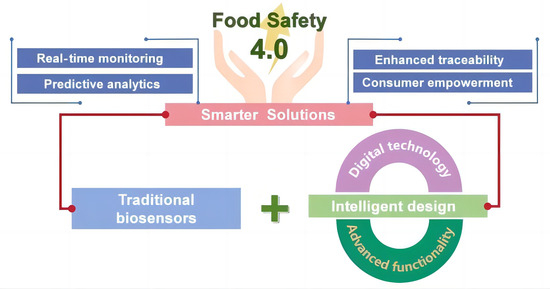

Intelligent Biosensors Promise Smarter Solutions in Food Safety 4.0

Abstract

:1. Introduction

2. Intension and Extension Intelligent Biosensors

3. Applications of Intelligent Biosensors in Food Safety

3.1. Deep Learning-Based Intelligent Biosensors

3.2. IoT-Based Intelligent Biosensors

3.3. Smartphone-Based Intelligent Biosensors

3.4. QR Codes-Based Intelligent Biosensors

3.5. Smart Packaging with Intelligent Biosensors

4. Conclusions and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, M.; Huang, D.; Hu, X.J.; Tong, W.H.; Han, B.L.; Tian, J.P.; Luo, H.B. Application of hyperspectral technology in detection of agricultural products and food: A Review. Food Sci. Nutr. 2020, 8, 5206–5214. [Google Scholar] [CrossRef]

- Lin, D.-Y.; Yu, C.-Y.; Ku, C.-A.; Chung, C.-K. Design, Fabrication, and Applications of SERS Substrates for Food Safety Detection: Review. Micromachines 2023, 14, 1343. [Google Scholar] [CrossRef] [PubMed]

- Colombo, A.W.; Karnouskos, S.; Yu, X.; Kaynak, O.; Luo, R.C.; Shi, Y.; Leitao, P.; Ribeiro, L.; Haase, J. A 70-Year Industrial Electronics Society Evolution Through Industrial Revolutions: The Rise and Flourishing of Information and Communication Technologies. IEEE Ind. Electron. Mag. 2021, 15, 115–126. [Google Scholar] [CrossRef]

- Cavas, B. Industry 4.0 And Science Education. J. Balt. Sci. Educ. 2019, 18, 652–653. [Google Scholar] [CrossRef]

- Vrchota, J.; Pech, M. Readiness of Enterprises in Czech Republic to Implement Industry 4.0: Index of Industry 4.0. Appl. Sci. 2019, 9, 5405. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current Status, Enabling Technologies, and Research Challenges. IEEE Trans. Ind. Inform. 2021, 17, 4322–4334. [Google Scholar] [CrossRef]

- Chen, C.-J.; Huang, Y.-Y.; Li, Y.-S.; Chang, C.-Y.; Huang, Y.-M. An AIoT Based Smart Agricultural System for Pests Detection. IEEE Access 2020, 8, 180750–180761. [Google Scholar] [CrossRef]

- Colombo-Mendoza, L.O.; Paredes-Valverde, M.A.; Salas-Zárate, M.d.P.; Valencia-García, R. Internet of Things-Driven Data Mining for Smart Crop Production Prediction in the Peasant Farming Domain. Appl. Sci. 2022, 12, 1940. [Google Scholar] [CrossRef]

- Ahn, H.S.; Sa, I.; Dayoub, F. Introduction to the Special Issue on Precision Agricultural Robotics and Autonomous Farming Technologies. IEEE Robot. Autom. Lett. 2018, 3, 4435–4438. [Google Scholar] [CrossRef]

- Bossert, L.; Hagendorff, T. Animals and AI. The role of animals in AI research and application—An overview and ethical evaluation. Technol. Soc. 2021, 67, 101678. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Memon, M.A.; Mahoto, N.A.; Zeadally, S.; Nebhen, J. Artificial Intelligence Best Practices in Smart Agriculture. IEEE Micro 2022, 42, 17–24. [Google Scholar] [CrossRef]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.-J. Big Data in Smart Farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Guan, S.; Wang, Z.; Cao, Y. A Novel Blockchain-Based Model for Agricultural Product Traceability System. IComM 2023, 61, 124–129. [Google Scholar] [CrossRef]

- Hassoun, A.; Jagtap, S.; Garcia-Garcia, G.; Trollman, H.; Pateiro, M.; Lorenzo, J.M.; Trif, M.; Rusu, A.V.; Aadil, R.M.; Šimat, V.; et al. Food quality 4.0: From traditional approaches to digitalized automated analysis. J. Food Eng. 2023, 337, 111216. [Google Scholar] [CrossRef]

