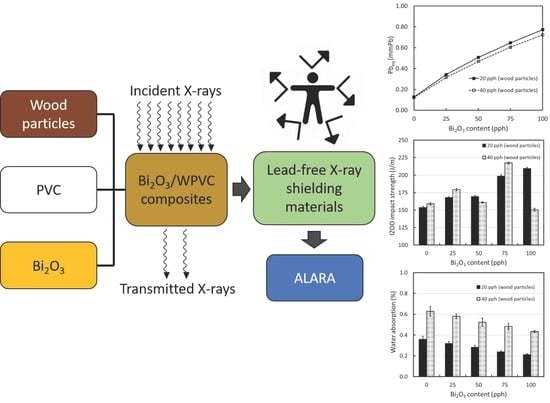

X-ray Shielding, Mechanical, Physical, and Water Absorption Properties of Wood/PVC Composites Containing Bismuth Oxide

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Chemicals

2.2. Preparation of WPVC Composites

2.3. Characterization

2.3.1. X-ray Shielding Measurement

2.3.2. Mechanical Properties

2.3.3. Morphology and Density Measurement

2.3.4. Water Absorption Measurement

3. Results and Discussion

3.1. Mechanical Properties

3.2. Water Absorption

3.3. X-ray Shielding Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, R.; Lewis, J.H.; Jia, X.; Gu, X.; Folkerts, M.; Men, C.; Song, W.Y.; Jiang, S.B. 3D tumor localization through real-time volumetric x-ray imaging for lung cancer radiotherapy. Med. Phys. 2011, 38, 2783–2794. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; He, C.; Guo, N.; Chan, C.; Ni, K.; Lan, G.; Tang, H.; Pelizzari, C.; Fu, Y.X.; Spiotto, M.T.; et al. Low-dose X-ray radiotherapy–radiodynamic therapy via nanoscale metal-organic frameworks enhances checkpoint blockade immunotherapy. Nat. Biomed. Eng. 2018, 2, 600–610. [Google Scholar] [CrossRef]

- Rowe, H.; Hughes, N.; Robinson, K. The quantification and application of handheld energy-dispersive x-ray fluorescence (ED-XRF) in mudrock chemostratigraphy and geochemistry. Chem. Geol. 2012, 324–325, 122–131. [Google Scholar] [CrossRef]

- Lalhmangaihzuala, S.; Laldinpuii, Z.; Lalmuanpuia, C.; Vanlaldinpuia, K. Glycolysis of poly(ethylene terephthalate) using biomass-waste derived recyclable heterogeneous catalyst. Polymers 2021, 13, 37. [Google Scholar] [CrossRef]

- Baron, R.I.; Biliuta, G.; Socoliuc, V.; Coseri, S. Affordable magnetic hydrogels prepared from biocompatible and biodegradable sources. Polymers 2021, 13, 1693. [Google Scholar] [CrossRef]

- Forster, B.P.; Till, B.J.; Ghanim, A.M.A.; Huynh, H.O.A.; Burstmayr, H.; Caligari, P.D.S. Accelerated plant breeding. CAB Rev. 2014, 9, 43. [Google Scholar] [CrossRef] [Green Version]

- Thomas, G.A.; Symonds, P. Radiation exposure and health effects—Is it time to reassess the real consequences? Clin. Oncol. 2016, 28, 231–236. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, L.; Tashiro, S. Estimation of the effects of medical diagnostic radiation exposure based on DNA damage. J. Radiat. Res. 2018, 59 (Suppl. 2), ii121–ii129. [Google Scholar] [CrossRef]

- Bevelacqua, J.J. Practical and effective ALARA. Health Phys. 2010, 98, S39–S47. [Google Scholar] [CrossRef]

- Omolola, M.A.; Bidemil, A.; Ademola, J.A.; Olutayo, A.S. Entrance surface dose from pediatric diagnostic X-ray examinations in a developing world setting: Are we ‘ALARA principle’ compliant? J. Adv. Med. Med. Res. 2013, 3, 2288–2298. [Google Scholar]

