Yarding System; Prace Komisji nauk rolniczych, leśnych i weterynaryjnych PAU, zv. Nr. 15; Polska Akademia Umiejętności: Krakow, Poland, 2011; pp. 177–186. ISSN 1733-5183. [Google Scholar]

- Cosola, G.; Grigolato, S.; Ackerman, P.; Monterotti, S.; Cavalli, R. Carbon footprint of forest operations under different management regimes. Croat. J. For. Eng. 2016, 37, 201–217. [Google Scholar]

- Munteanu, C.; Yoshida, M.; Iordache, E.; Borz, S.A.; Ignea, G. Performance and cost of downhill cable yarding operations in a group shelterwood system. J. For. Res. 2019. [Google Scholar] [CrossRef]

- Fischer, A.; Fischer, H.S.; Kopecky´, M.; Macek, M.; Wild, J. Small changes in species composition despite stand-replacing bark beetle outbreak in Picea abies mountain forests. Can. J. Res. 2015, 1171, 1164–1171. [Google Scholar] [CrossRef]

- Nováková, M.H.; Edwards-Jonášová, M. Restoration of Central-European mountain Norway spruce forest 15 years after natural and anthropogenic disturbance. Ecol. Manag. 2015, 344, 120–130. [Google Scholar] [CrossRef]

- Borz, S.A.; Birda, M.; Ignea, G.; Oprea, I. Technological aspects regarding timber exploitation using Mounty 4100 cable yarder. Bull. Transilv. Univ. Bras. Ser. II For. Wood Ind. Agric. Food Eng. 2011, 4, 1–6. [Google Scholar]

- Stampfer, K.; Visser, R.; Kanzian, C. Cable corridor installation times for European yarders. Int. J. For. Eng. 2006, 17, 71–77. [Google Scholar] [CrossRef]

- Borz, S.A. A computational algorithm for cutting volumes determination with application in the tractor logging network design. Bull. Transilv. Univ. Bras. Ser. II For. Wood Ind. Agric. Food Eng. 2010, 3, 5–10. [Google Scholar]

- Proto, A.R.; Sperandio, G.; Costa, C.; Maesano, M.; Antonucci, F.; Macrì, G.; Scarascia Mugnozza, G.; Zimbalatti, G. A three-step neural network artificial intelligence modeling approach for time, productivity and costs prediction: A case study in Italian forestry. Croat. J. For. Eng. 2020, 41, 35–47. [Google Scholar] [CrossRef]

- Borz, S.A.; Ignea, G.; Popa, B.; Spârchez, G.; Iordache, E. Estimating time consumption and productivity of roundwood skidding in group shelterwood system—A case study in a broadleaved mixed stand located in reduced accessibility conditions. Croat. J. For. Eng. 2015, 36, 137–146. [Google Scholar]

- Duta, C.I.; Borz, A.; Salajan, A. Estimating current state of soil erosion induced by skid trails geometry in mountainous conditions. Environ. Eng. Manag. J. 2018, 17, 697–704. [Google Scholar]

- Kühmaier, M.; Harrill, H.; Ghaffariyan, M.R.; Hofer, M.; Stampfer, K.; Brown, M.; Visser, R. Using conjoint analyses to improve cable yarder design characteristics: An Austrian yarder case study to advance cost-effective extraction. Forests 2019, 10, 165. [Google Scholar] [CrossRef] [Green Version]

- Findeisen, E.; Markoff, I.; Gluschkov, S. Fully mechanized logging in Bulgaria—First steps and prospects. In Proceedings of the 41th International Symposium on Forestry Mechanization, Schmallenberg, Germany, 2–5 June 2008; German Center for Forest Work and Technology (KWF): Schmallenberg, Germany, 2008. ISBN 978-3-9811335-2-3. [Google Scholar]

- Dvôrák, J.; Walczyk, J.; Natov, P.; Hošková, P. Struktura czasu pracy harwesterów podczas pozyskania przygodnego (Structure of the operating time of the harvesters during casual logging). Sylwan 2015, 159, 300–306. [Google Scholar]

- Brzózko, J.; Szereszewiec, B.; Szereszewiec, E. Productivity of machine timber harvesting at the wind-damaged site. Ann. Wars. Univ. Life Sci. Sggw Agric. 2009, 54, 41–49. [Google Scholar]

