A Case Study of Turbulent Free Jet Flows Issuing from Rectangular Slots on Process Performances and Quality of Hot-Air-Dried Apple

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material and Sample Preparation

2.2. Drying Processes

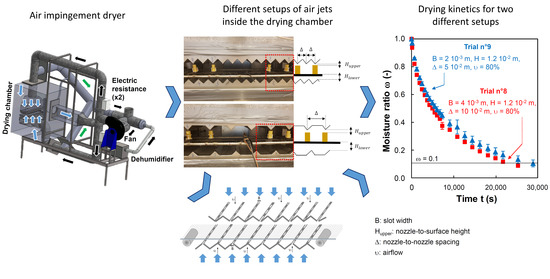

2.2.1. Air Impingement Drying

2.2.2. Oven Drying

2.2.3. Equilibrium Moisture Content and Dry Solids Content

2.3. Sorption Isotherms

2.4. Heat and Mass Transfer Parameters

2.4.1. Heat Transfer Coefficient

2.4.2. Mass Transfer Parameters

2.4.3. Goodness of Fit

2.5. Quality Attributes

2.5.1. Texture Analysis

2.5.2. Rehydration Ratio

2.6. Design of Experiments

3. Results and Discussion

3.1. Influence of Operating Parameters on the Drying Process Performances

3.1.1. Effect of Design Jet Parameters on Drying Time

3.1.2. Effect of Design Jet Parameters on Heat and Mass Transfer Coefficients

3.2. Influence of Operating Parameters on Quality Attributes of Dried Apple

3.2.1. Effect of Design Jet Parameters on the Apparent Moisture Diffusivity

3.2.2. Effect of Design Jet Parameters on Textural Properties

3.2.3. Effect of Design Jet Parameters on Functional Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schadle, E.R.; Burns, E.E.; Talley, L.J. Forced air drying of partially freeze-dried compressed carrot bars. J. Food Sci. 1983, 48, 193–196. [Google Scholar] [CrossRef]

- Yang, C.S.T.; Atallah, W.A. Effect of four drying methods on the quality of intermediate moisture lowbush blueberries. J. Food Sci. 1985, 50, 1233–1237. [Google Scholar] [CrossRef]

- Yongsawatdigul, J.; Gunasekaran, S. Microwave-vacuum drying of cranberries: Part II. Quality evaluation. J. Food Process Pres. 1996, 20, 145–156. [Google Scholar] [CrossRef]

- Lin, T.M.; Durance, T.D.; Scaman, C.H. Characterization of vaccum microwave, air and freeze dried carrot slices. Food Res. Int. 1998, 31, 111–117. [Google Scholar] [CrossRef]

- Xiao, H.W.; Bai, J.W.; Xie, L.; Sun, D.W.; Gao, Z.J. Thin-layer air impingement drying enhances drying rate of American ginseng (Panax quinquefolium L.) slices with quality attributes considered. Food Bioprod. Process. 2015, 94, 581–591. [Google Scholar] [CrossRef]

- Anderson, B.A.; Singh, R.P. Modeling the thawing of frozen foods using air impingement technology. Int. J. Refrig. 2006, 29, 233–240. [Google Scholar] [CrossRef]

- Mujumdar, A.S. Handbook of Industrial Drying, 4th ed.; CRC Press: Boca Raton, FL, USA, 2014; p. 1282. [Google Scholar]

- Xiao, H.W.; Mujumdar, A.S. Impingement drying: Application and future trends. In Drying Technologies for Foods, 1st ed.; Nema, P.K., Kaur, B.P., Mujumdar, A.S., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 279–299. [Google Scholar]

- Dewan, A.; Dutta, R.; Srinivasan, B. Recent trends in computational of turbulent jet impingement heat transfer. Heat. Transfer. Eng. 2012, 33, 447–460. [Google Scholar] [CrossRef]

- Hardisty, H.; Can, M. An experimental investigation into the effects of changes in the geometry of a slot nozzle on the heat transfer characteristics of an impinging air jet. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1983, 197, 7–15. [Google Scholar] [CrossRef]

- Can, M.; Etemoğlu, A.B.; Avci, A. Experimental study of convective heat transfer under arrays of impinging air jets from slots and circular holes. Heat. Mass. Transfer. 2002, 38, 251–259. [Google Scholar] [CrossRef]

