Influence of Crystal Structure of Nitride Compound Layer on Torsion Fatigue Strength of Alloy Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Condition of Potential-Controlled Nitriding and Gas Nitrocarburizing

2.2. Compound Layer Removal

2.3. Material Characterization of the Test Specimens

2.4. Fatigue Test Method

3. Results

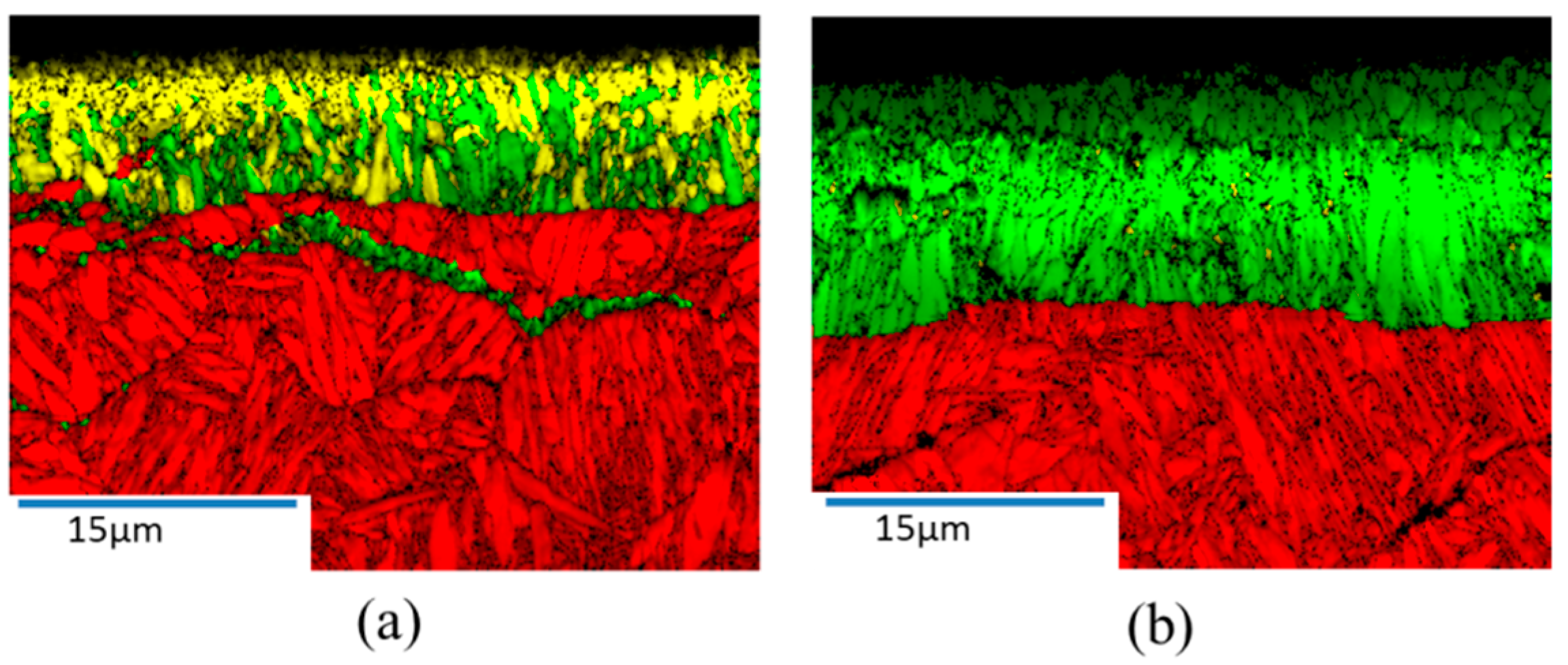

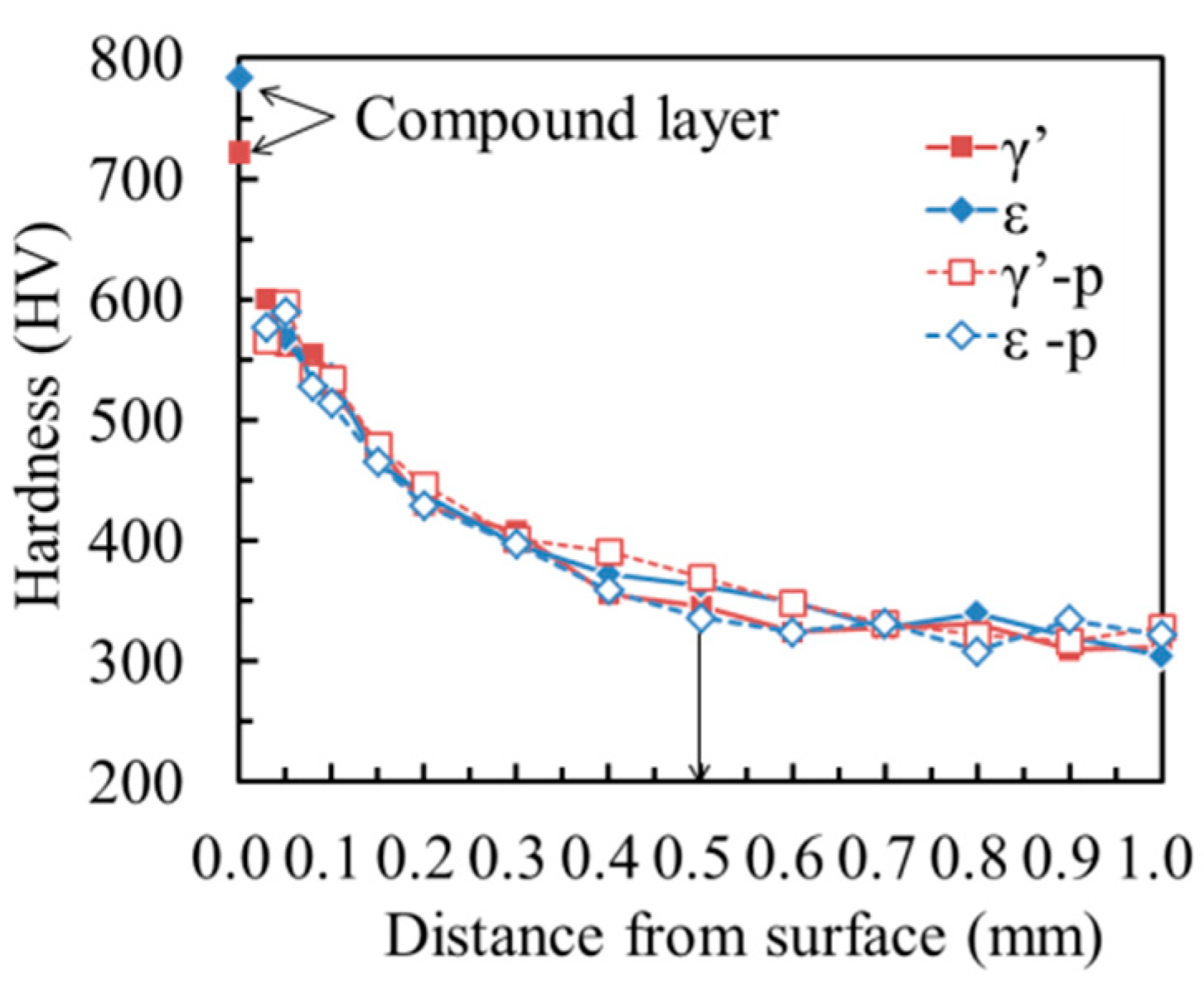

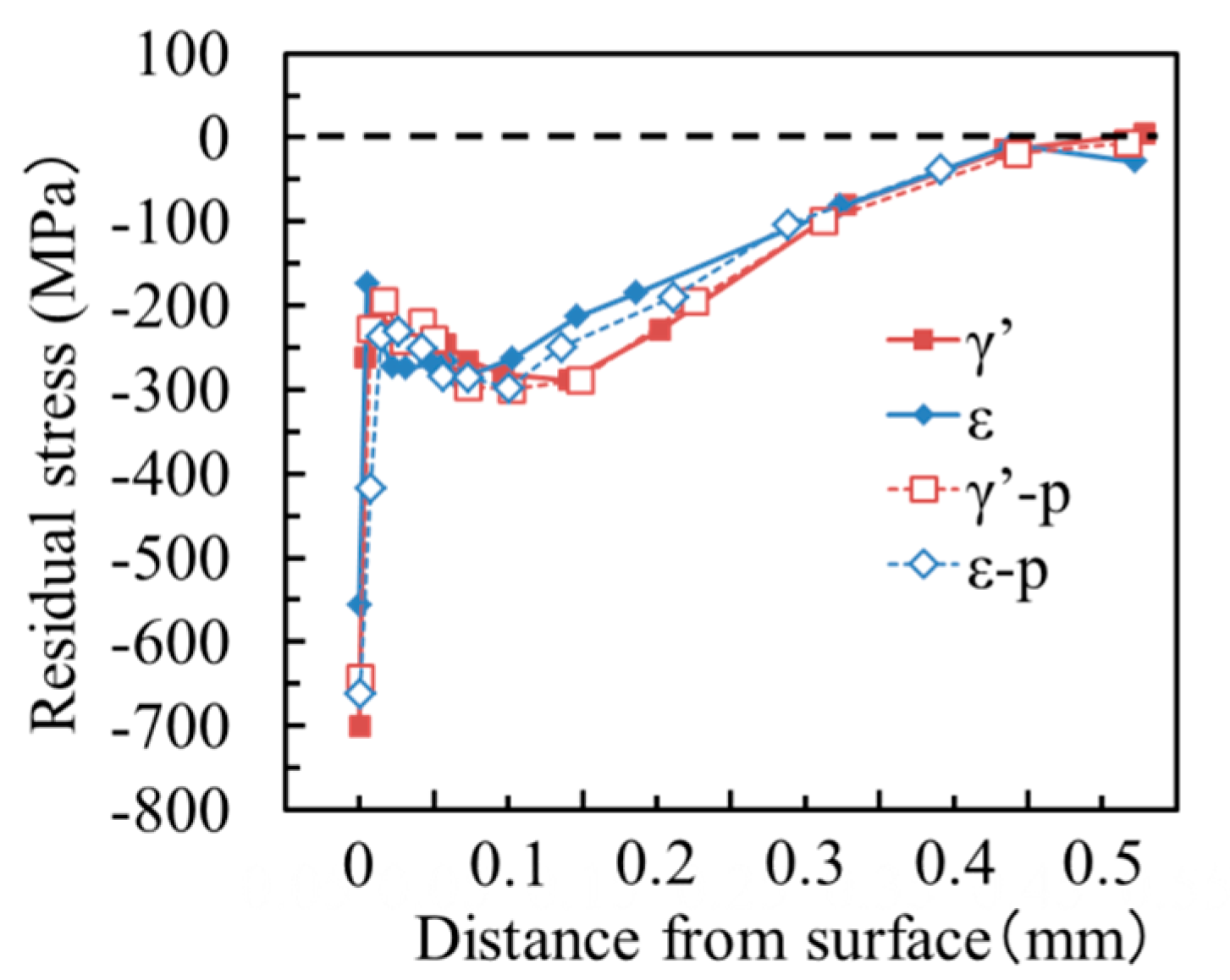

3.1. Crystal Structure Identification of