Facile Fabrication of N-Type Flexible CoSb3-xTex Skutterudite/PEDOT:PSS Hybrid Thermoelectric Films

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

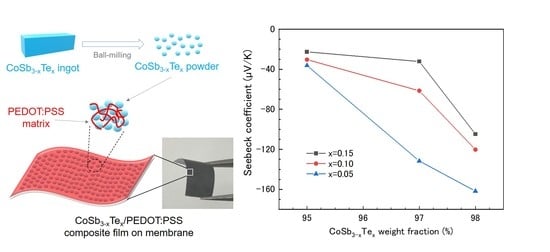

2.2. Preparation of CoSb3-xTex Skutterudite

2.3. Fabrication of the CoSb3-xTex Skutterudite/PEDOT:PSS Composite Films

2.4. Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gunnarsdottir, I.; Davidsdottir, B.; Worrell, E.; Sigurgeirsdottir, S. Sustainable energy development: History of the concept and emerging themes. Renew. Sustain. Energy Rev. 2021, 141, 110770. [Google Scholar] [CrossRef]

- Ikram, M. Models for Predicting Non-Renewable Energy Competing with Renewable Source for Sustainable Energy Development: Case of Asia and Oceania Region. Glob. J. Flex. Syst. Manag. 2021, 22, 133–160. [Google Scholar] [CrossRef]

- Siwal, S.S.; Zhang, Q.; Devi, N.; Saini, A.K.; Saini, V.; Pareek, B.; Gaidukovs, S.; Thakur, V.K. Recovery processes of sustainable energy using different biomass and wastes. Renew. Sustain. Energy Rev. 2021, 150, 111483. [Google Scholar] [CrossRef]

- He, J.; Tritt, T.M. Advances in thermoelectric materials research: Looking back and moving forward. Science 2017, 357, eaak9997. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bell, L.E. Cooling, Heating, Generating Power, and Recovering Waste Heat with Thermoelectric Systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Sato, N.; Gao, W.; Yubuta, K.; Kawamoto, N.; Mitome, M.; Kurashima, K.; Owada, Y.; Nagase, K.; Lee, C.; et al. Demonstration of ultrahigh thermoelectric efficiency of 7.3 % in Mg3Sb2/MgAgSb module for low-temperature energy harvesting. Joule 2021, 5, 1196–1208. [Google Scholar] [CrossRef]

- Shi, X.; Zou, J.; Chen, Z.-G. Advanced Thermoelectric Design: From Materials and Structures to Devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef]

- Mori, T. Novel Principles and Nanostructuring Methods for Enhanced Thermoelectrics. Small 2017, 13, 1702013. [Google Scholar] [CrossRef] [Green Version]

- Mao, J.; Liu, Z.; Zhou, J.; Zhu, H.; Zhang, Q.; Chen, G.; Ren, Z. Advances in thermoelectrics. Adv. Phys. 2018, 67, 69–147. [Google Scholar] [CrossRef]

- Zebarjadi, M.; Joshi, G.; Zhu, G.; Yu, B.; Minnich, A.; Lan, Y.; Wang, X.; Dresselhaus, M.; Ren, Z.; Chen, G. Power Factor Enhancement by Modulation Doping in Bulk Nanocomposites. Nano Lett. 2011, 11, 2225–2230. [Google Scholar] [CrossRef] [PubMed]

- Watson, B.W.; Meng, L.; Fetrow, C.; Qin, Y. Core/Shell Conjugated Polymer/Quantum Dot Composite Nanofibers through Orthogonal Non-Covalent Interactions. Polymers 2016, 8, 408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tamaki, H.; Sato, H.K.; Kanno, T. Isotropic Conduction Network and Defect Chemistry in Mg3+δSb2-Based Layered Zintl Compounds with High Thermoelectric Performance. Adv. Mater. 2016, 28, 10182–10187. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Deng, H.; Fu, Q. Recent progress on PEDOT:PSS based polymer blends and composites for flexible electronics and thermoelectric devices. Mater. Chem. Front. 2020, 4, 3130–3152. [Google Scholar] [CrossRef]

- Zianni, X. The annealed-nanograin phase: A route to simultaneous increase of the conductivity and the Seebeck coefficient and high thermoelectric performance. J. Appl. Phys. 2019, 126, 194301. [Google Scholar] [CrossRef]

- Bailey, T.; Lu, R.; Poudeu, P.; Uher, C. Mictomagnetic full-Heusler nanoprecipitates in (Ti, Zr, Hf)NiFexSn half-Heusler composites. Mater. Today Phys. 2019, 11, 100155. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, W.; Zhang, W.; Sato, N.; Guo, Q.; Mori, T. High Power Factor and Enhanced Thermoelectric Performance in Sc and Bi Codoped GeTe: Insights into the Hidden Role of Rhombohedral Distortion Degree. Adv. Energy Mater. 2020, 10, 2002588. [Google Scholar] [CrossRef]

