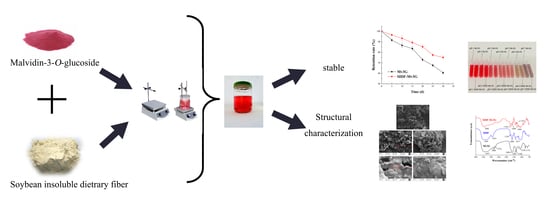

Protective Effect and Mechanism of Soybean Insoluble Dietary Fiber on the Color Stability of Malvidin-3-O-glucoside

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Optimal Design of SIDF-Mv3G Stable System

2.3. Stability of SIDF-Mv3G2.3.1. pH Stability

2.3.1. pH Stability

2.3.2. Thermal Stability

2.3.3. Sunlight Stability

2.4. Structural Characterization of SIDF-Mv3G

2.4.1. UV–VIS Spectroscopy

2.4.2. FT-IR Spectroscopy

2.4.3. XRD

2.5. Statistical Analysis

3. Results

3.1. Optimal Design of SIDF-Mv3G Stable System

3.2. Stability of SIDF-Mv3G

3.2.1. pH Stability

3.2.2. Thermal Stability

3.2.3. Sunlight Stability

3.3. Structural Characterization of SIDF-Mv3G

3.3.1. UV–VIS Spectroscopy

3.3.2. FT-IR Spectroscopy

3.3.3. XRD

3.3.4. SEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maciel, L.G.; do Carmo, M.A.V.; Azevedo, L.; Daguer, H.; Molognoni, L.; de Almeida, M.M.; Granato, D.; Rosso, N.D. Hibiscus sabdariffa anthocyanins-rich extract: Chemical stability, in vitro antioxidant and antiproliferative activities. Food Chem. Toxicol. 2018, 113, 187–197. [Google Scholar] [CrossRef] [PubMed]

- Hamed, Y. Antioxidant and anti-inflammatory activities of target anthocyanins di-glucosides isolated from syzygium cumini pulp by high speed counter-current chromatography. J. Food Biochem. 2020, 44, 1050–1062. [Google Scholar]

- Han, F.; Yang, P.; Wang, H.; Fernandes, I.; Mateus, N.; Liu, Y. Digestion and absorption of red grape and wine anthocyanins through the gastrointestinal tract. Trends Food Sci. Technol. 2019, 83, 211–224. [Google Scholar] [CrossRef]

- Cai, X.; Du, X.; Cui, D.; Wang, X.; Yang, Z.; Zhu, G. Improvement of stability of blueberry anthocyanins by carboxymethyl starch/xanthan gum combinations microencapsulation. Food Hydrocoll. 2019, 91, 238–245. [Google Scholar] [CrossRef]

- Khoo, H.E.; Azlan, A.; Tang, S.T.; Lim, S.M. Anthocyanidins and anthocyanins: Colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr. Res. 2017, 61, 1361779. [Google Scholar] [CrossRef] [Green Version]

- Castañeda-Ovando, A.; Pacheco-Hernández, M.d.L.; Páez-Hernández, M.E.; Rodríguez, J.A.; Galán-Vidal, C.A. Chemical studies of anthocyanins: A review. Food Chem. 2009, 113, 859–871. [Google Scholar] [CrossRef]

- He, Y.; Wen, L.; Yu, H.; Zheng, F.; Wang, Z.; Xu, X.; Zhang, H.; Cao, Y.; Wang, B.; Chu, B.; et al. Effects of high hydrostatic pressure-assisted organic acids on the copigmentation of vitis amurensis rupr anthocyanins. Food Chem. 2018, 268, 15–26. [Google Scholar] [CrossRef]

- He, Y.; Wen, L.; Yu, H.; Cao, Y.; Nan, H.; Gou, M.; Xie, C.; Xue, H. Isolation and structural identification of the main anthocyanin monomer in vitis amurensis rupr. Nat. Prod. Res. 2018, 32, 867–870. [Google Scholar] [CrossRef]

- Fernandes, A.; Brandão, E.; Raposo, F.; Maricato, É.; Oliveira, J.; Mateus, N.; Coimbra, M.A.; de Freitas, V. Impact of grape pectic polysaccharides on anthocyanins thermostability. Carbohydr. Polym. 2020, 239, 116240. [Google Scholar] [CrossRef]

- Cortez, R.; Luna-Vital, D.A.; Margulis, D.; Gonzalez de Mejia, E. Natural pigments: Stabilization methods of anthocyanins for food applications. Compr. Rev. Food Sci. Food Saf. 2017, 16, 180–198. [Google Scholar] [CrossRef]

