1. Introduction

The traditional motor drive mode is that of a motor plus a reducer. The existence of the reducer not only increases the overall energy consumption of the transmission system, but also reduces the stability and reliability of the transmission system. PMSMs have the advantages of small torque ripple, high efficiency, simple structure, small size, etc., so they are widely used in direct drive systems [

1,

2,

3,

4]. A direct drive system can reduce the intermediate links of the transmission system (such as reducers, coupling, etc.), and “near zero transmission” can be achieved. However, because a direct drive system does not have a transmission mechanism, disturbance on the load side will affect the stability of the PMSM speed control system. In addition, because the PMSM is a complex system of nonlinear, strong coupling, and multivariable systems, it also has problems such as modeling errors, complex operating conditions, and uncertain factors. The control performance and reliability of the PMSM will directly affect the stable operation of the entire system. Therefore, a PMSM need a robust control strategy to improve the anti-disturbance ability of the motor.

At present, to make PMSM suitable for various and complicated applications, higher requirements have bene put forward for its speed regulation system. The common control algorithms include fuzzy control [

5,

6], predictive control [

7,

8], adaptive control [

9,

10,

11], and sliding mode control [

12,

13,

14,

15], etc. In [

5], the researchers designed a fuzzy logic speed controller which not only improved the ability to suppress torque pulsation but also improved the dynamic quality of the speed control system. In [

7], the researchers proposed a continuous control set sliding mode predictive control for a PMSM speed control system. In [

8], the researchers proposed a model prediction method to overcome the limitations of the motion control of an unconstrained PMSM. In [

10], the researchers adopted adaptive fault-tolerant control to ensure the normal operation of the actuator when it failed. In [

11], the researchers proposed a combination of neural networks and adaptive control for the application of improved speed following. In [

11,

12,

13,

14,

15,

16], the researchers proposed that integral sliding mode control [

12], fuzzy sliding mode control [

13], terminal sliding mode control [

14,

15], and backstepping sliding mode control [

16], respectively, all can be used for the speed control of a PMSM. In [

12], the researchers proposed a memorial and memory-based integral sliding mode control and applied it to motor control. In [

13], the researchers proposed a robust fuzzy neural network sliding mode control method for the control of permanent magnet linear motors. In [

14], the researchers proposed a terminal sliding mode control that was applied to uncertain dynamic systems, but their systems suffered from singularity problems. Therefore, in [

17], the researchers designed a nonsingular terminal sliding mode control to solve the singularity problems of the system, and it was analyzed, inferred, and proven in detail. In [

18], the researchers proposed an adaptive second-order nonsingular terminal sliding mode method which was applied to the trajectory tracking of autonomous underwater vehicles. Compared to other control methods, the sliding mode of the system was designed independently, so it is not affected by parameter disturbances or external disturbances. The NTSM has the advantages of fast dynamic response, finite time convergence, and high steady-state accuracy, so it is widely used in the field of high precision control.

However, the superior performance of sliding mode control is traded for high-frequency chattering, which is directly associated with the switching function contained in the reaching law. Different approaches had been developed to suppress chattering, such as the higher-order sliding mode [

19,

20], adaptive algorithms [

21,

22], the researchers prposed disturbance observers [

23,

24,

25] and reaching law methods [

26,

27,

28,

29]. In [

19,

20], the researchers proposed a high-order sliding mode control strategy and gave a detailed overview. The discontinuous control in the higher-order sliding mode control is hidden in its higher-order derivatives, which effectively suppress chattering. But this control structure is complicated. In [

22], the researchers proposed an adaptive algorithm acting on the parameter estimation of the sliding mode and provided a parametric fitting mechanism to learn the dynamic properties of the system, which made the system reach speed. In [

23], the researchers proposed a control method that not only effectively improved the incompatibility between rapidity and stability, but also solved the problem that the constant rate reaching law cannot satisfy both rapidity and low chattering in the sliding mode observer. In [

24,

25], the researchers proposed an extended state observer to observe lumped disturbances, and the estimated disturbances were introduced into feedforward compensation technology to improve the robustness of the system. Uncertainty disturbances are the main source of chattering in sliding mode control, which can be solved by using an observer. The reaching law method is simple to design, easy to implement, and widely used. In [

26], Weibing Gao proposed the reaching law and analyzed it in the three modes of sliding, arriving, and steady-state. The most applied is the exponential reaching law. This reaching law not only shortens the arrival time but also reduces the speed of the moving point when it reaches the switching surface. In [

27,

28], the researchers proposed a new reaching law takes the sliding mode surface as the research mechanism and designed different functions to make the exponential function adapt to changes to the sliding mode surface and state. In [

29], the researchers proposed a power reaching law for electronic throttle control in automobiles. The power reaching law uses the property of exponential functions to accelerate the speed of the approach in different stages. In addition, there are other methods to suppress system chattering, such as the neural networks were used for the online approximation of interference to reduce the gain of switching items [

30], multi-objective optimization of sliding modes [

31], etc.