- Tiamduangtawan, P.; Kamkaew, C.; Kuntonwatchara, S.; Wimolmala, E.; Saenboonruang, K. Comparative mechanical, self-healing, and gamma attenuation properties of PVA hydrogels containing either nano- or micro-sized Bi2O3 for use as gamma-shielding materials. Radiat. Phys. Chem. 2020, 177, 109164. [Google Scholar] [CrossRef]

- Thumwong, A.; Wimolmala, E.; Markpin, T.; Sombatsompop, N.; Saenboonruang, K. Enhanced X-ray shielding properties of NRL gloves with nano-Bi2O3 and their mechanical properties under aging conditions. Radiat. Phys. Chem. 2021, 186, 109530. [Google Scholar] [CrossRef]

- Ninyong, K.; Wimolmala, E.; Sombatsompop, N.; Saenboonruang, K. Properties of natural rubber (NR) and wood/NR composites as gamma shielding materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 526, 012038. [Google Scholar] [CrossRef]

- Reis, L.S.L.S.; Pardo, P.E.; Camargos, A.S.; Oba, E. Mineral element and heavy metal poisoning in animals. J. Med. Med. Sci. 2010, 1, 560–579. [Google Scholar]

- Liu, G.; Yu, Y.; Hou, J.; Xue, W.; Liu, X.; Liu, Y.; Wang, W.; Alsaedi, A.; Hayat, T.; Liu, Z. An ecological risk assessment of heavy metal pollution of the agricultural ecosystem near a lead-acid battery factory. Ecol. Indic. 2014, 47, 210–218. [Google Scholar] [CrossRef]

- Warniment, C.; Tsang, K.; Galazka, S. Lead poisoning in children. Am. Fam. Physician 2010, 81, 751–757. [Google Scholar] [PubMed]

- Singh, A.K.; Singh, R.K.; Sharma, B.; Tyagi, A.K. Characterization and biocompatibility studies of lead free X-ray shielding polymer composite for healthcare application. Radiat. Phys. Chem. 2017, 138, 9–15. [Google Scholar] [CrossRef]

- Chai, H.; Tang, X.; Ni, M.; Chen, F.; Zhang, Y.; Chen, D.; Qiu, Y. Preparation and properties of novel, flexible, lead-free X-ray-shielding materials containing tungsten and bismuth(III) oxide. J. Appl. Polym. Sci. 2016, 133, 43012. [Google Scholar] [CrossRef]

- Poltabtim, W.; Wimolmala, E.; Saenboonruang, K. Properties of lead-free gamma-ray shielding materials from metal oxide/EPDM rubber composites. Radiat. Phys. Chem. 2018, 153, 1–9. [Google Scholar] [CrossRef]

- Poltabtim, W.; Toyen, D.; Saenboonruang, K. Theoretical determination of high-energy photon attenuation and recommended protective filler contents for flexible and enhanced dimensionally stable wood/NR and NR composites. Polymers 2021, 13, 869. [Google Scholar] [CrossRef]

- Sheela, M.; Kamat, V.A.; Kiran, K.; Eshwarappa, K.M. Preparation and characterization of bismuth-filled high-density polyethylene composites for gamma-ray shielding. Radiat. Prot. Environ. 2019, 42, 180–186. [Google Scholar]

- Toyen, D.; Saenboonruang, K. Comparative X-ray shielding properties of bismuth oxide/natural rubber composites using a Monte Carlo code of PHITS. IOP Conf. Ser. Mater. Sci. Eng. 2020, 773, 012024. [Google Scholar] [CrossRef]

- Toyen, D.; Rittirong, A.; Poltabtim, W.; Saenboonruang, K. Flexible, lead-free, gamma-shielding materials based on natural rubber/metal oxide composites. Iran. Polym. J. 2018, 27, 33–41. [Google Scholar] [CrossRef]