- Bodaghi, A.I.; Nikooy, M.; Naghdi, R.; Venanzi, R.; Latterini, F.; Tavankar, F.; Picchio, R. Ground-based extraction on salvage logging in two high forests: A productivity and cost analysis. Forests 2018, 9, 1–18. [Google Scholar]

- Borz, S.A.; Dinulică, F.; Bîrda, M.; Ignea, G.; Ciobanu, V.; Popa, B. Time consumption and productivity of skidding Silver fir (Abies alba Mill.) round wood in reduced accessibility conditions: A case study in windthrow salvage logging form Romanian Carpathians. Ann. For. Res. 2013, 363–375. [Google Scholar] [CrossRef]

- Cȃkša, L.; Šenhofa, S.; Šnepsts, G.; Elferts, D.; Liepa, L.; Jansons, A. Effect of stem snapping on aspen timber assortment recovery in hemiboreal forests. Forests 2021, 12, 28. [Google Scholar] [CrossRef]

- Ackerman, P.; Gleasure, E.L.; Ackerman, S.; Shuttleworth, B. Standards for time studies for the South African forest industry. ICFR/FESA 2014. Available online: https://natura2000.eea.europa.eu/# (accessed on 9 September 2020).

- Olsen, E.D.; Hossain, M.M.; Miller, M.E. Statistical Comparison of Methods Used in Harvesting Work Studies; College of Forestry, Forest Research Laboratory; Oregon State University: Corvallis, OR, USA, 1998; p. 45. [Google Scholar]

- Munteanu, C.; Ignea, G.; Akay, A.E.; Borz, S. Yarding Pre-Bunched Stems in Thinning Operations: Estimates on Time Consumption; Special issue No. 1—2017 Series II—Forestry, wood industry, agricultural and food engineering; Transilvania University of Brasov: Brasov, Romania, 2017; Volume 10, ISSN 2065-2135. [Google Scholar]

- Huyler, N.K.; LeDoux, C.B. Yarding cost for the Koller K300 cable yarder: Results from field trials and simulations. North. J. Appl. For. 1997, 14, 5–9. [Google Scholar] [CrossRef] [Green Version]

- Proto, A.R.; Zimbalatti, G. Firewood cable extraction in the southern Mediterranean area of Italy. For. Sci. Technol. 2016, 12, 16–23, ISSN 2158-0103 (Print) 2158-0715. [Google Scholar] [CrossRef]

- Ackerman, P.; Belbo, H.; Eliasson, L.; de Jong, A.; Lazdins, A.; Lyons, J. The COST model for calculation of forest operations costs. Int. J. Eng. 2014, 25, 75–81. [Google Scholar] [CrossRef]

- Dimitrov, D. Investigation on work time and productivity of forest skyline Koller K 300 in Ograzhden Mountain. For. Ideas 2012, 18, 92–96. [Google Scholar]

- Spinelli, R.; Visser, R.J.M. Analyzing and estimating delays in harvester operations. Int. J. For. Eng. 2008, 19, 36–41. [Google Scholar] [CrossRef]

- Borz, S.A.; Ignea, G.; Popa, B. Modelling and comparing timber winching performance in windthrow and uniform selective cuttings for two Romanian skidders. J. For. Res. 2014, 19, 473–482. [Google Scholar] [CrossRef]

- Kellogg, L.D.; Milota, G.V.; Miller, M., Jr. A Comparison of Skyline Harvesting Costs for Alternative Commercial Thinning Prescriptions. J. For. Eng. 1996, 7, 7–23. [Google Scholar] [CrossRef]

- Schweier, J.; Klein, M.-L.; Kristen, H.; Jaeger, D.; Brieger, F.; Sauter, U.H. Productivity and cost analysis of tower yarder systems using the Koller 507 and the Valentini 400 in Southwest Germany. Int. J. Eng. 2020, 31, 172–183. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Visser, R. Productivity models for cable yarding in Alpine forests. Eur. J. For. Eng. 2015, 1, 9–14. [Google Scholar]

- Melemez, K.; Tunay, M.; Emir, T. A comparison of productivity in five small-scale harvesting systems. Small-Scale For. 2014, 13, 35–45. [Google Scholar] [CrossRef]

- Zimbalatti, G.; Proto, A.R. Cable logging opportunities for firewood in Calabrian forests. Biosyst. Eng. 2009, 102, 63–68. [Google Scholar] [CrossRef]

