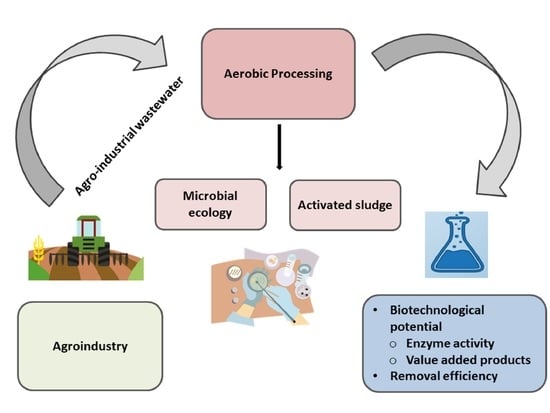

Biotreatment Potential and Microbial Communities in Aerobic Bioreactor Systems Treating Agro-Industrial Wastewaters

Abstract

:1. Introduction

2. Agricultural By-Products and Wastewaters

3. Quantities, Composition, and General Valorization Aspects of Agro-Industrial Wastewaters

- Case-by-case analysis of the production process and the characteristics of agro-industrial waste and residues, taking into account organic load, seasonality, chemical stability, and volume of produced wastewater

- Selection of one or more objectives, such as recycling of compounds and/or water, and recovery of molecules and components, as well as energy production.

- Assessment of possible technological and economic advantages in order to select appropriate disposal and exploitation alternatives.

- Identification of possible biotechnological approaches to achieve the initial goal.

4. Main Bioreactor Types, Nutrient Removal Processes, and Factors Affecting Systems Performance under Aerobic Conditions

5. Biotreatment of Agro-Industrial Wastewaters in Aerobic Bioreactor Systems

6. Biomass Valorization of Aerobic Biosystems Treating Agro-Industrial Wastewaters

7. Microbial Communities’ Structure in Aerobic Biosystems Treating Agro-Industrial Wastewaters

| System | Effluent /Method | HRT (d) | OLR (g COD/ L.d) | COD (g/L) | NH4+-N (g/L) | CODrem (%) | NH4+-Nrem (%) | Microbial Community | Reference |

|---|---|---|---|---|---|---|---|---|---|

| Activated sludge reactor | Winery/ Isolates | 2.1–4.4 | 0.4–5.9 | 0.8–12.8 | 0.001–2.0 | 90–98 | 100 | Bacteria: Bacillus sp., Pseudomons paucimobilis, Pseudomonas sp., Agrobacterium radiobacter, Acinetobacter. Fungi: Saccharomyces cerevisiae, Candida sp., Candida humicola, Candida kefyr, Trichosporum capitatum, Geotrichum penicillatum. | [101] |

| Aerobic batch reactors | Rice winery/ Illumina | 0.5 | 1.2, 2.4, 3.6 | 170 | 2.3 (as TN) | 91.8–93.2 | - | PHA-accumulating microorganisms: Zoogloea (5–41.1%), Rhodobacter (0.6–3.2%), Rubrivivax (0.1–2.6%), Leptothrix (0.1–2.5%), Burkholderiaceae, Comamonas, Haliscomenobacter, Rhodobacteraceae, Amaricoccus and Plasticicumulans. Under OLR of 2.4 g COD/L.d PHA-accumulating microorganisms covered 29.6% of the relative abundance. Phylum level: Proteobacteria, Bacteroidetes, Verrucomicrobia, Patescibacteria, Acidpbacteria, Chloroflexi. | [90] |

| Full-scale A/O | Dairy/ Clone library | 7 | - | 0.4–2.9 (as BOD) | 10.1 | 98 (as BOD) | 87 | Lactococcus, Veillonela, Atopobium, Olsenella, Zoogloea spp., Dechloromonas spp., Leptothrix spp. | [102] |

| Activated sludge system | Dairy/ Clone library | 5 | - | 14.9 | 0.8 | 77 (as BOD) | 88 | Phylum: Proteobacteria (55.1%), Bacteroidetes (15.4%), Actinobacteria (10.9%), Firmicutes (9.5%), TM7 (4.5%) Species Aerobic effluent: Thuera terpenica, Aeromicrobium marinum, Pseudomonas sp., Dyella japonica, Roseobacter sp., Sphingobacterium thalpophilum, Xanthomonas axonopodis, Dyella koreensis, UBA318142, AF507866. Aerobic storage: Thauera terpenica, Pirellula sp., Roseobacter sp., Rhodobacter praeacuta, AY570630, Xanthomonas axonopodis, Tissierella praeacuta, AY438740, Thermononas hydrothermalis, Petrimonas sulfuriphila | [34] |

| SBR | Dairy/ Illumina | 4 | - | 10.1 | 0.3 | 89 | 99 | Phyla: Proteobacteria (73–75%) Bacteroidetes (15–18%) Verrucomicrobia (0.6–3%) Planctomycetes (0.5–3%), Actinobacteria (1.2–1.8%), Chloroflexi (0.7–1%). Class: Alphaproteobacteria (43–68%), Betaproteobacteria (5–21%), Deltaroteobacteria (1.5–9%), Gammaproteobacteria (1–7%). Sphingobacteriia (10–11%), Flavobacteriia (3–6%). Genus: Terrimonas (2.6–4.6%), Thauera (2.2–12%), Nannocystis (2–6%), Flavitalea (2.7–6%), Hyphomonas (2.7%). | [103] |