- Khan, A.U.; Kobayashi, K.; Tang, D.; Yamauchi, Y.; Hasegawa, K.; Mitome, M.; Xue, Y.; Jiang, B.; Tsuchiya, K.; Golberg, D.; et al. Nano Energy Nano-micro-porous skutterudites with 100 % enhancement in ZT for high performance thermoelectricity. Nano Energy 2017, 31, 152–159. [Google Scholar] [CrossRef]

- Lee, S.; Esfarjani, K.; Luo, T.; Zhou, J.; Tian, Z.; Chen, G. Resonant bonding leads to low lattice thermal conductivity. Nat. Commun. 2014, 5, 3525. [Google Scholar] [CrossRef]

- Du, B.; Chen, K.; Yan, H.; Reece, M.J. Efficacy of lone-pair electrons to engender ultralow thermal conductivity. Scr. Mater. 2016, 111, 49–53. [Google Scholar] [CrossRef]

- Miyazaki, Y.; Hamada, H.; Nagai, H.; Hayashi, K. Crystal Structure and Thermoelectric Properties of Lightly Substituted Higher Manganese Silicides. Materials 2018, 11, 926. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roychowdhury, S.; Jana, M.K.; Pan, J.; Guin, S.N.; Sanyal, D.; Waghmare, U.V.; Biswas, K. Soft Phonon Modes Leading to Ultralow Thermal Conductivity and High Thermoelectric Performance in AgCuTe. Angew. Chem. 2018, 130, 4107–4111. [Google Scholar] [CrossRef]

- Zapata-Arteaga, O.; Perevedentsev, A.; Marina, S.; Martin, J.; Reparaz, J.S.; Campoy-Quiles, M. Reduction of the Lattice Thermal Conductivity of Polymer Semiconductors by Molecular Doping. ACS Energy Lett. 2020, 5, 2972–2978. [Google Scholar] [CrossRef] [PubMed]

- Long, S.O.; Powell, A.V.; Hull, S.; Orlandi, F.; Tang, C.C.; Supka, A.R.; Fornari, M.; Vaqueiro, P. Jahn–Teller Driven Electronic Instability in Thermoelectric Tetrahedrite. Adv. Funct. Mater. 2020, 30, 1909409. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, W.; Gao, W.; Mori, T. A material catalogue with glass-like thermal conductivity mediated by crystallographic occupancy for thermoelectric application. Energy Environ. Sci. 2021, 14, 3579–3587. [Google Scholar] [CrossRef]

- Zhu, Y.; Han, Z.; Jiang, F.; Dong, E.; Zhang, B.-P.; Zhang, W.; Liu, W. Thermodynamic criterions of the thermoelectric performance enhancement in Mg2Sn through the self-compensation vacancy. Mater. Today Phys. 2021, 16, 100327. [Google Scholar] [CrossRef]

- Li, G.; He, J.; An, Q.; Morozov, S.I.; Hao, S.; Zhai, P.; Zhang, Q.; Goddard, W.A., III; Snyder, G.J. Dramatically reduced lattice thermal conductivity of Mg2Si thermoelectric material from nanotwinning. Acta Mater. 2019, 169, 9–14. [Google Scholar] [CrossRef] [Green Version]

- Proto, A.; Penhaker, M.; Conforto, S.; Schmid, M. Nanogenerators for Human Body Energy Harvesting. Trends Biotechnol. 2017, 35, 610–624. [Google Scholar] [CrossRef]

- Haras, M.; Skotnicki, T. Thermoelectricity for IoT—A review. Nano Energy 2018, 54, 461–476. [Google Scholar] [CrossRef]

- Bharti, M.; Singh, A.; Samanta, S.; Aswal, D.K. Conductive polymers: Creating their niche in thermoelectric domain. Prog. Mater. Sci. 2017, 93, 270–310. [Google Scholar] [CrossRef]

- Yao, C.-J.; Zhang, H.-L.; Zhang, Q. Recent Progress in Thermoelectric Materials Based on Conjugated Polymers. Polymers 2019, 11, 107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Park, S.-J. Flexible Organic Thermoelectric Materials and Devices for Wearable Green Energy Harvesting. Polymers 2019, 11, 909. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Masoumi, S.; O’Shaughnessy, S.; Pakdel, A. Organic-based flexible thermoelectric generators: From materials to devices. Nano Energy 2022, 92, 106774. [Google Scholar] [CrossRef]

- Nandihalli, N.; Liu, C.-J.; Mori, T. Polymer based thermoelectric nanocomposite materials and devices: Fabrication and characteristics. Nano Energy 2020, 78, 105186. [Google Scholar] [CrossRef]