Compound Layer, Vickers Hardness, and Residual Stress at Surface Layer

3.2. Fatigue Test Results

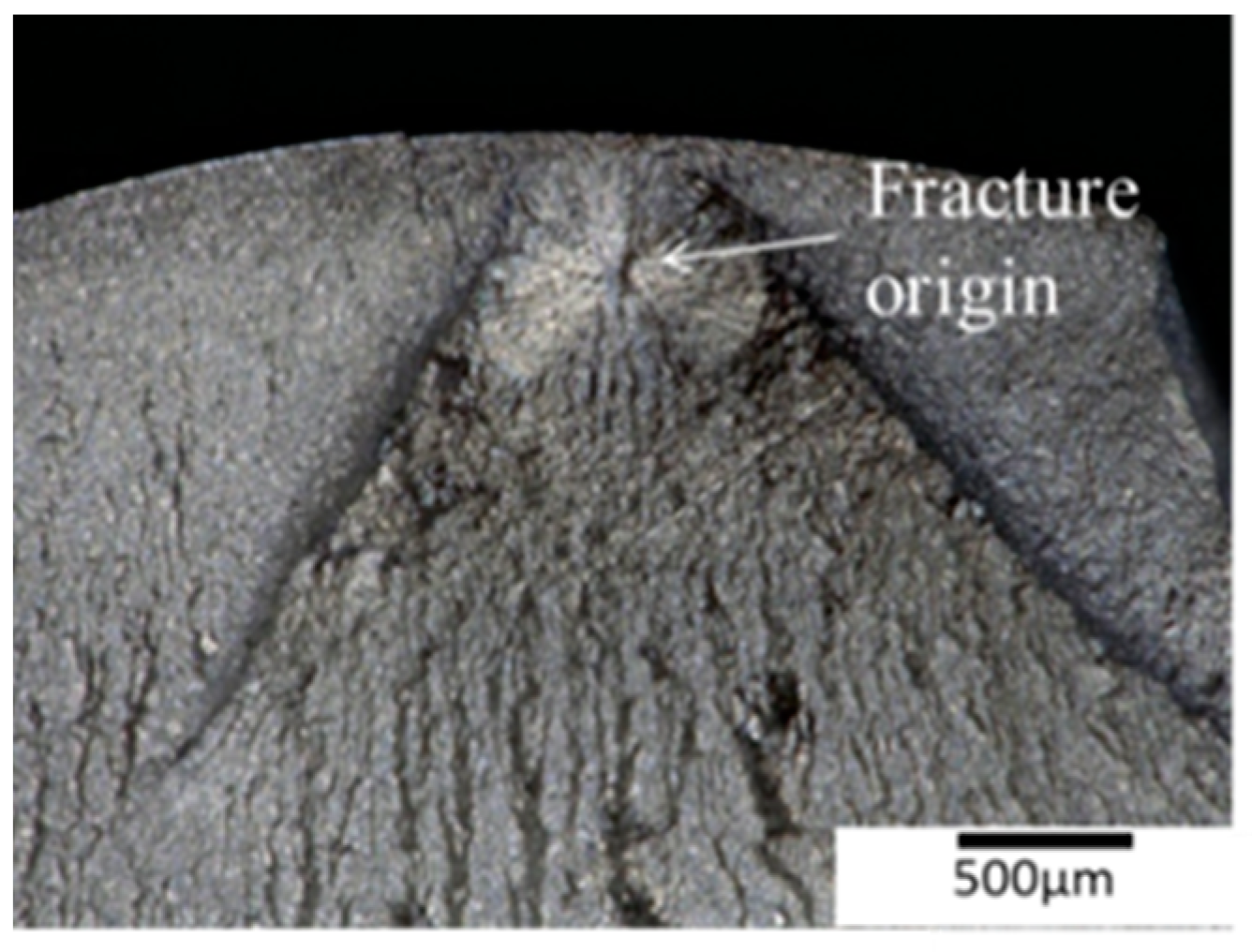

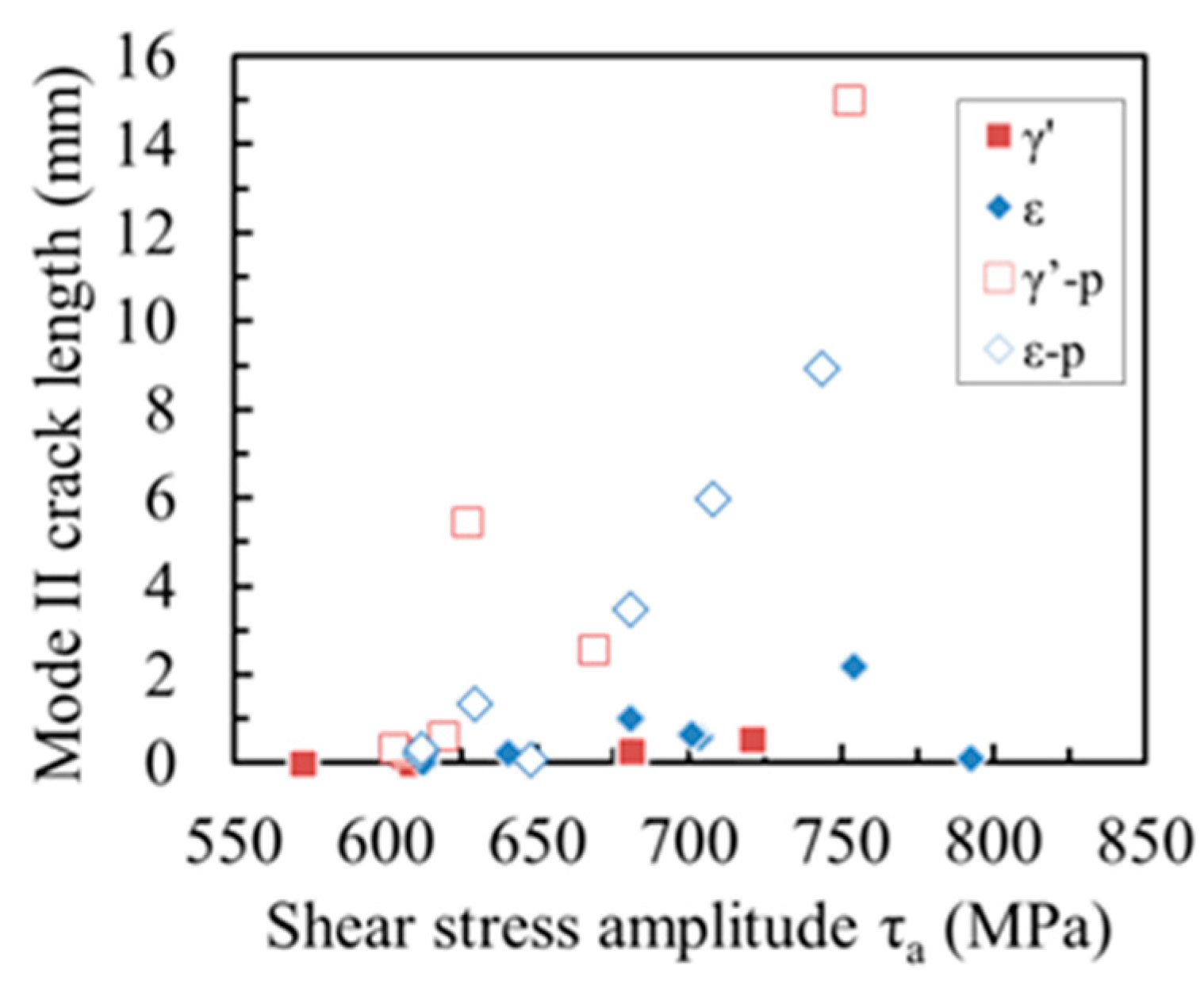

3.3. Observation of Fatigue Cracks and Fractures

4. Discussions

5. Conclusions

- (1)

- The crystal structure and presence of the nitride compound layer did not affect the torsional fatigue limit because the origin of the torsional fatigue failure is inside the specimen.

- (2)

- It was found that the fatigue life is extended by changing the crystal structure of the compound layer from ε (HCP) to γ’ (FCC).

- (3)

- The presence or absence of the compound layer affected the torsional fatigue life because the compound layer suppressed Mode II crack propagation.