| Immobilized cell bioreactor | Pepper processing/ Illumina- Isolates | 2.75 | 0.31–0.70 | 1.92 | 0.01 | 81.0–92.2 | 83.3–95.0 | AOB: Nitrosospira (1.45–9.21%), NOB: Nitrospira (1.73–7.53%), Nitrobacter (0.04–0.13%), AOB abundance (2.00–9.77%), NOB abundance (71.77–7.66%), Pirellula, Nakamurella, Nitrospira, Planctomyces (54.03 to 19.10%), Gemmata, Nitrosospira, Chitinophaga (from 4.40 to 24.20%). Fungal taxa: Rhizopus, Paramicrosporidium, Candida, Acaulospora, Neobulgaria, (94.93 and 87.64%). Isolated microorganisms: Paracoccus laeviglucosivorans, P. lutimaris, Microbacterium lacus, Microbacterium aurum, Sphingopyxis soli, Pseudoxanthomonas japonensis and P. mexicana, Gordonia hongkongensis, G. terrae, Oleiharenicola sp. | [5] |

| Immobilized cell bioreactor | Capper processing/ Illumina | 2.75–13.75 | 0.22–0.59 | 0.8–8.5 | 0.05–0.4 (as TKN) | 70 | 37–70 | Periods I and II: Pirellula, Amaricoccus and Planctomyces, Arenibacter (31.50 and 35.76%). Period III: Amaricoccus (16.14%), Planctomyces (12.39%), Defluviimonas (10.04%), Formosa (6.13%), Arenibacter (5.96%). Periods IV and V: Defluviimonas, Formosa, Muricauda, Arenibacter, Rhodobacter, Roseovarius (56.57 and 55.61%). Period VI: Halomonas (45.16%), Roseovarius (18.12%), Idiomarina (7.01%), Cyclobacterium (5.68%) | [4] |

| Full scale SBRs | Dairy/ DGGE- Pyrosequencing | - | 2.5 | 1.8 | 0.7 (as TN) | 94 | 95 (as TN) | Bacteria: Proteiniphilum (35.9%), Byssovorax (14.5%), Acidobacterium (10.1%), Zoogloea (8.3%), Rhodomicrobium (3,8%), Roseomonas (3.8%), Comamonas (3.8%), Leptothrix (2.1%), Hydrogenophaga (1.7%), Ingella (1.7%), Thiothrix (1.1%), Gemmatimonas (1.1%) DGGE: Candidatus Accumulibacter sp., Lysobacter brunescens, Thauera sp., Saprospiraceae, Xanthomonadaceae, Caldilineaceae, Micrococcineae (order Actinomycetales), Zoogloea caeni, Amaricoccus sp., Chiayiivirga flava, Candidatus Competibacter sp. | [94] |

| Full-scale WWTP | Coffee/ Isolates | - | - | 13.3 | 0.1 (as TN) | - | - | Bacteria: Acetobacter indonesiensis, Chrysobacterium bovls, Corynebacterium flavescens, Serratia marcescens, Enterobacter sp., Corynebacterium callunae, Moxarela osloensis, Arthrobacter woluwenis Fungi: Wickerhamomyces anomalus, Torulaspora delbrueckii, Kazachstania gamospora, Saturnispora gosingensis, Meyerozyma caribbica, Kazachstania exigua, Hanseniaspora uvarum, Pichia fermentans Filamentous fungi: Fusarium oxysporum, Geotrichum silvicola, Geotrichum candidum, Alternaria alternata | [98] |

| Full scale SBR | Winery/FISH- Clone library | 0.5 | - | 5–16 | - | - | - | FISH: Amaricoccus spp., Defluviicoccus cluster I and II, Candidatus ‘Alysiosphaera europaea’, Zoogloea sp., Azoarcus sp., type 0803, type 1851, Haliscomenobacter hydrosis. Clone library: Amaricoccus kaplicensis, A. capsulatus, A. veronensis, A. tamworthnensis, Rhodocyclus tenuis, Geminococcus roseus, Tetracoccus cechii. | [92] |

| Jet loop reactor | Winery/ Isolates | 0.8–1 | - | 3.1–27.2 | 0.02–0.06 (as TKN) | 63–84 | - | Bacteria: Acinetobacter sp., Bacillus sp., Pseudomonas sp., Sphingomonas paucimobilis, Agrobacerium radiobacter Fungi: Blastoschizomyces capitalis, Candida sp., Saccharomyces cerevisiae | [96] |

| SBR | Olive mill/ Isolates | 30 | - | 75.1 | 0.6 (as TKN) | 60 | - | Phyla: Firmicutes (57.1%), Proteobacteria (35.2%), Actinobacteria (7.7%) Genera: Bacillus, Lysinibacillus, Brevibacillus, Paenibacillus, Roseomonas, Ochrobactrum, Pseudomonas, Klebsiella, Rhodococcus Species: Bacillus amyloliquefaciens (11 isolates), B. cereus (8 isolates), B. nealsonii (7 isolates), B. thioparans (4 isolates), B. thuringiensis (3 isolates), B. subtilis (1 isolate), Lysinibacillus macroids (6 isolates), Brevibacillus laterosporus (6 isolates), Paenibacillus xylanilyticus (6 isolates), Klebsiella oxytoca (6 isolates), Pseudomonas aeruginosa (1 isolate), Kocuria rosea (1 isolate), Cellulosimicrobium cellulans (1 isolate) | [95] |

8. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jenkins, D.; Wanner, J. (Eds.) Activated Sludge-100 Years and Counting; IWA Publishing: London, UK, 2014. [Google Scholar]

