3.1. Explanation of PLS Model

The numerical simulation result data were put into the PLS model as response variables. The fitting results could be obtained by regressing the predictor variables on the response variables in the latent space.

In the PLS model, we assumed that the system under study was actually influenced by a combination of variables into latent variables; the predictor variables were linearly combined into a latent variable t, the response variables were linearly combined into a latent variable v, and the latent variables t and v were tensored into a latent space. Therefore, the interpretation of the PLS fit results needs to be performed in the latent space.

We regarded the variance of the data as the information contained in the data. Usually, a pair of latent variables

t and

v are called components, which extract information from the original variables in turn, and different components have different abilities to extract information. Cross Validation (CV) is a practical and reliable method to determine the number of components (latent variable pairs) [

35]. In this study, two components were determined to be sufficient to extract all the information by CV, as shown in

Table 2.

It can be seen that component 1 extracted 56.86% of the information in the response variable

Y. Therefore, we only needed to focus on the relationship between latent variables

v and

t in the two-dimensional latent space spanned by component 1, as shown in

Figure 6.

Figure 6 shows the latent space for component 1, with the latent variable

t, consisting of the predictor variable

as the horizontal coordinate. The latent variable

v, consisting of the response variable

and

as the vertical coordinate, and the 20 design points were projected into this latent variable space. The red region is the 95% confidence interval, and the regression errors for all points were within 10%, which indicates that the PLS model could be used to analyze the design of a non-standard Kenics static mixer with the introduction of an eccentricity factor

.

The numerical simulation results were put into the PLS as response variables, and the fitting results were obtained by regressing the

and

and

in the latent space as follows:

Transforming the fit results, we obtained the statistical correlations (12) and (13).

The PLS model with the introduction of the eccentricity factor was analyzed using regression coefficient plots and variable importance plots. As shown in

Figure 7, the regression coefficients between the

and the response variable

were −0.285, −0.366, and 0.258, respectively, indicating that

were negatively correlated with the

; meanwhile,

was positively correlated with it. All three variables had a strong effect on the relative Nusselt number.

For the relative friction factor, the coefficient of the variable was –1.22, which was strong negative correlated with , while the coefficient of the variable was 0.293, which was weakly positively correlated with . The variable was 1.47, which indicated a strong positive correlation with the relative friction factor.

Overall, the aspect ratio, which characterizes the structural properties of the Kenics static mixer, had the largest regression coefficient for heat transfer and pressure drop. The introduction of the eccentricity factor also had a significant effect on both response variables, which indicated that the fluid was affected by the symmetric structure during the fluid flow through elements, and this effect was neglected in previous studies.

Figure 8 shows the projection of the three ’variables’ importance. It can be seen that, as with the analysis of the regression coefficients, the effect of the aspect ratio

and the eccentricity factor

on the heat transfer performance was more significant. This is due to the fact that in the iterative process of stepwise regression, the data fluctuations of

and

had a more significant influence on the response variable

and

, relative to the Reynolds number

, which resulted in the situation that during the process of extracting information, the aspect ratio and the eccentricity factor were more able to explain the degree of variation of the response variable in the variation of the structural parameters. Therefore,

and

had a higher weight in the statistical index of the importance of the response variable.

The 3D contour plots of the thermal–hydraulic performance factor

η for each physical model under the introduction of the eccentricity factor are shown in

Figure 9. The higher the value of

η, the better the heat transfer performance. At

and

,

η reached maximum at 1.895.

In

Figure 9, three of the 20 design points were the extreme values of the thermal-hydraulic performance factor in the sample space, namely DP12, DP14, and DP15. However, the conventional symmetric structure of the Kenics static mixer, where

increases with decreasing

and increasing

, did not have an extreme value point [

36,

37], as could be derived from the empirical correlations. To further investigate the effect of the eccentricity factor

on the dimensionless number

, and the thermal–hydraulic performance factor

η, we selected two design conditions for a univariate analysis.

3.2. Univariate Analysis

In the one-way analysis, we modified the centrosymmetric position under the two design points and investigated the

and

by only changing

from 0.25 to 0.75. Data is shown in

Table A3.

In the two design points of

Figure 10, we can see that the

represented by the red column increased with the increase of the eccentricity factor

, which is consistent with the positive regression coefficient of

on

in the PLS model. The friction factor

represented by the green column tended to decrease and then increase with the eccentricity factor

. The friction factor at

was the smallest, which corresponds to the classical centrosymmetric Kenics static mixer structure.