Aiming at PMSM starting speed overshoot, sudden speed changes are caused by the slow dynamic response and other problems. In this paper, an improved exponential reaching law was proposed based on [

27], which is used to improve the transient response time and anti-disturbance performance of a PMSM speed regulation system. A speed controller was designed using an improved exponential reaching law. When the uncertainties in the system could not be measured, a sliding mode observer was proposed to achieve the estimation of disturbances. The other parts of this paper are organized as follows: in

Section 2, an improved exponential reaching law is designed.

Section 3 presents the mathematical model of the PMSM with uncertainty disturbance and designs the speed controller using an improved exponential reaching law. In

Section 4, the SMO is designed using the improved exponential reaching law.

Section 5 compares the proposed method with simulations.

Section 6 concludes with a summary.

2. Improved Exponential Reaching Law Design

2.1. Commonly Used Sliding Mode Reaching Law

The sliding mode structure means that the system is forced to follow a certain trajectory of modal motion by purposeful and constant changes according to the current state of the system. The advantages of sliding mode control include insignificant parameter changes, external disturbance changes, fast response of the system, and simple implementation. However, the disadvantage is that the state variable cannot always move along the prescribed track. The chattering phenomenon is caused by repeated traversal on the sliding mode surface. Therefore, the reaching law method is proposed to suppress chattering, and the exponential reaching law is as follow [

26]:

where

is the sliding mode surface,

is the signum function, and

are the system parameters.

In (1), when

, it can be obtained that

and the reaching time can be calculated by integrating (1) from 0 to

, with

The exponential approach rate method is widely used. However, although the accessibility problem can be solved by adding the constant velocity term

, the exponential arrival law of the velocity to the sliding mode surface is determined by the value of the design parameter

. Therefore, it is important to balance arrival speed and suppress chattering. The chattering phenomenon and slow reaching speed in the traditional sliding mode approach law are discussed. At present, in [

32], the researchers combined the exponential reaching law and single power reaching law to propose a fast power reaching law which shortens the approach time and makes the approaching process smoother, but the chattering phenomenon still exists. In [

33], the researchers proposed the double-power combination function reaching law, which improved the convergence speed in the interval and avoided chattering. The reaching law of [

33] is as follows:

where

.

Although the function has a piecewise characteristic, the reaching law of the double-power combination function is faster than the traditional law of reaching, but the second term of the function term has a slower convergence rate than the first term. The convergence of the two terms of the function differs greatly, and the law of reaching cannot have the ability to adapt.

2.2. Proposed Improved Exponential Reaching Law

Based on the above analysis, this paper proposes a segmented rate adjustment sliding mode reaching law, which performs segmented rate adjustment to increase the rate of the system.

In this paper, a segmented rate adjustment sliding mode reaching law is designed as:

where

x is the state variable of the system.

When , . Among them, is the variable speed reaching law, and is the variable index reaching law. This means that when the system approaches the sliding mode surface, the reaching law rate increases and the chattering is suppressed. When , . Among them, the variable index reaching law is . Moreover, , which increases the arrival speed. It realizes the function of adaptive adjustment according to different stages in the process of system approach, greatly improves the reaching speed of the system, and has the characteristics of global finite time convergence.

Theorem 1. For the sliding mode reaching law (5), the system stateconverges to the equilibrium zero under its action.

Proof. According to Equation (5), we can get:

if

, there is

.

According to the existence and reachability conditions of the continuous system sliding mode, if is satisfied, the reaching law exists, and the equilibrium point can be reached. □

Theorem 2. For Equation (5), suppose the initial state ofis, then the stateconverges to 0 within the finite time, and the upper limit ofis.

Where,.

Proof. When

, Equation (5) can be expressed as:

When

, it can be seen that the system will reach the sliding mode surface in finite time by integrating Equation (7) from

to

:

Because

,

in Equation (8), it can be rewritten as:

When

, Equation (5) can be expressed as:

When

, it can be seen that the system will reach the sliding mode surface in finite time by integrating (10) from

to

:

Because

in Equation (11), it can be rewritten as:

Therefore, when the initial state is not in the sliding mode surface, i.e.,

, the time taken for the initial state to reach the sliding mode surface is:

In summary, the convergence time of the reaching law (5) is less than . □

2.3. Discrete Form of NSMRL

In engineering applications, real-time computer control is a discrete control system. From the perspective of discrete analysis, when

is close to 0, the discrete form of NSMRL is given, and the performance of the exponential reaching law in the discrete state is compared. In a discrete system, the sliding mode surface function is designed as follows:

where

.

Next, the switching band surrounding the switching surface is represented as follows:

If

is close to 0, the improved exponential reaching law proposed by Equation (5) can be simplified to

, and the discrete expression is as follows:

where

represents the sampling period.