- Jagtap, S.; Bader, F.; Garcia-Garcia, G.; Trollman, H.; Fadiji, T.; Salonitis, K. Food Logistics 4.0: Opportunities and Challenges. Logistics 2020, 5, 2. [Google Scholar] [CrossRef]

- Zeng, X.; Cao, R.; Xi, Y.; Li, X.; Yu, M.; Zhao, J.; Cheng, J.; Li, J. Food flavor analysis 4.0: A cross-domain application of machine learning. Trends Food Sci. Technol. 2023, 138, 116–125. [Google Scholar] [CrossRef]

- Hassoun, A.; Kamiloglu, S.; Garcia-Garcia, G.; Parra-López, C.; Trollman, H.; Jagtap, S.; Aadil, R.M.; Esatbeyoglu, T. Implementation of relevant fourth industrial revolution innovations across the supply chain of fruits and vegetables: A short update on Traceability 4.0. Food Chem. 2023, 409, 135303. [Google Scholar] [CrossRef]

- Hassoun, A.; Jagtap, S.; Trollman, H.; Garcia-Garcia, G.; Abdullah, N.A.; Goksen, G.; Bader, F.; Ozogul, F.; Barba, F.J.; Cropotova, J.; et al. Food processing 4.0: Current and future developments spurred by the fourth industrial revolution. Food Control 2023, 145, 109507. [Google Scholar] [CrossRef]

- Lezoche, M.; Hernandez, J.E.; Alemany Díaz, M.d.M.E.; Panetto, H.; Kacprzyk, J. Agri-food 4.0: A survey of the supply chains and technologies for the future agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Campuzano-Bolarín, F. A General Outline of a Sustainable Supply Chain 4.0. Sustainability 2020, 12, 7978. [Google Scholar] [CrossRef]

- Echegaray, N.; Hassoun, A.; Jagtap, S.; Tetteh-Caesar, M.; Kumar, M.; Tomasevic, I.; Goksen, G.; Lorenzo, J.M. Meat 4.0: Principles and Applications of Industry 4.0 Technologies in the Meat Industry. Appl. Sci. 2022, 12, 6986. [Google Scholar] [CrossRef]

- Hassoun, A.; Garcia-Garcia, G.; Trollman, H.; Jagtap, S.; Parra-López, C.; Cropotova, J.; Bhat, Z.; Centobelli, P.; Aït-Kaddour, A. Birth of dairy 4.0: Opportunities and challenges in adoption of fourth industrial revolution technologies in the production of milk and its derivatives. Curr. Res. Food Sci. 2023, 7, 100535. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, K.; Kim, J.; Seo, J. Packaging 4.0: The threshold of an intelligent approach. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2615–2638. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, M.; Pang, X.; Huang, K.; Yao, Z.; Mei, X.; Cheng, N. Comparative study of Pd@Pt nanozyme improved colorimetric N-ELISA for the paper-output portable detection of Staphylococcus aureus. Talanta 2022, 247, 123503. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, H.; Song, G.; Huang, K.; Luo, Y.; Liu, Q.; He, X.; Cheng, N. Intelligent biosensing strategies for rapid detection in food safety: A review. Biosens. Bioelectron. 2022, 202, 114003. [Google Scholar] [CrossRef]

- Cui, F.; Yue, Y.; Zhang, Y.; Zhang, Z.; Zhou, H.S. Advancing Biosensors with Machine Learning. ACS Sens. 2020, 5, 3346–3364. [Google Scholar] [CrossRef]

- Janiesch, C.; Zschech, P.; Heinrich, K. Machine learning and deep learning. Electron. Mark. 2021, 31, 685–695. [Google Scholar] [CrossRef]

- Dong, S.; Wang, P.; Abbas, K. A survey on deep learning and its applications. Comput. Sci. Rev. 2021, 40, 100379. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Kamilaris, A.; Prenafeta-Boldú, F.X. Deep learning in agriculture: A survey. Comput. Electron. Agric. 2018, 147, 70–90. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, L.; Phene, S.; Peng, L. Lessons learnt from harnessing deep learning for real-world clinical applications in ophthalmology: Detecting diabetic retinopathy from retinal fundus photographs. In Artificial Intelligence in Medicine; Academic Press: Cambridge, MA, USA, 2021; pp. 247–264. [Google Scholar]

