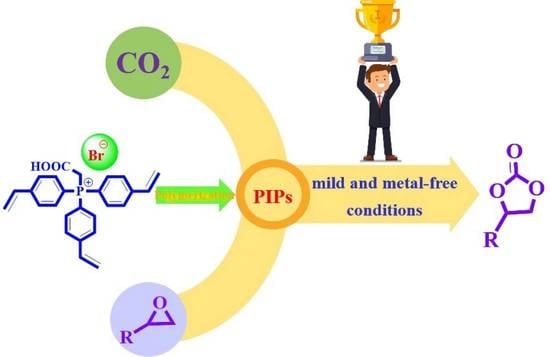

Functional Porous Ionic Polymers as Efficient Heterogeneous Catalysts for the Chemical Fixation of CO2 under Mild Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Catalyst Preparation

2.3. Catalytic Activity Test

2.4. Characterizations

3. Results

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mandil, C. Tracking Industrial Energy Efficiency and CO2 Emissions; IEA Publications: Paris, France, 2007. [Google Scholar]

- Spalding, M.D.; Brown, B.E. Warm-water coral reefs and climate change. Science 2015, 350, 769–771. [Google Scholar] [CrossRef] [PubMed]

- Hughes, T.P.; Baird, A.H.; Bellwood, D.R.; Card, M.; Connolly, S.R.; Folke, C.; Grosberg, R.; Hoegh-Guldberg, O.; Jackson, J.B.C.; Kleypas, J.; et al. Climate change, human impacts, and the resilience of coral reefs. Science 2003, 301, 929–933. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Chen, Z.; Zhao, X.; Yao, T.; Chen, W.; You, R.; Zhao, C.; Wu, G.; Wang, J.; Huang, W.; et al. Regulation of coordination number over single Co sites: Triggering the efficient electroreduction of CO2. Angew. Chem. Int. Ed. 2018, 57, 1944–1948. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Lu, L.; Zhu, Q.; Wu, C.; Yang, D.; Chen, C.; Han, B. MoP nanoparticles supported on indium-doped porous carbon: Outstanding catalysts for highly efficient CO2 electroreduction. Angew. Chem. Int. Ed. 2018, 57, 2427. [Google Scholar] [CrossRef] [PubMed]

- Matsubu, J.C.; Yang, V.N.; Christopher, P. Isolated metal active site concentration and stability control catalytic CO2 reduction selectivity. J. Am. Chem. Soc. 2015, 137, 3076–3084. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Guan, E.; Wang, L.; Chu, X.; Wu, Z.; Zhang, J.; Yang, Z.; Jiang, Y.; Zhang, L.; Meng, X.; et al. Product selectivity controlled by nanoporous environments in zeolite crystals enveloping rhodium nanoparticle catalysts for CO2 hydrogenation. J. Am. Chem. Soc. 2019, 141, 8482–8488. [Google Scholar] [CrossRef]

- Behrens, M.; Studt, F.; Kasatkin, I.; Kühl, S.; Hävecker, M.; Abild-Pedersen, F.; Zander, S.; Girgsdies, F.; Kurr, P.; Kniep, B.-L.; et al. The active site of methanol synthesis over Cu/ZnO/Al2O3 industrial catalysts. Science 2012, 336, 893–897. [Google Scholar] [CrossRef]

- Lam, E.; Larmier, K.; Wolf, P.; Tada, S.; Safonova, O.V.; Coperet, C. Isolated Zr surface sites on silica promote hydrogenation of CO2 to CH3OH in supported Cu catalysts. J. Am. Chem. Soc. 2018, 140, 10530. [Google Scholar] [CrossRef]

- North, M.; Pasquale, R.; Young, C. Synthesis of cyclic carbonates from epoxides and CO2. Green Chem. 2010, 12, 1514–1539. [Google Scholar] [CrossRef]