- Gwaily, S.E.; Madani, M.; Hassan, H.H. Lead-Natural rubber composites as gamma radiation shields. II: High concentration. Polym. Compos. 2012, 23, 495–499. [Google Scholar] [CrossRef]

- Mohan, R. Green bismuth. Nature 2010, 2, 336. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Lie, S.; Yang, H.; Li, Z.; Sayyed, M.I.; Agar, O. Using iron concentrate in Liaoning Province, China, to prepare material for X-Ray shielding. J. Clean. Prod. 2019, 210, 653–659. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Yang, Z.; Li, M.; Hou, Y.; Zhang, Z. Gamma ray shielding property, shielding mechanism and predicting model of continuous basalt fiber reinforced polymer matrix composite containing functional filler. Mater. Des. 2017, 124, 121–130. [Google Scholar] [CrossRef]

- Guermazi, N.; Hadder, N.; Elleuch, K.; Ayedi, H.F. Effect of filler addition and weathering conditions on the performance of PVC/CaCO3 composites. Polym. Compos. 2016, 37, 2171–2183. [Google Scholar] [CrossRef]

- Kajaks, J.; Kalnins, K.; Naburgs, R. Wood plastic composites (WPC) based on high-density polyethylene and birch wood plywood production residues. Int. Wood Prod. J. 2018, 9, 15–21. [Google Scholar] [CrossRef]

- Pulngern, T.; Chitsamran, T.; Chucheepsakul, S.; Rosarpitak, V.; Patcharaphun, S.; Sombatsompop, N. Effect of temperature on mechanical properties and creep responses for wood/PVC composites. Constr. Build. Mater. 2016, 111, 191–198. [Google Scholar] [CrossRef]

- Srimalanon, P.; Yamsaengsung, W.; Kositchaiyong, A.; Wimolmala, E.; Isarangkura, K.; Sombatsompop, N. Effects of UV-accelerated weathering and natural weathering conditions on anti-fungal efficacy of wood/PVC composites doped with propylene glycol-based HPQM. Express Polym. Lett. 2016, 10, 289–301. [Google Scholar] [CrossRef]

- Chen, J.; Teng, Z.; Zhao, Y.; Liu, W. Electromagnetic interference shielding properties of wood-plastic composites filled with graphene decorated carbon fiber. Polym. Compos. 2018, 39, 2110–2116. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, X.; Wen, B. Asymmetric Ni/PVC films for high-performance electromagnetic interference shielding. Chin. J. Polym. Sci. 2015, 33, 899–907. [Google Scholar] [CrossRef]

- Yotkaew, P.; Kositchaiyong, A.; Wimolmala, E.; Rosarpitak, V.; Sombatsompop, N. Use of synthetic fibers as co-reinforcing agents in wood/PVC hybrid composites: Effect on tribological properties. J. Reinf. Plast. Compos. 2014, 33, 964–976. [Google Scholar] [CrossRef]

- Juntunen, R.P.; Kumar, V.; Weller, J.E.; Bezubic, W.P. Impact strength of high density microcellular poly(vinyl chloride) foams. J. Vinyl Addit. Technol. 2000, 6, 93–99. [Google Scholar] [CrossRef]

- The Characteristics, Properties and Uses of Plantation Timbers—Rubberwood and Acacia mangium. Available online: https://www.researchgate.net/publication/237672441_The_characteristics_properties_and_uses_of_plantation_timbers_-_rubberwood_and_Acacia_mangium (accessed on 2 June 2021).

- Chan-Hom, T.; Yamsaengsung, W.; Prapagdee, B.; Markpin, T.; Sombatsompop, N. Flame retardancy, antifungal efficacies, and physical–mechanical properties for wood/polymer composites containing zinc borate. Fire Mater. 2017, 41, 675–687. [Google Scholar] [CrossRef]

- Terraflex: Hoses and Compound. Available online: https://www.terraflexhoses.com/terra_product/plasticized-compound/ (accessed on 28 June 2021).