Assuming that the system gradually reaches the sliding surface in a finite time, this indicates that the system will reach the sliding surface in two situations

or

, then the equation of the next period can be obtained with

Similarly, when

, Equation (16) can be expressed as:

Through Equations (17) and (18), the thickness

of the discrete improved exponential reaching law for (16) is:

Then, the switch thickness

of the traditional sliding mode reaching law is expressed as:

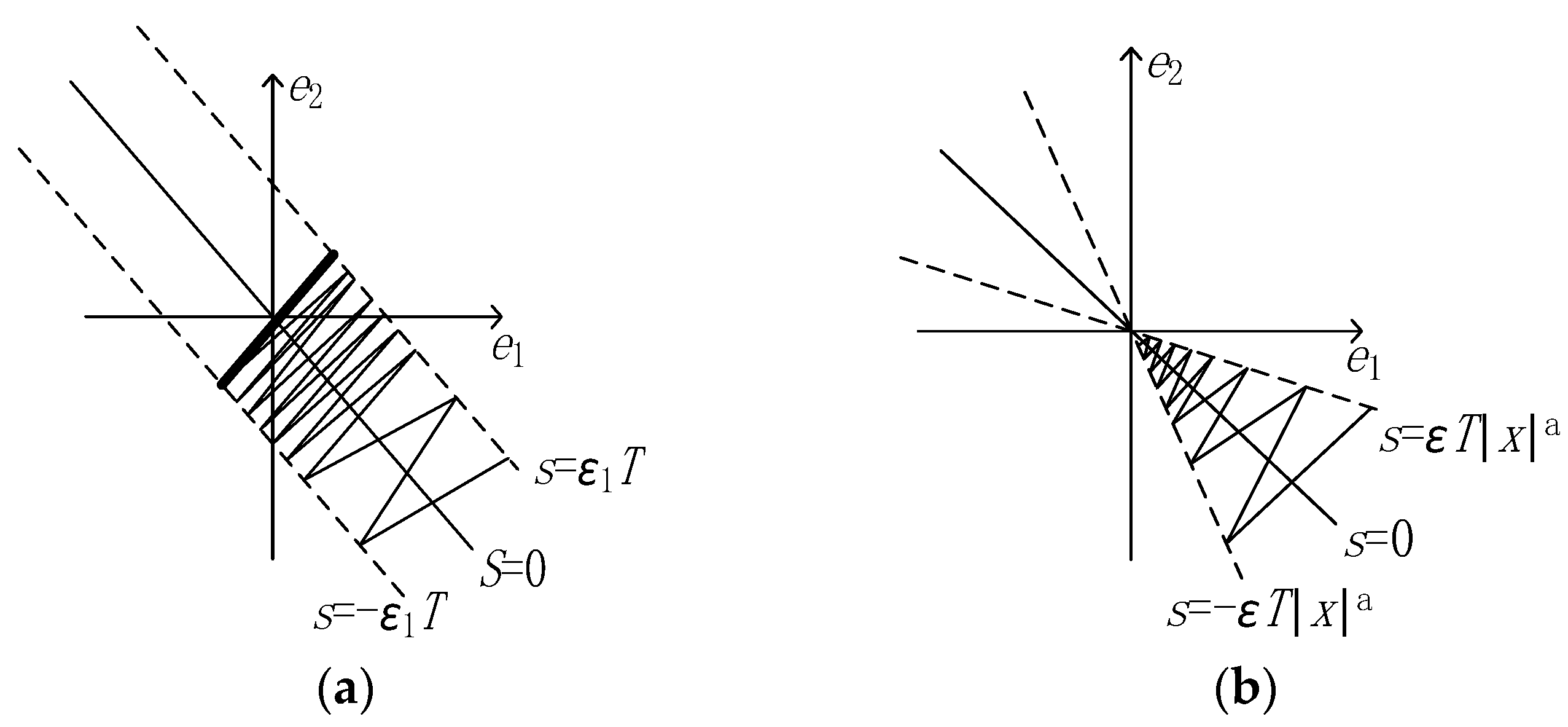

Combining

Figure 1, it can be seen that the improved exponential sliding mode reaching law, due to the introduction of the power of the state variable, enables the system to stably reach the origin and cause smaller chattering.

On the other hand, for the PMSM speed regulation system, the speed of the motor follows its ideal value rapidly and stably, which is an important performance index of the control system. In this paper, the speed error is directly used in the design of the reaching speed of the sliding mode, and it can accelerate the rate of the system state variable reaching the sliding mode surface and reduce chattering.

2.4. Simulation Analysis

To verify the dynamic properties of the proposed sliding mode reaching law (5), the second-order nonlinear system is established as follows:

The sliding mode surface function

is described as follows:

where

satisfies system stability.

The derivative of the sliding mode surface is obtained as follows:

Using the reaching law in (5) and substituting it into (23), the control input of (21) can be obtained as follows:

To verify the dynamic performance of the NSMRL, the ESMRL and the reaching law in [

27] were selected for comparison experiments, where

and

, and the controller parameters were

,

, and

. The initial state of the system

.

