Light Extraction Enhancement Techniques for Inorganic Scintillators

Abstract

:1. Introduction

2. Light Extraction Techniques: State-of-the-Art

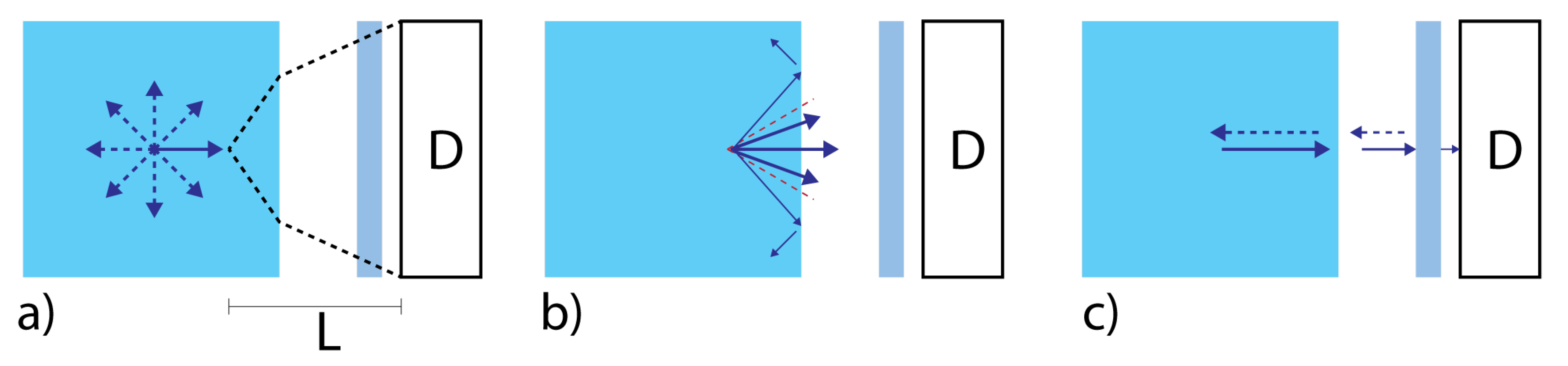

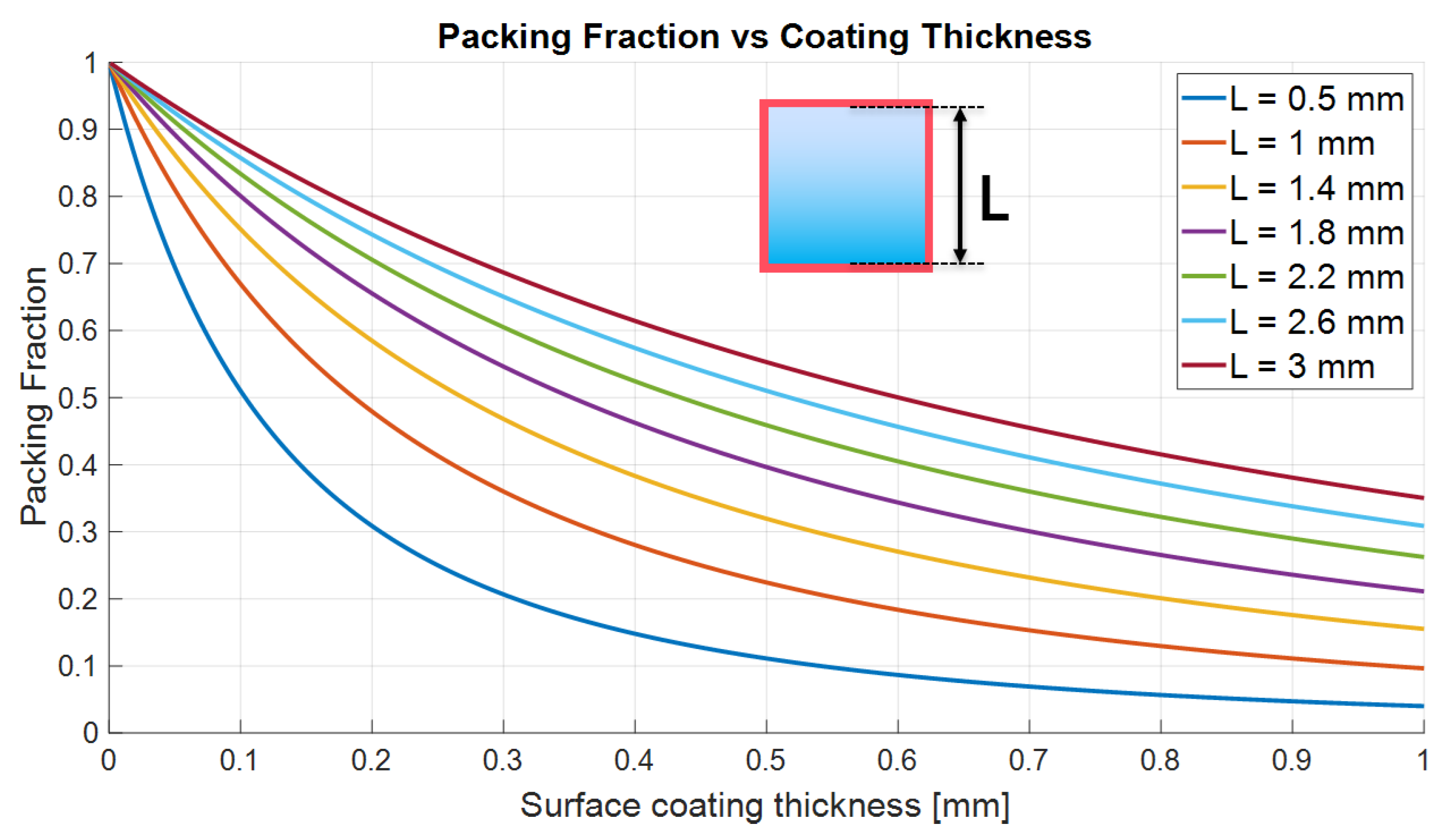

2.1. Conventional Light Extraction Enhancement Techniques

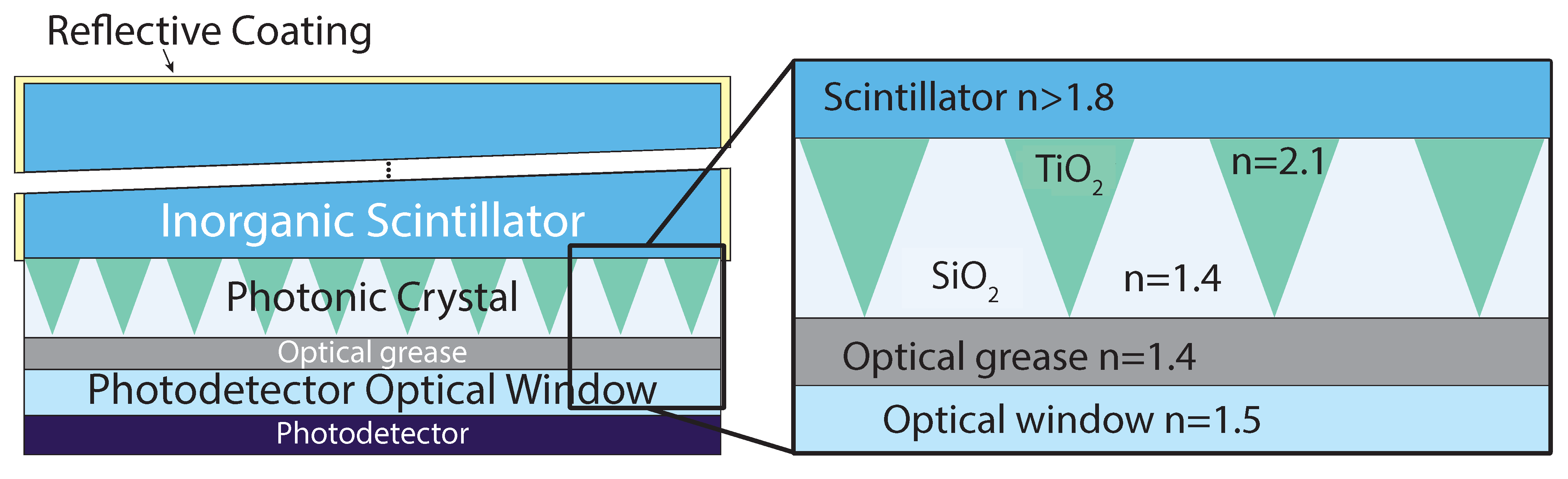