- Chung, C.; Rojanasasithara, T.; Mutilangi, W.; McClements, D.J. Enhancement of colour stability of anthocyanins in model beverages by gum arabic addition. Food Chem. 2016, 201, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Sakulnak, R.; Wang, S. Effect of black tea on antioxidant, textural, and sensory properties of chinese steamed bread. Food Chem. 2016, 194, 1217–1223. [Google Scholar] [CrossRef] [PubMed]

- Quan, W.; He, W.; Qie, X.; Chen, Y.; Zeng, M.; Qin, F.; Chen, J.; He, Z. Effects of β-cyclodextrin, whey protein, and soy protein on the thermal and storage stability of anthocyanins obtained from purple-fleshed sweet potatoes. Food Chem. 2020, 320, 126655. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Tian, Y.; Chen, L.; Jin, Z. Linear dextrin as curcumin delivery system: Effect of degree of polymerization on the functional stability of curcumin. Food Hydrocoll. 2018, 77, 911–920. [Google Scholar] [CrossRef]

- Li, S.; Li, J.; Zhu, Z.; Cheng, S.; He, J.; Lamikanra, O. Soluble dietary fiber and polyphenol complex in lotus root: Preparation, interaction and identification. Food Chem. 2020, 314, 126219. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Ding, Z.; Zhang, M.; Sun, J. Microencapsulation of bayberry polyphenols by ethyl cellulose: Preparation and characterization. J. Food Eng. 2011, 104, 89–95. [Google Scholar] [CrossRef]

- Préstamo, G.; Rupérez, P.; Espinosa-Martos, I.; Villanueva, M.J.; Lasunción, M.A. The effects of okara on rat growth, cecal fermentation, and serum lipids. Eur. Food Res. Technol. 2007, 225, 925–928. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-S.; Yu, O.-K.; Byun, M.-S.; Cha, Y.-S. Okara, a soybean by-product, prevents high fat diet-induced obesity and improves serum lipid profiles in c57bl/6j mice. Food Sci. Biotechnol. 2016, 25, 607–613. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Y.; Zhang, H.; Mai, Q.; Zhang, B.; Li, H.; Deng, Z. The degradation rules of anthocyanins from eggplant peel and antioxidant capacity in fortified model food system during the thermal treatments. Food Biosci. 2020, 38, 100701. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Q.; Huang, J.; Fang, D.; Zhuang, W.; Luo, X.; Zou, X.; Zheng, B.; Cao, H. Hypoglycemic effect of dietary fibers from bamboo shoot shell: An in vitro and in vivo study. Food Chem. Toxicol. 2019, 127, 120–126. [Google Scholar] [CrossRef]

- Zhao, G.; Zhang, R.; Dong, L.; Huang, F.; Tang, X.; Wei, Z.; Zhang, M. Particle size of insoluble dietary fiber from rice bran affects its phenolic profile, bioaccessibility and functional properties. LWT—Food Sci. Technol. 2018, 87, 450–456. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Li, Y.; Yu, H.; Wang, Y.; Piao, C. Insoluble dietary fibre from okara (soybean residue) modified by yeast kluyveromyces marxianus. LWT—Food Sci. Technol. 2020, 134, 110252. [Google Scholar] [CrossRef]

- Wang, B.; Yu, H.; He, Y.; Wen, L.; Gu, J.; Wang, X.; Miao, X.; Qiu, G.; Wang, H. Effect of soybean insoluble dietary fiber on prevention of obesity in high-fat diet fed mice via regulation of the gut microbiota. Food Funct. 2021, 12, 7923–7937. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, Y.; Wang, Y.; Guo, J.; Xia, Q.; Tu, Y.; Nie, P. Compensation benefits allocation and stability evaluation of cascade hydropower stations based on variation coefficient-shapley value method. J. Hydrol. 2021, 599, 126277. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Zhang, L. An active and ph-responsive film developed by sodium carboxymethyl cellulose/polyvinyl alcohol doped with rose anthocyanin extracts. Food Chem. 2022, 373, 131367. [Google Scholar] [CrossRef]

- Fan, L.; Wang, Y.; Xie, P.; Zhang, L.; Li, Y.; Zhou, J. Copigmentation effects of phenolics on color enhancement and stability of blackberry wine residue anthocyanins: Chromaticity, kinetics and structural simulation. Food Chem. 2019, 275, 299–308. [Google Scholar] [CrossRef]

- Koh, J.; Xu, Z.; Wicker, L. Binding kinetics of blueberry pectin-anthocyanins and stabilization by non-covalent interactions. Food Hydrocoll. 2020, 99, 105354. [Google Scholar] [CrossRef]

- Patras, A.; Brunton, N.P.; O’Donnell, C.; Tiwari, B.K. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci. Technol. 2010, 21, 3–11. [Google Scholar] [CrossRef]