- Martinez-Burgos, W.J.; Bittencourt Sydney, E.; Bianchi Pedroni Medeiros, A.; Magalhães, A.I.; de Carvalho, J.C.; Karp, S.G.; Soccol, C.R. Agro-industrial wastewater in a circular economy: Characteristics, impacts and applications for bioenergy and biochemicals. Bioresour. Technol. 2021, 341, 125795. [Google Scholar] [CrossRef] [PubMed]

- Villa-Montoya, A.C.; Ferro, M.I.T.; de Oliveira, R.A. Removal of phenols and methane production with coffee processing wastewater supplemented with phosphorous. Int. J. Environ. Sci. Technol. 2017, 14, 61–74. [Google Scholar] [CrossRef]

- Zerva, I.; Remmas, N.; Melidis, P.; Ntougias, S. Biotreatment efficiency, hydrolytic potential and bacterial community dynamics in an immobilized cell bioreactor treating caper processing wastewater under highly saline conditions. Bioresour. Technol. 2021, 325, 124694. [Google Scholar] [CrossRef]

- Zerva, I.; Remmas, N.; Melidis, P.; Sylaios, G.; Stathopoulou, P.; Tsiamis, G.; Ntougias, S. Biotreatment, microbial community structure and valorization potential of pepper processing wastewater in an immobilized cell bioreactor. Waste Biomass Valorization 2022, 13, 1431–1447. [Google Scholar] [CrossRef]

- Tanaka, Y.; Yatagai, A.; Masujima, H.; Waki, M.; Yokoyama, H. Autotrophic denitrification and chemical phosphate removal of agro-industrial wastewater by filtration with granular medium. Bioresour. Technol. 2017, 98, 787–791. [Google Scholar] [CrossRef]

- Usubiaga, A.; Butnar, I.; Schepelmann, P. Wasting food, wasting resources: Potential environmental savings through food waste reductions. J. Ind. Ecol. 2018, 22, 574–584. [Google Scholar] [CrossRef]

- Kosseva, M.R. Processing of food wastes. Adv. Food Nutr. Res. 2009, 58, 57–136. [Google Scholar]

- Leite, P.; Sousa, D.; Fernandes, H.; Ferreira, M.; Costa, A.R.; Filipe, D.; Salgado, J.M. Recent advances in production of lignocellulolytic enzymes by solid-state fermentation of agro-industrial wastes. Curr. Opin. Green Sustain. Chem. 2021, 27, 100407. [Google Scholar] [CrossRef]

- Ravindran, R.; Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. A review on bioconversion of agro-industrial wastes to industrially important enzymes. Bioengineering 2018, 5, 93. [Google Scholar] [CrossRef]

- European Union. Available online: https://food.ec.europa.eu/safety/food-waste_en (accessed on 1 August 2022).

- Food and Agriculture Organization. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 1 August 2022).

- European Commission. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 1 August 2022).

- Food Loss and Waste Protocol. Available online: https://flwprotocol.org/ (accessed on 1 August 2022).

- Blakeney, M. Food Loss and Food Waste: Causes and Solutions; Edward Elgar Publishing: Cheltenham, UK, 2019; pp. 1–204. [Google Scholar]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial wastes and their utilization using solid state fermentation: A review. Bioresour. Bioprocess. 2018, 5, 35–42. [Google Scholar] [CrossRef]

- El-Tayeb, T.S.; Abdelhafez, A.A.; Ali, S.H.; Ramadan, E.M. Effect of acid hydrolysis and fungal biotreatment on agro-industrial wastes for obtainment of free sugars for bioethanol production. Braz. J. Microbiol. 2012, 43, 1523–1535. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Motte, J.C.; Trably, E.; Escudié, R.; Hamelin, J.; Steyer, J.P.; Bernet, N.; Delgenes, J.P.; Dumas, C. Total solids content: A key parameter of metabolic pathways in dry anaerobic digestion. Biotechnol. Biofuels 2013, 6, 164. [Google Scholar] [CrossRef] [PubMed]

- Alayu, E.; Yirgu, Z. Advanced technologies for the treatment of wastewaters from agro-processing industries and cogeneration of by-products: A case of slaughterhouse, dairy and beverage industries. Int. J. Environ. Sci. Technol. 2018, 15, 1581–1596. [Google Scholar] [CrossRef]

- Rezzadori, K.; Benedetti, S.; Amante, E.R. Proposals for the residues recovery: Orange waste as raw material for new products. Food Bioprod. Processing 2012, 90, 606–614. [Google Scholar] [CrossRef]

- Christofoletti, C.A.; Escher, J.P.; Correia, J.E.; Marinho, J.F.U.; Fontanetti, C.S. Sugarcane vinasse: Environmental implications of its use. Waste Manag. 2013, 33, 2752–2761. [Google Scholar] [CrossRef]

- Ahmed, Y.; Yaakob, Z.; Akhtar, P.; Sopian, K. Production of biogas and performance evaluation of existing treatment processes in palm oil mill effluent (POME). Renew. Sustain. Energy Rev. 2015, 42, 1260–1278. [Google Scholar] [CrossRef]

- Tran, T.; Da, G.; Moreno-Santander, M.A.; Vélez-Hernández, G.A.; Giraldo-Toro, A.; Piyachomkwan, K.; Dufour, D. A comparison of energy use, water use and carbon footprint of cassava starch production in Thailand, Vietnam and Colombia. Resour. Conserv. Recycl. 2015, 100, 31–40. [Google Scholar] [CrossRef]

- Zema, D.A.; Calabro, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Wastewater management in citrus processing industries: An overview of advantages and limits. Water 2019, 11, 2481. [Google Scholar] [CrossRef]