- (4)

- It was found that the failure origin can be estimated from the relationship between the predicted fatigue limit and applied stress distribution.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sugimoto, K.I.; Hojo, T.; Mizuno, Y. torsional fatigue strength of newly developed case hardening TRIP-aided steel. Metals 2017, 7, 375. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, K.; Mizuno, Y.; Hojo, T. Effects of vacuum-carburizing conditions on surface-hardened layer properties of transformation-induced plasticity-aided martensitic steel. Metals 2017, 7, 301. [Google Scholar] [CrossRef]

- Xiaohui, Z.; Zhaoyi, S.; Desheng, X.; Yu, L. Local fatigue strength evaluation of shot peened 40Cr notched steel. Metals 2016, 8, 681. [Google Scholar]

- Sirin, S.Y.; Sirin, K.; Kaluc, E. Effect of the ion nitriding surface hardening process on fatigue behavior of AISI 4340 steel. Mater. Charact. 2008, 59, 351–358. [Google Scholar] [CrossRef]

- Alsaran, A.; Karakan, M.; Çelik, A. The investigation of mechanical properties of ion-nitrided AISI 5140 low-alloy steel. Mater. Charact. 2002, 48, 323–327. [Google Scholar] [CrossRef]

- Genel, K.; Demirkol, M.; Çapa, M. Effect of ion nitriding on fatigue behaviour of AISI 4140 steel. Mater. Sci. Eng. A 2000, 279, 207–216. [Google Scholar] [CrossRef]

- Çelik, A.; Karadeniz, S. Improvement of the fatigue strength of AISI 4140 steel by an ion nitriding process. Surf. Coat. Technol. 1995, 72, 169–173. [Google Scholar] [CrossRef]

- Aoyama, S.; Ogawa, K. Rotating bending fatigue strength of Cr-Mo structural steel specimens carbonitrided at low temperature. J. Soc. Mater. Sci. Jpn. 1997, 26, 62–67. [Google Scholar] [CrossRef]

- Ashrafizadeh, F. Influence of plasma and gas nitriding on fatigue resistance of plain carbon (Ck45) steel. Surf. Coat. Technol. 2003, 174, 1196–1200. [Google Scholar] [CrossRef]

- Limodin, N.; Verreman, Y. Fatigue strength improvement of a 4140 steel by gas nitriding: Influence of notch severity. Mater. Sci. Eng. A 2006, 435, 460–467. [Google Scholar] [CrossRef]

- Fernández Pariente, I.; Guagliano, M. About the role of residual stresses and surface work hardening on fatigue ΔKth of a nitrided and shot peened low-alloy steel. Surf. Coat. Technol. 2008, 202, 3072–3080. [Google Scholar] [CrossRef]

- Croccolo, D.; Cristofolini, L.; Bandini, M.; Freddi, A. Fatigue strength of shot-peened nitrided steel: Optimization of process parameters by means of design of the experiment. Fatigue Fract. Eng. M 2002, 25, 695–707. [Google Scholar] [CrossRef]

- Kawata, K. Gas Nitrocarburizing Furnace with Nitriding Potential Control System. J. Jpn. Soc. Heat Treat. 2009, 49, 64–68. [Google Scholar]

- Lehrer, E. Über das Eisen Wasserstoff Ammoniak Gleichgewicht. Z. Elektrochem. 1930, 36, 383–392. [Google Scholar]

- Hiraoka, Y.; Watanabe, Y.; Umezawa, O. Effect of Phase in surface compound layer on rotating bending fatigue strength for Gas-nitrided SCM435 steel. Mater. Trans. 2017, 57, 64–72. [Google Scholar]

- Takagi, S.; Tonozuka, Y.; Nakamura, N.; Itou, T. Effect of crystal structure of surface compound layer on fatigue strength of nitrided SCM 435 steel. Tetsu Hagane J. Iron Steel Inst. Jpn. 2018, 10, 594–601. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, A.; Maeda, S.; Imataka, H.; Gyotoku, Y.; Yuya, M.; Shimizu, Y.; Kanayama, M. Strengthening of low carbon alloy steel nitrided gear by generating γ’-Fe4N phase. Trans. Soc. Automov. Eng. Jpn. 2014, 45, 1153–1158. [Google Scholar]