- Zakhrouf, M.; Hamid, B.; Kim, S.; Madani, S. Novel insights for streamflow forecasting based on deep learning models combined the evolutionary optimization algorithm. PhGeo 2021, 44, 31–54. [Google Scholar] [CrossRef]

- Singh, A.; Sharma, A.; Ahmed, A.; Sundramoorthy, A.K.; Furukawa, H.; Arya, S.; Khosla, A. Recent Advances in Electrochemical Biosensors: Applications, Challenges, and Future Scope. Biosensors 2021, 11, 336. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Yang, W.; Peng, S.; Zhou, J. A Survey of Convolutional Neural Networks: Analysis, Applications, and Prospects. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 6999–7019. [Google Scholar] [CrossRef] [PubMed]

- Guselnikova, O.; Trelin, A.; Skvortsova, A.; Ulbrich, P.; Postnikov, P.; Pershina, A.; Sykora, D.; Svorcik, V.; Lyutakov, O. Label-free surface-enhanced Raman spectroscopy with artificial neural network technique for recognition photoinduced DNA damage. Biosens. Bioelectron. 2019, 145, 111718. [Google Scholar] [CrossRef] [PubMed]

- Tun, W.S.T.; Talodthaisong, C.; Daduang, S.; Daduang, J.; Rongchai, K.; Patramanon, R.; Kulchat, S. A machine learning colorimetric biosensor based on acetylcholinesterase and silver nanoparticles for the detection of dichlorvos pesticides. Mater. Chem. Front. 2022, 6, 1487–1498. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, S.; Duan, H.; Liu, Y. A Fluorescent Biosensor for Sensitive Detection of Salmonella typhimurium Using Low-Gradient Magnetic Field and Deep Learning via Faster Region-Based Convolutional Neural Network. Biosensors 2021, 11, 447. [Google Scholar] [CrossRef] [PubMed]

- Nehal, S.A.; Roy, D.; Devi, M.; Srinivas, T. Highly sensitive lab-on-chip with deep learning AI for detection of bacteria in water. Int. J. Inf. Technol. 2019, 12, 495–501. [Google Scholar] [CrossRef]

- Jia, X.; Ma, P.; Tarwa, K.; Mao, Y.; Wang, Q. Development of a novel colorimetric sensor array based on oxidized chitin nanocrystals and deep learning for monitoring beef freshness. Sens. Actuators B Chem. 2023, 390, 133931. [Google Scholar] [CrossRef]

- Ma, P.; Zhang, Z.; Xu, W.; Teng, Z.; Luo, Y.; Gong, C.; Wang, Q. Integrated Portable Shrimp-Freshness Prediction Platform Based on Ice-Templated Metal–Organic Framework Colorimetric Combinatorics and Deep Convolutional Neural Networks. ACS Sustain. Chem. Eng. 2021, 9, 16926–16936. [Google Scholar] [CrossRef]

- Iheonye, A.C.; Raghavan, V.; Ferrie, F.P.; Orsat, V.; Gariepy, Y. Monitoring Visual Properties of Food in Real Time During Food Drying. Food Eng. Rev. 2023, 15, 242–260. [Google Scholar] [CrossRef]

- Yang, Z.; Miao, N.; Zhang, X.; Li, Q.; Wang, Z.; Li, C.; Sun, X.; Lan, Y. Employment of an electronic tongue combined with deep learning and transfer learning for discriminating the storage time of Pu-erh tea. Food Control 2021, 121, 107608. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, H.; Gu, Y. A Model Transfer Learning Framework With Back-Propagation Neural Network for Wine and Chinese Liquor Detection by Electronic Nose. IEEE Access 2020, 8, 105278–105285. [Google Scholar] [CrossRef]

- Asghari, P.; Rahmani, A.M.; Javadi, H.H.S. Internet of Things applications: A systematic review. Comput. Netw. 2019, 148, 241–261. [Google Scholar] [CrossRef]

- Bertino, E.; Choo, K.-K.R.; Georgakopolous, D.; Nepal, S. Internet of Things (IoT). ACM Trans. Internet Technol. 2016, 16, 22. [Google Scholar] [CrossRef]

- Alfian, G.; Syafrudin, M.; Rhee, J. Real-Time Monitoring System Using Smartphone-Based Sensors and NoSQL Database for Perishable Supply Chain. Sustainability 2017, 9, 2073. [Google Scholar] [CrossRef]