- Akpomie, O.O.; Buzugbe, H.S.; Eze, P.M. Effect of brewery effluent on the microbiological quality of Ikpoba River and surrounding borehole waters in Benin City, Nigeria. Microbiol. Res. J. Int. 2014, 5, 76–82. [Google Scholar] [CrossRef]

- Vergine, P.; Salerno, C.; Libutti, A.; Beneduce, L.; Gatta, G.; Berardi, G.; Pollice, A. Closing the water cycle in the agro-industrial sector by reusing treated wastewater for irrigation. J. Clean. Prod. 2017, 164, 587–596. [Google Scholar] [CrossRef]

- Choi, H. Effect of mg-sericite flocculant for treatment of brewery wastewater. Appl. Clay Sci. 2015, 115, 145–149. [Google Scholar] [CrossRef]

- Tonhato Junior, A.; Hasan, S.D.M.; Sebastien, N.Y. Optimization of Coagulation/Flocculation treatment of brewery wastewater employing organic flocculant based of vegetable tannin. Water Air Soil Pollut. 2019, 230, 202. [Google Scholar] [CrossRef]

- Xu, S.; Zhu, J.; Meng, Z.; Li, W.; Ren, S.; Wang, T. Hydrogen and methane production by co-digesting liquid swine manure and brewery wastewater in a two-phase system. Bioresour. Technol. 2019, 293, 122041. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Liu, Y.; Liu, K.; Hu, L.; Yang, J.; Wang, X.; Wang, R. Bacterial community composition of internal circulation reactor at different heights for large-scale brewery wastewater treatment. Bioresour. Technol. 2021, 331, 125027. [Google Scholar] [CrossRef]

- Auphimai, C.; Rukruam, W.; Chaiprasert, P. Efficacies of various inoculum sources on methane production from agro-industrial wastewaters. Energy Procedia 2014, 52, 167–172. [Google Scholar] [CrossRef]

- Lucas, S.D.M.; Peixoto, G.; Mockaitis, G.; Zaiat, M.; Gomes, S.D. Energy recovery from agro-industrial wastewaters through biohydrogen production: Kinetic evaluation and technological feasibility. Renew. Energy 2015, 75, 496–504. [Google Scholar] [CrossRef]

- Fleck, L.; Tavares, M.H.; Eyng, E.; Andrade, M.A.D.M.; Frare, L.M. Optimization of anaerobic treatment of cassava processing wastewater. Eng. Agrícola 2017, 37, 574–590. [Google Scholar] [CrossRef]

- Jiang, Q.; Xin, Y.; Jiang, Y.; Huang, L.; Shen, P. Improving the efficiency of anaerobic digestion of molasses alcohol wastewater using cassava alcohol wastewater as a mixed feedstock. Bioresour. Technol. 2022, 344, 126179. [Google Scholar] [CrossRef]

- Demirer, G.N.; Duran, M.; Güven, E.; Ugurlu, O.; Tezel, U.; Ergüder, T.H. Anaerobic treatability and biogas production potential studies of different agro-industrial wastewaters in Turkey. Biodegradation 2000, 11, 401–405. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Gypakis, A.; Kyriakou, A.; Lasaridi, K.; Manios, T. Pilot-scale anaerobic co-digestion of sewage sludge with agro-industrial by-products for increased biogas production of existing digesters at wastewater treatment plants. Waste Manag. 2017, 59, 362–370. [Google Scholar] [CrossRef]

- Cruz-Salomón, A.; Ríos-Valdovinos, E.; Pola-Albores, F.; Meza-Gordillo, R.; Lagunas-Rivera, S.; Ruíz-Valdiviezo, V.M. Anaerobic treatment of agro-industrial wastewaters for COD removal in expanded granular sludge bed bioreactor. Biofuel Res. J. 2017, 4, 715–720. [Google Scholar] [CrossRef]

- Thanos, D.; Maragkaki, A.; Venieri, D.; Fountoulakis, M.; Manios, T. Enhanced Biogas Production in Pilot Digesters Treating a Mixture of Olive Mill Wastewater and Agro-industrial or Agro-livestock By-Products in Greece. Waste Biomass Valorization 2021, 12, 135–143. [Google Scholar] [CrossRef]

- Sounni, F.; Elgnaoui, Y.; El Bari, H.; Merzouki, M.; Benlemlih, M. Effect of mixture ratio and organic loading rate during anaerobic co-digestion of olive mill wastewater and agro-industrial wastes. Biomass Convers. Biorefinery 2021, 11, 1–7. [Google Scholar] [CrossRef]

- Andiloro, S.; Bombino, G.; Tamburino, V.; Zema, D.A.; Zimbone, S.M. Aerated lagooning of agro-industrial wastewater: Depuration performance and energy requirements. J. Agric. Eng. 2013, 44, 827–832. [Google Scholar] [CrossRef]

- Guzmán, J.; Mosteo, R.; Ormad, M.P.; Ovelleiro, J.L. Combined photo-fenton-SBR processes for the treatment of wastewater from the citrus processing industry. J. Agric. Food Chem. 2015, 63, 391–397. [Google Scholar] [CrossRef]

- Guzmán, J.; Mosteo, R.; Sarasa, J.; Alba, J.A.; Ovelleiro, J.L. Evaluation of solar photo-fenton and ozone based processes as citrus wastewater pre-treatments. Sep. Purif. Technol. 2016, 164, 155–162. [Google Scholar] [CrossRef]