We analyzed the similarities and differences between the PLS model and the univariate analysis with the introduction of the eccentricity factor.

(1) The total information extraction ratio of the model for X and Y was 85.29% and 67.58%, which indicates that the LHS-PLS is applicable to the Kenich static mixer with the introduction of eccentricity factor but that the limited fitting capability causes some information loss. By analyzing the study cases in which PLS was applied, we suggest that although the study subjects are all Kenics static mixers, the underlying logic of the fluid exerted by Kenics static mixers with extreme eccentricity factors and those with near-centrosymmetric structures may have changed in the 20 samples after the introduction of eccentricity factors. This is the reason why the results of PLS were not consistent with those of the univariate analysis. Considered from a different perspective, this is evidence that the “centrosymmetric structure” in the design of the Kenics static mixer was not only due to mechanical constraints, but also due to the rationality of the structure itself, which is why the friction factor was minimal at

in the univariate analysis. This possible variation of the underlying logic is further explained in

Section 3.3 from the view of the flow field.

(2) In the CFD simulation of the Kenics static mixer with a changing centrosymmetric position, we found that compared to the classical one, the combination of variables of some design points will get an abnormal

and

; the points constituted exceeded the 95% confidence limits of the latent variable space, i.e., the confidence ellipse with DP14 and DP15 in

Figure 6, and these two points happened to be the 20 sample points with the largest coefficients of thermal–hydraulic performance. This proves that the underlying logic of the Kenics static mixer with an asymmetric structure became more complex, ensuring the reliability of the CFD simulation.

(3) In the PLS model, we conclude that the regression coefficient of the eccentricity factor

on

was 1.47, where this was different from the results of the univariate analysis. In the univariate analysis in

Figure 10, we found that the friction factor increased when the centrosymmetric position moved in the direction of the two extremes, i.e.,

or

. Since the regression of PLS on the variables only yields one coefficient, more consideration was given to the degree of variance of the variables in the fitting process, which reflects the relationship between the variance and the responses. This was the reason why the results of the regression coefficients analysis in the PLS model differed from those of the univariate analysis; if the degree of deviation from the center of the symmetric position was taken into account in the univariate analysis, i.e.,

, the results of the univariate analysis corresponded to the regression coefficients of the PLS model. The results of the univariate analysis also explained the decrease in the information extraction rate of the PLS model.

In this section, we modified the structure of the standard Kenics static mixer to study the guide effect of the Kenics static mixer on the fluid by changing its centrosymmetric position. In our study, we found that the information extraction ability of the LHS-PLS for 20 sample points was reduced after the introduction of the eccentricity factor. By comparing the results with those of the univariate analysis, we attribute this discrepancy to the fact that some non-standard Kenics static mixers with extreme asymmetric structures differ in their effect on fluid guidance from classical ones. This conclusion corroborates that the default centrosymmetric structure of the Kenics static mixer is the one that has a direct impact on mixing and heat transfer during fluid flow. When studying the structure of Kenics static mixer, it is not reasonable to consider only the cutting effect of the crossover on the fluid and ignore the pressure drop and mixing caused by the rotation of the fluid along the course. In addition, in the univariate analysis, changing only the centrosymmetric position, we found that the default structure did have the lowest pressure drop, but the backward eccentric Kenics static mixer had a higher Nusselt number and thermal–hydraulic performance factor, for which we analyzed the differences in the flow field at different design points in

Section 3.3.

3.3. Analysis through Flow Field Simulation

Through flow field simulation, we investigated the mechanism that affects the heat transfer efficiency by describing the fluid flow in the case of an asymmetric Kenics static mixer structure. The mechanism by which the Kenics static mixer triggers fluid rotation to generate vortices, and thus affects mixing and heat transfer, has been discussed in literature [

13,

25,

38,

39]. With the introduction of the eccentricity factor, the generation of vortices remains the primary factor for enhanced heat transfer. After the introduction of vortices, firstly, we should be more concerned with the extent to which the velocity boundary layer and the thermal boundary layer were effectively thinned. Secondly, the asymmetric position of the elements changed the flow path of the fluid. The fluid was distorted differently during the guideline process, which affected the impact of the fluid on the boundary layer and the formation of vortices, further affecting the heat transfer performance.

