Polymer-Based Additive Manufacturing: Process Optimisation for Low-Cost Industrial Robotics Manufacture

Abstract

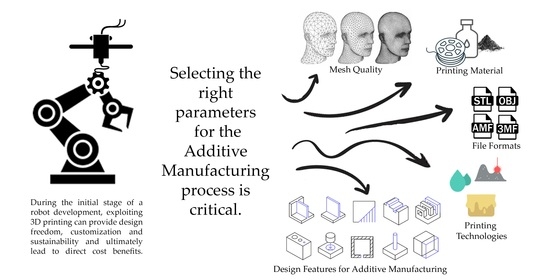

:1. Introduction

2. Materials and Methods

2.1. From Digital Model/CAD to a 3D Printable Mesh

2.1.1. Standard Tessellation/Triangulation Language (STL)

2.1.2. OBJ

2.1.3. AMF

2.1.4. 3MF

2.2. From Mesh to Print

2.3. 3D Printing Parameters

2.3.1. Layer Height

2.3.2. Infill

2.3.3. Shell Thickness

2.3.4. Supports

2.3.5. Printing Orientation

2.4. Various Polymer-Based AM Processes

2.4.1. Vat Polymerisation

2.4.2. Material Extrusion

2.4.3. Material Jetting (MJ)

2.4.4. Powder Bed Fusion

2.5. Design Considerations for Various AM Processes

2.5.1. Print Orientation

2.5.2. Feature Specific Considerations

- Supported Walls: The walls that are connected to the rest of the print on at least two sides.

- Unsupported Walls: These are connected to the rest of the print on one side.

- Support and Overhangs: The maximum inclination a structure can be printed without support.

- Embossed and Engraved Details: Features on the model that are raised or recessed.

- Horizontal Bridge: The printable horizontal span without support.

- Holes: Minimum diameter of a printable hole.

- Connecting/moving Parts: Recommended clearance between two moving or connecting parts.

- Escape Holes: The minimum diameter for escape holes to allow for removal of build material.

- Pin Diameter: Minimum diameter a pin can be 3D printed at.

- Tolerance: Expected dimensional accuracy.

- Minimum Feature: The recommended minimum size of any feature to ensure it will not fail to print.

2.5.3. Avoiding Supports

2.6. Material Libraries

2.6.1. Vat Polymerisation

2.6.2. Material Extrusion

- PLA: Polylactic Acid; a preferred material due to ease of use and low cost;

- ABS: Acrylonitrile Butadiene Styrene; low-cost material for tough and durable parts;

- Flexible: TPU or TPE (Thermoplastic polyurethane and Thermoplastic elastomer respectively); known for elasticity;

- PETG: Polyethylene terephthalate glycol; ease of printability, smooth surface finish, and water resistance;

- Nylon: tough and semi-flexible material that offers high impact and abrasion resistance;

- PC: Polycarbonate; known for its strength, durability and a very high heat and impact resistance;

- PP: Polypropylene; high-cycle, low strength applications due to its fatigue resistance, semi-flexible, and lightweight characteristics;

- Composites: Metal filled, glow in the dark, magnetic, conductive, colour changing, biodegradable, clay, wax, etc. There are some composite materials available with carbon fibre and glass fibre micro-particles infused.

- PVA: Polyvinyl alcohol; dissolves in water and is often used as a support material for complex prints;

- HIPS: High Impact Polystyrene; dissolves in d-Limonene, most used as a dissolvable support structure for ABS models.

2.6.3. Material Jetting

2.6.4. Powder Bed Fusion

3. Results

4. Discussion

4.1. Significance of AM Integration with Robotics

In the past few years, advanced industrial companies have made solid progress in improving productivity along the manufacturing value chain. In the U.S., for instance, the productivity of industrial workers has increased by 47% over the past 20 years. However, the traditional levers that have driven these gains, such as lean operations, Six Sigma, and total quality management, are starting to run out of steam, and the incremental benefits they deliver are declining. As a result, leading companies are now looking to disruptive technologies for their next horizon of performance improvement.