- Lulianelli, G.; Tavares, M.B.; Luetkmeyer, L. Water absorption behavior and impact strength of PVC/wood flour composites. Chem. Chem. Technol. 2010, 4, 225–229. [Google Scholar] [CrossRef]

- Zheng, Y.; Zheng, Y.; Ning, R. Effects of nanoparticles SiO2 on the performance of nanocomposites. Mater. Lett. 2003, 57, 2940–2944. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, X.; Fan, X.; Zhu, C.; Yao, X.; Liu, Z. Mechanical and thermal properties of epoxy resin nanocomposites reinforced with graphene oxide. Polym. Plast. Technol. Eng. 2012, 51, 251–256. [Google Scholar] [CrossRef]

- Jeamtrakull, S.; Kositchaiyong, A.; Markpin, T.; Rosarpitak, V.; Sombatsompop, N. Effects of wood constituents and content, and glass fiber reinforcement on wear behavior of wood/PVC composites. Compos. B Eng. 2012, 43, 2721–2729. [Google Scholar] [CrossRef]

- Lu, H.; Hao, Q.; Chen, D.; Chao, M.; Yao, W.; Zhu, Y. A high-performance Bi2O3/Bi2SiO5 p-n heterojunction photocatalyst induced by phase transition of Bi2O3. Appl. Catal. B 2018, 237, 59–67. [Google Scholar] [CrossRef]

- Nurhazwani, O.; Jawaid, M.; Paridah, M.T.; Juliana, A.H.; Hamid, S.A. Hybrid Particleboard Made from Bamboo (Dendrocalamus asper) Veneer Waste and Rubberwood (Hevea brasilienses). Bioresources 2016, 11, 306–323. [Google Scholar] [CrossRef] [Green Version]

- Berger, M.J.; Hubbell, J.H.; Seltzer, S.M.; Chang, J.; Coursey, J.S.; Sukumar, R.; Zucker, D.S.; Olsen, K. XCOM: Photon Cross Section Database; version 1.5; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2010. Available online: http://physics.nist.gov/xcom (accessed on 3 June 2021).

- Hashemi, S.A.; Mousavi, S.M.; Faghihi, R.; Arjmand, M.; Rahsepar, M.; Bahrani, S.; Ramakrishna, S.; Lai, C.W. Superior X-ray radiation shielding effectiveness of biocompatible polyaniline reinforced with hybrid graphene oxide-iron tungsten nitride flakes. Polymers 2020, 12, 1407. [Google Scholar] [CrossRef]

- Saenboonruang, K.; Poltabtim, W.; Thumwong, A.; Pianpanit, T.; Rattanapongs, C. Rare-earth oxides as alternative high-energy photon protective fillers in HDPE composites: Theoretical aspects. Polymers 2021, 13, 1930. [Google Scholar] [CrossRef] [PubMed]

- X-Roc Board, Product Data Sheet. Available online: https://saint-gobain.gr/sites/default/files/xroc_en_0.pdf (accessed on 3 June 2021).

- GIB X-BLOCK Product Data Sheet. Available online: https://www.usgboral.com/content/dam/USGBoral/Australia/Website/Documents/English/brochures-catalogues/XBlockRadiationSheildingSystemsApril091.pdf (accessed on 3 June 2021).

- Knauf Safe Board. Available online: http://www.knauf.com.hk/uploadedFile/20217833961468477067.pdf (accessed on 3 June 2021).

