Agronomic Characteristics of the Compost-Bedded Pack Made with Forest Biomass or Sawdust

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bedding and Compost Management

2.2. Sampling

2.3. Chemical Analysis

2.4. Statistical Analysis

3. Results and Discussion

3.1. Comparison between Bedding Materials

3.2. Comparison between Compost-Bedded Pack (CBP)

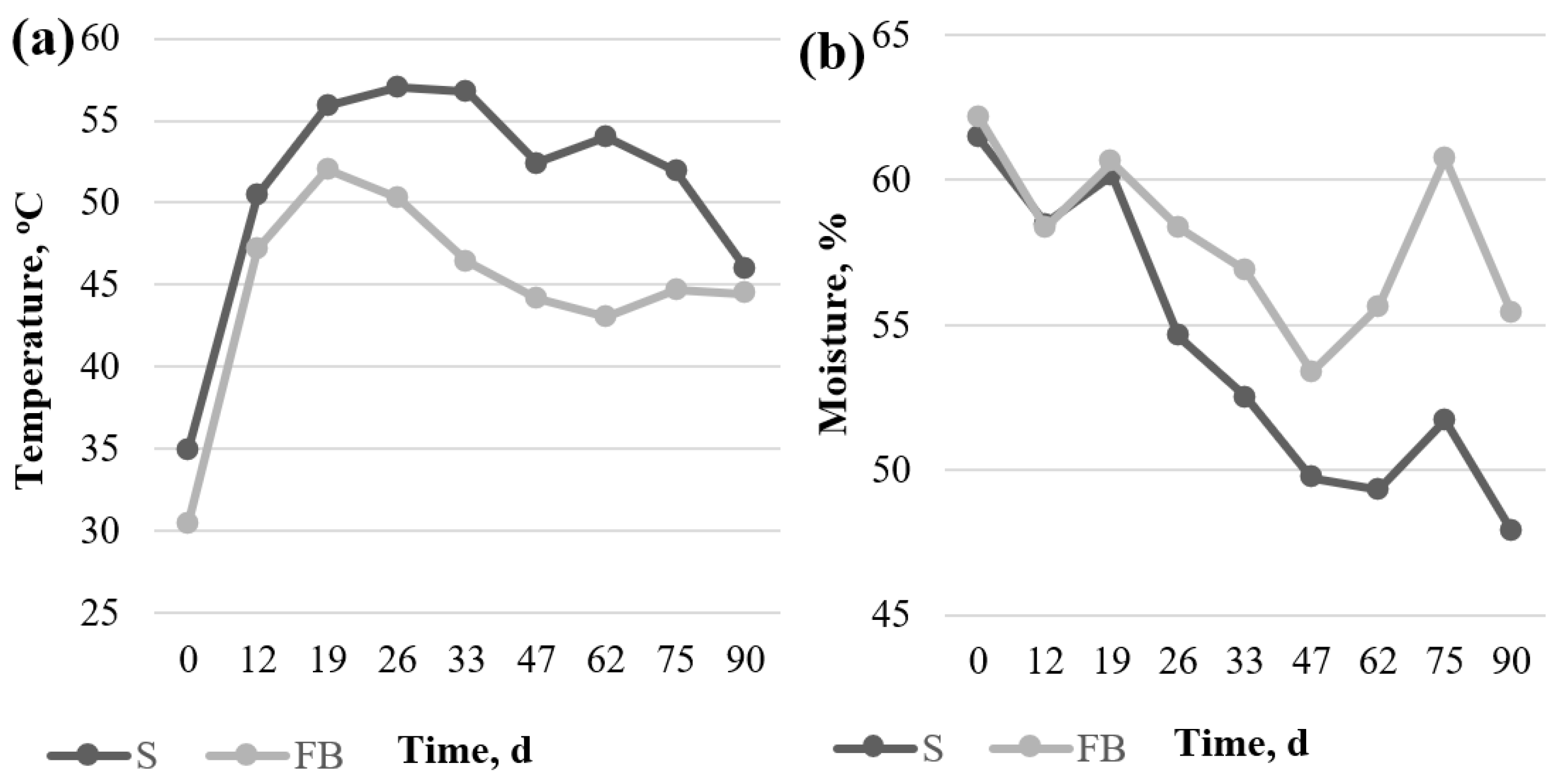

3.2.1. Temperature and Moisture

3.2.2. Chemical Characteristics