- Ema, T.; Miyazaki, Y.; Shimonishi, J.; Maeda, C.; Hasegawa, J. Bifunctional porphyrin catalysts for the synthesis of cyclic carbonates from epoxides and CO2: Structural optimization and mechanistic study. J. Am. Chem. Soc. 2014, 136, 15270–15279. [Google Scholar] [CrossRef]

- Babu, R.; Kathalikkattil, A.C.; Roshan, R.; Tharun, J.; Kimb, D.; Park, D. Dual-porous metal organic framework for room temperature CO2 fixation via cyclic carbonate synthesis. Green Chem. 2016, 18, 232. [Google Scholar] [CrossRef]

- Kathalikkattil, A.C.; Babu, R.; Roshan, R.K.; Lee, H.; Kim, H.; Tharun, J.; Suresh, E.; Park, D. An lcy-topology amino acid MOF as eco-friendly catalyst for cyclic carbonate synthesis from CO2: Structure-DFT corroborated study. J. Mater. Chem. A 2015, 3, 22636. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Qiao, C.; Fu, H.; He, L. Betaine catalysis for hierarchical reduction of CO2 with amines and hydrosilane to form formamides, aminals, and methylamines. Angew. Chem. Int. Ed. 2017, 56, 7425–7429. [Google Scholar] [CrossRef]

- Paddock, R.L.; Nguyen, S.T. Chemical CO2 fixation: Cr(III) salen complexes as highly efficient catalysts for the coupling of CO2 and epoxides. J. Am. Chem. Soc. 2001, 123, 11498–11499. [Google Scholar] [CrossRef]

- Sun, J.; Fujita, S.-I.; Zhao, F.; Arai, M. Synthesis of styrene carbonate from styrene oxide and carbon dioxide in the presence of zinc bromide and ionic liquid under mild conditions. Green Chem. 2004, 6, 613–616. [Google Scholar] [CrossRef]

- Qin, Y.; Guo, H.; Sheng, X.; Wang, X.; Wang, F. An aluminum porphyrin complex with high activity and selectivity for cyclic carbonate synthesis. Green Chem. 2015, 17, 2853–2858. [Google Scholar] [CrossRef]

- Zhang, M.; Chu, B.; Li, G.; Xiao, J.; Zhang, H.; Peng, Y.; Li, B.; Xie, P.; Fan, M.; Dong, L. Triethanolamine-modified mesoporous SBA-15: Facile one-pot synthesis and its catalytic application for cycloaddition of CO2 with epoxides under mild conditions. Micropor. Mesopor. Mat. 2019, 274, 363–372. [Google Scholar] [CrossRef]

- Liu, D.; Li, G.; Liu, J.; Wei, Y.; Guo, H. Mesoporous titanium-silicalite zeolite containing organic templates as a bifunctional catalyst for cycloaddition of CO2 and epoxides. ACS Appl. Mater. Inter. 2018, 10, 22119–22129. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Han, L.; Cheng, W.; Wang, J.; Zhang, X.; Zhang, S. Efficient acid–base bifunctional catalysts for the fixation of CO2 with epoxides under metal- and solvent-free conditions. ChemSusChem 2011, 4, 502–507. [Google Scholar] [CrossRef] [PubMed]

- Su, Q.; Qi, Y.; Yao, X.; Cheng, W.; Dong, L.; Chen, S.; Zhang, S. Ionic liquids tailored and confined by one-step assembly with mesoporous silica for boosting the catalytic conversion of CO2 into cyclic carbonates. Green Chem. 2018, 20, 3232–3241. [Google Scholar] [CrossRef]