- Etemoğlu, A.B.; Can, M. Performance studies of energy consumption for single and multiple nozzle systems under impinging air jets. Heat. Mass. Transfer. 2013, 49, 1057–1070. [Google Scholar] [CrossRef]

- Koç, B.; Kaymak-Ertekin, F. Response surface methodology and food processing applications. Gida 2010, 35, 63–70. [Google Scholar]

- Majdi, H.; Esfahani, J.A.; Mohebbi, M. Optimization of convective drying by response surface methodology. Comput. Electron. Agric. 2019, 156, 574–584. [Google Scholar] [CrossRef]

- Parthasarathi, S.; Anandharamakrishnan, C. Modeling of shrinkage, rehydration and textural changes for food structural analysis: A review. J. Food Process. Eng. 2014, 37, 199–210. [Google Scholar] [CrossRef]

- Hammami, C.; René, F.; Marin, M. Process-quality optimization of the vacuum freeze-drying of apple slices by the response surface method. Int. J. Food Sci. Technol. 1999, 34, 145–160. [Google Scholar] [CrossRef]

- Ben Haj Said, L.; Bellaghou, S.; Allaf, K. Optimization of instant pressure drop (DIC)—Assisted dehydrofreezing using mechanical texture measurement versus initial water content of apple. Food Bioprocess Technol. 2015, 8, 1102–1112. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Ah-Hen, K.; Chacana, M.; Vergara, J.; Martínez-Monzó, J.; García-Segovia, P.; Lemus-Mondaca, R.; Di Scala, K. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 2012, 132, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Sá, M.M.; Figueiredo, A.M.; Sereno, A.M. Glass transitions and state diagrams for fresh and processed apple. Thermochim. Acta 1999, 329, 31–38. [Google Scholar] [CrossRef]

- Moraes, M.A.; Rosa, G.S.; Pinto, L.A.A. Moisture sorption isotherms and thermodynamic properties of apple Fuji and garlic. Int. J. Food Sci. Technol. 2008, 43, 1824–1831. [Google Scholar] [CrossRef]

- Lomauro, C.J.; Bakshi, A.S.; Labuza, T.P. Evaluation of food moisture sorption isotherm equations. Part I: Fruit, vegetable and meat products. Lebensm. Wiss. Technol. 1985, 18, 111–117. [Google Scholar]

- Atlasbig.com. Available online: https://www.atlasbig.com/en-cn/countries-by-apple-production (accessed on 28 September 2021).

- Boy, V.; Liu, X.; Chamaa, M.A.; Lemée, Y.; Sabourin, C.; Lendormi, T.; Lanoisellé, J.L. Air impingement drying of digestate. Experimental and modelling study. Chem. Eng. Res. Des. 2019, 146, 436–448. [Google Scholar] [CrossRef]

- Boy, V.; Ben Khalifa, W.; Drévillon, L.; Lemée, Y.; Lendormi, T.; Lanoisellé, J.L. Air impingement and intermittent drying: Application to apple and to mango. Can. J. Chem. Eng. 2021, 99, 120–134. [Google Scholar] [CrossRef]

- De Boer, J.H. The Dynamical Character of Adsorption, 1st ed.; Oxford University Press: Oxford, UK, 1953; p. 239. [Google Scholar]

- Lide, D.R. Handbook of Chemistry and Physics, 82th ed.; CRC Press: Boca Raton, FL, USA, 2001–2002; p. 2661. [Google Scholar]

- Green, D.W.; Perry, R.H. Perry’s Chemical Engineers’ Handbook, 8th ed.; The Mc Graw-Hill Companies Inc.: New York, NY, USA, 2008; p. 2737. [Google Scholar]

- Agnelli, M.E.; Mascheroni, R.H. Cryomechanical freezing. A model for the heat transfer process. J. Food Eng. 2001, 47, 263–270. [Google Scholar] [CrossRef]

- Mohamed, I.O. An inverse lumped capacitance method for determination of heat transfer coefficients for industrial air blast chillers. Food Res. Int. 2008, 41, 404–410. [Google Scholar] [CrossRef]

- Geankoplis, C.J. Transport Processes and Unit Operations, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1993; p. 935. [Google Scholar]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford University Press: New York, NY, USA, 1975; p. 414. [Google Scholar]

- Bejaei, M.; Stanich, K.; Cliff, M.A. Modelling and classification of apple textural attributes using sensory, instrumental and compositional analyses. Foods 2021, 10, 384. [Google Scholar] [CrossRef]