3.3. Comparison between the Composted Piles

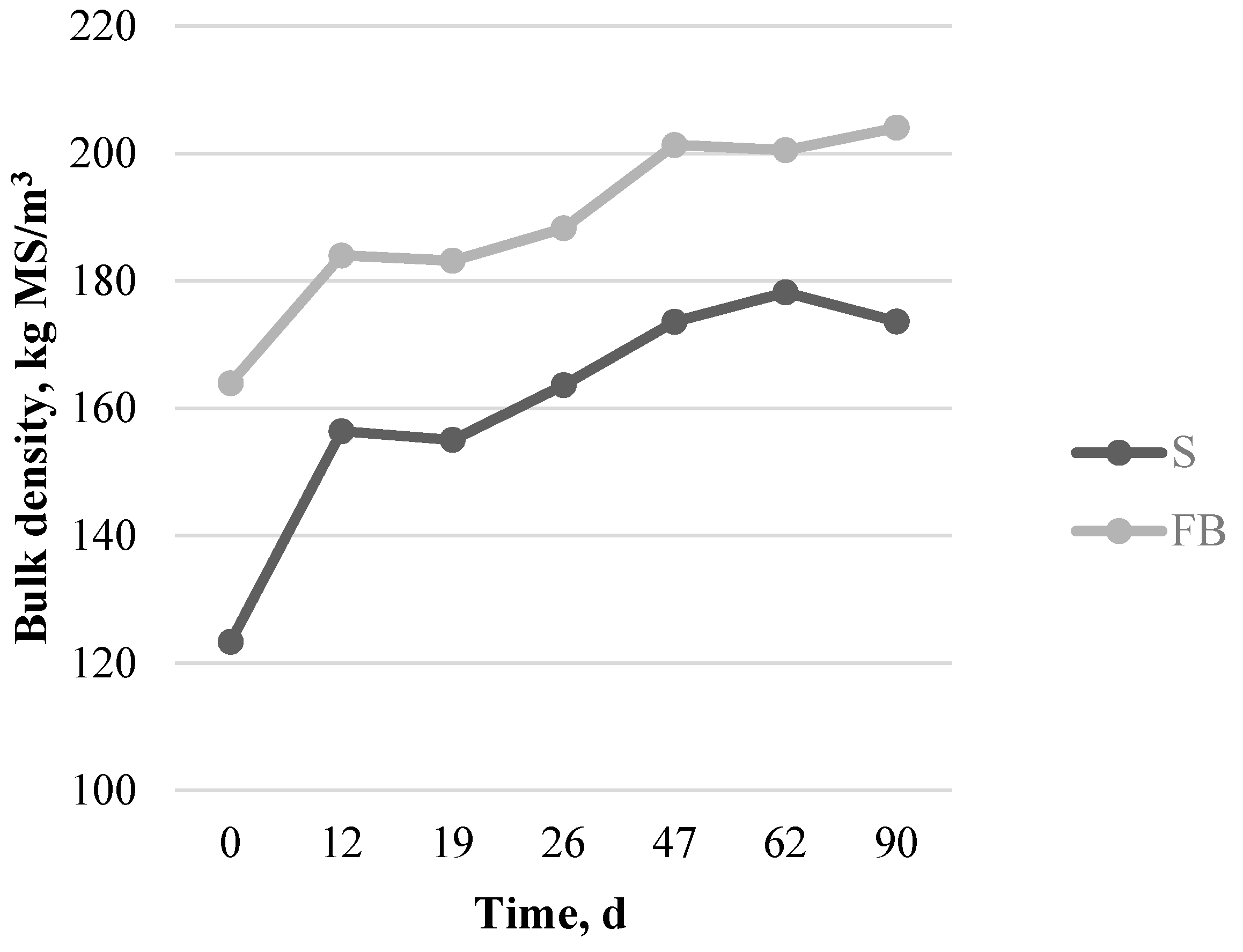

3.3.1. Temperature, Moisture and Bulk Density

3.3.2. Chemical Characteristics

3.4. Agronomic Suitability of the Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- 68% of the World Population Projected to Live in Urban Areas by 2050. Available online: https://www.un.org/development/desa/en/news/population/2018-revision-of-world-urbanization-prospects.html (accessed on 18 February 2021).