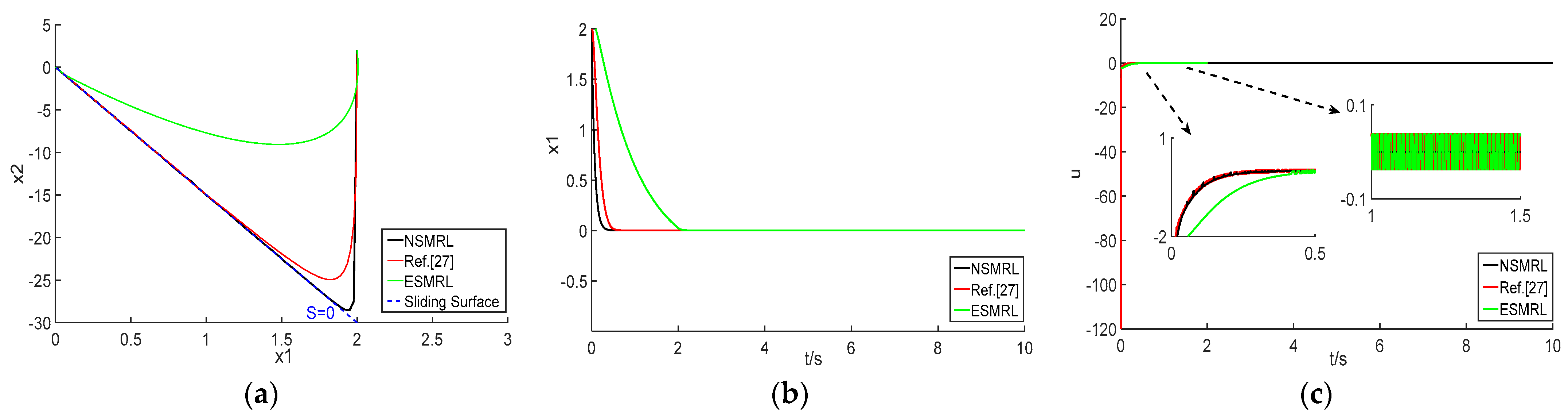

Figure 2a–c shows the performance comparison among NSMRL, ESMRL, and [

27]. We can conclude that NSMRL has the advantages of fast arrival speed and smooth controller output.