- Fabani, M.P.; Román, M.C.; Rodriguez, R.; Mazza, G. Minimization of the adverse environmental effects of discarded onions by avoiding disposal through dehydration and food-use. J. Environ. Manag. 2020, 271, 110947. [Google Scholar] [CrossRef]

- Ndisya, J.; Mbuge, D.; Kulig, B.; Gitau, A.; Hensel, O.; Sturm, B. Hot air drying of purple-specled Cocoyam (Colocasia esculenta (L.) Schott) slices: Optimisation of drying conditions for improved product quality and energy savings. Therm. Sci. Eng. Progress. 2020, 18, 100557. [Google Scholar] [CrossRef]

- Contreras, C.; Martín-Esparza, M.E.; Chiralt, A.; Martínez-Navarrete, N. Influence of microwave application on convective drying: Effects on drying kinetics, and optical and mechanical properties of apple and strawberry. J. Food Eng. 2008, 88, 55–64. [Google Scholar] [CrossRef]

- Zhu, D.M.; Wang, Y.T.; Zhu, J.H. Heat transfer characteristics of multinozzle air impingement jet during die steel plate cooling progress. Adv. Mech. Eng. 2014, 7, 1–7. [Google Scholar] [CrossRef]

- Kaya, A.; Aydin, O.; Demirtaş, C. Drying kinetics of red delicious apple. Biosyst. Eng. 2007, 96, 517–524. [Google Scholar] [CrossRef]

- Doymaz, I. Effect of citric acid and blanching pre-treatments on drying and rehydration of Amasya red apples. Food Bioprod. Process. 2010, 88, 124–132. [Google Scholar] [CrossRef]

- ElGamal, R.; Kishk, S.; Al-Rejaie, S.; ElMasry, G. Incorporation of a solar tracking system for enhancing the performance of solar air heaters in drying apple slices. Renew Energ. 2021, 167, 676–684. [Google Scholar] [CrossRef]

- Cruz, A.C.; Guiné, R.P.F.; Gonçalves, J.C. Drying kinetics and product quality for convective drying of apples (cvs. Golden Delicious and Granny Smith). Int. J. Fruit Sci. 2015, 15, 54–78. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, Y. Effect of pulsed vacuum and ultrasound osmopretreatments on glass transition temperature, texture, microstructure and calcium penetration of dried apples (Fuji). LWT-Food Sci. Technol. 2008, 41, 1575–1585. [Google Scholar] [CrossRef]

- Boateng, I.D.; Yang, X.M.; Aly Tahany, A.A.; Li, Y.Y. Yolandani Drying methods affect organoleptic and physicochemical properties of rehydrated ginkgo seed slices. Ind. Crop. Prod. 2021, 160, 113166. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Changes in quality of microwave-treated agricultural products—A review. Biosyst. Eng. 2007, 98, 1–16. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Zura-Bravo, L.; Lemus-Mondaca, R.; Martinez-Monzó, J.; Quispe-Fuentes, I.; Puente, L.; Di Scala, K. Influence of drying temperature on dietary fibre, rehydration properties, texture and microstructure of Cape gooseberry (Physalis peruviana L.). J. Food Sci. Technol. 2015, 52, 2304–2311. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lewicki, P.P.; Wiczkowska, J. Rehydration of apple dried by different methods. Int. J. Food Prop. 2006, 9, 217–226. [Google Scholar] [CrossRef]

- Krokida, M.; Marinos-Kouris, D. Rehydration kinetics of dehydrated products. J. Food Eng. 2003, 57, 1–7. [Google Scholar] [CrossRef]

- Prawiranto, K.; Defraeye, T.; Derome, D.; Verboven, P.; Nicolai, B.; Carmeliet, J. New insights into the apple fruit dehydration process at the cellular scale by 3D continuum modeling. J. Food Eng. 2018, 239, 52–63. [Google Scholar] [CrossRef] [Green Version]

- Lewicki, P.P. Water as the determinant of food engineering properties. A review. J. Food Eng. 2004, 61, 483–495. [Google Scholar] [CrossRef]