- Tang, B.; He, Y.; Liu, J.; Zhang, J.; Li, J.; Zhou, J.; Ye, Y.; Wang, J.; Wang, X. Kinetic investigation into ph-dependent color of anthocyanin and its sensing performance. Dye. Pigment. 2019, 170, 107643. [Google Scholar] [CrossRef]

- Wu, Y.; Geng, F.; Chang, P.R.; Yu, J.; Ma, X. Effect of agar on the microstructure and performance of potato starch film. Carbohydr. Polym. 2009, 76, 299–304. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, J.; Chen, F.; Wang, X.; Zhu, Q.; Ao, Q. Surface characterization of corn stalk superfine powder studied by ftir and xrd. Colloids Surf. B Biointerfaces 2013, 104, 207–212. [Google Scholar] [CrossRef] [PubMed]

- Le Bourvellec, C.; Guyot, S.; Renard, C.M.G.C. Non-covalent interaction between procyanidins and apple cell wall material: Part i. Effect of some environmental parameters. Biochim. Biophys. Acta (BBA)—Gen. Subj. 2004, 1672, 192–202. [Google Scholar] [CrossRef] [PubMed]

- Ullah, I.; Yin, T.; Xiong, S.; Huang, Q.; Ziaud, D.; Zhang, J.; Javaid, A.B. Effects of thermal pre-treatment on physicochemical properties of nano-sized okara (soybean residue) insoluble dietary fiber prepared by wet media milling. J. Food Eng. 2018, 237, 18–26. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, Y.; Yong, H.; Liu, J.; Zhang, X.; Liu, J. Preparation and characterization of active and intelligent packaging films based on cassava starch and anthocyanins from lycium ruthenicum murr. Int. J. Biol. Macromol. 2019, 134, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Pan, F.; Mehmood, A.; Zhang, Y.; Hao, S.; Rehman, A.U.; Li, J.; Wang, C.; Wang, Y. Protective effect and mechanism of action of xanthan gum on the color stability of black rice anthocyanins in model beverage systems. Int. J. Biol. Macromol. 2020, 164, 3800–3807. [Google Scholar] [CrossRef] [PubMed]

- Mansour, M.; Salah, M.; Xu, X. Effect of microencapsulation using soy protein isolate and gum arabic as wall material on red raspberry anthocyanin stability, characterization, and simulated gastrointestinal conditions. Ultrason. Sonochem. 2020, 63, 104927. [Google Scholar] [CrossRef]

- Wang, S.; Sun, W.; Swallah, M.S.; Amin, K.; Lyu, B.; Fan, H.; Zhang, Z.; Yu, H. Preparation and characterization of soybean insoluble dietary fiber and its prebiotic effect on dyslipidemia and hepatic steatosis in high fat-fed c57bl/6j mice. Food Funct. 2021, 12, 8760–8773. [Google Scholar] [CrossRef]

- Gao, R.; Liu, H.; Peng, Z.; Wu, Z.; Wang, Y.; Zhao, G. Adsorption of (−)-epigallocatechin-3-gallate (egcg) onto oat β-glucan. Food Chem. 2012, 132, 1936–1943. [Google Scholar] [CrossRef]

- Guan, Y.; Zhong, Q. The improved thermal stability of anthocyanins at ph 5.0 by gum arabic. LWT—Food Sci. Technol. 2015, 64, 706–712. [Google Scholar] [CrossRef]

- Pradhan, P.C.; Mandal, A.; Dutta, A.; Sarkar, R.; Kundu, A.; Saha, S. Delineating the behavior of berberis anthocyanin/β-cyclodextrin inclusion complex in vitro: A molecular dynamics approach. LWT—Food Sci. Technol. 2022, 157, 113090. [Google Scholar] [CrossRef]

| Samples | A: SIDF 1–Mv3G 2 Ratio | B: SIDF Particle Size (Mesh Sieve) | C: Emulsification Temperature (°C) | D: Emulsification Time (min) | Absorbance | Precipitation Eccentricity (%) | Composite Scores |

|---|---|---|---|---|---|---|---|

| 1 | 1 (1:20) | 1 (200) | 1 (20) | 1 (30) | 0.807 | 0.855 | −1.128 |

| 2 | 1 | 2 (300) | 2 (30) | 2 (40) | 0.880 | 0.786 | 1.2 |

| 3 | 1 | 3 (400) | 3 (40) | 3 (50) | 0.855 | 0.800 | 0.195 |

| 4 | 2 (1:30) | 1 | 2 | 3 | 0.885 | 0.781 | 1.246 |

| 5 | 2 | 2 | 3 | 1 | 0.850 | 0.786 | 0.719 |

| 6 | 2 | 3 | 1 | 2 | 0.830 | 0.857 | −0.793 |

| 7 | 3 (1:40) | 1 | 3 | 2 | 0.819 | 0.889 | −1.507 |

| 8 | 3 | 2 | 1 | 3 | 0.828 | 0.829 | −0.355 |

| 9 | 3 | 3 | 2 | 1 | 0.864 | 0.818 | 0.406 |

| K1 | 0.27 | −1.39 | −2.28 | 0.00 | |||

| K2 | 1.17 | 1.56 | 2.85 | −1.10 | |||

| K3 | −1.46 | −0.19 | −0.59 | 1.09 | |||

| R | 0.88 | 0.98 | 1.71 | 0.73 | |||

| Index | Average value | Standard deviation | Variable coefficient | Weight | |||