4.2. Adoption in Research and Industry

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dalle Mura, M.; Dini, G. Designing assembly lines with humans and collaborative robots: A genetic approach. CIRP Ann. Manuf. Technol. 2019, 68, 1–4. [Google Scholar] [CrossRef]

- Bogue, R. Europe continues to lead the way in the collaborative robot business. Ind. Robot Int. J. 2016, 43, 6–11. [Google Scholar] [CrossRef]

- Bloss, R. Collaborative robots are rapidly providing improvements in productivity, safety, programming ease, portability and cost while addressing many new applications. Ind. Robot Int. J. 2016, 43, 463–468. [Google Scholar] [CrossRef]

- How Much Do Industrial Robots Cost? Available online: https://www.robots.com/faq/how-much-do-industrial-robots-cost (accessed on 27 July 2021).

- Wallin, P.J. Robotics in the food industry: An update. Trends Food Sci. Technol. 1997, 8, 193–198. [Google Scholar] [CrossRef]

- Iqbal, J.; Khan, Z.H.; Khalid, A. Prospects of robotics in food industry. Food Sci. Technol. 2017, 37, 159–165. [Google Scholar] [CrossRef] [Green Version]

- Mueller, M.; Kuhlenkoetter, B.; Nassmacher, R. Robots in Food Industry Challenges and Chances. In Proceedings of the ISR/Robotik 2014, 41st International Symposium on Robotics, Munich, Germany, 2–3 June 2014; pp. 1–7. [Google Scholar]

- Moreno Masey, R.J.; Gray, J.O.; Dodd, T.J.; Caldwell, D.G. Guidelines for the design of low-cost robots for the food industry. Ind. Robot 2010, 37, 509–517. [Google Scholar] [CrossRef]

- Nayik, G.A.; Muzaffar, K.; Gull, A. Robotics and food technology: A mini review. J. Nutr. Food Sci. 2015, 5, 1–11. [Google Scholar]

- Campbell, T.; Williams, C.; Ivanova, O.; Garrett, B. Could 3D Printing Change the World? Technologies, Potential, and Implications of Additive Manufacturing; Atlantic Council: Washington, DC, USA, 2011. [Google Scholar]

- Gealy, D.V.; McKinley, S.; Yi, B.; Wu, P.; Downey, P.R.; Balke, G.; Zhao, A.; Guo, M.; Thomasson, R.; Sinclair, A.; et al. Quasi-direct drive for low-cost compliant robotic manipulation. In Proceedings of the International Conference on Robotics and Automation-IEEE, Montreal, QC, Canada, 20–24 May 2019; pp. 437–443. [Google Scholar]

- ISO/ASTM 52900:2015. Available online: https://www.iso.org/standard/69669.html (accessed on 27 July 2021).

- Won, J.; Laurentis, K.J.D.; Mavroidis, C. Rapid prototyping of robotic systems. In Proceedings of the International Conference on Robotics and Automation-IEEE, San Francisco, CA, USA, 24–28 April 2000; pp. 3077–3082. [Google Scholar]

- Mavroidis, C.; DeLaurentis, K.; Won, J.; Alam, M. Fabrication of non-assembly mechanisms and robotic systems using rapid prototyping. ASME J. Mech. Des. 2001, 123, 516–524. [Google Scholar] [CrossRef]

- Syed, A.M.T.; Elias, P.K.; Amit, B.; Susmita, B.; Lisa, O.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2017, 1, 1–16. [Google Scholar]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Fischer, A.; Rommel, S.; Verl, A. 3D printed objects and components enabling next generation of true soft robotics. In Soft Robotics; Verl, A., Albu-Schäffer, A., Brock, O., Raatz, A., Eds.; Springer: Berlin, Germany, 2015; pp. 198–208. [Google Scholar]

- Rupal, B.S.; Qureshi, A.J. Geometric Deviation Modeling and Tolerancing in Additive Manufacturing: A GD&T Perspective. In Proceedings of the 1st Conference of NSERC Network for Holistic Innovation in Additive Manufacturing, Waterloo, ON, Canada, 22–23 May 2018; pp. 1–6. [Google Scholar]

- Islam, M.N.; Boswell, B.; Pramanik, A. An investigation of dimensional accuracy of parts produced by three-dimensional printing. In Proceedings of the World Congress on Engineering, IAENG, London, UK, 3–5 July 2013; Volume I, pp. 522–525. [Google Scholar]