2.2. Novel Light Extraction Enhancement Techniques

3. Materials and Methods

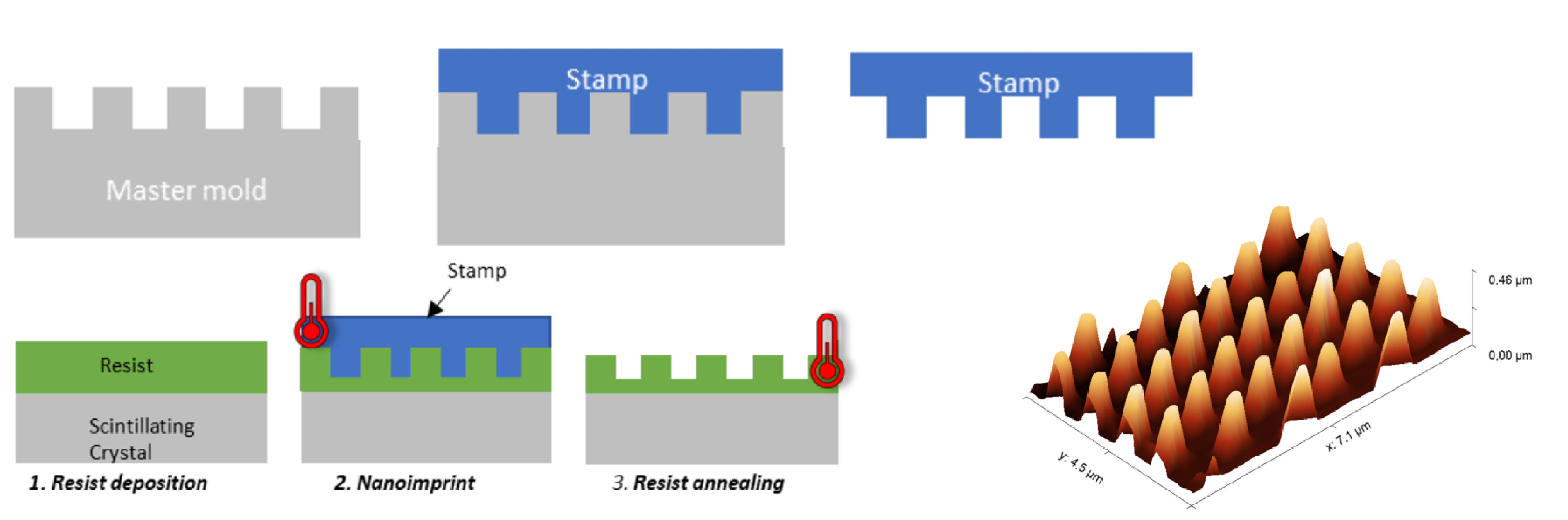

3.1. Coating Fabrication

3.2. Experimental Setup

3.3. Data Analysis

4. Results

5. Discussion

6. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gundacker, F.A.S. Understanding and simulating SiPMs. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2019, 16–35. [Google Scholar] [CrossRef]

- Gundacker, S.; Heering, A. The silicon photomultiplier: Fundamentals and applications of a modern solid-state photon detector. Phys. Med. Biol. 2020, 65, 17TR01. [Google Scholar] [CrossRef]

