1. Introduction

Spray drying represents a well-known example of particle-laden flow where a hot-gas jet interacts with a spray cloud to produce high-quality powders. General aspects of spray drying processes are well documented in the literature, e.g., Santos et al. [

1]. The interaction between the gas and liquid phases is complex [

2] and involves several thermo-physical processes affecting the properties of the powder [

3]. These processes are strongly related to the gas-flow dynamics inside the drying chamber [

4], and its modeling is essential to predict the performance of a spray dryer [

5]. A large number of previous studies using computational fluid dynamics (CFD) have assumed a steady-state approach to model the airflow inside the drying chamber, such as Woo et al. [

6], but the current trend towards using a transient approach is now widely accepted [

4]. The assumption of a steady-flow field has been found to be inaccurate, as demonstrated by various experimental and CFD studies.

In a pilot-scale spray chamber, Southwell and Langrish [

7] used visual techniques, which revealed a swirl-dependent chaotic behavior of the flow in significant portions of the drying chamber. They also visualized a central vortex that exhibited temporal and spatial unsteadiness. Using laser-Doppler anemometry, Southwell and Langrish [

8] further investigated the effect of swirl on flow stability. Their findings showed that, for all studied swirl settings (ranging from 0° to 45°) at the inlet, no swirl angle resulted in steady flow behavior within the drying chamber. They also reported the existence of slow, large, and unsteady recirculation regions that altered the flow direction. These flow instabilities are more pronounced in short-form spray dryers [

9] with lower swirl values at the inlet jet. Lebarbier et al. [

10] employed image analysis techniques (light sheet) to study the flow patterns in a 1/31 scale model of an industrial-sized spray chamber. These observations also revealed a strong time-dependent precessing behavior in the central jet.

Transient CFD studies have also confirmed the time-dependent nature of the airflow. In a CFD study of gas flow inside a pilot-scale spray dryer with and without swirl, Langrish et al. [

11] explored the time-dependent nature of flow patterns. In this study, they found that even under zero inlet swirl conditions, the central jet exhibited slight precession around the axis, challenging the validity of the steady-state assumption. In a three-dimension transient study of gas-particle interactions in an industrial-scale spray dryer, Jin and Chen [

12] reported low-frequency oscillations of the central jet and three-dimensionality in the flow field, leading to a more realistic dispersion of particles within the chamber. Using a large-eddy simulation approach (LES) to model airflow in a semi-industrial-sized spray chamber, Jongsma et al. [

13] reported the existence of large-scale flow structures that exhibited a transient nature, particularly when the central jet was deflected towards the walls. This mechanism is particularly significant for an accurate prediction of the wall deposition of particles.

A further drawback of the steady-state approach is its apparent inability to reach a converged state, a matter debated by Fletcher and Langrish [

14] and verified by Lebarbier et al. [

10]. This limitation also emerged in preliminary simulations conducted in this study. While some authors have reported residual convergence in steady-state simulations, coarse grids may attenuate these instabilities [

9], hence failing to replicate critical flow phenomena within the drying chamber and potentially resulting in misleading results. If sufficient computational resources are available, a transient approach within a three-dimensional domain should be used for CFD simulations of spray dryers [

2].

The main difficulty of applying the transient approach lies in its numerical cost [

15]. This is due to the ranges of flow time-scales inside the drying chamber [

16], which vary from microseconds in the inlet diffuser to seconds in the external recirculation zones and in the precessing motion of the jet. As a consequence, the number of resolved time steps required by the solution must be long enough to develop instabilities, settling the flow to its quasi-steady limits [

9] and capturing sufficient information. In previous studies, simulation times vary widely, making it difficult to determine whether conditions for developed flows were achieved or whether run times were selected under computational constraints. Examples of such simulation times reported in pilot- and semi-industrial-size chamber simulations vary between

in Fletcher and Langrish [

14], Gimbun et al. [

17],

in Benavides-Morán et al. [

18],

to

in Jongsma et al. [

13],

in Jin and Chen [

12],

in Saleh and Nahi Saleh [

19], and up to

in Langrish et al. [

11]. Computational costs become even more relevant for industrial-scale simulations with atomization of liquids, where parametrization and process optimization require running numerous simulation cases. These limitations are a relevant challenge for future numerical development to facilitate the use of the CFD technique on a more routine basis [

15].