- Petsagkourakis, I.; Tybrandt, K.; Crispin, X.; Ohkubo, I.; Satoh, N.; Mori, T. Thermoelectric materials and applications for energy harvesting power generation. Sci. Technol. Adv. Mater. 2018, 19, 836–862. [Google Scholar] [CrossRef]

- Toshima, N.; Ichikawa, S. Conducting Polymers and Their Hybrids as Organic Thermoelectric Materials. J. Electron. Mater. 2015, 44, 384–390. [Google Scholar] [CrossRef]

- Gueye, M.N.; Carella, A.; Faure-Vincent, J.; Demadrille, R.; Simonato, J.-P. Progress in understanding structure and transport properties of PEDOT-based materials: A critical review. Prog. Mater. Sci. 2020, 108, 100616. [Google Scholar] [CrossRef]

- Du, Y.; Niu, H.; Li, J.; Dou, Y.; Shen, S.Z.; Jia, R.; Xu, J. Morphologies Tuning of Polypyrrole and Thermoelectric Properties of Polypyrrole Nanowire/Graphene Composites. Polymers 2018, 10, 1143. [Google Scholar] [CrossRef] [Green Version]

- Shi, K.; Zhang, F.; Di, C.; Yan, T.; Zou, Y.; Zhou, X.; Zhu, D.; Wang, J.; Pei, J. Toward High Performance n-Type Thermoelectric Materials by Rational Modi fi cation of BDPPV Backbones. J. Am. Chem. Soc. 2015, 137, 6979–6982. [Google Scholar] [CrossRef]

- Sun, Y.; Sheng, P.; Di, C.-A.; Jiao, F.; Xu, W.; Qiu, D.; Zhu, D. Organic Thermoelectric Materials and Devices Based on p- and n-Type Poly(metal 1,1,2,2-ethenetetrathiolate)s. Adv. Mater. 2012, 24, 932–937. [Google Scholar] [CrossRef]

- Bae, E.J.; Kang, Y.H.; Jang, K.-S.; Cho, S.Y. Enhancement of Thermoelectric Properties of PEDOT:PSS and Tellurium-PEDOT:PSS Hybrid Composites by Simple Chemical Treatment. Sci. Rep. 2016, 6, 18805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fan, Z.; Li, P.; Du, D.; Ouyang, J. Significantly Enhanced Thermoelectric Properties of PEDOT:PSS Films through Sequential Post-Treatments with Common Acids and Bases. Adv. Energy Mater. 2017, 7, 1602116. [Google Scholar] [CrossRef]

- Yemata, T.A.; Zheng, Y.; Kyaw, A.K.K.; Wang, X.; Song, J.; Chin, W.S.; Xu, J. Modulation of the doping level of PEDOT:PSS film by treatment with hydrazine to improve the Seebeck coefficient. RSC Adv. 2020, 10, 1786–1792. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, H.; Lee, S.H.; Kim, F.S.; Choi, H.H.; Cheong, I.W.; Kim, J.H. Enhanced thermoelectric properties of PEDOT:PSS nanofilms by a chemical dedoping process. J. Mater. Chem. A 2014, 2, 6532–6539. [Google Scholar] [CrossRef]

- Choi, J.; Jung, Y.; Yang, S.J.; Oh, J.Y.; Oh, J.; Jo, K.; Son, J.G.; Moon, S.E.; Park, C.R.; Kim, H. Flexible and Robust Thermoelectric Generators Based on All-Carbon Nanotube Yarn without Metal Electrodes. ACS Nano 2017, 11, 7608–7614. [Google Scholar] [CrossRef]

- Jiang, C.; Ding, Y.; Cai, K.; Tong, L.; Lu, Y.; Zhao, W.; Wei, P. Ultrahigh Performance of n-Type Ag2Se Films for Flexible Thermoelectric Power Generators. ACS Appl. Mater. Interfaces 2020, 12, 9646–9655. [Google Scholar] [CrossRef]

- Kong, D.; Zhu, W.; Guo, Z.; Deng, Y. High-performance flexible Bi2Te3 films based wearable thermoelectric generator for energy harvesting. Energy 2019, 175, 292–299. [Google Scholar] [CrossRef]

- Wang, Y.; Pang, H.; Guo, Q.; Tsujii, N.; Baba, T.; Baba, T.; Mori, T. Flexible n-Type Abundant Chalcopyrite/PEDOT:PSS/Graphene Hybrid Film for Thermoelectric Device Utilizing Low-Grade Heat. ACS Appl. Mater. Interfaces 2021, 13, 51245–51254. [Google Scholar] [CrossRef]

- Liu, Z.-Y.; Zhu, J.-L.; Tong, X.; Niu, S.; Zhao, W.-Y. A review of CoSb3-based skutterudite thermoelectric materials. J. Adv. Ceram. 2020, 9, 647–673. [Google Scholar] [CrossRef]