- Erber, G.; Haberl, A.; Pentek, T.; Stampfer, K. Impact of operational parameters on the productivity of whole tree cable yarding—Astatistical analysis based on operation data. Austrian J. Sci. 2017, 134, 1–18. [Google Scholar]

- Senturk, N.; Ozturk, T.; Demir, M. Productivity and costs in the course of timber transportation with the Koller K300 cable system in Turkey. Build. Environ. 2007, 42, 2107–2113. [Google Scholar] [CrossRef]

- Tavankar, F.; Nikooy, M.; Picchio, R.; Venanzi, R.; Lo Monaco, A. Long-term effects of single-tree selection cutting management on coarse woody debris in natural mixed beech stands in the Caspian forest (Iran). iForest 2017, 10, 652–658. [Google Scholar] [CrossRef] [Green Version]

- Stampfer, K. Perspectives on whole tree cable yarding systems for thinnings operations in Austria. In Proceedings of the Cable Yarding Suitable for Sustainable Forest Management, Idrija, Slovenia, 23 September 2004. [Google Scholar]

- Bugoš, M.; Stanovský, M.; Lieskovský, M. Time analysis of the operations during yarding by Konrad Mounty 4000 mountain processor. Acta Facultatis Xylologiae Zvolen 2008, 50, 163–174. [Google Scholar]

- Tajboš, J.; Slugeň, J.; Ilčík, Š. Popis lanovky Mounty 4000. In Manažment podnikov; Přeložil Mária LACIKOVÁ: Prešov, Slovenská, 2012; Volume 2, pp. 15–18. [Google Scholar]

- Borz, S.A.; Bîrda, M.; Ignea, G.; Popa, B.; Câmpu, V.R.; Iordache, E.; Derczeni, R.A. Efficiency of a Woody 60 processor attached to a Mounty 4100 tower yarder when processing coniferous timber from thinning operations. Ann. Res. 2014, 57, 333–345. [Google Scholar] [CrossRef] [Green Version]

- Visser, R.; Baker, S.; Sloan, H. Cable logging opportunities in the Appalachian Mountains. In Proceedings of the Workshop Proceedings New Trends in Wood Harvesting with Cable Systems for Sustainable Forest Management in the Mountains; Ossiach, Austria, 18–24 June 2001; Arzberger, U., Grimoldi, M., Eds.; Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training with the participation of the IUFRO. FAO: Rome, Italy, 2003. [Google Scholar]

- Peterson, C.J.; Leach, A.D. Limited Salvage Logging Effects on Forest Regeneration After moderate-severity Windthrow. Ecol. Appl. 2008, 18, 407–420. [Google Scholar] [CrossRef] [PubMed]

- Donis, J.; Saleniece, R.; Krisans, O.; Dubrovskis, E.; Kitenberga, M.; Jansons, A. A Financial Assessment of Windstorm Risks for Scots Pine Stands in Hemiboreal Forests. Forests 2020, 11, 566. [Google Scholar] [CrossRef]

- Picchio, R.; Proto, A.R.; Civitarese, V.; Di Marzio, N.; Latterini, F. Recent contributions of some fields of the electronics in development of forest operations technologies. Electronics 2019, 8, 1465. [Google Scholar] [CrossRef] [Green Version]

| Site | Kriva reka, subcompartment 9019-a1 |

| Elevation | 1200 m asl |

| Protection function/designation | Natura 2000: BG 0001389, BG 0002054, habitat 91CA |

| Species composition | Scots pine (Pinus sylvestris L.) |

| Stand age (years) | 40 |

| Stand type by age | Even-aged |

| Stand density (trees ha−1) | 1784 |

| Logging operation | Salvage cutting after wet snow, windbreaks and windthrow damage |

| Average tree height (m) | 15 |

| Average DBH of tree (cm) | 24 |

| Site volume (m3 over bark) | 540 |

| Removal volume (m3 over bark) | 175 |

| Altitudinal difference between the corridor endpoints (m) | 45 |

| Average sag (m) | 12 |

| Average lateral yarding distance (m) | 17.8 |

| Parameter | Value |

|---|---|

| Skyline capacity 600 m, ø 24 mm | 120 kN (tension section) |

| Mainline 600 m, ø 14 mm | 43 kN (average drum) |

| Guylines | 4 × 75 m2, ø 16 mm/2 × 15 m2 (extension) |

| Foldable telescopic tower, height | 13.5 m |

| Power station | Autonomous engine and hydrostatic transmission |

| Engine power | 250 kW (340 HP) |

| Skyline | Manually actuated band brake |

| Mainline | Hydraulically actuated band brake |

| Operation | Hydro-mechanical/electro-hydraulic single lever operation with dead-man’s control |