- Boogaard, B.K.; Oosting, S.J.; Bock, B.B.; Wiskerke, J.S.C. The sociocultural sustainability of livestock farming: An inquiry into social perceptions of dairy farming. Animal 2011, 5, 1458–1466. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, X.P.; Hansen, M.C.; Stehman, S.V.; Potapov, P.V.; Tyukavina, A.; Vermote, E.F.; Townshend, J.R. Global land change from 1982 to 2016. Nature 2018, 560, 639–643. [Google Scholar] [CrossRef] [PubMed]

- Minnich, R.A. An integrated model of two fire regimes. Conserv. Biol. 2001, 15, 1549–1553. [Google Scholar] [CrossRef]

- Oliveras, I.; Piñol, J.; Viegas, D.X. Modelling the long term effect of changes in fire frequency on the total area burnt. Orsis 2005, 20, 73–81. Available online: https://www.raco.cat/index.php/Orsis/article/view/51789 (accessed on 18 February 2021).

- Barberg, A.E.; Endres, M.I.; Salfer, J.A.; Reneau, J.K. Performance and welfare of dairy cows in an alternative housing system in Minnesota. J. Dairy Sci. 2007, 90, 1575–1583. [Google Scholar] [CrossRef]

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Bewley, J.M. Compost bedded pack dairy barn management, performance, and producer satisfaction. J. Dairy Sci. 2013, 96, 8060–8074. [Google Scholar] [CrossRef] [PubMed]

- Fernández, A.; Mainau, E.; Manteca, X.; Siurana, A.; Castillejos, L. Impacts of compost bedded pack barns on the welfare and comfort of dairy cows. Animals 2020, 10, 431. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barberg, A.E.; Endres, M.I.; Janni, K.A. Compost dairy barns in Minnesota: A descriptive study. Appl. Eng. Agric. 2007, 23, 231–238. [Google Scholar] [CrossRef]

- Janni, K.A.; Endres, M.I.; Reneau, J.K.; Schoper, W.W. Compost dairy barn layout and management recommendations. Appl. Eng. Agric. 2007, 23, 97–102. [Google Scholar] [CrossRef]

- Shane, E.M.; Endres, M.I.; Janni, K.A. Alternative bedding materials for compost bedded pack barns in Minnesota: A descriptive study. Appl. Eng. Agric. 2010, 26, 465–473. [Google Scholar] [CrossRef]

- Llonch, L.; Castillejos, L.; Mainau, E.; Manteca, X.; Ferret, A. Effect of forest biomass as bedding material on compost-bedded pack performance, microbial content, and behavior of nonlactating dairy cows. J. Dairy Sci. 2020, 103, 10676–10688. [Google Scholar] [CrossRef]

- Huerta-Pujol, O.; Soliva, M.; Martínez-Farré, F.X.; Valero, J.; López, M. Bulk density determination as a simple and complementary tool in composting process control. Bioresour. Technol. 2010, 101, 995–1001. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- López, M.; Huerta-Pujol, O.; Martínez-Farré, F.X.; Soliva, M. Approaching compost stability from Klason lignin modified method: Chemical stability degree for OM and N quality assessment. Resour. Conserv. Recycl. 2010, 55, 171–181. [Google Scholar] [CrossRef]

- Zucconi, F.; de Bertoldi, M. Compost specifications for the production and characterization of compost from municipal solid waste. In Compost: Production, Quality and Use; de Bertoldi, M., Ferranti, M.P., l’Hermite, P., Zucconi, F., Eds.; Elsevier: Barking, UK, 1987; pp. 30–50. [Google Scholar]

- Ferraz, P.F.P.; Ferraz, G.A.S.; Leso, L.; Klopcic, M.; Barbari, M.; Rossi, G. Properties of conventional and alternative bedding materials for dairy cattle. J. Dairy Sci. 2020, 103, 8661–8674. [Google Scholar] [CrossRef]

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited review: Compost-bedded pack barns for dairy cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef] [PubMed]

- Rowell, R.M.; Pettersen, R.; Tshabalala, M.A. Cell Wall Chemistry. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Kirchman, H. Losses, plant uptake and utilisation of manure nitrogen during a production cycle. Acta Agric. Scand. 1985, 24, 1–77. [Google Scholar]

- Rynk, R.; van de Kamp, M.; Willson, G.B.; Singley, M.E.; Richard, T.L.; Kolega, J.J.; Gouin, F.R.; Laliberty, L.; Kay, D.; Murphy, D.W.; et al. On-Farm Composting Handbook (NRAES 54); Northeast Regional Agricultural Engineering Service (NRAES): New York, NY, USA, 1992. [Google Scholar]

- Guidelines for Managing Compost Bedded-Pack Barns. Available online: https://www.dairypc.org/catalog/guidelines-for-managing-compost-bedded-pack-barns (accessed on 4 June 2014).