5. Experimental Validation

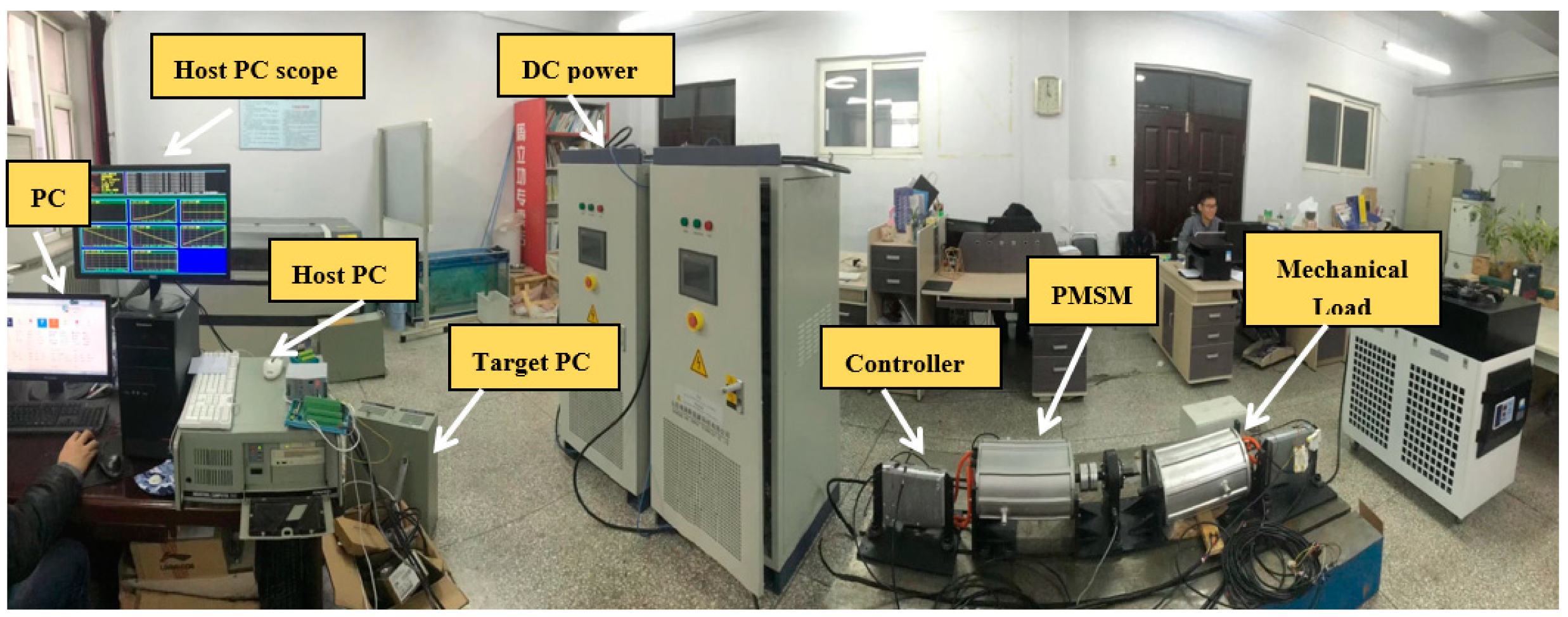

To verify the effectiveness of the method proposed in this paper, an xPC-Target-based hardware-in-the-loop testbed was built as shown in

Figure 3. The testbed includes two industrial control machines, motors, and controllers. One of the IPCs was used as the host PC and equipped with the PMSM control algorithm. The Simulink model was compiled into real-time operational C code and downloaded to the target PC. Another IPC was used as the xPC target PC, running DOS-dependent xPC real-time cores to execute RTW-compiled real-time C code. The two PCs connected and communicated through