- Corsino, S.F.; Di Trapani, D.; Torregrossa, M.; Viviani, G. Aerobic granular sludge treating high strength citrus wastewater: Analysis of pH and organic loading rate effect on kinetics, performance and stability. J. Environ. Manag. 2018, 214, 23–35. [Google Scholar] [CrossRef]

- Kulandaivelu, V.; Bhat, R. Changes in the physico-chemical and biological quality attributes of soil following amendment with untreated coffee processing wastewater. Eur. J. Soil Biol. 2012, 50, 39–43. [Google Scholar] [CrossRef]

- Alemayehu, Y.A.; Asfaw, S.L.; Tirfie, T.A. Management options for coffee processing wastewater. A review. J. Mater. Cycles Waste Manag. 2020, 22, 454–469. [Google Scholar] [CrossRef]

- Samuel, Z.A. Treatment of combined coffee processing wastewater using constructed wetland/Cyperus ustulatus and typha latifolia plants process. Glob. Nest J. 2021, 23, 429–433. [Google Scholar]

- Sujatha, G.; Shanthakumar, S.; Chiampo, F. UV light-irradiated photocatalytic degradation of coffee processing wastewater using TiO2 as a catalyst. Environments 2020, 7, 47. [Google Scholar] [CrossRef]

- Fountoulakis, M.S.; Drakopoulou, S.; Terzakis, S.; Georgaki, E.; Manios, T. Potential for methane production from typical Mediterranean agro-industrial by-products. Biomass Bioenergy 2008, 32, 155–161. [Google Scholar] [CrossRef]

- Lucas, M.S.; Peres, J.A. Treatment of olive mill wastewater by a combined process: Fenton’s reagent and chemical coagulation. J. Environ. Sci. Health-Part A Toxic/Hazard. Subst. Environ. Eng. 2009, 44, 198–205. [Google Scholar] [CrossRef] [PubMed]

- Dias, B.; Lopes, M.; Ramõa, R.; Pereira, A.S.; Belo, I. Candida tropicalis as a promising oleaginous yeast for olive mill waste water bioconversion. Energies 2021, 14, 640. [Google Scholar] [CrossRef]

- Kamyab, H.; Md Din, M.F.; Ponraj, M.; Keyvanfar, A.; Rezania, S.; Taib, S.M.; Abd Majid, M.Z. Isolation and screening of microalgae from agro-industrial wastewater (POME) for biomass and biodiesel sources. Desalin. Water Treat. 2016, 57, 29118–29125. [Google Scholar] [CrossRef]

- Shak, K.P.Y.; Wu, T.Y. Synthesis and characterization of a plant-based seed gum via etherification for effective treatment of high-strength agro-industrial wastewater. Chem. Eng. J. 2017, 307, 928–938. [Google Scholar] [CrossRef]

- Aka, B.E.Z.; Djeni, T.N.; Amoikon, S.L.T.; Kannengiesser, J.; Ouazzani, N.; Dje, M.K. High-throughput 16S rRNA gene sequencing of the microbial community associated with palm oil mill effluents of two oil processing systems. Sci. Rep. 2021, 11, 13232. [Google Scholar] [CrossRef]

- Nasrullah, M.; Ansar, S.; Krishnan, S.; Singh, L.; Peera, S.G.; Zularisam, A.W. Electrocoagulation treatment of raw palm oil mill effluent: Optimization process using high current application. Chemosphere 2022, 299, 134387. [Google Scholar] [CrossRef]

- Hernández, D.; Riaño, B.; Coca, M.; García-González, M.C. Treatment of agro-industrial wastewater using microalgae-bacteria consortium combined with anaerobic digestion of the produced biomass. Bioresour. Technol. 2013, 135, 598–603. [Google Scholar] [CrossRef]

- Muniraj, I.K.; Xiao, L.; Hu, Z.; Zhan, X.; Shi, J. Microbial lipid production from potato processing wastewater using oleaginous filamentous fungi Aspergillus oryzae. Water Res. 2013, 47, 3477–3483. [Google Scholar] [CrossRef]

- Antwi, P.; Li, J.; Boadi, P.O.; Meng, J.; Shi, E.; Deng, K.; Bondinuba, F.K. Estimation of biogas and methane yields in an UASB treating potato starch processing wastewater with backpropagation artificial neural network. Bioresour. Technol. 2017, 228, 106–115. [Google Scholar] [CrossRef] [PubMed]

- İnce, E.; İnce, M.; Önkal Engin, G. Comparison of thermophilic and mesophilic anaerobic treatments for potato processing wastewater using a contact reactor. Glob. Nest J. 2017, 19, 318–326. [Google Scholar]

- Bouchareb, R.; Bilici, Z.; Dizge, N. Potato processing wastewater treatment using a combined process of chemical coagulation and membrane filtration. Clean Soil Air Water 2021, 49, 2100017. [Google Scholar] [CrossRef]

- Daskalaki, V.M.; Marakas, H.; Mantzavinos, D.; Katsaounis, A.; Gikas, P. Use of seawater for the boron-doped diamond electrochemical treatment of diluted vinasse wastewater. Water Sci. Technol. 2013, 68, 2344–2350. [Google Scholar] [CrossRef]

- Petta, L.; De Gisi, S.; Casella, P.; Farina, R.; Notarnicola, M. Evaluation of the treatability of a winery distillery (vinasse) wastewater by UASB, anoxic-aerobic UF-MBR and chemical precipitation/adsorption. J. Environ. Manag. 2017, 201, 177–189. [Google Scholar] [CrossRef]