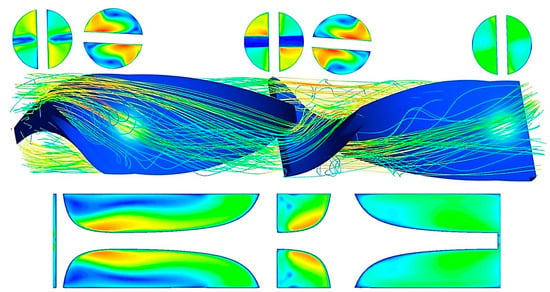

To further analyze the vortex generation and dissipation, we continued from the radial section and axial interface.

Figure 11 shows the velocity field of DP7 and DP15, and each design point contained two adjacent cells that were twisted by a total of 360°, where the inlet

, the center of the first element

, the crossover

, the center of the second element

and the exit

. We found that a significant vortex was formed in the velocity field of both DP7 and DP15 at

with

, and this stronger velocity gradient gradually weakened at the crossover, i.e.,

. This indicates that the vortices formed during the fluid being guided by the components were relatively intense at the center of the cell, and this vortex was the main reason for the thinning of the thermal and velocity boundary layers. Comparing the two design points, we found that the degree of the vortex was greater in DP15 than in DP7, which had a higher thermal–hydraulic performance factor, and the former was therefore due to this stronger vortex. It makes sense to introduce an eccentricity factor in the study of Kenics static mixers.

Figure 12 shows the velocity fields of the two adjacent elements’ axial cross-sections at the two design points of DP7 and DP15. Comparing

Figure 12a,b, it is obvious that the pattern of fluid flow changed due to the introduction of the eccentricity factor. DP15 with a smaller eccentricity factor

had a stronger velocity gradient at the axial interface and a greater degree of fluid rotation. The flow simulation showed that the twisting of the fluid was more intense in the part near the inlet section, due to the change of the center position, which corresponds to an element with a smaller

. Naturally the larger is the

the smaller the pressure drop and the better the heat transfer performance. This is reflected in the backward part of DP15, where the velocity boundary layer was thin, and the velocity gradient was small. Comparing with DP7, we realize that when the center of the Kenics static mixer was changed, it was equivalent to connecting two Kenics static mixers with the same diameter but different aspect ratios at

. This connection resulted in the formation of vortices more quickly when the fluid struck the element surface due to the large distortion of the insert with a smaller

, but with a cost of a higher pressure drop. This velocity gradient could be released backwards on the side with a larger

, and the number of crossovers during per element length was reduced, which reduced the pressure drop to some extent. This was finally reflected in the univariate analysis, where the pressure drop showed a trend of decreasing and then increasing with the eccentricity factor

increased.

Figure 13 shows the streamline after combining two adjacent elements of DP7 and DP15, and it can be seen that DP7 with a shorter aspect ratio had a more distorted flow. By analyzing the axial interface, we obtained that the essence of changing the centrosymmetric position was the combination of two elements with different aspect ratios at

. Comparing

Figure 13a,b, when the fluid entering DP15 passed through the shorter front end, the back mixing was obvious due to the higher torque and the strong strike of the fluid on the wall. This is reflected in the part of

Figure 13 where the red flow line intersected with the green flow line, corresponding to a larger velocity gradient. Afterward, this vortex structure continued to move forward with the flow body and wss gradually dissipated backward.

Throughout the process, the vortex generation and dissipation mechanism in the non-standard Kenics static mixer with an eccentricity factor were the same as in the standard Kenics static mixer but to a different extent due to the eccentricity. This happens to be the underlying logic of how the Kenics modify the fluid, but this logic cannot be explored and explained in the standard Kenics static mixer with only a change in the aspect ratio.

The above explanation made in conjunction with the flow field simulation proves what we concluded in

Section 3.1 and

Section 3.2: when the center of symmetry of the Kenics static mixer is shifted, its mechanism acting on the flow field is changed, which eventually leads to a decrease in the amount of information extracted from the sample set by the PLS model and the difference between the univariate analysis and the PLS model.

In this section, the velocity field of a non-standard Kenics static mixer with the introduction of an eccentricity factor was visualized. Starting from the vortices generated and dissipated by the twisted flow path, this asymmetric structure was studied. The result showed that the nature of the eccentric structure is a combination of two components with different aspect ratios at . This articulation led to a non-standard Kenics static mixer with different combinations having different underlying mechanisms; even though the mechanisms of vortex generation and dissipation were the same, the intensity of generation and the time required for dissipation were different. These explained the differences between the PLS models and the univariate analysis.