| Carriage | Koller SKA-2.5, manual slack-pulling carriage |

| Choker system | Bardon choker |

| Lifting moment | 270 kNm |

| Carrier | 6 × 4 Mercedes-Benz truck |

| Yarding Time Consumption Variables | Cycle Time, s | Distance, m | ||||

|---|---|---|---|---|---|---|

| Mean Value ± St. Dev. | Min | Max | Mean Value ± St. Dev. | Min | Max | |

| Carriage Outhaul | 39.5 ± 10.0 | 22 | 70 | 100.7± 31.8 | 60 | 130 |

| Corridor A | 39.5 ± 10.2 | 22 | 70 | 96 ± 31.2 | 60 | 130 |

| Corridor B | 39.5 ± 10.3 | 22 | 70 | 96 ± 31.2 | 60 | 130 |

| Corridor C | 39.6 ± 9.6 | 22 | 60 | 108.4 ± 28.7 | 60 | 130 |

| Lateral outhaul and hook | 69.2 ± 51.8 | 20 | 200 | 17.8 ± 11.3 | 9 | 42 |

| Corridor A | 83.0 ± 58.6 | 20 | 200 | 20.8 ± 12.8 | 9 | 42 |

| Corridor B | 36.5 ± 25.3 | 20 | 180 | 14.7 ± 4.1 | 7 | 22 |

| Corridor C | 44.0 ± 25.3 | 20 | 120 | 12.1 ± 2.5 | 9 | 19 |

| Lateral inhaul | 36.0± 25.3 | 15 | 100 | 17.8 ± 11.3 | 9 | 42 |

| Corridor A | 41.5 ± 28.7 | 15 | 100 | 20.8 ± 12.8 | 9 | 42 |

| Corridor B | 41.3 ± 28.7 | 15 | 100 | 14.7 ± 4.1 | 7 | 22 |

| Corridor C | 27.7 ± 17.6 | 15 | 100 | 12.1 ± 2.5 | 9 | 19 |

| Carriage Inhaul | 28.3± 7.2 | 15 | 45 | 100.7± 31.8 | 60 | 130 |

| Corridor A | 33.5 ± 7.2 | 15 | 45 | 96 ± 31.2 | 60 | 130 |

| Corridor B | 26.6 ± 4.7 | 20 | 35 | 96 ± 31.2 | 60 | 130 |

| Corridor C | 24.8 ± 6.0 | 20 | 35 | 108.4 ± 28.7 | 60 | 130 |

| Unhook | 38.3± 11.1 | 10 | 60 | |||

| Corridor A | 38.2 ± 11.1 | 10 | 60 | |||

| Corridor B | 38.1 ± 11.3 | 10 | 60 | |||

| Corridor C | 38.9 ± 11.1 | 10 | 60 | |||

| Delay | 120.0± 131.1 | 0 | 550 | |||

| Corridor A | 109.7 ± 131.1 | 0 | 525 | |||

| Corridor B | 102.9 ± 127.8 | 0 | 525 | |||

| Corridor C | 142.7 ± 136.8 | 0 | 550 | |||

| Total cycle time | 331.3± 120.9 | 151 | 715 | |||

| Corridor A | 345.4 ± 127.8 | 154 | 690 | |||

| Corridor B | 331.6 ± 114.1 | 151 | 695 | |||

| Corridor C | 317.4 ± 135.3 | 154 | 715 | |||

| Delay-free cycle time | 211.3 ± 77.5 | 135 | 430 | |||

| Corridor A | 235.7 ± 88.7 | 145 | 430 | |||

| Corridor B | 228.7 ± 85.4 | 140 | 421 | |||

| Corridor C | 317.4 ± 135.4 | 140 | 330 | |||

| Mean Value ± St. Dev. | Min | Max | |

|---|---|---|---|

| Payload per cycle (site), m3 | 1.1 ± 0.38 | 0.4 | 1.8 |

| Corridor A | 1.04 ± 0.38 | 0.5 | 1.8 |

| Corridor B | 1.05 ± 0.38 | 0.5 | 1.8 |

| Corridor C | 1.10 ± 0.30 | 0.4 | 1.6 |

| Productivity (site), m3 SMH−1 | 12.8 ± 6.40 | 4.47 | 29.45 |

| Corridor A | 11.86 ± 6.11 | 4.47 | 29.45 |

| Corridor B | 12.45 ± 6.60 | 5.42 | 29.45 |

| Corridor C | 14.04 ± 6.40 | 4.97 | 24.51 |

