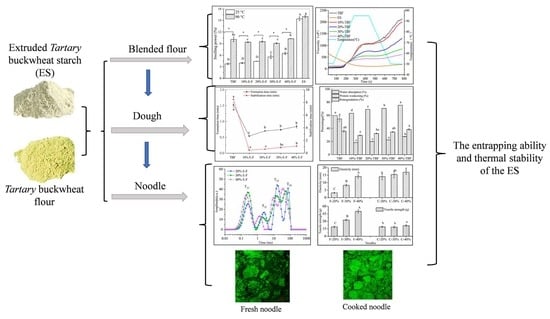

Influence of the Addition of Extruded Endogenous Tartary Buckwheat Starch on Processing and Quality of Gluten-Free Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Extruded Starch and Blended Flour

2.3. Swelling Power and Solubility Analysis

2.4. Dynamic Viscosity and Pasting Viscosity Analysis

2.5. Dough Rheological Properties

2.6. Preparation of Fresh and Dried Noodles

2.7. Cooking Properties of the Dried Noodles

2.8. Tensile Properties of Fresh Noodles and Cooked Noodles

2.9. Microstructure Characteristics of Fresh Noodles and Cooked Noodles

2.10. NMR Measurement of Fresh Noodles and Cooked Noodles

2.11. Statistical Analysis

3. Results and Discussion

3.1. Effect of Extruded Starch on Solubility and Swelling Power of Blended Flour

3.2. Effect of Extruded Starch on Dynamic Viscosity and Pasting Properties of Blended Flour

3.3. Effect of Extruded Starch on Rheological Properties of Dough

3.4. Effect of Extruded Starch on Cooking Characteristics, Tensile Properties, and Microstructure of Noodles

3.5. Effect of Extruded Starch on Water Migration of Noodles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Lee, J.; Sung, J. Influence of acid treatment on flavonoid content and biological activity in Tartary buckwheat grains and its application for noodles. LWT 2021, 145, 111488. [Google Scholar] [CrossRef]

- Gullón, B.; Lú-Chau, T.A.; Moreira, M.T.; Lema, J.M.; Eibes, G. Rutin: A review on extraction, identification and purification methods, biological activities and approaches to enhance its bioavailability. Trends Food. Sci. Technol. 2017, 67, 220–235. [Google Scholar] [CrossRef]

- Min, B.; Lee, S.M.; Yoo, S.H.; Inglett, G.E.; Lee, S. Functional characterization of steam jet-cooked buckwheat flour as a fat replacer in cake-baking. J. Agric. Food Chem. 2010, 90, 2208–2213. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Meng, L.; Tang, X. Retrogradation behavior of extruded whole buckwheat noodles: An innovative water pre-cooling retrogradation treatment. J. Cereal. Sci. 2021, 99, 103234. [Google Scholar] [CrossRef]

- Sun, X.; Yu, C.; Fu, M.; Wu, D.; Gao, C.; Feng, X.; Tang, X. Extruded whole buckwheat noodles: Effects of processing variables on the degree of starch gelatinization, changes of nutritional components, cooking characteristics and in vitro starch digestibility. Food Funct. 2019, 10, 6362–6373. [Google Scholar] [CrossRef]

- Hu, J.; Li, X.; Jing, Y.; Hu, X.; Ma, Z.; Liu, R.; Zhang, D. Effect of gaseous ozone treatment on the microbial and physicochemical properties of buckwheat-based composite flour and shelf-life extension of fresh noodles. J. Cereal. Sci. 2020, 95, 103055. [Google Scholar] [CrossRef]

- Sun, X.; Li, W.; Hu, Y.; Zhou, X.; Ji, M.; Yu, D.; Luan, G. Comparison of pregelatinization methods on physicochemical, functional and structural properties of tartary buckwheat flour and noodle quality. J. Cereal. Sci. 2018, 80, 63–71. [Google Scholar] [CrossRef]

- Guo, Y.; Qiao, D.; Zhao, S.; Zhang, B.; Xie, F. Starch-based materials encapsulating food ingredients: Recent advances in fabrication methods and applications. Carbohydr. Polym. 2021, 270, 118358. [Google Scholar] [CrossRef]

- Han, X.M.; Xing, J.J.; Han, C.; Guo, X.N.; Zhu, K.X. The effects of extruded endogenous starch on the processing properties of gluten-free Tartary buckwheat noodles. Carbohydr. Polym. 2021, 267, 118170. [Google Scholar] [CrossRef]

- Anderson, R.; Conway, H.; Pfeifer, V.; Griffin, E. Gelatinization of corn grits by roll-and extrusion-cooking. Cereal. Sci. Today 1969, 14, 10–12. [Google Scholar]

- Cheng, W.; Gao, L.; Wu, D.; Gao, C.; Meng, L.; Feng, X.; Tang, X. Effect of improved extrusion cooking technology on structure, physiochemical and nutritional characteristics of physically modified buckwheat flour: Its potential use as food ingredients. LWT 2020, 133, 109872. [Google Scholar] [CrossRef]