- Kechagias, J.P.A.I.; Stavropoulos, P.; Koutsomichalis, A.; Ntintakis, I.; Vaxevanidis, N. Dimensional accuracy optimization of prototypes produced by PolyJet direct 3D printing technology. In Proceedings of the International Conference on Industrial Engineering, Santorini Island, Greece, 17–21 July 2014; pp. 61–65. [Google Scholar]

- Huang, Q.; Zhang, J.; Sabbaghi, A.; Dasgupta, T. Optimal offline compensation of shape shrinkage for three-dimensional printing processes. IIE. Trans. 2015, 47, 431–441. [Google Scholar] [CrossRef]

- Ha, S.; Ransikarbum, K.; Han, H.; Kwon, D.; Kim, H.; Kim, N. A dimensional compensation algorithm for vertical bending deformation of 3D printed parts in selective laser sintering. Rapid Prototyp. J. 2018, 23, 955–963. [Google Scholar] [CrossRef]

- Hernandez, D.D. Factors affecting dimensional precision of consumer 3D printing. Int. J. Aviat. Aeronaut. Aerosp. 2015, 2, 2. [Google Scholar] [CrossRef] [Green Version]

- Mahesh, M.; Wong, Y.S.; Fuh, J.Y.H.; Loh, H.T. Benchmarking for comparative evaluation of RP systems and processes. Rapid Prototyp. J. 2004, 10, 123–135. [Google Scholar] [CrossRef]

- Moylan, S.; Slotwinski, J.; Cooke, A.; Jurrens, K.; Donmez, M.A. Proposal for a standardized test artifact for additive manufacturing machines and processes. In Proceedings of the Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 6–8. [Google Scholar]

- Yang, L.; Anam, M.A. An investigation of standard test part design for additive manufacturing. In Proceeding of the Solid Free Form Fabrication Symposiums, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- Iancu, C. About 3D printing file formats. Annals of the Constantin Brancusi University of Targu Jiu-Letters & Social Sciences Series. 1 April 2018, pp. 25–29. Available online: https://www.utgjiu.ro/rev_ing/pdf/2018-2/23_C.IANCU%20-%20ABOUT%203D%20PRINTING%20FILE%20FORMATS.pdf (accessed on 30 May 2021).

- Iancu, C.; Iancu, D.; Stăncioiu, A. From CAD model to 3D print via “stl” file format. Fiability Durab. Fiabil. Si. Durabilitate 2010, 1, 73–80. [Google Scholar]

- STL File Format (3D Printing)—Simply Explained. Available online: https://all3dp.com/what-is-stl-file-format-extension-3d-printing/ (accessed on 11 May 2021).

- Grenda, E. The Most Important Commercial Rapid Prototyping Technologies at a Glance. Castle Isl 2008. Available online: http://home.att.net/~castleisland/rp_int1.htm (accessed on 30 May 2021).

- McHenry, K.; Bajcsy, P. An overview of 3d data content, file formats and viewers. Natl. Cent. Supercomput. Appl. 2008, 1205, 22. [Google Scholar]

- Klein, S.; Avery, M.; Adams, G.; Pollard, S.; Simske, S. From scan to print: 3D printing as a means for replication. In Proceeding of the NIP & Digital Fabrication Conference, Society for Imaging Science and Technology, Philadelphia, PA, USA, 7–11 September 2014; pp. 417–421. [Google Scholar]

- Hiller, J.D.; Lipson, H. August. STL 2.0: A proposal for a universal multi-material additive manufacturing file format. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 3–4 August 2009; Volume 3, pp. 266–278. [Google Scholar]

- Tanaka, H. New File Format for 3D Printing, its extensions and applications. In Proceedings of the NIP and Digital Fabrication Conference, Society for Imaging Science and Technology, Portland, OR, USA, 1 January 2015; Volume 2015, pp. 3–6. [Google Scholar]

- Hällgren, S.; Pejryd, L.; Ekengren, J. 3D data export for additive manufacturing-improving geometric accuracy. Procedia. Cirp. 2016, 50, 518–523. [Google Scholar] [CrossRef] [Green Version]

- Vaissier, B.; Pernot, J.P.; Chougrani, L.; Véron, P. Lightweight Mesh File Format Using Repetition Pattern Encoding for Additive Manufacturing. Comput. Aided Des. 2020, 129, 102914. [Google Scholar] [CrossRef]

- 3MF Consortium, 3D Manufacturing Format Core Specification & Reference Guide, v.1.2.3. Available online: https://github.com/3MFConsortium/spec_core/blob/master/3MF%20Core%20Specification.md (accessed on 11 May 2021).