- Leso, L.; Uberti, M.; Morshed, W.; Barbari, M. A survey on italian compost dairy barns. J. Agric. Eng. 2013, 44, 203–207. [Google Scholar] [CrossRef]

- Eckelkamp, E.A.; Taraba, J.L.; Akers, K.A.; Harmon, R.J.; Bewley, J.M. Understanding compost bedded pack barns: Interactions among environmental factors, bedding characteristics, and udder health. Livest. Sci. 2016, 190, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Haug, R.T. The Practical Handbook of Compost Engineering, 1st ed.; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- DeLaune, P.B.; Moore, P.A.; Daniel, T.C.; Lemunyon, J.L. Effect of chemical and microbial amendments on ammonia volatilization from composting poultry litter. J. Environ. Qual. 2004, 33, 728–734. [Google Scholar] [CrossRef] [PubMed]

| Item | Material | SEM | p-Value | |

|---|---|---|---|---|

| S 1 | FB 2 | |||

| pH | 5.01 | 6.01 | 0.112 | 0.001 |

| EC, mS/cm | 0.43 | 0.23 | 0.011 | 0.001 |

| Moisture, % | 10.2 | 32.1 | 1.97 | 0.001 |

| OM, % DM | 99.1 | 88.6 | 0.43 | 0.001 |

| Stability, % | 28.6 | 52.2 | 0.22 | 0.001 |

| Organic N, % DM | 0.20 | 0.35 | 0.026 | 0.001 |

| C/N ratio | 286 | 131 | 20.0 | 0.001 |

| P, % DM | 0.006 | 0.024 | 0.0020 | 0.001 |

| K, % DM | 0.054 | 0.131 | 0.0088 | 0.001 |

| Particle size, % | ||||

| >25 mm | 0.0 | 0.0 | 0.02 | 0.434 |

| 25–12.5 mm | 0.6 | 8.6 | 0.76 | 0.001 |

| 12.5–10 mm | 0.7 | 6.2 | 0.50 | 0.001 |

| 10–6.3 mm | 8.3 | 13.2 | 0.74 | 0.001 |

| 6.3–5 mm | 6.8 | 10.3 | 1.26 | 0.077 |

| 5–2 mm | 34.3 | 39.7 | 2.99 | 0.232 |

| <2 mm | 49.2 | 22.0 | 4.62 | 0.002 |

| Period 1 | Period 2 | |

|---|---|---|

| Climatic conditions | ||

| Temperature, °C | 14.7 ± 3.63 | 11.2 ± 2.49 |

| Humidity, % | 81.5 ± 4.21 | 74.5 ± 7.18 |

| CBP temperature, °C | ||

| CBP-S | 34.7 ± 5.64 | 31.2 ± 5.88 |

| CBP-FB | 28.3 ± 6.87 | 25.9 ± 3.08 |

| CBP moisture, % | ||

| CBP-S | 54.1 ± 16.97 | 55.0 ± 16.43 |

| CBP-FB | 62.0 ± 14.00 | 59.4 ± 7.21 |

| Item | Period 1 | Period 2 | SEM | p-Value | ||||

|---|---|---|---|---|---|---|---|---|

| CBP-S 1 | CBP-FB 2 | CBP-S | CBP-FB | T | P | T × P | ||

| pH | 8.00 c | 8.43 b | 8.96 a | 7.81 c | 0.078 | 0.001 | 0.021 | 0.001 |

| EC, mS/cm | 3.78 a | 2.39 b | 3.84 a | 3.79 a | 0.163 | 0.001 | 0.001 | 0.003 |

| Moisture, % | 61.3 b | 69.7 a | 63.7 b | 63.2 b | 1.09 | 0.002 | 0.037 | 0.001 |

| OM, % DM | 91.1 a | 83.4 c | 89.9 a | 85.7 b | 0.54 | 0.001 | 0.115 | 0.008 |

| Stability, % | ND | ND | 31.7 | 49.2 | 1.25 | 0.001 | ND | ND |

| N, % DM | ||||||||

| Organic | 0.89 | 1.12 | 1.07 | 1.21 | 0.036 | 0.001 | 0.002 | 0.101 |

| Ammonia | 0.07 | 0.08 | 0.05 | 0.04 | 0.014 | 0.999 | 0.034 | 0.444 |

| Total | 0.96 | 1.19 | 1.12 | 1.24 | 0.039 | 0.001 | 0.005 | 0.109 |

| C/N ratio | 48:1 a | 35:1 c | 40:1 b | 35:1 c | 1.1 | 0.001 | 0.002 | 0.005 |

| P, % DM | 0.24 b | 0.28 a | 0.28 a | 0.25 a,b | 0.009 | 0.879 | 0.458 | 0.003 |