- Aguila, B.; Sun, Q.; Wang, X.; O’Rourke, E.; Al-Enizi, A.M.; Nafady, A.; Ma, S. Lower activation energy for catalytic reactions through host-guest cooperation within metal-organic frameworks. Angew. Chem. Int. Ed. 2018, 57, 10107–10111. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; He, C.; Xiu, J.; Yang, L.; Duan, C. Metal–organic polymers containing discrete single-walled nanotube as a heterogeneous catalyst for the cycloaddition of carbon dioxide to epoxides. J. Am. Chem. Soc. 2015, 137, 15066–15069. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhong, M.; Tao, L.; Liu, L.; Jayakumar, S.; Li, C.; Li, H.; Yang, Q. The cooperation of porphyrin-based porous polymer and thermal-responsive ionic liquid for efficient CO2 cycloaddition reaction. Green Chem. 2018, 20, 903–911. [Google Scholar] [CrossRef]

- Jayakumar, S.; Li, H.; Chen, J.; Yang, Q. Cationic Zn–porphyrin polymer coated onto CNTs as a cooperative catalyst for the synthesis of cyclic carbonates. ACS Appl. Mater. Inter. 2018, 10, 2546–2555. [Google Scholar] [CrossRef]

- Dai, Z.; Sun, Q.; Liu, X.; Bian, C.; Wu, Q.; Pan, S.; Wang, L.; Meng, X.; Deng, F.; Xiao, F.-S. Metalated porous porphyrin polymers as efficient heterogeneous catalysts for cycloaddition of epoxides with CO2 under ambient conditions. J. Catal. 2016, 338, 202–209. [Google Scholar] [CrossRef]

- Clegg, W.; Harrington, R.W.; North, M.; Pasquale, R. Cyclic carbonate synthesis catalysed by bimetallic aluminium–salen complexes. Chem. Eur. J. 2010, 16, 6828–6843. [Google Scholar] [CrossRef]

- North, M.; Wang, B.; Young, C. Influence of flue gas on the catalytic activity of an immobilized aluminium(salen) complex for cyclic carbonate synthesis. Energy Environ. Sci. 2011, 4, 4163. [Google Scholar] [CrossRef]

- Dai, Z.; Tang, Y.; Zhang, F.; Xiong, Y.; Wang, S.; Sun, Q.; Wang, L.; Meng, X.; Zhao, L.; Xiao, F.-S. Combination of binary active sites into heterogeneous porous polymer catalysts for efficient transformation of CO2 under mild conditions. Chin. J. Catal. 2021, 42, 618–626. [Google Scholar] [CrossRef]

- Ding, M.; Liu, X.; Ma, P.; Yao, J. Porous materials for capture and catalytic conversion of CO2 at low concentration. Coord. Chem. Rev. 2022, 465, 214576. [Google Scholar] [CrossRef]

- Fischer, S.; Schmidt, J.; Strauch, P.; Thomas, A. An anionic microporous polymer network prepared by the polymerization of weakly coordinating anions. Angew. Chem. Int. Ed. 2013, 52, 12174–12178. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, B.; Ma, S. Dual functionalization of porous aromatic frameworks as a new platform for heterogeneous cascade catalysis. Chem. Commun. 2014, 50, 8507–8510. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Dai, Z.; Meng, X.; Xiao, F.-S. Porous polymer catalysts with hierarchical structures. Chem. Soc. Rev. 2015, 44, 6018–6034. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhu, D.; Chen, Y.; Yan, Q.; Liu, C.-Y.; Ling, K.; Liu, Y.; Lee, D.; Wu, X.; Senftle, T.P.; et al. Porphyrin-based donor–acceptor COFs as efficient and reusable photocatalysts for PET-RAFT polymerization under broad spectrum excitation. Chem. Sci. 2021, 12, 16092–16099. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Wang, X.; Gardner, A.M.; Wang, X.; Chong, S.Y.; Neri, G.; Cowan, A.J.; Liu, L.; Li, X.; Vogel, A.; et al. A stable covalent organic framework for photocatalytic carbon dioxide reduction. Chem. Sci. 2020, 11, 543–550. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Li, H.; Veith, G.M.; Dai, S. Soluble porous coordination polymers by mechanochemistry: From metal-containing films/membranes to active catalysts for aerobic oxidation. Adv. Mater. 2015, 27, 234–239. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Dai, Z.; Liu, X.; Sheng, N.; Deng, F.; Meng, X.; Xiao, F.-S. Highly efficient heterogeneous hydroformylation over Rh-metalated porous organic polymers: Synergistic effect of high ligand concentration and flexible framework. J. Am. Chem. Soc. 2015, 137, 5204–5209. [Google Scholar] [CrossRef]