| Absorbance | 0.846 | 0.026 | 0.030 | 0.411 | |||

| Precipitation eccentricity | 0.825 | 0.035 | 0.043 | 0.589 | |||

| Samples | Standardized index | ||||||

| Absorbance | Precipitation eccentricity | ||||||

| 1 | −1.520 | −0.855 | |||||

| 2 | 1.325 | 1.112 | |||||

| 3 | 0.351 | 0.086 | |||||

| 4 | 1.520 | 1.054 | |||||

| 5 | 0.156 | 1.112 | |||||

| 6 | −0.623 | −0.912 | |||||

| 7 | −1.052 | −1.825 | |||||

| 8 | −0.701 | −0.114 | |||||

| 9 | 0.701 | 0.200 | |||||

| Projects | Sums of squared deviations | Freedom | Mean square | F value | Significance | ||

| SIDF–Mv3G ratio | 1.19 | 2 | 0.59 | 4.48 | * | ||

| SIDF particle size | 1.47 | 2 | 0.74 | 5.54 | * | ||

| Emulsification temperature | 4.56 | 2 | 2.28 | 17.16 | ** | ||

| Emulsification time | 0.80 | 2 | 0.40 | 3.00 | |||

| Error | 0.80 | 6 | 0.13 | ||||

| L* | a* | b* | ∆E | |

|---|---|---|---|---|

| pH 1 Mv3G solution | 43.02 b | 9.34 a | 2.11 bc | 38.88 gh |

| pH 1 Mv3G-SIDF 1 | 49.06 a | 10.14 a | 3.37 a | 38.31 h |

| pH 2 Mv3G solution | 43.18 b | 7.62 b | 1.43 c | 37.51 hi |

| pH 2 Mv3G-SIDF | 46.28 a | 9.15 a | 2.63 ab | 37.81 hi |

| pH 3 Mv3G solution | 42.88 b | 6.02 d | −2.48 d | 37.69 hi |

| pH 3 Mv3G-SIDF | 43.84 b | 7.21 bc | 2.56 abc | 36.57 i |

| pH 4 Mv3G solution | 37.94 c | 5.73 d | −7.20 f | 41.26 ef |

| pH 4 Mv3G-SIDF | 41.26 b | 7.38 bc | −3.99 e | 39.95 fg |

| pH 5 Mv3G solution | 33.76 de | 3.96 e | −8.43 g | 42.15 e |

| pH 5 Mv3G-SIDF | 35.45 cd | 6.61 cd | −6.85 f | 42.62 de |

| pH 6 Mv3G solution | 31.69 ef | 2.79 f | −12.32 h | 44.49 c |

| pH 6 Mv3G-SIDF | 32.76 ef | 6.07 d | −7.81 fg | 43.80 cd |

| pH 7 Mv3G solution | 26.70 g | 2.64 f | −14.83 i | 48.36 a |

| pH 7 Mv3G-SIDF | 30.59 f | 4.18 e | −12.91 h | 46.27 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Chen, D.; Liu, Y.; Sun, X.; Guo, W.; An, L.; Shi, Z.; Wen, L.; Wang, Z.; Yu, H. Protective Effect and Mechanism of Soybean Insoluble Dietary Fiber on the Color Stability of Malvidin-3-O-glucoside. Foods 2022, 11, 1474. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11101474

He Y, Chen D, Liu Y, Sun X, Guo W, An L, Shi Z, Wen L, Wang Z, Yu H. Protective Effect and Mechanism of Soybean Insoluble Dietary Fiber on the Color Stability of Malvidin-3-O-glucoside. Foods. 2022; 11(10):1474. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11101474

Chicago/Turabian StyleHe, Yang, Dongxia Chen, Yuheng Liu, Xiaozhen Sun, Wenrui Guo, Lingyu An, Zhenming Shi, Liankui Wen, Zhitong Wang, and Hansong Yu. 2022. "Protective Effect and Mechanism of Soybean Insoluble Dietary Fiber on the Color Stability of Malvidin-3-O-glucoside" Foods 11, no. 10: 1474. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11101474