- Mao, R.; Zhang, L.; Zhu, R. Optical and Scintillation Properties of Inorganic Scintillators in High Energy Physics. IEEE Trans. Nucl. Sci. 2008, 55, 2425–2431. [Google Scholar] [CrossRef] [Green Version]

- Mao, R.; Zhang, L.; Zhu, R. Crystals for the HHCAL Detector Concept. IEEE Trans. Nucl. Sci. 2012, 59, 2229–2236. [Google Scholar] [CrossRef] [Green Version]

- Wieczorek, H.; Thon, A.; Dey, T.; Khanin, V.; Rodnyi, P. Analytical model of coincidence resolving time in TOF-PET. Phys. Med. Biol. 2016, 61, 4699–4710. [Google Scholar] [CrossRef] [PubMed]

- Vinogradov, S. Approximations of coincidence time resolution models of scintillator detectors with leading edge discriminator. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2018, 149–153. [Google Scholar] [CrossRef]

- Lerondel, G.; Le Cunff, L.; Montiel, R.S.; Lecoq, P.; Turover, D.; Grosso, D. Method for Optimizing the Collection of Photons in Scintillator Crystals, and Related Crystal and Uses. Patent Application Number: WIPO (PCT) WO2015136165A1, 17 September 2015. [Google Scholar]

- Brunner, S.E.; Schaart, D.R. BGO as a hybrid scintillator/Cherenkov radiator for cost-effective time-of-flight PET. Phys. Med. Biol. 2017, 62, 4421–4439. [Google Scholar] [CrossRef]

- Janecek, M. Reflectivity Spectra for Commonly Used Reflectors. IEEE Trans. Nucl. Sci. 2012, 59, 490–497. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, S.; Haefner, J.; Martín-Albo, J.; Guenette, R.; Li, X.; Villalpando, A.L.; Burch, C.; Adams, C.; Álvarez, V.; Arazi, L.; et al. Dependence of polytetrafluoroethylene reflectance on thickness at visible and ultraviolet wavelengths in air. J. Instrum. 2020, 15, P11031. [Google Scholar] [CrossRef]

- ter Weele, D.N.; Schaart, D.R.; Dorenbos, P. Picosecond Time Resolved Studies of Photon Transport Inside Scintillators. IEEE Trans. Nucl. Sci. 2015, 62, 1961–1971. [Google Scholar] [CrossRef]

- Yang, F.; Hu, C.; Zhang, L.; Zhu, R.Y. UV–Visible reflectance of common light reflectors and their degradation after an ionization dose up to 100 Mrad. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2021, 992, 165043. [Google Scholar] [CrossRef]

- Kuntner, C.; Stout, D. Quantitative preclinical PET imaging: Opportunities and challenges. Front. Phys. 2013, 2. [Google Scholar] [CrossRef] [Green Version]

- 3M. Enhanced Specular Reflector (ESR). 2019. Available online: http://multimedia.3m.com/mws/media/374730O/vikuiti-tm-esr-sales-literature.pdf?fn=ESR%20ss2.pdf (accessed on 17 October 2019).

- Loignon-Houle, F.; Pepin, C.M.; Charlebois, S.A.; Lecomte, R. Reflectivity quenching of ESR multilayer polymer film reflector in optically bonded scintillator arrays. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2017, 62–67. [Google Scholar] [CrossRef]

- Knapitsch, A.R. Photonic Crystals: Enhancing the Light Output of Scintillation Based Detectors. Ph.D. Thesis, Vienna University Technology, Atominst, Vienna, Austria, 2012. [Google Scholar]

- Knapitsch, A.; Lecoq, P. Review on photonic crystal coatings for scintillators. Int. J. Mod. Phys. A 2014, 29, 1430070. [Google Scholar] [CrossRef]

- Salomoni, M.; Pots, R.; Auffray, E.; Lecoq, P. Enhancing Light Extraction of Inorganic Scintillators Using Photonic Crystals. Crystals 2018, 8, 78. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Zhu, Z.; Liu, B.; Cheng, C.; Chen, H.; Gu, M.; Liu, J.; Chen, L.; Ouyang, X. Effect of a conformal layer on the photonic crystal for light extraction of scintillator. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2020, 162953. [Google Scholar] [CrossRef]