An alternative to reduce computational costs is the use of adaptive mesh refinement (AMR) strategies. Mesh adaptation is accomplished by dividing or coarsening groups of cells following a refinement criterion [

20]. The criterion must be related to the physical features of the flow problem and the turbulence approach used. Examples of criteria discussed in the literature include the ratio of modeled to resolved turbulent kinetic energies [

21], the residual velocity magnitude and the vorticity [

20], and the gradient-based relative error [

22]. Although AMR has not yet been used in spray dryer simulations, it can provide relevant advantages due to the unstable nature of the flow, which causes the position of the main flow structures to change with time. For eddy-resolving approaches, such as detached eddy simulation (DES) and large eddy simulation (LES), the capture of large eddies requires grid adaptation along their path. For this reason, it would be impractical to attempt a mesh optimization using a static-grid approach.

For related cases such as jets and separated flows, the use of AMR has given very good results. Muralidharan and Menon [

23] studied a transverse jet into a cross-flow configuration with and without reaction using mixed AMR criteria based on the pressure gradient and the vorticity. The results agreed very well with direct numerical simulation (DNS) data. Mozaffari et al. [

24] successfully used fast- and slow-evolving AMR criteria along with a hybrid LES/RANS scheme to model the flow over a backward-facing step. The backward-facing step is a classic flow problem that greatly resembles the discharge of annular jets, typically found in spray drying chambers. Still, for modeling of full-size spray drying processes, there is uncertainty as to which AMR criterion might work best. For example, Wackers et al. [

25] mentions that a pressure gradient-based refinement criterion has advantages over a velocity gradient-based refinement criterion when the simulation interest is far from the boundary layer, as is the case of spray dryer modeling. However, Gutiérrez Suárez et al. [

26] found that refinement in the high-gradient zones downstream of the discharge, where the high-velocity jet interacts with its surroundings, has a direct effect on the accuracy of the results. As for AMR parameters, such as refinement level and threshold, they are not sufficiently discussed in all studies, and it is assumed that their adjustment varies for each specific application.

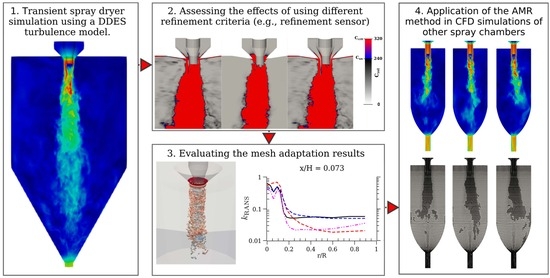

This paper proposes the application of AMR methods to reduce computational costs in transient simulations of spray dryers. To the authors’s knowledge, the application of AMR methods in spray dryer simulations is a novel approach. Consequently, there is uncertainty about whether using specific AMR configuration parameters that have demonstrated effectiveness in other applications will be suitable in this context. This study evaluates three refinement criteria and two AMR configuration parameters to model airflow in two distinct spray drying chambers operating with a co-current flow configuration. The criteria for evaluation are based on the relative errors associated with velocity gradient, pressure gradient, and vorticity, while the AMR configuration parameters are the refinement level and threshold. The first drying chamber is of pilot size, has an annular inlet with Re = 19,600, and has been studied by Gutiérrez Suárez [

27] and by Benavides-Morán et al. [

18]. The second drying chamber is of semi-industrial size, has an annular inlet with Re = 41,200, and was studied by Kieviet [

3]. For both drying chambers, the cited studies provide experimental airflow data obtained by hotwire anemometry (HWA), serving as a base for validation. To account for the unsteady nature of the internal airflow, a transient modeling approach in a fully three-dimensional domain is used. Turbulence resolution capability is provided by a delayed-DES model, which is suitable for the simulation of spray dryers [

26]. Special attention is paid to the full development of flow instabilities. The primary objective is to determine an AMR configuration that reduces the computational costs of transient CFD simulations of spray dryers while maintaining solution accuracy.

This paper is organized into five sections.

Section 2 provides a description of the numerical methods employed in the study. In

Section 3, the computational configuration is discussed, including details about the domain, base grid, and boundary conditions.