- De Laurentis, K.J.; Kong, F.F.; Mavroidis, C. Procedure for Rapid Fabrication of Non-Assembly Mechanisms with Embedded Components. In Proceedings of the ASME, International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC-CIE 2002), Montreal, QC, Canada, 29 September–2 October 2002; Volume 5, pp. 1239–1245. [Google Scholar]

- Glukchov, V.I.; Varepo, L.G.; Nagornova, I.V.; Doronin, F.A. Strength and geometry parameters accuracy improvement of 3D-printed polymer gears. J. Phys. Conf. Ser. 2019, 1260, 032019. [Google Scholar] [CrossRef]

- Baumann, F.; Bugdayci, H.; Grunert, J.; Keller, F.; Roller, D. Influence of slicing tools on quality of 3D printed parts. Comput. Aided Des. Appl. 2016, 13, 14–31. [Google Scholar] [CrossRef]

- Hiller, J.; Lipson, H. Design and analysis of digital materials for physical 3D voxel printing. Rapid Prototyp. J. 2009, 15, 137–149. [Google Scholar] [CrossRef]

- Fernandez-Vicente, M.; Calle, W.; Ferrandiz, S.; Conejero, A. Effect of Infill Parameters on Tensile Mechanical Behavior in Desktop 3D Printing. 3D Print. Addit. Manuf. 2016, 3, 183–192. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Hu, J. Study on STL-based slicing process for 3D printing. In Proceedings of the 28th Annual International, Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017; pp. 7–9. [Google Scholar]

- Wang, W.; Chao, H.; Tong, J.; Yang, Z.; Tong, X.; Li, H.; Liu, X.; Liu, L. Saliency-preserving slicing optimization for effective 3d printing. Comput. Graph. Forum 2015, 34, 148–160. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, P.; Huang, L.; Wei, Q.; Liang, Y. An adaptive slicing thickness adjustment method based on cloud point in 3D printing. In Proceedings of the 2016 13th International Conference on Embedded Software and Systems (ICESS), IEEE, Chengdu, China, 13–14 August 2016; pp. 108–113. [Google Scholar]

- Liu, L.; Shamir, A.; Wang, C.C.; Whiting, E. 3D printing oriented design: Geometry and optimization. In Proceedings of the Siggraph Asia Courses, Shenzhen, China, 5 December 2014; p. 1. [Google Scholar]

- Chacón, J.; Caminero, M.; García-Plaza, E.; Núñez, P. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Luzanin, O.; Movrin, D.; Plancak, M. Effect of layer thickness, deposition angle, and infill on maximum flexural force in FDM-built specimens. J. Technol. Plast. 2014, 39, 49–57. [Google Scholar]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental optimization of fused deposition modelling processing parameters: A design-for-manufacturing approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Page, C.; Kreuzer, S.; Ansari, F.; Eason, D.; Hamed, E.; Watson, H. Optimizing 3D printed components: A methodological approach to assessing print parameters on tensile properties. In Proceedings of the Technical Conference and Exhibition, Anaheim, CA, USA, 8–10 May 2017; pp. 82–88. [Google Scholar]

- Sukindar, N.; Ariffin, M.; Baharudin, B.; Jaafar, C.; Ismail, M. Analysis on the impact process parameters on tensile strength using 3D printer repetier-host software. ARPN J. Eng. Appl. Sci. 2017, 12, 3341–3346. [Google Scholar]

- Tymrak, B.; Kreiger, M.; Pearce, L. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A. The influence of manufacturing parameters on the mechanical behaviour of PLA and ABS pieces manufactured by FDM: A comparative analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [Green Version]

- Moradi, M.; Meiabadi, S.; Kaplan, A. 3D printed parts with honeycomb internal pattern by Fused Deposition Modelling; experimental characterization and production optimization. Met. Mater. Int. 2019, 25, 1–14. [Google Scholar] [CrossRef]

- Alani, T.; Othman, F.; Ali, H. Effect of infill parameter on compression property in FDM process. Int. J. Eng. Res. Appl. 2017, 7, 16–19. [Google Scholar]

- Johnson, G.; French, J. Evaluation of infill effect on mechanical properties of consumer 3D printing materials. Adv. Technol. Innov. 2018, 3, 179. [Google Scholar]

- Ebel, E.; Sinnemann, T. Fabrication of FDM 3D objects with ABS and PLA and determination of their mechanical properties. RTejournal 2014, 1. Available online: https://www.rtejournal.de/ausgabe11/3872/view?set_language=en (accessed on 30 May 2021).