- Sowmya, N.; Ponnusamy, V. Development of Spectroscopic Sensor System for an IoT Application of Adulteration Identification on Milk Using Machine Learning. IEEE Access 2021, 9, 53979–53995. [Google Scholar] [CrossRef]

- Seo, S.-M.; Kim, S.-W.; Jeon, J.-W.; Kim, J.-H.; Kim, H.-S.; Cho, J.-H.; Lee, W.-H.; Paek, S.-H. Food contamination monitoring via internet of things, exemplified by using pocket-sized immunosensor as terminal unit. Sens. Actuators B Chem. 2016, 233, 148–156. [Google Scholar] [CrossRef]

- Massah, J.; Asefpour Vakilian, K. An intelligent portable biosensor for fast and accurate nitrate determination using cyclic voltammetry. Biosyst. Eng. 2019, 177, 49–58. [Google Scholar] [CrossRef]

- Chung, H.; Li, J.; Kim, Y.; Van Os, J.M.C.; Brounts, S.H.; Choi, C.Y. Using implantable biosensors and wearable scanners to monitor dairy cattle’s core body temperature in real-time. Comput. Electron. Agric. 2020, 174, 105453. [Google Scholar] [CrossRef]

- Song, Z.; Zhou, S.; Qin, Y.; Xia, X.; Sun, Y.; Han, G.; Shu, T.; Hu, L.; Zhang, Q. Flexible and Wearable Biosensors for Monitoring Health Conditions. Biosensors 2023, 13, 630. [Google Scholar] [CrossRef]

- Ma, J.; Cui, Z.; Du, Y.; Xu, Q.; Deng, Q.; Zhu, N. Multifunctional Prussian blue/graphene ink for flexible biosensors and supercapacitors. Electrochim. Acta 2021, 387, 138496. [Google Scholar] [CrossRef]

- Mishra, R.K.; Hubble, L.J.; Martín, A.; Kumar, R.; Barfidokht, A.; Kim, J.; Musameh, M.M.; Kyratzis, I.L.; Wang, J. Wearable Flexible and Stretchable Glove Biosensor for On-Site Detection of Organophosphorus Chemical Threats. ACS Sens. 2017, 2, 553–561. [Google Scholar] [CrossRef]

- Zheng, M.M.; Zhang, S.S.; Zhang, Y.D.; Hu, B.Z. Construct Food Safety Traceability System for People’s Health Under the Internet of Things and Big Data. IEEE Access 2021, 9, 70571–70583. [Google Scholar] [CrossRef]

- Li, C.; Wang, J.; Ding, X.; Zhang, N. Acoustic Imaging Using the Built-In Sensors of a Smartphone. Symmetry 2021, 13, 1065. [Google Scholar] [CrossRef]

- Han, D.C.; Takabatake, T.; Esteban, M.; Shibayama, T. Development and Implementation of a Smartphone Application for Tsunami Evacuation. Int. J. Disaster Risk Reduct. 2023, 96, 103915. [Google Scholar] [CrossRef]

- Jung, C.-Y.; Kim, Y.; Kim, H.W.; Han, S.H.; Yoo, T.-H.; Kang, S.-W.; Park, J.T. Effectiveness of a Smartphone Application for Dietary Sodium Intake Measurement. Nutrients 2023, 15, 3590. [Google Scholar] [CrossRef] [PubMed]

- Sandim, A.; Amaro, M.; Silva, M.E.; Cunha, J.; Morais, S.; Marques, A.; Ferreira, A.; Lousada, J.L.; Fonseca, T. New Technologies for Expedited Forest Inventory Using Smartphone Applications. Forests 2023, 14, 1553. [Google Scholar] [CrossRef]

- Zangheri, M.; Di Nardo, F.; Calabria, D.; Marchegiani, E.; Anfossi, L.; Guardigli, M.; Mirasoli, M.; Baggiani, C.; Roda, A. Smartphone biosensor for point-of-need chemiluminescence detection of ochratoxin A in wine and coffee. Anal. Chim. Acta 2021, 1163, 338515. [Google Scholar] [CrossRef]

- Wang, S.; Zheng, L.; Cai, G.; Liu, N.; Liao, M.; Li, Y.; Zhang, X.; Lin, J. A microfluidic biosensor for online and sensitive detection of Salmonella typhimurium using fluorescence labeling and smartphone video processing. Biosens. Bioelectron. 2019, 140, 111333. [Google Scholar] [CrossRef]