- Saravacos, G.D. Effect of the drying method on the water sorption of dehydrated apple and potato. J. Food Sci. 1967, 32, 81–84. [Google Scholar] [CrossRef]

| Parameter | Level | |

|---|---|---|

| −1 | +1 | |

| Slot width B × 103 (m) | 2 | 4 |

| Nozzle-to-surface height H × 102 (m) | 1.2 | 2.4 |

| Nozzle-to-nozzle spacing Δ × 102 (m) | 5 | 10 |

| Airflow υ (%) | 80 | 99 |

| Trial Number | Factors | Responses | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Design Jet Parameters | Process Performances | Quality Attributes | ||||||||

| B × 103 (m) | H × 102 (m) | Δ × 102 (m) | υ (%) | t (s) | h (W m−2 K−1) | km × 104 (m s−1) | F (N) | W × 103 (N m) | RR (%) | |

| 1 | 2 | 1.2 | 10 | 80 | 4860 | 180 | 1.68 | 2.67 ± 0.48 | 38.39 ± 7.86 | 43.08 ± 1.22 |

| 2 | 2 | 1.2 | 10 | 99 | 6060 | 159 | 1.48 | 2.06 ± 0.50 | 30.34 ± 7.86 | 45.20 ± 2.46 |

| 3 | 2 | 2.4 | 10 | 99 | 5460 | 242 | 2.25 | 2.34 ± 1.01 | 30.81 ± 15.47 | 44.70 ± 0.15 |

| 4 | 2 | 2.4 | 10 | 80 | 4860 | 165 | 1.54 | 2.15 ± 0.31 | 32.75 ± 6.91 | 44.03 ± 1.59 |

| 5 | 4 | 2.4 | 10 | 80 | 5460 | 201 | 1.87 | 1.74 ± 0.48 | 26.62 ± 7.56 | 39.68 ± 5.07 |

| 6 | 4 | 2.4 | 10 | 99 | 5460 | 162 | 1.51 | 1.69 ± 0.50 | 25.55 ± 9.36 | 41.55 ± 0.30 |

| 7 | 4 | 1.2 | 10 | 99 | 5460 | 178 | 1.66 | 2.11 ± 0.96 | 26.93 ± 7.18 | 41.02 ± 4.33 |

| 8 | 4 | 1.2 | 10 | 80 | 4860 | 157 | 1.46 | 1.88 ± 0.32 | 27.31 ± 2.97 | 41.08 ± 4.24 |

| 9 | 2 | 1.2 | 5 | 80 | 6060 | 273 | 2.54 | 1.84 ± 0.91 | 24.70 ± 13.19 | 46.33 ± 0.89 |

| 10 | 2 | 1.2 | 5 | 99 | 4860 | 206 | 1.92 | 2.62 ± 0.54 | 32.49 ± 9.99 | 43.20 ± 2.86 |

| 11 | 2 | 2.4 | 5 | 99 | 4860 | 198 | 1.85 | 1.99 ± 0.32 | 29.21 ± 2.58 | 45.25 ± 5.03 |

| 12 | 2 | 2.4 | 5 | 80 | 4860 | 233 | 2.17 | 1.93 ± 0.48 | 27.81 ± 6.20 | 46.43 ± 4.34 |

| 13 | 4 | 2.4 | 5 | 80 | 5460 | 167 | 1.56 | 1.52 ± 0.33 | 22.27 ± 7.54 | 44.38 ± 2.50 |

| 14 | 4 | 2.4 | 5 | 99 | 5460 | 204 | 1.91 | 1.91 ± 0.32 | 27.50 ± 6.10 | 47.54 ± 2.22 |

| 15 | 4 | 1.2 | 5 | 99 | 5460 | 230 | 2.14 | 1.53 ± 0.49 | 21.88 ± 9.18 | 49.32 ± 1.95 |

| 16 | 4 | 1.2 | 5 | 80 | 4860 | 222 | 2.07 | 1.72 ± 0.18 | 27.08 ± 4.61 | 45.53 ± 2.76 |

| Parameter | Sum of Square | Df 1 | Mean Square | F-Ratio | p-Value | Estimated Effect | Optimum |