- Dieter, L.; Ulrich, B.; Joachim, B.; Uwe, H.; Heinrich, K.; Wolfgang, L.; Heinz, -J.S. Wärmebehandlung von Eisenwerkstoffen II: Nitrieren und Nitrocarburieren, 5th ed.; Expert-Verlag Gmbh: Munich, Germany, 2009; pp. 11–12. [Google Scholar]

- Tanaka, K.; Gu, Q.P.; Mikuriya, T.; Akiniwa, T. X-Ray residual stress measurement of gas-soft nitrided steel. Trans. Jpn. Soc. Mech. Eng. Ser. A 1996, 62, 2734–2740. [Google Scholar] [CrossRef] [Green Version]

- Morino, K.; Kawagoishi, N.; Fukuda, K.; Wang, Q.; Kondo, E. Influence of compound layer on fatigue strength of radical nitrided SNCM439 steel. Trans. Jpn. Soc. Mech. Eng. Ser. A 2003, 69, 1490–1496. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Akid, R. Mechanisms and fatigue performance of two steels in cyclic torsion with axial static tension/compression. Fatigue Fract. Eng. Mater. Struct. 1997, 20, 547–557. [Google Scholar] [CrossRef]

- Wakita, M.; Kuno, T.; Hasegawa, T.; Sakurai, K.; Tanaka, T. Effect of shot peening on torsional fatigue strength of high strength spring steel and prediction of fatigue strength. Trans. Jpn. Soc. Spr. Eng. 2009, 54, 7–12. [Google Scholar]

- Kanazawa, K.; Abe, T.; Nishizima, Y. NIMS Material Data Base; Date sheet No.9; National Research Institute for Metals: Tokyo, Japan, 1995. [Google Scholar]

- Nakamura, H.; Horikawa, T. Strength of Metal and Application of Fatigue Strength, 2nd ed.; Corona Publishing: Tokyo, Japan, 2008; p. 44. [Google Scholar]

| C | Si | Mn | P | S | Ni | Cr | Mo | |

|---|---|---|---|---|---|---|---|---|

| SCM435 | 0.35 | 0.23 | 0.7 | 0.021 | 0.017 | 0.08 | 1.07 | 0.18 |

| Method | ε-Fe2–3N | γ’-Fe4N | α-Fe |

|---|---|---|---|

| Characteristic X-ray | Cr-Kα | ||

| Diffraction plane | (1,0,3) | (2,2,0) | (2,1,1) |

| Stress constant (MPa/deg) | −611 | −611 | −318 |

| Specimen | Maximum Compressive Residual Stress (MPa) | |

|---|---|---|

| Compound Layer | Diffusion Layer | |

| γ’ | 701 | 288 |

| ε | 557 | 288 |

| γ’-p | - | 660 |

| ε-p | - | 641 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamada, Y.; Hirohito, E.; Takahashi, K. Influence of Crystal Structure of Nitride Compound Layer on Torsion Fatigue Strength of Alloy Steel. Metals 2019, 9, 1352. https://0-doi-org.brum.beds.ac.uk/10.3390/met9121352

Yamada Y, Hirohito E, Takahashi K. Influence of Crystal Structure of Nitride Compound Layer on Torsion Fatigue Strength of Alloy Steel. Metals. 2019; 9(12):1352. https://0-doi-org.brum.beds.ac.uk/10.3390/met9121352

Chicago/Turabian StyleYamada, Yoshitomi, Eto Hirohito, and Koji Takahashi. 2019. "Influence of Crystal Structure of Nitride Compound Layer on Torsion Fatigue Strength of Alloy Steel" Metals 9, no. 12: 1352. https://0-doi-org.brum.beds.ac.uk/10.3390/met9121352