Spatial Positioning and Operating Parameters of a Rotary Bell Sprayer: 3D Mapping of Droplet Size Distributions

Abstract

:1. Introduction

2. Mathematical Formulation

3. Experimental Setup

3.1. Rotary Bell

3.2. Infrared Thermography Visualization

4. Results and Discussion

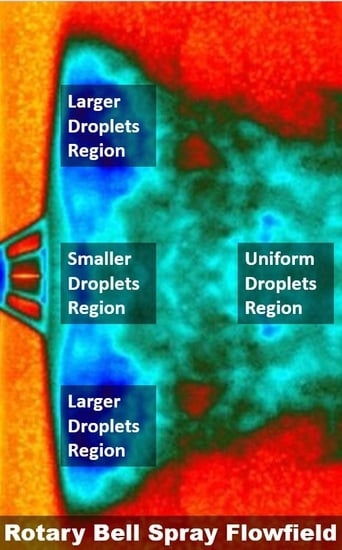

4.1. Sauter Mean Diameter Analysis

4.1.1. Three-Dimensional Analysis of Droplet Size, Bell Speed, Spatial Location within the Spray Flow Field along the Radial Direction at a Fluid Flow Rate of 150 ccm

4.1.2. Three-Dimensional Analysis of Droplet Size, Bell Speed, Spatial Location within the Spray Flow Field along Radial Direction at Fluid Flow Rate of 250 ccm

4.1.3. Three Dimensional Analysis of Droplet Size, Bell Speed, Spatial Location within the Spray Flow Field along Radial Direction at Fluid Flow Rate of 350 ccm

4.1.4. Three-Dimensional Analysis of Droplet Size, Bell Speed, Spatial Location within the Spray Flow Field along Streamwise Flow Direction at a Variable Fluid Flow Rate

4.1.5. Comparison between Theoretical model and Experimental Data of the SMD

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| velocity in radial direction (spherical) L/T | |

| velocity in azimuthal direction (spherical) L/T | |

| velocity in azimuthal direction (rotating system spherical) L/T | |

| polar angle (spherical) | |

| radial dimension (spherical) L | |

| density M/L3 | |

| angular velocity/T | |

| half cone angle | |

| Perpendicular distance from axis of rotation at (=) | |

| centrally supplied volumetric flow rate L3/T | |

| dynamic viscosity FT/L2 | |

| film thickness at L | |

| N | number of ligaments |

| non dimensional radial velocity | |

| non dimensional azimuthal velocity | |

| non dimensional film coordinate | |

| non dimensional film thickness | |

| non dimensional complex function | |

| arc from point on surface of film to bell surface ( |

References

- Abreu, C.; Izquierdo, M.; Merino, P.; Novoa, X.; Perez, C. A new approach to the determination of the cathodic protection period in zinc-rich paints. Corrosion 1999, 55, 1173–1181. [Google Scholar] [CrossRef]

- Fukuta, K.; Murate, M.; Ohashi, Y.; Toda, K. New rotary bell for metallic paint application. Met. Finish. 1993, 91, 39–42. [Google Scholar]

- Im, K.-S.; Lai, M.-C.; Liu, Y.; Sankagiri, N.; Loch, T.; Nivi, H. Visualization and measurement of automotive electrostatic rotary-bell paint spray transfer processes. J. Fluids Eng. 2001, 123, 237–245. [Google Scholar] [CrossRef]

- Ray, R.; Henshaw, P. Evaporation of clearcoat solvents from a rotary bell atomizer and its relationship with bell speed, flow rate, and electrostatic potential. J. Coat. Technol. Res. 2018, 15, 41–49. [Google Scholar] [CrossRef]

- Ray, R.; Henshaw, P.; Biswas, N.; Sak, C. Effects of bell speed and flow rate on evaporation of water spray from a rotary bell atomizer. Coatings 2015, 5, 186–194. [Google Scholar] [CrossRef]

- Li, W.; Qian, L.; Song, S.; Zhong, X. Numerical Study on the Influence of Shaping Air Holes on Atomization Performance in Pneumatic Atomizers. Coatings 2019, 9, 410. [Google Scholar] [CrossRef]

- Pendar, M.R.; Pascoa, J. Numerical investigation of Electrostatic Spray Painting Transfer Processes for vehicle Coating. SAE MOBILUS 2019. Unpublished work. [Google Scholar]

- Shen, B.; Ye, Q.; Guettler, N.; Tiedje, O.; Domnick, J. Primary breakup of a non-Newtonian liquid using a high-speed rotary bell atomizer for spray-painting processes. J. Coat. Technol. Res. 2019. [Google Scholar] [CrossRef]

- Domnick, J.; Scheibe, A.; Ye, Q. The Simulation of the Electrostatic Spray Painting Process with High-Speed Rotary Bell Atomizers. Part I: Direct Charging. Part. Part. Syst. Char. 2005, 22, 141–150. [Google Scholar] [CrossRef]

- Domnick, J.; Scheibe, A.; Ye, Q. The Simulation of Electrostatic Spray Painting Process with High-Speed Rotary Bell Atomizers. Part II: External Charging. Part. Part. Syst. Char. 2006, 23, 408–416. [Google Scholar] [CrossRef]