- Ouhsti, M.; El Haddadi, B.; Belhouideg, S. Effect of printing parameters on the mechanical properties of parts fabricated with open-source 3D printers in PLA by Fused Deposition Modeling. Mech. Mech. Eng. 2018, 22, 895–907. [Google Scholar] [CrossRef]

- Farbman, D.; McCoy, C. Materials testing of 3D printed ABS and PLA samples to guide mechanical design. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016; Volume 2, p. 15. [Google Scholar]

- Żur, P.; Baier, A.; Żur, A. Influence of 3D-printing parameters on mechanical properties of PLA defined in the static bending test. Eur. J. Eng. Sci. Technol. 2019, 2, 64–70. [Google Scholar] [CrossRef] [Green Version]

- Lubombo, C.; Huneault, M. Effect of infill patterns on the mechanical performance of lightweight 3D-printed cellular PLA parts. Mater. Today Commun. 2018, 17, 214–228. [Google Scholar] [CrossRef]

- Qattawi, A. Investigating the effect of fused deposition modeling processing parameters using Taguchi design of experiment method. J. Manuf. Process. 2018, 36, 164–174. [Google Scholar]

- Vanek, J.; Galicia, J.A.G.; Benes, B. Clever support: Efficient support structure generation for digital fabrication. Comput. Graph. Forum 2014, 33, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Mirzendehdel, A.M.; Suresh, K. Support structure constrained topology optimization for additive manufacturing. Comput. Aided Des. 2016, 81, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Redwood, B.; Schöffer, F.; Garret, B. The 3D Printing Handbook: Technologies, Design and Applications; 3D Hubs: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Additive Manufacturing Technologies. Available online: https://www.hubs.com/get/am-technologies/ (accessed on 12 May 2021).

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [Green Version]

- Powerful, Affordable 3D Printers for Professionals. Available online: https://formlabs.com/uk/3d-printers/ (accessed on 29 July 2021).

- Zhang, Z.C.; Li, P.L.; Chu, F.T.; Shen, G. Influence of the three-dimensional printing technique and printing layer thickness on model accuracy. J. Orofac. Orthop. 2019, 8, 194–204. [Google Scholar] [CrossRef]

- Layani, M.; Wang, X.; Magdassi, S. Novel materials for 3D printing by photopolymerization. Adv. Mater. 2018, 30, 1706344. [Google Scholar] [CrossRef]

- Balli, J.; Kumpaty, S.; Anewenter, V. Continuous liquid interface production of 3D objects: An unconventional technology and its challenges and opportunities. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 10 January 2018; Volume 58400, p. V005T06A038. [Google Scholar]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Rosen, D.W.; Stucker, B. Extrusion-based systems. In Additive Manufacturing Technologies; Springer: Boston, MA, USA, 2010; pp. 160–186. [Google Scholar]

- Chua, C.K.; Leong, K.F.; Lim, C.S. Rapid Prototyping: Principles and Applications (with Companion CD-R004FM); World Scientific Publishing Company: Singapore, 2010; p. 448. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Material jetting. In Additive Manufacturing Technologies; Springer: Boston, MA, USA, 2021; pp. 203–235. [Google Scholar]

- Yang, H.; Lim, J.C.; Liu, Y.; Qi, X.; Yap, Y.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Performance evaluation of projet multi-material jetting 3D printer. Virtual Phys. Prototyp. 2017, 12, 95–103. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M.J.L.A.M. Powder bed fusion processes: An overview. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing Series in Electronic and Optical Materials; Elseview: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for additive manufacturing: A systematic review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Rosen, D.W. Research supporting principles for design for additive manufacturing: This paper provides a comprehensive review on current design principles and strategies for AM. Virtual Phys. Prototyp. 2014, 9, 225–232. [Google Scholar] [CrossRef]