- Liu, F.; Yang, Y.; Liu, Y.; Tang, W.; Zhu, J.; Wang, P.; Ouyang, X.; Zhao, N.; Qi, F.; Wang, H.; et al. Large energy resolution improvement of LYSO scintillator by electron beam lithography method. AIP Adv. 2020. [Google Scholar] [CrossRef]

- Pots, R.; Salomoni, M.; Gundacker, S.; Zanettini, S.; Gâté, V.; Usureau, E.; Turover, D.; Lecoq, P.; Auffray, E. Improving light output and coincidence time resolution of scintillating crystals using nanoimprinted photonic crystal slabs. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2019, 940. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, B.; Zhang, H.; Ren, W.; Cheng, C.; Wu, S.; Gu, M.; Chen, H. Improvement of light extraction of LYSO scintillator by using a combination of self-assembly of nanospheres and atomic layer deposition. Opt. Express 2015, 23, 7085–7093. [Google Scholar] [CrossRef]

- Singh, B.; Marshall, M.S.J.; Waterman, S.; Pina-Hernandez, C.; Koshelev, A.; Munechika, K.; Knapitsch, A.; Salomoni, M.; Pots, R.; Lecoq, P.; et al. Enhanced Scintillation Light Extraction Using Nanoimprinted Photonic Crystals. IEEE Trans. Nucl. Sci. 2018, 65, 1059–1065. [Google Scholar] [CrossRef]

- Xiao, O.; Liu, B.; Xiang, X.; Chen, L.; Xu, M.; Song, X.; Li, Y. Enhanced light output of CsI(Na) scintillators by photonic crystals. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2020, 164007. [Google Scholar] [CrossRef]

- Xiao, O.; Liu, B.; Xiang, X.; Zhu, Z.; Chen, L.; Song, X.; Yuan, D.; Chen, C. Enhancement of the energy resolution of CsI(Na) scintillators by photonic crystals prepared with dry-transfer technique. Opt. Express 2020, 28, 33077–33083. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, F.; Tang, W.; Yang, Y.; Zhu, J.; Zhao, N.; Qi, F.; Xiao, O. Light extraction enhancement of BGO scintillator by monolayers of SiO2 periodic array. AIP Adv. 2019. [Google Scholar] [CrossRef] [Green Version]

- Gramuglia, F.; Lee, M.; Venialgo, E.; Bruschini, C.; Charbon, E. Towards 10 ps SPTR and Ultra-Low DCR in SiPMs Through the Combination of Microlenses and Photonic Crystals. In Proceedings of the 2017 IEEE Nuclear Science Symposium and Medical Imaging Conference (NSS/MIC), Atlanta, GA, USA, 21–28 October 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Sun, Q.; Peng, Q.; Wu, Z.; Huang, Q.; Xu, J. Ultra-thin high-reflector film designed for LYSO scintillators. In Proceedings of the 2016 IEEE Nuclear Science Symposium, Medical Imaging Conference and Room-Temperature Semiconductor Detector Workshop (NSS/MIC/RTSD), Strasbourg, France, 29 October–6 November 2016; pp. 1–2. [Google Scholar] [CrossRef]

- Sun, Q.; Peng, Q.; Wu, Z.; Xie, S.; Huang, Q.; Xu, J. Design of ultra-thin anti-reflection films directly coated on LYSO scintillators. In Proceedings of the 2017 IEEE Nuclear Science Symposium and Medical Imaging Conference (NSS/MIC), Atlanta, GA, USA, 21–28 October 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Gramuglia, F.; Descharmes, N.; Venialgo, E.; Herzig, H.P.; Charbon, E.; Bruschini, C. Light Extraction Enhancement in Scintillation Crystals Using Thin Film Coatings. In Proceedings of the 2018 IEEE Nuclear Science Symposium and Medical Imaging Conference Proceedings (NSS/MIC), Sydney, Australia, 10–17 November 2018; pp. 1–2. [Google Scholar] [CrossRef]