- García-Depraect, O.; Valdez-Vázquez, I.; Rene, E.R.; Gómez-Romero, J.; López-López, A.; León-Becerril, E. Lactate- and acetate-based biohydrogen production through dark co-fermentation of tequila vinasse and nixtamalization wastewater: Metabolic and microbial community dynamics. Bioresour. Technol. 2019, 282, 236–244. [Google Scholar] [CrossRef]

- Santos, C.; Lucas, M.S.; Dias, A.A.; Bezerra, R.M.F.; Peres, J.A.; Sampaio, A. Winery wastewater treatment by combination of Cryptococcus laurentii and fenton’s reagent. Chemosphere 2014, 117, 53–58. [Google Scholar] [CrossRef]

- Moreira, F.C.; Boaventura, R.A.R.; Brillas, E.; Vilar, V.J.P. Remediation of a winery wastewater combining aerobic biological oxidation and electrochemical advanced oxidation processes. Water Res. 2015, 75, 95–108. [Google Scholar] [CrossRef]

- Rodríguez-Chueca, J.; Amor, C.; Silva, T.; Dionysiou, D.D.; Li Puma, G.; Lucas, M.S.; Peres, J.A. Treatment of winery wastewater by sulphate radicals: HSO5−/transition metal/UV-A LEDs. Chem. Eng. J. 2017, 310, 473–483. [Google Scholar] [CrossRef]

- Amor, C.; Rodríguez-Chueca, J.; Fernandes, J.L.; Domínguez, J.R.; Lucas, M.S.; Peres, J.A. Winery wastewater treatment by sulphate radical based-advanced oxidation processes (SR-AOP): Thermally vs UV-assisted persulphate activation. Process Saf. Environ. Prot. 2019, 122, 94–101. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Matos, C.C.; Lucas, M.S.; Peres, J.A. Combination of coagulation–flocculation–decantation and ozonation processes for winery wastewater treatment. Int. J. Environ. Res. Public Health 2021, 18, 8882. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Barragán-Huerta, B.E.; Fíla, V.; Denis, P.C.; Ruby-Figueroa, R. Current role of membrane technology: From the treatment of agro-industrial by-products up to the valorization of valuable compounds. Waste Biomass Valorization 2018, 9, 513–529. [Google Scholar] [CrossRef]

- Tatoulis, T.I.; Zapantiotis, S.; Frontistis, Z.; Akratos, C.S.; Tekerlekopoulou, A.G.; Pavlou, S.; Vayenas, D.V. A hybrid system comprising an aerobic biological process and electrochemical oxidation for the treatment of black table olive processing wastewaters. Int. Biodeterior. Biodegrad. 2016, 109, 104–112. [Google Scholar] [CrossRef]

- Vergine, P.; Salerno, C.; Berardi, G.; Pappagallo, G.; Pollice, A. The self-forming dynamic membrane BioReactor (SFD MBR) as a suitable technology for agro-industrial wastewater treatment. New Biotechnol. 2020, 56, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Carucci, A.; Cappai, G.; Erby, G.; Milia, S. Aerobic granular sludge formation in a sequencing batch reactor treating agro-industrial digestate. Environ. Technol. 2021, 42, 3932–3941. [Google Scholar] [CrossRef]

- Levett, K.J.; Vanderzalm, J.L.; Page, D.W.; Dillon, P.J. Factors affecting the performance and risks to human health of on-site wastewater treatment systems. Water Sci. Technol. 2010, 62, 1499–1509. [Google Scholar] [CrossRef]

- Seviour, R.; Nielsen, P.H. (Eds.) Microbial Ecology of Activated Sludge; IWA Publishing: London, UK, 2010. [Google Scholar]

- Ibarbalz, F.M.; Figuerola, E.L.; Erijman, L. Industrial activated sludge exhibit unique bacterial community composition at high taxonomic ranks. Water Res. 2013, 47, 3854–3864. [Google Scholar] [CrossRef]

- Eusébio, A.; Mateus, M.; Baeta-Hall, L.; Almeida-Vara, E.; Duarte, J.C. Microflora evaluation of two agro-industrial effluents treated by the JACTO jet-loop type reactor system. Water Sci. Technol. 2005, 51, 107–112. [Google Scholar] [CrossRef]

- Ochando-Pulido, J.M.; Stoller, M.; Martinez-Ferez, A. Boundary flux modelling for purification optimization of differently-pretreated agro-industrial wastewater with nanofiltration. Sep. Purif. Technol. 2018, 193, 147–154. [Google Scholar] [CrossRef]

- Davididou, K.; Frontistis, Z. Advanced oxidation processes for the treatment of winery wastewater: A review and future perspectives. J. Chem. Technol. Biotechnol. 2021, 96, 2436–2450. [Google Scholar] [CrossRef]

- Riffat, R.; Husnain, T. Fundamentals of Wastewater Treatment and Engineering; CRC Press: Boca Raton, FL, USA, 2013; pp. 1–324. [Google Scholar]

- Rajagopal, R.; Saady, N.M.C.; Torrijos, M.; Thanikal, J.V.; Hung, Y. Sustainable agro-food industrial wastewater treatment using high rate anaerobic process. Water 2013, 5, 292–311. [Google Scholar] [CrossRef]

- Meneses-Jácome, A.; Diaz-Chavez, R.; Velásquez-Arredondo, H.I.; Cárdenas-Chávez, D.L.; Parra, R.; Ruiz-Colorado, A.A. Sustainable energy from agro-industrial wastewaters in latin-america. Renew. Sustain. Energy Rev. 2016, 56, 1249–1262. [Google Scholar] [CrossRef]