- Wiberg, A.; Persson, J.; Ölvander, J. Design for additive manufacturing–a review of available design methods and software. Rapid Prototyp. J. 2019, 25, 1080–1094. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Dai, J.; Li, K.S.; Wang, J.; Wei, M.; Pang, M. Cost-effective printing of 3D objects with self-supporting property. Vis. Comput. 2019, 35, 639–651. [Google Scholar] [CrossRef]

- Ezair, B.; Massarwi, F.; Elber, G. Orientation analysis of 3D objects toward minimal support volume in 3D-printing. Comput. Graph. 2015, 51, 117–124. [Google Scholar] [CrossRef]

- Wulle, F.; Coupek, D.; Schäffner, F.; Verl, A.; Oberhofer, F.; Maier, T. Workpiece and Machine Design in Additive Manufacturing for Multi-Axis Fused Deposition Modeling. Procedia CIRP 2017, 60, 229–234. [Google Scholar] [CrossRef]

- Dai, C.; Wang, C.C.L.; Wu, C.; Lefebvre, S.; Fang, G.; Liu, Y.J. Support-free volume printing by multi-axis motion. ACM Trans. Graph. 2018, 37, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Zhang, H.; Hu, Q.; Liu, D.; Lammer, H. Research and implementation of a non-supporting 3D printing method based on 5-axis dynamic slice algorithm. Robot. Comput. Integr. Manuf. 2019, 57, 496–505. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Z.; Gong, S.; Chen, Y. Reusable support for additive manufacturing. Addit. Manuf. 2021, 39, 101840. [Google Scholar]

- Karasik, E.; Fattal, R.; Werman, M. Object Partitioning for Support-Free 3D-Printing. Comput. Graph. Forum. 2019, 38, 305–316. [Google Scholar] [CrossRef]

- Hu, K.; Jin, S.; Wang, C.C.L. Support slimming for single material based additive manufacturing, CAD Comput. Aided. Des. 2015, 65, 1–10. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Steinmann, B.; Steinmann, A. Nanoparticle-Filled Stereolithographic Resins. U.S. Patent Application No. US2005/0040562, 24 February 2005. [Google Scholar]

- Wu, T.; Das, S. Theoretical modeling and experimental characterization of stress development in parts manufactured through large area maskless photopolymerization. In Proceedings of the Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 748–760. [Google Scholar]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of discontinuous and continuous fibre composites using stereolithography. Addit. Manuf. 2018, 24, 521–527. [Google Scholar] [CrossRef]

- Formlabs Materials Library. Available online: https://formlabs.com/uk/materials/ (accessed on 12 May 2021).

- Markforged Materials–Continuous Fiber. Available online: https://markforged.com/materials/continuous-fibers/ (accessed on 29 July 2021).

- Melenka, G.W.; Cheung, B.K.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- PolyJet Materials. Available online: https://www.stratasys.com/en/materials/ (accessed on 12 May 2021).

- Ainsley, C.; Reis, N.; Derby, B. Freeform fabrication by controlled droplet deposition of powder filled melts. J. Mater. Sci. 2002, 37, 3155–3161. [Google Scholar] [CrossRef]

- Goering, K.; Kelley, R.; Mellors, N. The Next Horizon for Industrial Manufacturing: Adopting Disruptive Digital Technologies in Making and Delivering. Available online: https://www.mckinsey.com/business-functions/mckinsey-digital/our-insights/the-next-horizon-for-industrial-manufacturing (accessed on 15 May 2021).

- Kim, S.; Moon, S.K. A Part Consolidation Design Method for Additive Manufacturing based on Product Disassembly Complexity. Appl. Sci. 2020, 10, 1100. [Google Scholar] [CrossRef] [Green Version]

- Siemasz, R.; Tomczuk, K.; Malecha, Z. 3D printed robotic arm with elements of artificial intelligence. Procedia. Comput. Sci. 2020, 176, 3741–3750. [Google Scholar] [CrossRef]

- BCN3D Moveo Repository. Available online: https://github.com/BCN3D/BCN3D-Moveo (accessed on 29 July 2021).

- Zortrax Robotic Arm. Available online: https://library.zortrax.com/project/zortrax-robotic-arm/ (accessed on 29 July 2021).