| K, % DM | 1.22 b | 1.64 a | 1.78 a | 1.62 a | 0.098 | 0.038 | 0.001 | 0.015 |

| Item | S | FB | ||

|---|---|---|---|---|

| Day 0 | Day 90 | Day 0 | Day 90 | |

| pH | 8.72 ± 0.017 | 8.39 ± 0.035 | 7.45 ± 0.015 | 7.72 ± 0.100 |

| EC, mS/cm | 3.59 ± 0.145 | 5.58 ± 0.106 | 3.39 ± 0.025 | 3.10 ± 0.061 |

| Moisture, % | 61.5 ± 0.24 | 47.9 ± 0.15 | 62.2 ± 0.29 | 55.4 ± 0.18 |

| OM, % DM | 91.7 ± 0.18 | 87.4 ± 0.13 | 86.3 ± 0.30 | 82.9 ± 0.03 |

| Stability, % | 31.7 | 34.9 | 49.2 | 53.9 |

| N, % DM | ||||

| Organic | 0.88 ± 0.039 | 1.05 ± 0.058 | 1.16 ± 0.013 | 1.27 ± 0.054 |

| Ammonia | 0.049 ± 0.0004 | 0.004 ± 0.0002 | 0.013 ± 0.0006 | 0.001 ± 0.0005 |

| C/N ratio | 52.0 | 41.8 | 37.2 | 32.6 |

| P, % DM | 0.24 ± 0.017 | 0.31 ± 0.040 | 0.27 ± 0.021 | 0.24 ± 0.011 |

| K, % DM | 1.74 ± 0.071 | 2.02 ± 0.134 | 1.94 ± 0.269 | 1.87 ± 0.066 |

| Item | S | FB | ||||||

|---|---|---|---|---|---|---|---|---|

| Equation | R2 | p-Value | RMSE | Equation | R2 | p-Value | RMSE | |

| pH | 9.19 − 0.009d | 0.41 | 0.064 | 0.343 | 7.25 + 0.006d | 0.53 | 0.026 | 0.178 |

| EC, mS/cm | 3.66 + 0.023d | 0.95 | 0.001 | 0.176 | 2.03 + 0.001d | 0.02 | 0.745 | 0.252 |

| Moisture,% | 59.9 − 0.146d | 0.79 | 0.002 | 2.468 | 59.9 − 0.047d | 0.25 | 0.174 | 2.681 |

| OM, % DM | 91.0 − 0.041d | 0.90 | 0.001 | 0.499 | 85.3 − 0.027d | 0.65 | 0.028 | 0.688 |

| N, % DM | ||||||||

| Organic | 0.88 + 0.003d | 0.68 | 0.006 | 0.061 | 1.14 + 0.001d | 0.48 | 0.039 | 0.037 |

| Ammonia | 0.06 − 0.001d | 0.89 | 0.001 | 0.008 | 0.02 − 0.001d | 0.75 | 0.002 | 0.004 |

| C/N | 52.0 − 0.145d | 0.84 | 0.004 | 2.286 | 37.5 − 0.050d | 0.73 | 0.015 | 1.073 |

| P, % DM | 0.26 + 0.001d | 0.63 | 0.107 | 0.019 | 0.28 − 0.001d | 0.27 | 0.292 | 0.028 |

| K, % DM | 1.83 + 0.004d | 0.71 | 0.073 | 0.107 | 1.76 + 0.002d | 0.29 | 0.270 | 0.127 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llonch, L.; Gordo, C.; López, M.; Castillejos, L.; Ferret, A.; Balanyà, T. Agronomic Characteristics of the Compost-Bedded Pack Made with Forest Biomass or Sawdust. Processes 2021, 9, 546. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9030546

Llonch L, Gordo C, López M, Castillejos L, Ferret A, Balanyà T. Agronomic Characteristics of the Compost-Bedded Pack Made with Forest Biomass or Sawdust. Processes. 2021; 9(3):546. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9030546

Chicago/Turabian StyleLlonch, Lourdes, Cecilia Gordo, Marga López, Lorena Castillejos, Alfred Ferret, and Teresa Balanyà. 2021. "Agronomic Characteristics of the Compost-Bedded Pack Made with Forest Biomass or Sawdust" Processes 9, no. 3: 546. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9030546