- Petruccioli, M.; Duarte, J.C.; Federici, F. High-rate aerobic treatment of winery wastewater using bioreactors with free and immobilized activated sludge. J. Biosci. Bioeng. 2000, 90, 381–386. [Google Scholar] [CrossRef]

- Roveroto, G.P.; Teles, J.C.; Vuitik, G.A.; Batista, J.S.D.S.; Barana, A.C. Craft brewery wastewater treatment: A fixed-bed single-batch reactor with intermittent aeration to remove COD and TN. Braz. Arch. Biol. Technol. 2021, 64, 1–14. [Google Scholar] [CrossRef]

- Zema, D.A.; Andiloro, S.; Bombino, G.; Tamburino, V.; Sidari, R.; Caridi, A. Depuration in aerated ponds of citrus processing wastewater with a high concentration of essential oils. Environ. Technol. 2012, 33, 1255–1260. [Google Scholar] [CrossRef] [PubMed]

- Moore, A.W.; Zytner, R.G.; Chang, S. Potential water reuse for high strength fruit and vegetable processor wastewater with an MBR. Water Environ. Res. 2016, 88, 852–870. [Google Scholar] [CrossRef]

- International Coffee Organization. Available online: https://www.ico.org/new_historical.asp?section=Statistics (accessed on 10 August 2022).

- Rossmann, M.; de Matos, A.T.; Abreu, E.C.; e Silva, F.F.; Borges, A.C. Performance of constructed wetlands in the treatment of aerated coffee processing wastewater: Removal of nutrients and phenolic compounds. Ecol. Eng. 2012, 49, 264–269. [Google Scholar] [CrossRef]

- Coelho, A.L.S.; Orlandelli, R.C. Immobilized microbial lipases in the food industry: A systematic literature review. Crit. Rev. Food Sci. Nutr. 2020, 61, 1689–1703. [Google Scholar] [CrossRef]

- Sharari, M.; Roohani, M.; Jahan Latibari, A.; Guillet, A.; Aurousseau, M.; Sharari, A. Treatment of bagasse preparation effluent by phanerochaete chrysosporium immobilized on polyurethane foam: Enzyme production versus pollution removal. Ind. Crops Prod. 2013, 46, 226–233. [Google Scholar] [CrossRef]

- Mafakher, L.; Mirbagheri, M.; Darvishi, F.; Nahvi, I.; Zarkesh-Esfahani, H.; Emtiazi, G. Isolation of lipase and citric acid producing yeasts from agro-industrial wastewater. N. Biotechnol. 2010, 27, 337–340. [Google Scholar] [CrossRef]

- Fang, F.; Xu, R.; Huang, Y.; Wang, S.; Zhang, L.; Dong, J.; Cao, J. Production of polyhydroxyalkanoates and enrichment of associated microbes in bioreactors fed with rice winery wastewater at various organic loading rates. Bioresour. Technol. 2019, 292, 121978. [Google Scholar] [CrossRef] [PubMed]

- Inoue, D.; Fukuyama, A.; Ren, Y.; Ike, M. Optimization of aerobic dynamic discharge process for very rapid enrichment of polyhydroxyalkanoates-accumulating bacteria from activated sludge. Bioresour. Technol. 2021, 336, 125314. [Google Scholar] [CrossRef] [PubMed]

- McIlroy, S.J.; Speirs, L.B.M.; Tucci, J.; Seviour, R.J. In situ profiling of microbial communities in full-scale aerobic sequencing batch reactors treating winery waste in Australia. Environ. Sci. Technol. 2011, 45, 8794–8803. [Google Scholar] [CrossRef] [PubMed]

- Jachimowicz, P.; Cydzik-Kwiatkowska, A.; Szklarz, P. Effect of aeration mode on microbial structure and efficiency of treatment of TSS-rich wastewater from meat processing. Appl. Sci. 2020, 10, 7414. [Google Scholar] [CrossRef]

- Meunier, C.; Henriet, O.; Schroonbroodt, B.; Boeur, J.; Mahillon, J.; Henry, P. Influence of feeding pattern and hydraulic selection pressure to control filamentous bulking in biological treatment of dairy wastewaters. Bioresour. Technol. 2016, 221, 300–309. [Google Scholar] [CrossRef]

- Arous, F.; Jamdi, C.; Kmiha, S.; Khammassi, N.; Ayari, A.; Neifar, M.; Mechichi, T.; Jaouani, A. Treatment of olive mill wastewater through employing sequencing batch reactor: Performance and microbial diversity assessment. 3 Biotech 2018, 8, 481. [Google Scholar] [CrossRef]

- Eusébio, A.; Petruccioli, M.; Lageiro, M.; Federici, F.; Duarte, J.C. Microbial characterization of activated sludge in jet-loop bioreactors treating winery wastewaters. J. Ind. Microbiol. Biotechnol. 2004, 31, 29–34. [Google Scholar] [CrossRef]

- McGarvey, J.A.; Miller, W.G.; Zhang, R.; Ma, Y.; Mitloehner, F. Bacterial population dynamics in dairy waste during aerobic and anaerobic treatment and subsequent storage. Appl. Environ. Microbiol. 2007, 73, 193–202. [Google Scholar] [CrossRef]

- Pires, J.F.; Cardoso, L.S.; Schwan, R.F.; Silva, C.F. Diversity of microbiota found in coffee processing wastewater treatment plant. World J. Microbiol. Biotechnol. 2017, 33, 211. [Google Scholar] [CrossRef]