- Aliofkhazraei, M. Advances in Nanostructured Composites: Volume 1: Carbon Nanotube and Graphene Composites; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Fink, Y.; Winn, J.N.; Fan, S.; Chen, C.; Michel, J.; Joannopoulos, J.D.; Thomas, E.L. A Dielectric Omnidirectional Reflector. Science 1998, 282, 1679–1682. [Google Scholar] [CrossRef] [Green Version]

- Kadiri, H.; Kostcheev, S.; Turover, D.; Salas-Montiel, R.; Nomenyo, K.; Gokarna, A.; Lerondel, G. Topology assisted self-organization of colloidal nanoparticles: Application to 2D large-scale nanomastering. Beilstein J. Nanotechnol. 2014, 5, 1203–1209. [Google Scholar] [CrossRef]

- Zanchetta, E.; Auzelyte, V.; Brugger, J.; Savegnago, A.; Della Giustina, G.; Brusatin, G. Highly inorganic titania based solgel as directly patternable resist for micro- and nano- structured surfaces. Microelectron. Eng. 2012, 98, 176–179. [Google Scholar] [CrossRef]

- Ganesan, R.; Dumond, J.; Saifullah, M.S.M.; Lim, S.H.; Hussain, H.; Low, H.Y. Direct Patterning of TiO2 Using Step-and-Flash Imprint Lithography. ACS Nano 2012, 6, 1494–1502. [Google Scholar] [CrossRef]

- Ma, P.; Xu, Z.; Wang, M.; Lu, L.; Yin, M.; Chen, X.; Li, D.; Ren, W. Fast fabrication of TiO2 hard stamps for nanoimprint lithography. Mater. Res. Bull. 2017, 90, 253–259. [Google Scholar] [CrossRef]

- Yoon, K.; Yang, K.Y.; Lee, H. Fabrication of polycrystalline TiO2 nanopatterns by TiO2 sol base imprint lithography. Thin Solid Film. 2009, 518, 126–129. [Google Scholar] [CrossRef]

- Yoon, K.M.; Yang, K.Y.; Lee, H.; Kim, H.S. Formation of TiO2 nanopattern using reverse imprinting and sol-gel method. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2009, 27, 2810–2813. [Google Scholar] [CrossRef]

- Zanettini, S.; Gâté, V.; Usureau, E.; Ruscica, J.; Hamouda, F.; Nomenyo, K.; Le Cunff, L.; Kadiri, H.; Lerondel, G.; Salomoni, M.; et al. Improved Light Extraction Efficiency on 2 inches LYSO with Nanopatterned TiO2 Photonic Crystals. IEEE Strasbg. 2016. [Google Scholar]

- Valais, I.; Michail, C.; David, S.; Nomicos, C.; Panayiotakis, G.; Kandarakis, I. A comparative study of the luminescence properties of LYSO:Ce, LSO:Ce, GSO:Ce and BGO single crystal scintillators for use in medical X-ray imaging. Phys. Medica 2008, 24, 122–125. [Google Scholar] [CrossRef] [PubMed]

- Bienstman, P. Rigorous and Efficient Modelling of Wavelenght Scale Photonic Components. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2001. [Google Scholar]

- Yang, G.; Huang, H.; Wang, H. High-reflectance of hybrid reflector with distributed Bragg reflector and metal mirror for flip-chip ultra-violet light-emitting diodes. In Proceedings of the SPIE 9295, International Symposium on Optoelectronic Technology and Application 2014: Laser Materials Processing; and Micro/Nano Technologies, Beijing, China, 18 December 2014; Jin, G., Zhuang, S., Liu, J., Eds.; International Society for Optics and Photonics: Bellingham, WA, USA, 2014; Volume 9295, pp. 54–59. [Google Scholar] [CrossRef]