TCP/IP, and the developer downloaded the Simulink model to the target PC through the host PC. The two PCs could monitor/debug the operation of the target P in real time. The important parameters of the PMSM are given in

Table 1, and the controller section parameter selection was

,

,

, and

.

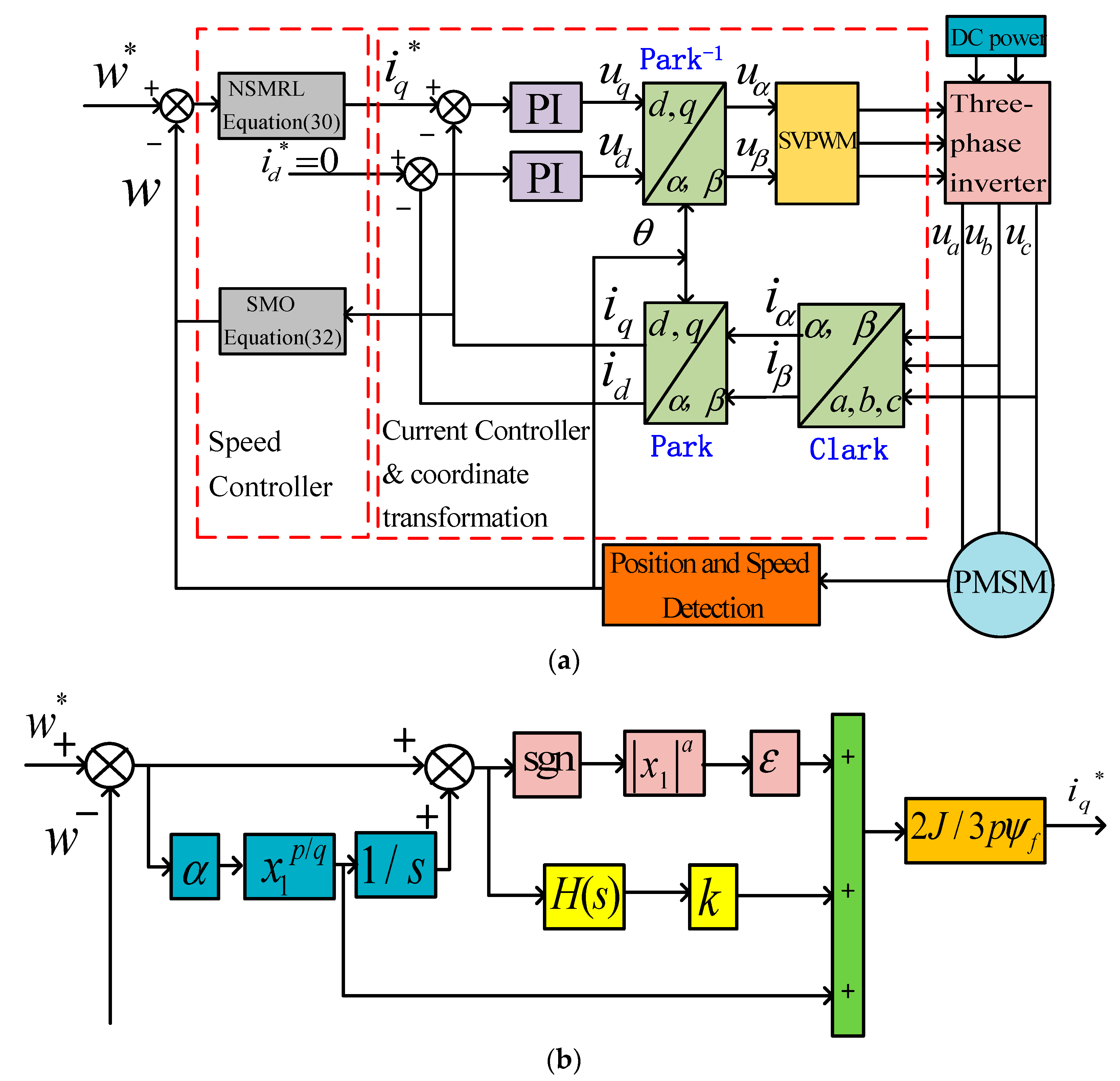

The block diagram of the PMSM speed regulation system is shown in

Figure 4a. The working principle of block diagram

Figure 4a is as follows: Firstly, through Clarke and Park transformation of the PMSM stator, the three-phase AC ia, ib, ic, the id excitation current and the iq torque current were obtained.