Section 4 outlines the numerical experiments and the simulation methodology employed. The results and discussion are presented in

Section 5, where the evaluation of each AMR criterion, threshold values, and refinement limits are discussed. Finally,

Section 6 presents the conclusions derived from the study.

6. Conclusions

In this study, adaptive mesh refinement (AMR) is used in conjunction with a hybrid LES/RANS turbulence model to simulate the airflow in two different spray drying chambers. The use of AMR allowed a significant computational cost reduction. Compared to the base case (fixed grid with two refinement levels), the cases evaluated showed a 70% to 91% reduction in computational cost. This computational cost reduction becomes critical due to the long simulation times required to develop the internal flow (). The AMR approach presented in this study can be used in parametric studies of spray drying processes and other confined jet applications where computational costs become a major limiting factor. In this way, it is possible to run numerous simulation cases using a high-end workstation. However, cost reduction strategies must be accompanied by a careful application of the AMR methods to avoid an impact on the accuracy of the results.

In general, the effect of different factors on mesh adaptation behavior must be assessed for all the criteria evaluated. In the absence of swirl at the discharge (as is the case in the semi-industrial-size dryer), the radial coverage of the refining zone is very different from that obtained in a low-swirl jet (pilot-size chamber). The size of the background grid (level 0) is also influential, since if it is excessively coarse, a sufficiently high relative error will not be generated to trigger the mesh adaptation. Finally, the refinement threshold must also be balanced against the maximum refinement level allowed. Based on the results of this study, it does not always seem appropriate to reduce refinement coverage by a higher level of refinement. It is estimated that the ideal refinement threshold should generate a grid containing between 25% and 40% of the elements of a fixed grid. The use of lower threshold values, such as that of case S3, which generates a grid with a proportion greater than 40%, does not seem to bring a noticeable improvement in the results.

In detail, the differences in results when using various AMR criteria (

,

,

) are small but significant. At first glance, the pressure gradient-based criterion allows for a better modeling of the jet discharge by ensuring its complete refinement. However, the transition between different refinement levels is abrupt, generating artificial oscillations. Moreover, as it focuses solely on a narrow region, at the jet discharge, it inaccurately models the kinetic energy

upstream. Both the

and

criteria generate a smoother transition between refinement levels in the inlet duct but are not consistent in refining to the highest level of the section with the highest axial velocity in the discharge. Due to these sporadic changes in the level of refinement, some artificial fluctuations are generated but of lesser intensity than in the case of the

criterion. To eliminate or reduce these fluctuations, there are several alternatives: The first one is to carry out a fixed prerefinement in the cells around the inlet diffuser. In this way, AMR-controlled unrefinement would not be allowed in such cells, and these artificial fluctuations would be eliminated. According to the results of Mozaffari et al. [

24], it is recommended to extend the prerefining to the recirculation zone under the bluff-body to remove truncation errors due to the high flow instability; the second is to increase the number of buffer cells between cells with different refinement levels. In this way, the transition between cell levels would be smoothed, and the results of the

criterion would be enhanced; the third alternative is to combine the

criterion with one of the other two to generate a more homogeneous refinement in the discharge and in the near-region of the jet; the fourth is incorporating nonlinear terms in the relative error calculation, such as

. This would smooth the transition between refinement levels and increase the coverage of transition cells.

Downstream of the discharge, the cases with higher jet refinement coverage (C1–C3 and S1–S3) manage to capture by dynamic grid adaptation the transient motion of the jet. The operational differences between the AMR methods are mainly observed in their interaction with the walls. The criterion does not perform refinements on the chamber walls (except for the inlet and outlet ducts). The and criteria do perform refinements on the walls. This can be an advantage in improving the accuracy of the results where there is impingement between the gas or particles with the chamber walls or internal ducts, as in the case of the semi-industrial-size dryer. Regarding the axial velocity profiles, all cases predict good results compared to experimental results and those obtained in previous studies. However, it is necessary to properly adjust the AMR method to reduce the generation of artificial oscillations in the jet discharge, which can potentially increase the turbulent kinetic energy dissipation rate and artificially increase the jet decay rate. To better assess this impact and improve the applicability of AMR methods along turbulence-resolving models in spray drying simulations, it is desirable that future work include experimental measurements of turbulence inside the chamber.