- Soni, A.; Surana, R.K.; Jha, S.K. Smartphone based optical biosensor for the detection of urea in saliva. Sens. Actuators B Chem. 2018, 269, 346–353. [Google Scholar] [CrossRef]

- Zhang, H.; Xue, L.; Huang, F.; Wang, S.; Wang, L.; Liu, N.; Lin, J. A capillary biosensor for rapid detection of Salmonella using Fe-nanocluster amplification and smart phone imaging. Biosens. Bioelectron. 2019, 127, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Lopreside, A.; Montali, L.; Wang, B.; Tassoni, A.; Ferri, M.; Calabretta, M.M.; Michelini, E. Orthogonal paper biosensor for mercury(II) combining bioluminescence and colorimetric smartphone detection. Biosens. Bioelectron. 2021, 194, 113569. [Google Scholar] [CrossRef] [PubMed]

- Montali, L.; Calabretta, M.M.; Lopreside, A.; D’Elia, M.; Guardigli, M.; Michelini, E. Multienzyme chemiluminescent foldable biosensor for on-site detection of acetylcholinesterase inhibitors. Biosens. Bioelectron. 2020, 162, 112232. [Google Scholar] [CrossRef]

- Sanaeifar, A.; ZakiDizaji, H.; Jafari, A.; Guardia, M.d.L. Early detection of contamination and defect in foodstuffs by electronic nose: A review. TrAC Trends Anal. Chem. 2017, 97, 257–271. [Google Scholar] [CrossRef]

- Kanchi, S.; Sabela, M.I.; Mdluli, P.S.; Bisetty, K. Smartphone based bioanalytical and diagnosis applications: A review. Biosens. Bioelectron. 2018, 102, 136–149. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Xiao, X.; Wang, J.; Wang, H. Identification of the Rice Wines with Different Marked Ages by Electronic Nose Coupled with Smartphone and Cloud Storage Platform. Sensors 2017, 17, 2500. [Google Scholar] [CrossRef]

- Nam, S.J. The effects of consumer empowerment on risk perception and satisfaction with food consumption. Int. J. Consum. Stud. 2019, 43, 429–436. [Google Scholar] [CrossRef]

- Bradford, H.; McKernan, C.; Elliott, C.; Dean, M. Consumer purchase intention towards a quick response (QR) code for antibiotic information: An exploratory study. NPJ Sci. Food 2022, 6, 23. [Google Scholar] [CrossRef]

- Böhm, S.; Klein, M.; Bayrak Meydanoğlu, E.S.; Çilingirtürk, A.M. QR code advertising: A cross-country comparison of Turkish and German consumers. Int. J. Internet Mark. Advert. 2018, 12, 40–68. [Google Scholar] [CrossRef]

- Kim, Y.G.; Woo, E. Consumer acceptance of a quick response (QR) code for the food traceability system: Application of an extended technology acceptance model (TAM). Food Res. Int. 2016, 85, 266–272. [Google Scholar] [CrossRef]

- Yuan, M.; Liu, K.-K.; Singamaneni, S.; Chakrabartty, S. Self-Powered Forward Error-Correcting Biosensor Based on Integration of Paper-Based Microfluidics and Self-Assembled Quick Response Codes. IEEE Trans. Biomed. Circuits Syst. 2016, 10, 963–971. [Google Scholar] [CrossRef]

- Khan, S.; Monteiro, J.K.; Prasad, A.; Filipe, C.D.M.; Li, Y.; Didar, T.F. Material Breakthroughs in Smart Food Monitoring: Intelligent Packaging and On-Site Testing Technologies for Spoilage and Contamination Detection. Adv. Mater. 2023, 36, 2300875. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.-L.; Xie, L.-H.; Joseph, E.A.; Li, J.-R.; Su, X.-O.; Zhou, H.-C. Metal–Organic Frameworks for Food Safety. Chem. Rev. 2019, 119, 10638–10690. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Duan, F.; Zhang, S.; Tian, J.-Y.; Zhang, Z.; Wang, Z.-W.; Liu, C.-S.; Xu, W.-M.; Du, M. Iron oxide@mesoporous carbon architectures derived from an Fe(ii)-based metal organic framework for highly sensitive oxytetracycline determination. J. Mater. Chem. A 2017, 5, 19378–19389. [Google Scholar] [CrossRef]