- Moza, J.; Gujral, H.S. Mixolab, retrogradation and digestibility behavior of chapatti made from hulless barley flours. J. Cereal. Sci. 2018, 79, 383–389. [Google Scholar] [CrossRef]

- Cao, Z.B.; Yu, C.; Yang, Z.; Xing, J.J.; Guo, X.N.; Zhu, K.X. Impact of gluten quality on textural stability of cooked noodles and the underlying mechanism. Food Hydrocoll. 2021, 119, 106842. [Google Scholar] [CrossRef]

- AACC. Approved methods of the American Association of Cereal Chemists, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2010. [Google Scholar]

- Donmez, D.; Pinho, L.; Patel, B.; Desam, P.; Campanella, O.H. Characterization of starch–water interactions and their effects on two key functional properties: Starch gelatinization and retrogradation. Curr. Opin. Food. Sci. 2021, 39, 103–109. [Google Scholar] [CrossRef]

- Mao, H.; Li, J.; Chen, Z.; Yan, S.; Li, H.; Wen, Y.; Wang, J. Molecular structure of different prepared pyrodextrins and the inhibitory effects on starch retrogradation. Food Res. Int. 2021, 110305. [Google Scholar] [CrossRef] [PubMed]

- Dolz, M.; Hernández, M.J.; Delegido, J.; Alfaro, M.C.; Muñoz, J. Influence of xanthan gum and locust bean gum upon flow and thixotropic behaviour of food emulsions containing modified starch. J. Food Eng. 2007, 81, 179–186. [Google Scholar] [CrossRef]

- Tao, H.; Zhu, X.F.; Nan, B.X.; Jiang, R.Z.; Wang, H.L. Effect of extruded starches on the structure, farinograph characteristics and baking behavior of wheat dough. Food Chem. 2021, 348, 129017. [Google Scholar] [CrossRef]

- Aleixandre, A.; Benavent-Gil, Y.; Moreira, R.; Rosell, C.M. In vitro digestibility of gels from different starches: Relationship between kinetic parameters and microstructure. Food Hydrocoll. 2021, 120, 106909. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, X.; Guo, H.; Li, J.; Ren, G. Effect of extruded adzuki bean flour on the quality and α-glucosidase inhibitory activity of Chinese steamed bread. Food Sci. Nutr. 2019, 7, 3244–3252. [Google Scholar] [CrossRef]

- Lavoisier, A.; Aguilera, J.M. Starch gelatinization inside a whey protein gel formed by cold gelation. J. Food Eng. 2019, 256, 18–27. [Google Scholar] [CrossRef]

- Lubowa, M.; Yeoh, S.Y.; Easa, A.M. Textural and physical properties of retort processed rice noodles: Influence of chilling and partial substitution of rice flour with pregelatinized high-amylose maize starch. Food Sci. Tech. Int. 2018, 24, 476–486. [Google Scholar] [CrossRef]

- Wu, J.; Li, L.; Wu, X.; Dai, Q.; Zhang, R.; Zhang, Y. Characterization of Oat (Avena nuda L.) β-Glucan Cryogelation Process by Low-Field NMR. J. Agric. Food Chem. 2016, 64, 310–319. [Google Scholar] [CrossRef]

- Hager, A.S.; Bosmans, G.M.; Delcour, J.A. Physical and Molecular Changes during the Storage of Gluten-Free Rice and Oat Bread. J. Agric. Food Chem. 2014, 62, 5682–5689. [Google Scholar] [CrossRef]

- Chen, L.; Tian, Y.; Tong, Q.; Zhang, Z.; Jin, Z. Effect of pullulan on the water distribution, microstructure and textural properties of rice starch gels during cold storage. Food Chem. 2017, 214, 702–709. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Cheng, L.; Zhang, H.; Wang, L.; Qian, H.; Qi, X.; Wu, G. Research on migration path and structuring role of water in rice grain during soaking. Food Hydrocoll. 2019, 92, 41–50. [Google Scholar] [CrossRef]

- Tang, H.R.; Godward, J.; Hills, B. The distribution of water in native starch granules—A multinuclear NMR study. Carbohydr. Polym. 2000, 43, 375–387. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, H.; Wu, G.; Qi, X.; Wang, L.; Qian, H. Effect of structure evolution of starch in rice on the textural formation of cooked rice. Food Chem. 2021, 342, 128205. [Google Scholar] [CrossRef]

- Chen, C.; Fu, W.; Chang, Q.; Zheng, B.; Zhang, Y.; Zeng, H. Water distribution model describes the effect of water content on the structural properties of lotus seed resistant starch. Food Chem. 2019, 286, 449–458. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chen, J.; Luo, S.; Li, C.; Ye, J.; Liu, C.; Gilbert, R.G. Physicochemical and structural properties of pregelatinized starch prepared by improved extrusion cooking technology. Carbohydr. Polym. 2017, 175, 265–272. [Google Scholar] [CrossRef] [Green Version]