|---|---|---|---|---|---|---|---|

| t | |||||||

| B | 22,500 | 1 | 22,500 | 0.16 | 0.7004 | +75 | n.a 3 |

| H | 22,500 | 1 | 22,500 | 0.16 | 0.7004 | −75 | n.a |

| Δ | 22,500 | 1 | 22,500 | 0.16 | 0.7004 | +75 | n.a |

| υ | 202,500 | 1 | 202,500 | 1.42 | 0.2637 | +225 | n.a |

| B · H | 562,500 | 1 | 562,500 | 3.95 | 0.07822 | +375 | |

| Δ · υ | 562,500 | 1 | 562,500 | 3.95 | 0.0782 | +375 | |

| Total error | 1.28 × 106 | 9 | 142,500 | ||||

| Corrected total error | 2.68 × 106 | 15 | |||||

| R2 (%) | 52.11 | Standard error | 377 | ||||

| R2 adjusted for df (%) | 20.17 | Mean absolute error | 230 | ||||

| h | |||||||

| B | 1139 | 1 | 1139 | 1.40 | 0.2644 | −16.875 | n.a |

| H | 68.06 | 1 | 68.06 | 0.08 | 0.7785 | −4.125 | n.a |

| Δ | 5220 | 1 | 5220 | 6.41 | 0.0298 | −36.125 | n.a |

| υ | 22.56 | 1 | 22.56 | 0.03 | 0.8712 | −2.375 | n.a |

| H · Δ | 3164 | 1 | 3164 | 3.88 | 0.0771 | +28.125 | |

| Total error | 8148 | 10 | 8148 | ||||

| Corrected total error | 17,762 | 15 | |||||

| R2 (%) | 54.13 | Standard error | 28.55 | ||||

| R2 adjusted for df (%) | 31.19 | Mean absolute error | 19.06 | ||||

| km | |||||||

| B | 9.77 × 10−10 | 1 | 9.77 × 10−10 | 1.40 | 0.2643 | −1.56 × 10−5 | n.a |

| H | 5.26 × 10−11 | 1 | 5.26 × 10−11 | 0.08 | 0.7894 | −3.63 × 10−6 | n.a |

| Δ | 4.59 × 10−9 | 1 | 4.59 × 10−9 | 6.57 | 0.0282 | −3.39 × 10−5 | n.a |

| υ | 1.81 × 10−11 | 1 | 1.81 × 10−11 | 0.03 | 0.8754 | −2.13 × 10−6 | n.a |

| H · Δ | 2.68 × 10−9 | 1 | 2.68 × 10−9 | 3.84 | 0.0786 | +2.59 × 10−5 | |

| Total error | 6.98 × 10−9 | 10 | 6.98 × 10−9 | ||||

| Corrected total error | 1.53 × 10−8 | 15 | |||||

| R2 (%) | 54.36 | Standard error | 2.64 × 10−5 | ||||

| R2 adjusted for df (%) | 31.54 | Mean absolute error | 1.77 × 10−5 | ||||

| F | |||||||

| B | 0.7656 | 1 | 0.7656 | 12.34 | 0.0049 ** | −0.4375 | 4 × 10−3 |

| H | 0.0841 | 1 | 0.0841 | 1.36 | 0.2689 | −0.145 | 2.4 × 10−2 |

| Δ | 0.1560 | 1 | 0.1560 | 2.52 | 0.1410 | +0.1975 | 5 × 10−2 |

| υ | 0.04 | 1 | 0.04 | 0.64 | 0.4389 | +0.1 | 80 |

| Total error | 0.6822 | 11 | 0.0620 | ||||

| Corrected total error | 1.7280 | 15 | |||||

| R2 (%) | 60.52 | Standard error | 0.25 | ||||

| R2 adjusted for df (%) | 46.16 | Mean absolute error | 0.15 | ||||

| W | |||||||

| B | 1.07 × 10−4 | 1 | 1.07 × 10−4 | 13.56 | 0.0042 ** | −5.16 × 10−3 | 4 × 10−3 |

| H | 2.64 × 10−6 | 1 | 2.64 × 10−6 | 0.34 | 0.5751 | −8.13 × 10−4 | 2.4 × 10−2 |

| Δ | 4.13 × 10−5 | 1 | 4.13 × 10−5 | 5.25 | 0.0449 | +3.21 × 10−3 | 5 × 10−2 |

| υ | 3.31 × 10−7 | 1 | 3.31 × 10−7 | 0.04 | 0.8416 | −2.88 × 10−4 | 80 |

| Δ · υ | 2.68 × 10−5 | 1 | 2.68 × 10−5 | 3.41 | 0.0948 | −2.59 × 10−3 | |

| Total error | 7.86 × 10−5 | 10 | 7.86 × 10−5 | ||||

| Corrected total error | 2.56 × 10−4 | 15 | |||||

| R2 (%) | 69.32 | Standard error | 2.80 × 10−3 | ||||