- Sun, L.-B.; Liu, X.-Q.; Zhou, H.-C. Design and fabrication of mesoporous heterogeneous basic catalysts. Chem. Soc. Rev. 2015, 44, 5092–5147. [Google Scholar]

- Sun, Q.; Dai, Z.; Meng, X.; Wang, L.; Xiao, F.-S. Task-specific design of porous polymer heterogeneous catalysts beyond homogeneous counterparts. ACS Catal. 2015, 5, 4556–4567. [Google Scholar] [CrossRef]

- Alsbaiee, A.; Smith, B.J.; Xiao, L.; Ling, Y.; Helbling, D.E.; Dichtel, W.R. Rapid removal of organic micropollutants from water by a porous β-cyclodextrin polymer. Nature 2016, 529, 190–194. [Google Scholar] [CrossRef]

- Dai, Z.; Sun, Q.; Liu, X.; Guo, L.; Li, J.; Pan, S.; Bian, C.; Wang, L.; Hu, X.; Meng, X.; et al. A hierarchical bipyridine-constructed framework for highly efficient CO2 capture and catalytic conversion. ChemSusChem 2017, 10, 1186–1192. [Google Scholar] [CrossRef]

- Welton, T. Ionic liquids in catalysis. Coord. Chem. Rev. 2004, 248, 2459–2477. [Google Scholar] [CrossRef]

- Liu, F.; Wang, L.; Sun, Q.; Zhu, L.; Meng, X.; Xiao, F.-S. Transesterification catalyzed by ionic liquids on superhydrophobic mesoporous polymers: Heterogeneous catalysts that are faster than homogeneous catalysts. J. Am. Chem. Soc. 2012, 134, 16948–16950. [Google Scholar] [CrossRef] [PubMed]

- Willa, C.; Yuan, J.Y.; Niederberger, M.; Koziej, D. When nanoparticles meet poly(ionic liquid)s: Chemoresistive CO2 sensing at room temperature. Adv. Funct. Mater. 2015, 25, 2537–2542. [Google Scholar] [CrossRef] [Green Version]

- Guo, Z.; Jiang, Q.; Shi, Y.; Li, J.; Yang, X.; Hou, W.; Zhou, Y.; Wang, J. Tethering dual hydroxyls into mesoporous poly(ionic liquid)s for chemical fixation of CO2 at ambient conditions: A combined experimental and theoretical study. ACS Catal. 2017, 7, 6770–6780. [Google Scholar] [CrossRef]

- Xie, Y.; Zhang, Z.; Jiang, T.; He, J.; Han, B.; Wu, T.; Ding, K. CO2 cycloaddition reactions catalyzed by an ionic liquid grafted onto a highly cross-linked polymer matrix. Angew. Chem. Int. Ed. 2007, 46, 7255–7258. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, Y.; Guo, Z.; Chen, G.; Li, J.; Shi, Y.; Liu, Y.; Wang, J. Heterogeneous conversion of CO2 into cyclic carbonates at ambient pressure catalyzed by ionothermal-derived meso-macroporous hierarchical poly(ionic liquid)s. Chem. Sci. 2015, 6, 6916–6924. [Google Scholar] [CrossRef] [Green Version]

- Liang, S.; Liu, H.; Jiang, T.; Song, J.; Yang, G.; Han, B. Highly efficient synthesis of cyclic carbonates from CO2 and epoxides over cellulose/KI. Chem. Commun. 2011, 47, 2131–2133. [Google Scholar] [CrossRef]