- Ganapathy, B.; Yahya, A.; Ibrahim, N. Bioremediation of palm oil mill effluent (POME) using indigenous meyerozyma guilliermondii. Environ. Sci. Pollut. Res. 2019, 26, 11113–11125. [Google Scholar] [CrossRef]

- Buratti, S.; Girometta, C.E.; Baiguera, R.M.; Barucco, B.; Bernardi, M.; De Girolamo, G.; Savino, E. Fungal diversity in two wastewater treatment plants in North Italy. Microorganisms 2022, 10, 1096. [Google Scholar] [CrossRef] [PubMed]

- Petruccioli, M.; Cardoso Duarte, J.; Eusebio, A.; Federici, F. Aerobic treatment of winery wastewater using a jet-loop activated sludge reactor. Process Biochem. 2002, 37, 821–829. [Google Scholar] [CrossRef]

- Hirota, K.; Yokota, Y.; Sekimura, T.; Uchiumi, H.; Guo, Y.; Ohta, H.; Yumoto, I. Bacterial communities in different locations, seasons and segments of a dairy wastewater treatment system consisting of six segments. J. Environ. Sci. 2016, 46, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Hanson, A.J.; Guho, N.M.; Paszczynski, A.J.; Coats, E.R. Community proteomics provides functional insight into polyhydroxyalkanoate production by a mixed microbial culture cultivated on fermented dairy manure. Appl. Microbiol. Biotechnol. 2016, 100, 7957–7976. [Google Scholar] [CrossRef]

| Agro-Industrial Wastewater | pH | BOD (g/L) | COD (g/L) | TS (g/L) | SS (g/L) | VSS (g/L) | TN/TP (g/L) | Phenols (g/L) | Oil and Grease/ Total Carbohydrates (g/L) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| Brewery | 5.1–10 | 2.0–5.0 | 3.6–49.5 | 1.7–38.9 | 0.7–5.7 | 38.9 | 0.07–0.17/0.07–0.06 | [27,28,29,30] | ||

| Caper processing | 6.8–7 | 1.5–4.0 | 2.2–8.4 | - | - | - | 0.12–0.35 | - | - | [4] |

| Cassava processing | 4.02–4.6 | 1.4–12.3 | 6.0–38.2 | 6.6–60.5 | - | 5.1–49.4 | 0.19–0.4/0.08–0.24 | - | 0.6/- | [31,32,33,34] |

| Cheese whey | 3.92–6.6 | 90.1 | 45.0–91.6 | 47.6–73.9 | 9.4 | 8.3–59.9 | 0.15–3.2 (TKN)/0.12–0.70 | 0.27 | - | [35,36,37,38,39] |

| Citrus processing | 3.21–3.8 | 4.7–6.6 | 2.3–32.1 | 16.5 | 1.2 | 15.1 | 0.15/0.013 | - | E.O. 0.04–1.0 | [32,40,41,42,43] |

| Coffee-processing | 3.50–4.4 | 4.3–37.9 | 7.6–45.9 | 3.8–19.5 | 2.9–8.6 | 1.9–8.2 | 0.27–0.7/0.01–0.04 | 0.05–0.28 | - | [37,44,45,46,47] |

| Olive mill | 4.0–5.7 | 10.2 | 36.7–299.0 | 38.9–94.9 | 24.7–42.8 | 23.2–83.2 | 0.1–0.6/0.06–0.2 | 0.54–11.0 | - | [35,36,38,39,48,49,50] |

| Palm oil mill | 4.11–4.8 | 0.32–15.6 | 25.5–86.2 | 20.0–60.1 | 12.3–35.3 | 17.5–50.2 | 0.5–1.1/0.09–0.35 | 0.26–0.46 | 2.0–42.8 | [31,51,52,53,54] |

| Pepper processing | 4.4 | 1.4 | 1.9 | - | - | - | 0.05 (TKN) 0.02(NH4+)/0.01 | - | - | [5] |

| Potato processing | 4.6–7.1 | 0.9–5.0 | 1.5–37.0 | 4.8–42.0 | 2.0–3.8 | 3.5–4.4 | 0.03–0.62/0.04–0.1 | - | - | [55,56,57,58,59] |

| Soyamilk | 4.1 | - | 7.3 | 4.7 | - | 4.1 | 0.3 | - | 0.8 | [31] |

| Vinasse | 3.6–4.5 | 14.4–54.8 | 44.7–131.0 | 52.2–64.9 | 4.5–29.0 | 48.5–49.8 | 0.2–1.6 /0.1–0.6 | 0.35–0.7 | -/25.1–47.30 | [37,60,61,62] |

| Winery | 3.6–4.9 | 0.15–8.0 | 0.5–15.9 | - | 0.08–2.4 | 0.07–1.6 | 0.06–0.2/0.01–0.055 | 0.03–0.2 | - | [48,63,64,65,66,67] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Remmas, N. Biotreatment Potential and Microbial Communities in Aerobic Bioreactor Systems Treating Agro-Industrial Wastewaters. Processes 2022, 10, 1913. https://0-doi-org.brum.beds.ac.uk/10.3390/pr10101913

Remmas N. Biotreatment Potential and Microbial Communities in Aerobic Bioreactor Systems Treating Agro-Industrial Wastewaters. Processes. 2022; 10(10):1913. https://0-doi-org.brum.beds.ac.uk/10.3390/pr10101913

Chicago/Turabian StyleRemmas, Nikolaos. 2022. "Biotreatment Potential and Microbial Communities in Aerobic Bioreactor Systems Treating Agro-Industrial Wastewaters" Processes 10, no. 10: 1913. https://0-doi-org.brum.beds.ac.uk/10.3390/pr10101913