Secondly, the double closed-loop system structure was used to control the speed of PMSM. The inner loop is a current loop, and PI control can eliminate the current error of the d–q axis and improve current tracking performance. By adjusting the PI controller parameters, the motor can meet the demand of rapid current response under different working conditions. The outer loop is a speed loop, and it is easily affected by load and parameter perturbation in the actual operation of the motor.

Therefore, this paper proposes an improved exponential reaching law based on the sliding mode control strategy of the PMSM speed loop to achieve speed following at start-up, given speed, and load changes.

Finally, after the current loop was adjusted, the voltage command in the d–q axis was obtained. The SVPWM space voltage vector synthesis method was used to control the motor.

The block diagram of the speed control structure is shown in

Figure 4b. The state variable of the speed control system is the speed error, i.e.,

. The first half is the calculation of the sliding mode surface function s, and the second half is the improved exponential reaching law. This part constitutes the speed control.

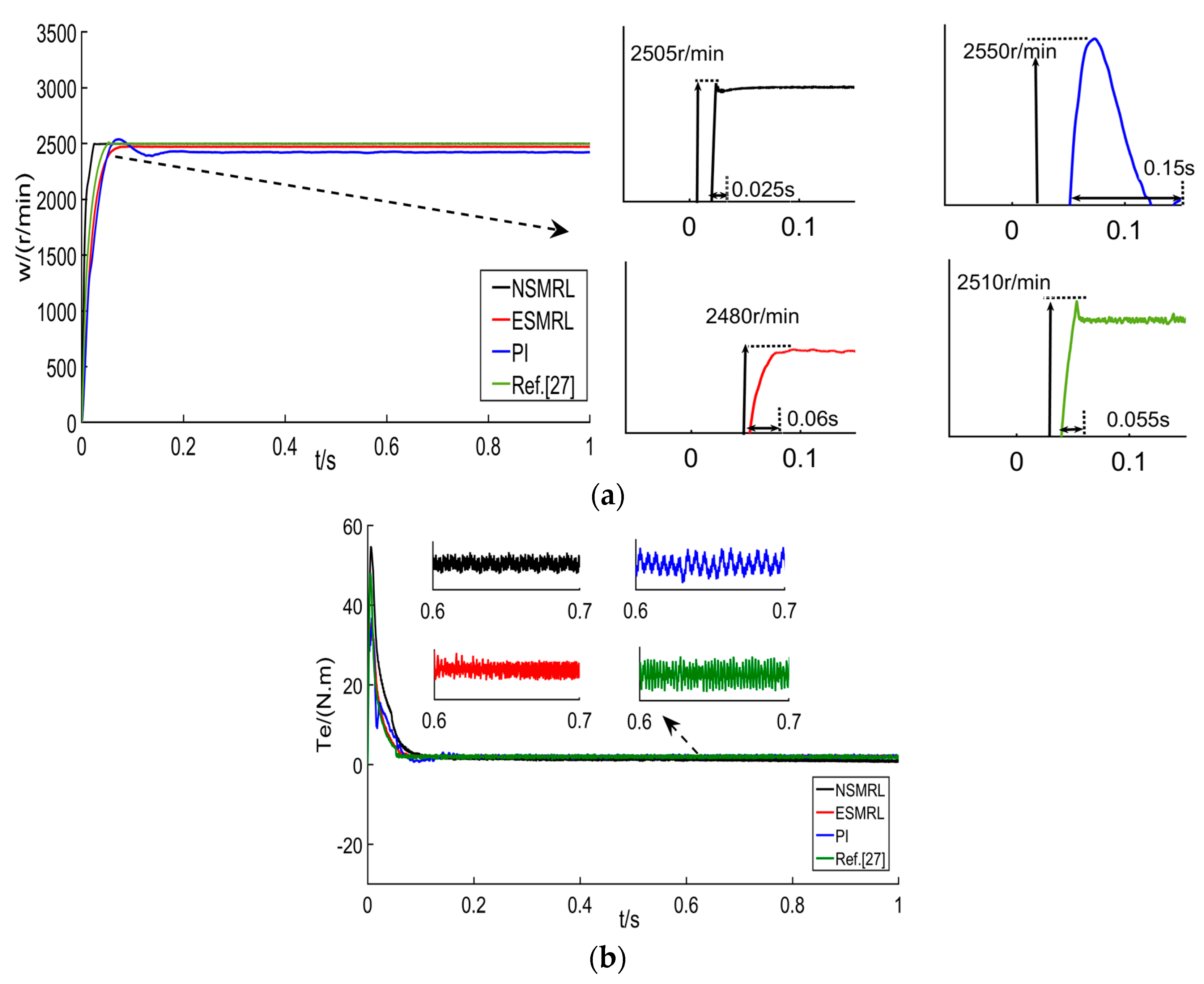

5.1. Start Process

The start speed performance of the PMSM under different reaching laws was compared in detail. The reference speed was 2500 r/min, and the torque responses under PI, NSMRL, ESMRL, and [

27] during the start transient process are shown in

Figure 4a,b.

It can be concluded from

Figure 5a,b that the start-up transient process NSMRL [

27], and PI had 0.2%, 0.4%, and 2% overshoot, respectively. Moreover, the settling process of the speed response under NSMRL, ESMRL, PI, and [

27] was 0.025 s, 0.06 s, 0.15 s, and 0.055 s, respectively. The speed response under Method 1 was 58.3%, 83.3%, and 54.5% faster than those of the ESMRL, PI, and [

27].

Figure 4b shows that the torque chattering phenomenon under NSMRL was smaller than those of ESMRL, PI, and [

27].

Furthermore,

Figure 6a,b show the reference speed of 1500 r/min and torque responses, respectively.

It can be concluded from

Figure 6a,b that the start-up transient process of PI, NSMRL, ESMRL, and [

27] had 17.3%, 0.16%, 14.7%, and 2.4% overshoot, respectively. NSMRL had a small fluctuation but still reached the reference speed without overshoot. The speed chattering phenomenon under NSMRL+SMO was smaller than that of ESMRL, PI, or [

27]. Furthermore,

Figure 6b shows that the torque chattering phenomenon under NSMRL was smaller than that of ESMRL, PI, and [

27]. The comparison data are listed in

Table 2.

5.2. Loading Process

The speed performance of the PMSM under PI, NSMRL, ESMRL, and [

27] were compared under loading conditions. The speed and torque responses were taken with a load of 20 Nm at a reference speed of 2500 r/min, as shown in

Figure 7a,b.

It can be concluded from

Figure 7a that because of the selection of the high speed of 2500 r/min and the large load of 20 Nm, both PI and ESMRL were unable to recover the reference speed after loading. In addition, as seen in

Figure 7a, the speed dropped under NSMRL and [

27] to 90 r/min and 240 r/min, respectively. Furthermore, the settling transient process of the speed responses at the loading point under NSMRL and [

27] were 0.13 s and 0.37 s, respectively.