- Si-Mohamed, S.; Cormode, D.P.; Bar-Ness, D.; Sigovan, M.; Naha, P.C.; Langlois, J.B.; Chalabreysse, L.; Coulon, P.; Blevis, I.; Roessl, E.; et al. Evaluation of spectral photon counting computed tomography K-edge imaging for determination of gold nanoparticle biodistribution in vivo. Nanoscale 2017, 46, 18246–18257. [Google Scholar] [CrossRef]

- Jayakumar, S.; Saravanan, T.; Philip, J. Thermal stability and X-ray attenuation studies on α-Bi2O3, β-Bi2O3 and Bi based nanocomposites for radiopaque fabrics. J. Nanosci. Nanotechnol. 2018, 18, 3969–3981. [Google Scholar] [CrossRef] [PubMed]

- Jayakumar, J.; Saravanan, T.; Philip, J. Polymer nanocomposites containing β-Bi2O3 and silica nanoparticles: Thermal stability, surface topography and X-ray attenuation properties. J. Appl. Polym. Sci. 2020, 137, 49048. [Google Scholar] [CrossRef]

- Muthamma, M.V.; Bubbly, S.G.; Gudennavar, S.B. Attenuation properties of epoxy-Ta2O5 and epoxy-Ta2O5- Bi2O3 composites at γ-ray energies 59.54 and 662 keV. J. Appl. Polym. Sci. 2020, 137, 49366. [Google Scholar] [CrossRef]

| Chemicals | Content (pph) | Function | Supplier |

|---|---|---|---|

| Suspension PVC grade SIAMVIC-258RB | 100 | Matrix | Vinythai Public Co., Ltd. (Rayong, Thailand) |

| Emulsion PVC grade SIAMVIC-167GZ | 4.0 | PVC additive | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| PF 608A, Pb-Ba based organic | 3.6 | Thermal stabilizer | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| PF 601 | 1.5 | Thermal stabilizer | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| Finalux G-741 | 0.6 | External lubricant | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| Calcium stearate | 0.6 | Internal lubricant | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| Calcium carbonate, Omyacarb-2T | 12.0 | Filler | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| Modified Chlorinated Polyethylene (CPE) | 7.7 | Impact modifier | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| PA-20 | 6.0 | Processing aid | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| Para rubber wood particles | 20 and 40 | Filler | V.P. Wood Co., Ltd. (Samut Prakan, Thailand) |

| N-2-(Aminoethyl)-3-aminopropyltrimethoxysilane (KBM603) | 1 wt.% of wood | Silane coupling agent | Shin-Etsu Chemical Co., Ltd., (Tokyo, Japan) |

| Bismuth oxide; Bi2O3 | 0, 25, 50, 75, and 100 | X-ray protective agent | Shanghai Ruizheng Chemical Technology Co., Ltd. (Shanghai, China) |

| Bi2O3 Content (pph) | Density (g/cm3) | |

|---|---|---|

| 20 pph Wood | 40 pph Wood | |

| 0 | 1.46 ± 0.01 | 1.43 ± 0.02 |

| 25 | 1.63 ± 0.02 | 1.60 ± 0.02 |

| 50 | 1.79 ± 0.03 | 1.78 ± 0.01 |

| 75 | 1.97 ± 0.01 | 1.90 ± 0.03 |

| 100 | 2.09 ± 0.04 | 2.04 ± 0.01 |

| Wood Content (pph) | Bi2O3 Content (pph) | µ (cm−1) | µm (cm2/g) | ||||

|---|---|---|---|---|---|---|---|

| 60 kV | 100 kV | 150 kV | 60 kV | 100 kV | 150 kV | ||

| 0 | 0 | 1.02 | 0.36 | 0.25 | 0.73 | 0.26 | 0.18 |

| 20 | 0 | 0.84 ± 0.01 | 0.35 ± 0.01 | 0.29 ± 0.01 | 0.57 ± 0.01 | 0.24 ± 0.01 | 0.20 ± 0.01 |

| 25 | 2.48 ± 0.01 | 0.94 ± 0.01 | 0.95 ± 0.01 | 1.53 ± 0.01 | 0.58 ± 0.01 | 0.58 ± 0.01 | |