- Soll, S.; Zhao, Q.; Weber, J.; Yuan, J. Activated CO2 sorption in mesoporous imidazolium-type poly(ionic liquid)-based polyampholytes. Chem. Mater. 2013, 25, 3003–3010. [Google Scholar] [CrossRef]

- Gao, C.; Chen, G.; Wang, X.; Li, J.; Zhou, Y.; Wang, J. A hierarchical meso-macroporous poly(ionic liquid) monolith derived from a single soft template. Chem. Commun. 2015, 51, 4969–4972. [Google Scholar] [CrossRef]

- Ji, G.; Yang, Z.; Zhang, H.; Zhao, Y.; Yu, B.; Ma, Z.; Liu, Z. Hierarchically mesoporous o-hydroxyazobenzene polymers: Synthesis and their applications in CO2 capture and conversion. Angew. Chem. Int. Ed. 2016, 55, 9685–9689. [Google Scholar] [CrossRef]

- Sun, Q.; Jin, Y.; Aguila, B.; Meng, X.; Ma, S.; Xiao, F.-S. Porous ionic polymers as a robust and efficient platform for capture and chemical fixation of atmospheric CO2. ChemSusChem 2017, 10, 1160–1165. [Google Scholar] [CrossRef] [PubMed]

- Thierbach, D.; Huber, F. Darstellung sowie Kristall−und Molekülstruktur von [(C6H5)3PO]2 · H2O · HBr. Z. Anorg. Allg. Chem. 1979, 457, 189–193. [Google Scholar] [CrossRef]

- Ravi, S.; Puthiaraj, P.; Ahn, W.-S. Hydroxylamine-anchored covalent aromatic polymer for CO2 adsorption and fixation into cyclic carbonates. ACS Sustain. Chem. Eng. 2018, 6, 9324–9332. [Google Scholar] [CrossRef]

- Cao, J.; Shan, W.; Wang, Q.; Ling, X.; Li, G.; Lyu, Y.; Zhou, Y.; Wang, J. Ordered porous poly(ionic liquid) crystallines: Spacing confifined ionic surface enhancing selective CO2 capture and fixation. ACS Appl. Mater. Interfaces 2019, 11, 6031–6041. [Google Scholar] [CrossRef]

- Guo, Z.; Cai, X.; Xie, J.; Wang, X.; Zhou, Y.; Wang, J. Hydroxyl-exchanged nanoporous ionic copolymer toward low-temperature cycloaddition of atmospheric carbon dioxide into carbonates. ACS Appl. Mater. Interfaces 2016, 8, 12812–12821. [Google Scholar] [CrossRef]

- Song, H.; Wang, Y.; Xiao, M.; Liu, L.; Liu, Y.; Liu, X.; Gai, H. Design of novel poly(ionic liquids) for the conversion of CO2 to cyclic carbonates under mild conditions without solvent. ACS Sustain. Chem. Eng. 2019, 7, 9489–9497. [Google Scholar] [CrossRef]

- Bahadori, M.; Tangestaninejad, S.; Bertmer, M.; Moghadam, M.; Mirkhani, V.; Mohammadpoor-Baltork, I.; Kardanpour, R.; Zadehahmadi, F. Task-specifific ionic liquid functionalized-MIL-101(Cr) as a heterogeneous and efficient catalyst for the cycloaddition of CO2 with epoxides under solvent free conditions. ACS Sustain. Chem. Eng. 2019, 7, 3962–3973. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, H.; Vardhan, H.; Aguila, B.; Zhong, C.; Perman, J.A.; Al-Enizi, A.M.; Nafady, A.; Ma, S. Facile approach to graft ionic liquid into MOF for improving the efficiency of CO2 chemical fixation. ACS Appl. Mater. Interfaces 2018, 10, 27124–27130. [Google Scholar] [CrossRef]

- Rabbani, M.G.; El-Kaderi, H.M. Template-Free Synthesis of a Highly Porous Benzimidazole-Linked Polymer for CO2 Capture and H2 Storage. Chem. Mater. 2011, 23, 1650–1653. [Google Scholar] [CrossRef]