- Krimpenis, A.A.; Papapaschos, V.; Bontarenko, E. HydraX, A 3D printed robotic arm for hybrid manufacturing. Part I: Custom design, manufacturing, and assembly. Procedia. Manuf. 2020, 51, 103–108. [Google Scholar] [CrossRef]

- Haddington Dynamics: 7-Axis Robotic Arm. Available online: https://markforged.com/resources/application-spotlights/7-axis-robotic-arm (accessed on 16 May 2021).

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9, 1–9. [Google Scholar] [CrossRef]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.T.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. A 3D-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef] [Green Version]

- Umedachi, T.; Trimmer, B.A. Design of a 3D-printed soft robot with posture and steering control. In Proceedings of the IEEE International Conference on Robotics and Automation, Hong Kong, China, 31 May–7 June 2014; pp. 2874–2879. [Google Scholar]

- Le Ferrand, H. Robotics: Science preceding science fiction. MRS Bull. 2019, 44, 295–301. [Google Scholar] [CrossRef] [Green Version]

- IFR Presents World Robotics Report 2020. Available online: https://ifr.org/ifr-press-releases/news/record-2.7-million-robots-work-in-factories-around-the-globe (accessed on 16 May 2021).

| Parameter | Effect |

|---|---|

| Layer Height | Print Resolution Dimensional Accuracy along Build DirectionPrint Duration |

| Infill | Weight (Material Consumed) Mechanical Strength and Rigidity |

| Shell Thickness | Mechanical Toughness Surface Hardness |

| Supports | Printability Print Duration Material Consumed Surface Finish |

| Printing Orientation | Printability Required Supports |

| Feature | Vat Polymerisation | Material Extrusion | Material Jetting | Powder Bed Fusion |

|---|---|---|---|---|

| Supported Walls | 0.4 mm | 0.8 mm | 1 mm | 0.7 mm |

| Unsupported Walls | 0.4 mm | 0.8 mm | 1 mm | 0.8 mm |

| Supports & Overhangs | Support always required | 45° | Support always required | No support required |

| Embossed & Engraved | 0.4 mm wide | 0.6 mm wide | 0.5 mm wide | 0.5 mm wide |

| 0.4 mm high | 1 mm high | 0.5 mm high | 0.6 mm high | |

| Horizontal Bridge | 21 mm | 10 mm | 0 mm | Not applicable |

| Hole | 0.8 mm | 2 mm | 0.5 mm | 1.5 mm |

| Connecting/Moving Parts | moving: 0.4 mm | moving: 0.5 mm | moving: 0.2 mm | moving: 0.2 mm |

| connecting: 0.2 mm | connecting: 0.3 mm | connecting: 0.1 mm | connecting: 0.1 mm | |

| Escape Holes | 3.5 mm | Not applicable | Not applicable | 5 mm |

| Pin Diameter | 0.5 mm | 3 mm | 0.5 mm | 0.8 mm |

| Tolerance | ±0.5% (lower limit ± 0.15 mm) | ±0.5% (lower limit ± 0.5 mm) | ±0.1 mm | ±0.3% (lower limit ± 0.3 mm) |

| Minimum Feature | 0.2 mm | 2 mm | 0.5 mm | 0.8 mm |

| AM Processes | Cost | Performance | Suitability |

|---|---|---|---|

| Vat Polymerisation | **** | **** | **** |

| Material Extrusion | ** | ** | *** |

| Material Jetting | **** | ***** | ***** |

| Powder Bed Fusion | ***** | **** | *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walia, K.; Khan, A.; Breedon, P. Polymer-Based Additive Manufacturing: Process Optimisation for Low-Cost Industrial Robotics Manufacture. Polymers 2021, 13, 2809. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13162809

Walia K, Khan A, Breedon P. Polymer-Based Additive Manufacturing: Process Optimisation for Low-Cost Industrial Robotics Manufacture. Polymers. 2021; 13(16):2809. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13162809

Chicago/Turabian StyleWalia, Kartikeya, Ahmed Khan, and Philip Breedon. 2021. "Polymer-Based Additive Manufacturing: Process Optimisation for Low-Cost Industrial Robotics Manufacture" Polymers 13, no. 16: 2809. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13162809