| 50 | 3.74 ± 0.01 | 1.39 ± 0.01 | 1.51 ± 0.01 | 2.08 ± 0.01 | 0.77 ± 0.01 | 0.84 ± 0.01 | |

| 75 | 4.48 ± 0.04 | 1.75 ± 0.03 | 2.03 ± 0.01 | 2.27 ± 0.02 | 0.89 ± 0.02 | 1.03 ± 0.01 | |

| 100 | 5.04 ± 0.07 | 2.11 ± 0.01 | 2.51 ± 0.01 | 2.41 ± 0.03 | 1.01 ± 0.01 | 1.20 ± 0.01 | |

| 40 | 0 | 0.76 ± 0.01 | 0.34 ± 0.01 | 0.27 ± 0.01 | 0.53 ± 0.01 | 0.23 ± 0.01 | 0.19 ± 0.01 |

| 25 | 2.23 ± 0.01 | 0.85 ± 0.01 | 0.85 ± 0.01 | 1.40 ± 0.01 | 0.53 ± 0.01 | 0.53 ± 0.01 | |

| 50 | 3.32 ± 0.01 | 1.28 ± 0.01 | 1.34 ± 0.01 | 1.86± 0.01 | 0.72 ± 0.01 | 0.75 ± 0.01 | |

| 75 | 4.23 ± 0.06 | 1.61 ± 0.02 | 1.86 ± 0.01 | 2.23 ± 0.01 | 0.85 ± 0.01 | 0.98 ± 0.01 | |

| 100 | 4.63 ± 0.04 | 1.86 ± 0.02 | 2.29 ± 0.01 | 2.27 ± 0.02 | 0.91 ± 0.01 | 1.13 ± 0.01 | |

| Pb sheet | 63.06 ± 0.05 | 25.99 ± 0.13 | 29.59 ± 0.03 | 5.56 ± 0.01 | 2.25 ± 0.01 | 2.61 ± 0.01 | |

| X-ray Tube Voltage (kV) | Recommended Bi2O3 Content (pph) | |

|---|---|---|

| 20 pph Wood | 40 pph Wood | |

| 60 | 35 | 40 |

| 100 | 85 | 100 |

| 150 | 40 | 45 |

| Matrix | Bi2O3 Content | X-ray Energy | µm (cm2/g) | Reference |

|---|---|---|---|---|

| WPVC | 100 pph (35 wt.%) | 100 kV (~40–60 keV) | 0.91–1.01 | This work |

| Natural rubber latex (NRL) | 100 phr (50 wt.%) | 80 kV (~30–50 keV) | 1.32 | [12] |

| Silicone rubber (SR) | 50 wt.% | 55 keV | 1.01–1.20 | [52] |

| SR | 50 wt.% | 59 keV | 0.08–0.22 | [53] |

| SR | 50 wt.% | 66 keV | 0.00–0.44 | [53] |

| Epoxy | 35 wt.% | 59.54 keV | 1.343 | [54] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poltabtim, W.; Wimolmala, E.; Markpin, T.; Sombatsompop, N.; Rosarpitak, V.; Saenboonruang, K. X-ray Shielding, Mechanical, Physical, and Water Absorption Properties of Wood/PVC Composites Containing Bismuth Oxide. Polymers 2021, 13, 2212. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13132212

Poltabtim W, Wimolmala E, Markpin T, Sombatsompop N, Rosarpitak V, Saenboonruang K. X-ray Shielding, Mechanical, Physical, and Water Absorption Properties of Wood/PVC Composites Containing Bismuth Oxide. Polymers. 2021; 13(13):2212. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13132212

Chicago/Turabian StylePoltabtim, Worawat, Ekachai Wimolmala, Teerasak Markpin, Narongrit Sombatsompop, Vichai Rosarpitak, and Kiadtisak Saenboonruang. 2021. "X-ray Shielding, Mechanical, Physical, and Water Absorption Properties of Wood/PVC Composites Containing Bismuth Oxide" Polymers 13, no. 13: 2212. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13132212