- Le Corre, D.; Bras, J.; Dufresne, A. Starch Nanoparticles: A Review. Biomacromolecules 2010, 11, 1139–1153. [Google Scholar] [CrossRef]

| Samples | Peak Viscosity (10−2 Pa.s) | Tough Viscosity (10−2 Pa.s) | Breakdown (10−2 Pa.s) | Final Viscosity (10−2 Pa.s) | Setback (10−2 Pa.s) | K* (10−2 Pa.sn) |

|---|---|---|---|---|---|---|

| ES | 536.00 ± 2.83 d | 106.00 ± 1.41 e | 430.00 ± 1.41 a | 180.50 ± 4.95 f | 74.50 ± 3.54 f | 155.70 ± 0.76 a |

| TBF | 1072.00 ± 2.83 a | 1020.50 ± 2.12 a | 51.50 ± 4.95 b | 2138.00 ± 5.66 a | 1117.50 ± 7.78 a | 2.49 ± 0.06 e |

| 10% E-F | 1085.00 ± 8.49 a | 1028.50 ± 0.71 a | 56.50 ± 7.78 b | 1996.50 ± 0.71 b | 964.50 ± 6.36 b | 7.40 ± 0.14 d |

| 20% E-F | 755.50 ± 6.36 b | 687.50 ± 6.36 b | 68.00 ± 0.00 b | 1281.00 ± 24.04 c | 593.50 ± 17.68 c | 7.98 ± 0.15 d |

| 30% E-F | 557.50 ± 2.12 c | 533.00 ± 12.73 c | 24.50 ± 10.61 c | 839.50 ± 20.51 d | 306.50 ± 7.78 d | 14.98 ± 0.15 c |

| 40% E-F | 432.00 ± 4.24 e | 422.50 ± 3.54 d | 9.50 ± 0.71 c | 610.50 ± 6.36 e | 188.00 ± 2.83 e | 30.02 ± 0.17 b |

| Noodles | T21 (ms) | T22 (ms) | T23 (ms) | T24 (ms) | A21 (%) | A22 (%) | A23 (%) | A24 (%) | |

|---|---|---|---|---|---|---|---|---|---|

| Fresh noodles | F-20% E-F | 0.31 ± 0.05 a | 4.19 ± 0.26 a | 41.26 ± 8.51 c | -- | 25.78 ± 0.69 a | 71.23 ± 0.80 b | 3.00 ± 0.19 a | -- |

| F-30% E-F | 0.38 ± 0.04 a | 4.82 ± 0.30 a | 61.51 ± 4.28 ab | -- | 21.73 ± 0.91b | 75.78 ± 0.98 a | 2.50 ± 0.25 ab | -- | |

| F-40% E-F | 0.38 ± 0.07 a | 4.49 ± 0.26 a | 76.02 ± 7.50 a | -- | 21.15 ± 0.38 b | 76.68 ± 0.40 a | 2.15 ± 0.15 b | -- | |

| Cooked noodles | C-20% E-F | 0.33 ± 0.07 A | 2.92 ± 0.23 A | 17.11 ± 2.28 A | 61.58 ± 9.22 A | 27.57 ± 1.99 B | 10.43 ± 2.98 A | 33.73 ± 3.65 A | 27.97 ± 5.07 B |

| C-30% E-F | 0.29 ± 0.03 A | 2.69 ± 0.49 A | 15.77 ± 1.06 AB | 58.02 ± 10.62 AB | 32.68 ± 1.68 AB | 9.13 ± 0.65 A | 32.83 ± 2.79 A | 25.25 ± 2.56 B | |

| C-40% E-F | 0.25 ± 0.04 A | 1.83 ± 0.72 A | 9.39 ± 1.31 B | 39.53 ± 3.26 B | 33.77 ± 2.17 A | 6.43 ± 2.14 A | 20.63 ± 1.46 B | 39.13 ± 0.49 A | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.-M.; Xing, J.-J.; Guo, X.-N.; Zhu, K.-X. Influence of the Addition of Extruded Endogenous Tartary Buckwheat Starch on Processing and Quality of Gluten-Free Noodles. Foods 2021, 10, 2693. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10112693

Han X-M, Xing J-J, Guo X-N, Zhu K-X. Influence of the Addition of Extruded Endogenous Tartary Buckwheat Starch on Processing and Quality of Gluten-Free Noodles. Foods. 2021; 10(11):2693. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10112693

Chicago/Turabian StyleHan, Xiao-Miao, Jun-Jie Xing, Xiao-Na Guo, and Ke-Xue Zhu. 2021. "Influence of the Addition of Extruded Endogenous Tartary Buckwheat Starch on Processing and Quality of Gluten-Free Noodles" Foods 10, no. 11: 2693. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10112693