Moreover,

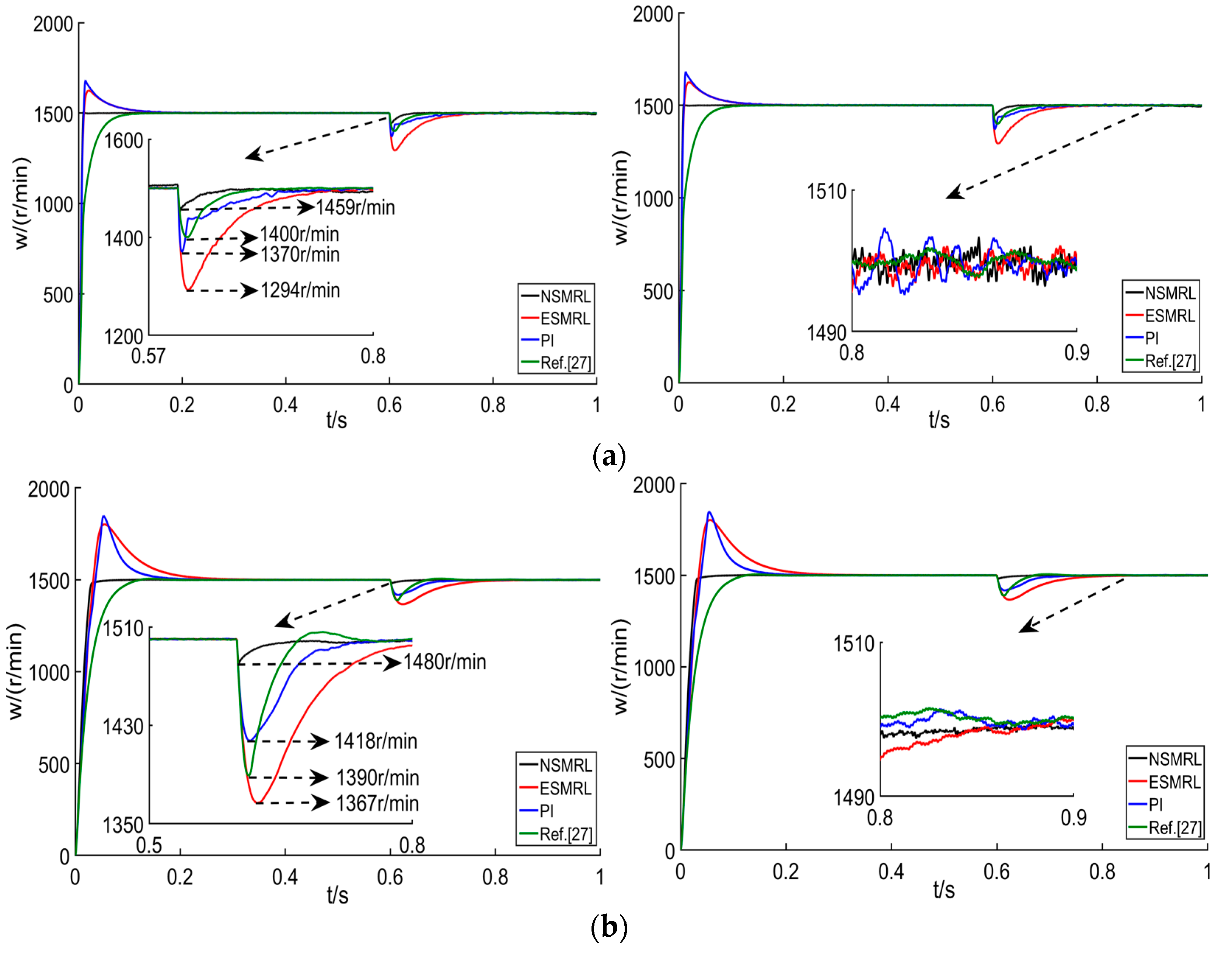

Figure 8a,b show the load of 10 Nm at the speed of 1500 r/min responses.

It can be concluded from

Figure 8a that the speed fluctuation range under PI, NSMRL, ESMRL, and [

27] was ±0.1 r/min, ±1 r/min, ±1.5 r/min, and ±0.3 r/min, respectively.

Figure 8b shows that the speed drops under NSMRL, EMERL, PI, and [

27] were 33 r/min, 190 r/min, 95 r/min, and 75 r/min, respectively. Therefore, the NSMRL had a small steady-state error range and low torque chattering. For more visual analysis, the comparison data are listed in

Table 3.

5.3. Variable Acceleration or Loading Process

The speed performances of the PMSM under PI, NSMRL, ESMRL, and [

27] were compared under variable acceleration and loading responses. The speed was from 2000 r/min to 2500 r/min, and the torque was from 15 Nm to 20 Nm, as shown in

Figure 9a,b.

It can be concluded from

Figure 9a that the start-up transient process of NSMRL and [

27] had 0.1% and 1.3% overshoot, respectively. In addition, when accelerating from 0.4 s to 2500 r/min, although there was a slight fluctuation in the speed of the NSMRL, the system could ensure that the motor reached the reference speed quickly, while the ESMRL and [

27] could not reach the reference speed.

Furthermore,

Figure 9b shows that the torque chattering phenomenon under NSMRL was smaller than that of ESMRL, and [

27].

5.4. Speed Process under Parameter Change

The speed performance of the PMSM under four control methods with 0.5 J and 2 J parameter changes under a load of 10 Nm are shown in

Figure 10a,b.

It can be concluded from

Figure 10a that the speed drop under NSMRL, EMERL, PI, and [

27] was 41 r/min, 206 r/min, 130 r/min, and 100 r/min, respectively. Although the speed fluctuation based on NSMRL was not the smallest at a steady-state, this method has a small speed drop and rapid recovery at a 0.5 J inertia mismatch. Furthermore,

Figure 10b show that the speed drop under NSMRL, EMERL, PI, and [

27] was 20 r/min, 133 r/min, 82 r/min, and 110 r/min, respectively. The comparison data are listed in

Table 4.

6. Conclusions

In this paper, nonsingular terminal sliding mode control of a PMSM based on an improved exponential reaching law was proposed to solve the problems of large overshooting speed, large torque pulsation at low speed, and slow dynamic response caused by sudden change of speed and load. Firstly, the improved exponential reaching law was applied to a nonlinear system, and the validity of the reaching law was verified by quantitative analysis from three aspects, trajectory motion of the sliding mode phase, the convergence process of the state variables, and the output curve. Secondly, an improved exponential reaching law-based PMSM speed loop sliding mode control strategy was proposed to realize speed following when upstart and speed load changed. Finally, considering the effects of uncertainty factors such as speed and disturbances under different working conditions, a SMO was designed using an improved exponential reaching law. The hardwire-in-loop experiment verifies that, compared with other methods, the SMO can realize no overshoot start, small torque pulsation at low speed, improved dynamic response when the speed changed, small load speed drop when the motor operated, and small torque pulsation when the torque changed. Therefore, this control strategy helps to improve the speed control quality and suppress torque pulsation.