| Productivity (site), m3 PMH−1 | 20.1 ± 9.9 | 5.42 | 43.2 |

| Corridor A | 17.8 ± 9.4 | 6.35 | 43.20 |

| Corridor B | 18.49 ± 9.9 | 5.42 | 43.20 |

| Corridor C | 23.73 ± 9.5 | 7.83 | 41.10 |

| Number of work cycles per SMH (site) | 10.86 | 5.03 | 23.84 |

| Corridor A | 10.42 | 5.22 | 23.38 |

| Corridor B | 10.84 | 7.18 | 23.84 |

| Corridor C | 11.34 | 5.03 | 23.38 |

| Equations | F | R2adjusted | Std. Error | p-Value |

|---|---|---|---|---|

| Tnet = −0.575 L + 5.193 l + 17.017 i + 23.972 dt | 18.30 | 0.54 | 52.63 | p < 0.05 |

| Tnet_A = 6.9005 l | 50.17 | 0.87 | 34.46 | p < 0.05 |

| Tnet_B = 15.2073 l | 15.92 | 0.67 | 48.82 | p < 0.05 |

| Tnet_C = 2.6206 l | 2.85 | 0.20 | 32.93 | p < 0.05 |

| Equations | F | R2adjusted | Std. Error |

|---|---|---|---|

| PPMH = 34.61 − 0.34 l + 17.46 Q − 1.58 i, (m3 h−1) | 42.14 | 0.73 | 5.09 |

| PPMH_A = 14.20 + 0.08 l + 3.48 Q, (m3 h−1) | 37.83 | 0.84 | 3.81 |

| PPMH_B = −0.71 l + 12.42 Q, (m3 h−1) | 12.69 | 0.62 | 4.08 |

| PPMH_C = 18.83 − 1.13 l + 9.02 Q, (m3 h−1) | 10.78 | 0.57 | 4.20 |

| PSMH = 12.87 Q, (m3 h−1) | 15.69 | 0.50 | 4.53 |

| PSMH_A = 13.827 Q, (m3 h−1) | 9.60 | 0.54 | 4.13 |

| PSMH_B = −0.717 l + 12.428 Q, (m3 h−1) | 12.69 | 0.62 | 4.08 |

| PSMH_C = 18.832 − 1.138 l + 9.027 Q, (m3 h−1) | 10.78 | 0.57 | 4.20 |

| Costs Category | Costs per PMH | Costs per m3 | % of Total | Costs per m3 | ||

|---|---|---|---|---|---|---|

| Site A Code 1A | Site B Code 1B | Site C Code 1C | ||||

| Fixed costs | 40.38 | 1.91 | 33.46 | 2.27 | 2.18 | 1.70 |

| Variable costs | 29.05 | 1.40 | 24.45 | 1.63 | 1.57 | 1.22 |

| Labor costs | 37.87 | 1.80 | 31.38 | 2.13 | 2.05 | 1.60 |

| Net costs (excluding profit) | 107.30 | 5.11 | 89.29 | 6.03 | 5.80 | 4.52 |

| Gross costs (including 12% profit) | 120.17 | 5.72 | 100 | 6.75 | 6.50 | 5.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoilov, S.; Proto, A.R.; Angelov, G.; Papandrea, S.F.; Borz, S.A. Evaluation of Salvage Logging Productivity and Costs in the Sensitive Forests of Bulgaria. Forests 2021, 12, 309. https://0-doi-org.brum.beds.ac.uk/10.3390/f12030309

Stoilov S, Proto AR, Angelov G, Papandrea SF, Borz SA. Evaluation of Salvage Logging Productivity and Costs in the Sensitive Forests of Bulgaria. Forests. 2021; 12(3):309. https://0-doi-org.brum.beds.ac.uk/10.3390/f12030309

Chicago/Turabian StyleStoilov, Stanimir, Andrea R. Proto, Georgi Angelov, Salvatore F. Papandrea, and Stelian Alexandru Borz. 2021. "Evaluation of Salvage Logging Productivity and Costs in the Sensitive Forests of Bulgaria" Forests 12, no. 3: 309. https://0-doi-org.brum.beds.ac.uk/10.3390/f12030309