- Liu, W.-S.; Zhang, B.-P.; Li, J.-F.; Zhang, H.-L.; Zhao, L.-D. Enhanced thermoelectric properties in CoSb3-xTex alloys prepared by mechanical alloying and spark plasma sintering. J. Appl. Phys. 2007, 102, 103717. [Google Scholar] [CrossRef]

- Rodríguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Phys. B Condens. Matter 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Roisnel, T.; Rodríguez-Carvajal, J. WinPLOTR, a graphic tool for powder diffraction. Mater. Sci. Forum 2001, 378, 118–123. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; Liu, C.; Xiao, Z.; Zhong, W.; Luo, Y.; Ou, H.; Wiezorek, J. Cooperative effect of carbon black and dimethyl sulfoxide on PEDOT:PSS hole transport layer for inverted planar perovskite solar cells. Sol. Energy 2017, 157, 125–132. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.; Using, C.M.T.; Electrodes, C.P.; Yang, J. Effect of localized surface plasmon resonance from incorporated gold nanoparticles in PEDOT:PSS hole transport layer for hybrid solar cell applications. J. Phys. 2018, 1080, 012010. [Google Scholar] [CrossRef]

- Park, D.; Kim, M.; Kim, J. Fabrication of PEDOT:PSS/Ag2Se Nanowires for Polymer-Based Thermoelectric Applications. Polymers 2020, 12, 2932. [Google Scholar] [CrossRef] [PubMed]

- Alleno, E.; Bérardan, D.; Byl, C.; Candolfi, C.; Daou, R.; Decourt, R.; Guilmeau, E.; Hébert, S.; Hejtmanek, J.; Lenoir, B.; et al. A round robin test of the uncertainty on the measurement of the thermoelectric dimensionless figure of merit of Co0.97Ni0.03Sb3. Rev. Sci. Instrum. 2015, 86, 011301. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Geng, L.; Yuan, T.; Liu, Y.; Guo, J.; Fang, L.; Qiu, J.; Wang, S. Solution-printable fullerene/TiS2 organic/inorganic hybrids for high-performance flexible n-type thermoelectrics. Energy Environ. Sci. 2018, 11, 1307–1317. [Google Scholar] [CrossRef]

- Lu, Y.; Qiu, Y.; Cai, K.; Li, X.; Gao, M.; Jiang, C.; He, J. Ultrahigh performance PEDOT/Ag2Se/CuAgSe composite film for wearable thermoelectric power generators. Mater. Today Phys. 2020, 14, 100223. [Google Scholar] [CrossRef]

- We, J.H.; Kim, S.J.; Cho, B.J. Hybrid composite of screen-printed inorganic thermoelectric film and organic conducting polymer for flexible thermoelectric power generator. Energy 2014, 73, 506–512. [Google Scholar] [CrossRef]

- Li, Z.; Sun, H.; Hsiao, C.; Yao, Y.; Xiao, Y.; Shahi, M.; Jin, Y.; Cruce, A.; Liu, X.; Jiang, Y.; et al. A Free-Standing High-Output Power Density Thermoelectric Device Based on Structure-Ordered PEDOT:PSS. Adv. Electron. Mater. 2018, 4, 1–8. [Google Scholar] [CrossRef]

| TE Materials | Seebeck Coefficient (µV/K) | Conductivity (S/cm) | Power Factor (µW/m K2) | Reference |

|---|---|---|---|---|

| SWCNT/PEI | −56 | 7850 | 2456 | [45] |

| C60/TiS2 | −101 | 390 | 375 | [57] |

| PEDOT/Ag2Se /CuAgSe | −121.8 | 1200 | 1603 | [58] |

| PEDOT:PSS/Bi2Te3 | −137.8 | 73 | 138.6 | [59] |

| CoSb2.95Te0.05 /PEDOT:PSS | −161.7 | 2.47 | 6.46 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kato, A.; Bourgès, C.; Pang, H.; Gutiérrez, D.; Sakurai, T.; Mori, T. Facile Fabrication of N-Type Flexible CoSb3-xTex Skutterudite/PEDOT:PSS Hybrid Thermoelectric Films. Polymers 2022, 14, 1986. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14101986

Kato A, Bourgès C, Pang H, Gutiérrez D, Sakurai T, Mori T. Facile Fabrication of N-Type Flexible CoSb3-xTex Skutterudite/PEDOT:PSS Hybrid Thermoelectric Films. Polymers. 2022; 14(10):1986. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14101986

Chicago/Turabian StyleKato, Asahi, Cédric Bourgès, Hong Pang, Daniel Gutiérrez, Takeaki Sakurai, and Takao Mori. 2022. "Facile Fabrication of N-Type Flexible CoSb3-xTex Skutterudite/PEDOT:PSS Hybrid Thermoelectric Films" Polymers 14, no. 10: 1986. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14101986