- Li, S.; Tang, W.; Chen, S.; Si, Y.; Liu, R.; Guo, X. Flexible Organic Polymer Gas Sensor and System Integration for Smart Packaging. Adv. Sens. Res. 2023, 2, 2300030. [Google Scholar] [CrossRef]

- Prasad, A.; Khan, S.; Monteiro, J.K.; Li, J.; Arshad, F.; Ladouceur, L.; Tian, L.; Shakeri, A.; Filipe, C.D.M.; Li, Y.; et al. Advancing In Situ Food Monitoring through a Smart Lab-in-a-Package System Demonstrated by the Detection of Salmonella in Whole Chicken. Adv. Mater. 2023, 35, 2302641. [Google Scholar] [CrossRef]

- Barandun, G.; Soprani, M.; Naficy, S.; Grell, M.; Kasimatis, M.; Chiu, K.L.; Ponzoni, A.; Güder, F. Cellulose Fibers Enable Near-Zero-Cost Electrical Sensing of Water-Soluble Gases. ACS Sens. 2019, 4, 1662–1669. [Google Scholar] [CrossRef]

| Terminology | Purpose | References |

|---|---|---|

| Food quality 4.0 | To ensure high food quality, save time and labor, and increase efficiency in the food industry | [14] |

| Food Logistics 4.0 | To minimize resources and waste and effectively manage the transport of food from farm to fork while meeting consumer demand | [15] |

| Food Flavor Analysis 4.0 | To achieve rapid detection of food additives, quality, and authenticity in food, and to accurately predict the flavor of unknown food samples | [16] |

| Food Traceability 4.0 | To ensure the authenticity, safety, and high quality of food | [17] |

| Food processing 4.0 | To improve the quality and safety of processed foods, reduce production costs and time, save energy and resources, and reduce food loss and waste | [18] |

| Agri-food 4.0 | To support better supply chain decision-making processes | [19] |

| Sustainable Supply Chain 4.0 | To organize a closed-loop product life cycle | [20] |

| Meat 4.0 | To advance meat processing, preservation, quality, safety, and authenticity analysis techniques | [21] |

| Birth of Dairy 4.0 | For more automation and optimization in the dairy industry | [22] |

| Packaging 4.0 | For decentralized data collection in the supply chain, in-store and post-purchase phases, leading to consistent lifecycle monitoring | [23] |

| Features | Traditional Biosensors | Intelligent Biosensors |

|---|---|---|

| Multiplexing and Specificity | Usually, they only detect a single analyte | Multiple substances can be detected simultaneously and higher sensitivity and specificity can be achieved |

| Data analysis and connection | The signals generated usually require external equipment for manual interpretation or processing | Autonomous analysis by intelligent devices and connectivity to digital systems and networks, enabling seamless integration and real-time data transfer |

| Real-time Monitoring and Alerts | Requires manual activation and data retrieval, which may require more time to collect and analyze data, resulting in delays in detecting and addressing problems | Continuous real-time monitoring of specific substances or conditions and triggering of alarms or notifications when specific thresholds are exceeded |

| Decision-making | Usually provides passive data, detects and reports on specific substances as prompted | Autonomous decision-making through continuous monitoring and real-time analysis of data |

| Remote Accessibility | / | Remote access and monitoring via web interface or mobile app |

| Predictive Analytics | / | Intelligent biosensors can be integrated with AI and data analytics, enabling them to analyze complex data patterns and make predictions |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wang, Y.; Zhang, Y.; Wang, X.; Zhang, C.; Cheng, N. Intelligent Biosensors Promise Smarter Solutions in Food Safety 4.0. Foods 2024, 13, 235. https://0-doi-org.brum.beds.ac.uk/10.3390/foods13020235

Chen Y, Wang Y, Zhang Y, Wang X, Zhang C, Cheng N. Intelligent Biosensors Promise Smarter Solutions in Food Safety 4.0. Foods. 2024; 13(2):235. https://0-doi-org.brum.beds.ac.uk/10.3390/foods13020235

Chicago/Turabian StyleChen, Yuehua, Yicheng Wang, Yiran Zhang, Xin Wang, Chen Zhang, and Nan Cheng. 2024. "Intelligent Biosensors Promise Smarter Solutions in Food Safety 4.0" Foods 13, no. 2: 235. https://0-doi-org.brum.beds.ac.uk/10.3390/foods13020235