- Lecoq, P.; Auffray, E.; Knapitsch, A. How Photonic Crystals Can Improve the Timing Resolution of Scintillators. IEEE Trans. Nucl. Sci. 2013, 60, 1653–1657. [Google Scholar] [CrossRef] [Green Version]

- Iltis, A.; Zanettini, S.; de Magalhaes, L.; Tata, C.; Soledade, A.; Hmissi, M.; Khadiri, H.; Gaté, V.; Turover, D. Impact on timing and light extraction of a photonic crystal as measured on a half patterned LYSO crystal: Implications for time of flight PET imaging. J. Instrum. 2019, 14, P06036. [Google Scholar] [CrossRef]

- Castro, C.S.; Cunff, L.L.; Vial, A.; Lerondel, G. Light management in scintillator crystals: A multi-scale computational study. In UV and Higher Energy Photonics: From Materials to Applications 2018; Lérondel, G., Kawata, S., Cho, Y.H., Eds.; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10727. [Google Scholar] [CrossRef]

| Comparison of Experimental Results | |||||

|---|---|---|---|---|---|

| ID | Crystal | Configuration | Light Gain | Energy Resolution (%) | Energy Resolution Improvement |

| 1 | BGO | Bare crystal & Opt. Grease | 0.55 | 20.8 ± 0.48 | 0.74 |

| 2 | BGO | Bare crystal & Opt. Grease & DBR (top) | 0.64 | 19.3 ± 0.26 | 0.80 |

| 3 | BGO | ESR & Opt. Grease | 0.98 | 15.6 ± 0.29 | 0.99 |

| 4 | BGO | Teflon & Opt. Grease | 1.00 | 15.4 ± 0.19 | 1.00 |

| 5 | BGO | PhC Pattern & Opt. Grease | 0.80 | 17.2 ± 0.58 | 0.90 |

| 6 | BGO | PhC Pattern, Teflon & Opt. Grease | 1.41 | 12.7 ± 0.36 | 1.21 |

| 7 | BGO | PhC Pattern & Opt. Grease & DBR (top) | 0.88 | 16.4 ± 0.57 | 0.94 |

| 1 | LYSO | Bare crystal & Opt. Grease | 0.74 | 12.2 ± 0.32 | 0.85 |

| 2 | LYSO | Bare crystal & Opt. Grease & DBR (top) | 0.79 | 11.8 ± 0.36 | 0.88 |

| 3 | LYSO | ESR & Opt. Grease | 1.00 | 10.4 ± 0.12 | 1.00 |

| 4 | LYSO | Teflon & Opt. Grease | 1.00 | 10.4 ± 0.15 | 1.00 |

| 5 | LYSO | PhC Pattern & Opt. Grease | 0.85 | 11.4 ± 0.33 | 0.91 |

| 6 | LYSO | PhC Pattern, Teflon & Opt. Grease | 1.10 | 10.0 ± 0.24 | 1.04 |

| 7 | LYSO | PhC Pattern & Opt. Grease & DBR (top) | 0.86 | 11.3 ± 0.34 | 0.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gramuglia, F.; Frasca, S.; Ripiccini, E.; Venialgo, E.; Gâté, V.; Kadiri, H.; Descharmes, N.; Turover, D.; Charbon, E.; Bruschini, C. Light Extraction Enhancement Techniques for Inorganic Scintillators. Crystals 2021, 11, 362. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11040362

Gramuglia F, Frasca S, Ripiccini E, Venialgo E, Gâté V, Kadiri H, Descharmes N, Turover D, Charbon E, Bruschini C. Light Extraction Enhancement Techniques for Inorganic Scintillators. Crystals. 2021; 11(4):362. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11040362

Chicago/Turabian StyleGramuglia, Francesco, Simone Frasca, Emanuele Ripiccini, Esteban Venialgo, Valentin Gâté, Hind Kadiri, Nicolas Descharmes, Daniel Turover, Edoardo Charbon, and Claudio Bruschini. 2021. "Light Extraction Enhancement Techniques for Inorganic Scintillators" Crystals 11, no. 4: 362. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11040362