| R2 adjusted for df (%) | 53.97 | Mean absolute error | 1.70 × 10−3 | ||||

| RR | |||||||

| B | 4.12 | 1 | 4.12 | 2.38 | 0.1570 | −1.015 | 4 × 10−3 |

| H | 0.09 | 1 | 0.09 | 0.05 | 0.8246 | −0.15 | 1.2 × 10−2 |

| Δ | 47.75 | 1 | 47.75 | 27.61 | 0.0005 ** | −3.455 | 5 × 10−2 |

| υ | 3.27 | 1 | 3.27 | 1.89 | 0.2020 | + 0.905 | 99 |

| Β · Δ | 23.14 | 1 | 23.14 | 13.38 | 0.0053 ** | −2.405 | |

| Β · υ | 6.60 | 1 | 6.60 | 3.82 | 0.0824 | + 1.285 | |

| Total error | 15.56 | 9 | 1.73 | ||||

| Corrected total error | 100.54 | 15 | |||||

| R2 (%) | 84.52 | Standard error | 1.31 | ||||

| R2 adjusted for df (%) | 74.20 | Mean absolute error | 0.81 | ||||

| Y | β0 | B | H | Δ | υ | B · H | Δ · υ | H · Δ | B · Δ | B · υ | Eq n° | R2 (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t | 11,087 | −525,000 | −100,000 | −69,158 | −47.37 | 3.13 × 10−7 | 789 | - | −1.76 × 10−10 | −3.33 × 10−10 | 15 | 52.11 |

| h | 422.00 | −8438 | −7375 | −2410 | −0.125 | - | - | 93,750 | - | - | 16 | 54.13 |

| km | 3.91 × 10−4 | −7.81 × 10−3 | −6.77 × 10−3 | −2.23 × 10−3 | −1.12 × 10−7 | - | - | 8.63 × 10−2 | - | - | 17 | 54.36 |

| F | 2.09 | −218.75 | −12.08 | 3.95 | 5.26 × 10−3 | - | - | - | - | - | 18 | 60.52 |

| W | −2.84 × 10−3 | −2.58 | −6.77 × 10−2 | 0.55 | 3.93 × 10−4 | - | −5.45 × 10−3 | - | - | - | 19 | 69.32 |

| RR | 54.27 | −2953 | −12.5 | 75.2 | −0.16 | - | - | - | −48,100 | 67.63 | 20 | 84.52 |

| Air impingement drying | Parameters | Oven drying | Parameters | ||

| Mm (kg kg−1) | 0.095 ± 0.005 | Mm (kg kg−1) | 0.102 ± 0.015 | ||

| Cg | 4.31 ± 1.48 × 102 | Cg | 2.30 ± 1.46 | ||

| K | 0.98 ± 0.01 | K | 0.97 ± 0.01 | ||

| R2 (%) | 99.95 ± 0.02 | R2 (%) | 99.96 ± 0.03 | ||

| RMSE | 7.70 ± 1.74 × 10−3 | RMSE | 6.96 ± 2.88 × 10−3 | ||

| χ2 | 9.20 ± 4.06 × 10−5 | χ2 | 8.09 ± 5.34 × 10−5 | ||

| RSS | 5.52 ± 2.44 × 10−4 | RSS | 4.85 ± 3.21 × 10−4 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boy, V.; Mlayah, S.; Giblaine, M.; Lemée, Y.; Lanoisellé, J.-L. A Case Study of Turbulent Free Jet Flows Issuing from Rectangular Slots on Process Performances and Quality of Hot-Air-Dried Apple. Processes 2021, 9, 1900. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9111900

Boy V, Mlayah S, Giblaine M, Lemée Y, Lanoisellé J-L. A Case Study of Turbulent Free Jet Flows Issuing from Rectangular Slots on Process Performances and Quality of Hot-Air-Dried Apple. Processes. 2021; 9(11):1900. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9111900

Chicago/Turabian StyleBoy, Virginie, Sahar Mlayah, Marina Giblaine, Yves Lemée, and Jean-Louis Lanoisellé. 2021. "A Case Study of Turbulent Free Jet Flows Issuing from Rectangular Slots on Process Performances and Quality of Hot-Air-Dried Apple" Processes 9, no. 11: 1900. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9111900