- Ben, T.; Li, Y.; Zhu, L.; Zhang, D.; Cao, D.; Xiang, Z.; Yao, X.; Qiu, S. Selective adsorption of carbon dioxide by carbonized porous aromatic framework (PAF). Energy Environ. Sci. 2012, 5, 8370–8376. [Google Scholar] [CrossRef]

- Ren, S.J.; Dawson, R.; Laybourn, A.; Jiang, J.X.; Khimyak, Y.; Adams, D.J.; Cooper, A.I. Functional conjugated microporous polymers: From 1,3,5-benzene to 1,3,5-triazine. Polym. Chem. 2012, 3, 928–934. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Q.; Zhang, Z.; Zhang, S. Functional microporous polyimides based on sulfonated binaphthalene dianhydride for uptake and separation of carbon dioxide and vapors. J. Mater. Chem. A 2013, 1, 10368–10374. [Google Scholar] [CrossRef]

- Liebl, M.R.; Senker, J. Microporous Functionalized Triazine-Based Polyimides with High CO2 Capture Capacity. Chem. Mater. 2013, 25, 970–980. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, Z.; Fu, H.; Wang, F.; Shen, M.; Wang, X.; Cao, R. Porous Anionic Indium-Organic Framework with Enhanced Gas and Vapor Adsorption and Separation Ability. ChemSusChem 2014, 7, 2647–2653. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, T.-T.; Liu, X.-H.; Zou, K.; Deng, W.-Q. Capture and conversion of CO2 at ambient conditions by a conjugated microporous polymer. Nat. Commun. 2013, 4, 1960. [Google Scholar] [CrossRef] [Green Version]

| Entry | Catalysts | Molar Ratio (mol.%) | Temp. (°C) | Yield (%) 2 | TON |

|---|---|---|---|---|---|

| 1 | POP-PBC (24.0 mg) | 0.5 | 40 | 35.1 | 70.2 |

| 2 | POP-PBC (24.0 mg) | 0.5 | 60 | 75.8 | 151.6 |

| 3 | POP-PBH (23.3 mg) | 0.5 | 60 | 76.8 | 153.6 |

| 4 | POP-PBC (48.0 mg) | 1.0 | 60 | 96.2 | 96.2 |

| 5 | POP-PBH (46.6 mg) | 1.0 | 60 | 97.5 | 97.5 |

| 6 | MePBC (18.2 mg) | 0.5 | 60 | 86.2 | 172.4 |

| 7 | PBH (19.4 mg) | 0.5 | 60 | 80.6 | 161.2 |

| 8 | POP-PPh3-BC (35.7 mg) | 0.5 | 60 | 45.7 | 91.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Z.; Long, Y.; Liu, J.; Bao, Y.; Zheng, L.; Ma, J.; Liu, J.; Zhang, F.; Xiong, Y.; Lu, J.-Q. Functional Porous Ionic Polymers as Efficient Heterogeneous Catalysts for the Chemical Fixation of CO2 under Mild Conditions. Polymers 2022, 14, 2658. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14132658

Dai Z, Long Y, Liu J, Bao Y, Zheng L, Ma J, Liu J, Zhang F, Xiong Y, Lu J-Q. Functional Porous Ionic Polymers as Efficient Heterogeneous Catalysts for the Chemical Fixation of CO2 under Mild Conditions. Polymers. 2022; 14(13):2658. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14132658

Chicago/Turabian StyleDai, Zhifeng, Yang Long, Jianliang Liu, Yuanfei Bao, Liping Zheng, Jiacong Ma, Jiayi Liu, Fei Zhang, Yubing Xiong, and Ji-Qing Lu. 2022. "Functional Porous Ionic Polymers as Efficient Heterogeneous Catalysts for the Chemical Fixation of CO2 under Mild Conditions" Polymers 14, no. 13: 2658. https://0-doi-org.brum.beds.ac.uk/10.3390/polym14132658