- Im, K.-S.; Lai, M.-C.; Yu, S.-T.J.; Matheson, R.R. Simulation of spray transfer processes in electrostatic rotary bell sprayer. J. Fluids Eng. 2004, 126, 449–456. [Google Scholar] [CrossRef]

- Colbert, S.; Cairncross, R. A discrete droplet transport model for predicting spray coating patterns of an electrostatic rotary atomizer. J. Electrostat. 2006, 64, 234–246. [Google Scholar] [CrossRef]

- Mark, A.; Andersson, B.; Tafuri, S.; Engstrom, K.; Sorod, H.; Edelvik, F.; Carlson, J.S. Simulation of electrostatic rotary bell spray painting in automotive paint shops. At. Sprays 2013, 23, 25–45. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Guo, Q. Experimental investigation of liquid disintegration by rotary cups. Chem. Eng. Sci. 2012, 73, 44–50. [Google Scholar] [CrossRef]

- Peng, H.; Wang, N.; Wang, D.; Ling, X. Experimental study on the critical characteristics of liquid atomization by a spinning disk. Ind. Eng. Chem. Res. 2016, 55, 6175–6185. [Google Scholar] [CrossRef]

- Akafuah, N.K.; Poozesh, S.; Salaimeh, A.; Patrick, G.; Lawler, K.; Saito, K. Evolution of the automotive body coating process—A review. Coatings 2016, 6, 24. [Google Scholar] [CrossRef]

- Bailey, A.G. Electrostatic atomization of liquids. Sci. Prog. (1933-) 1974, 61, 555–581. [Google Scholar]

- Dombrowski, N.; Lloyd, T. Atomisation of liquids by spinning cups. Chem. Eng. J. 1974, 8, 63–81. [Google Scholar] [CrossRef]

- Frost, A. Rotary atomization in the ligament formation mode. J. Agric. Eng. Res. 1981, 26, 63–78. [Google Scholar] [CrossRef]

- Papanastasiou, T.C.; Alexandrou, A.; Graebel, W. Rotating thin films in bell sprayers and spin coating. J. Rheol. 1988, 32, 485–509. [Google Scholar] [CrossRef]

- Corbeels, P.; Senser, D.W.; Lefebvre, A.H. Atomization characteristics of a highspeed rotary-bell paint applicator. At. Sprays 1992, 2, 87–99. [Google Scholar] [CrossRef]

- Bauckhage, K.; Schulte, G.; Scholz, T. Atomization of Water Based Metallic Paint by Means of Electrostation Rotary Atomizers. In Proceedings of the Sixth International Conference on Liquid Atomization and Spray Systems, Rouen, France, 18–22 July 1994. [Google Scholar]

- Wilson, J.; Grib, S.; Darwish Ahmad, A.; Renfro, M.; Adams, S.; Salaimeh, A. Study of near-cup droplet breakup of an automotive electrostatic rotary bell (esrb) atomizer using high-speed shadowgraph imaging. Coatings 2018, 8, 174. [Google Scholar] [CrossRef]

- Huang, H.; Lai, M.-C.; Meredith, M. Simulation of spray transport from rotary cup atomizer using KIVA-3V. In Proceedings of the 10th International KIVA User’s Group Meeting, Pasadena, CA, USA, 16–20 July 2000; pp. 1435–1437. [Google Scholar]

- Ye, Q.; Domnick, J. Analysis of droplet impingement of different atomizers used in spray coating processes. J. Coat. Technol. Res. 2017, 14, 467–476. [Google Scholar] [CrossRef]

- Domnick, J.; Thieme, M. Atomization characteristics of high-speed rotary bell atomizers. At. Sprays 2006, 16, 857–874. [Google Scholar]

- Babinsky, E.; Sojka, P. Modeling drop size distributions. Prog. Energy Combust. Sci. 2002, 28, 303–329. [Google Scholar] [CrossRef]

- Darwish Ahmad, A.; Abubaker, A.; Salaimeh, A.; Akafuah, N. Schlieren Visualization of Shaping Air during Operation of an Electrostatic Rotary Bell Sprayer: Impact of Shaping Air on Droplet Atomization and Transport. Coatings 2018, 8, 279. [Google Scholar] [CrossRef]

- Hinze, J.O.; Milborn, H.J. The Atomization of Liquids by Means of a Rotating Cup. J. Appl. Mech. 1950, 17, 147–153. [Google Scholar]

- Bruin, S. Velocity distributions in a liquid film flowing over a rotating conical surface. Chem. Eng. Sci. 1969, 24, 1647–1654. [Google Scholar] [CrossRef]

- Makarytchev, S.V.; Xue, E.; Langrish, T.A.G.; Prince, R.G.H. On modelling fluid flow over a rotating conical surface. Chem. Eng. Sci. 1997, 52, 1055–1057. [Google Scholar] [CrossRef]

- Sun, H.; Chen, G.; Wang, L.; Wang, F. Ligament and Droplet Generation by Oil Film on a Rotating Disk. Int. J. Aerosp. Eng. 2015, 2015, 769862. [Google Scholar] [CrossRef]

- Doerre, M.; Akafuah, N.K. Reduction of Order: Analytical Solution of Film Formation in the Electrostatic Rotary Bell Sprayer. Symmetry 2019, 11, 937. [Google Scholar] [CrossRef]

- Akafuah, N.K.; Salazar, A.J.; Saito, K. Infrared thermography-based visualization of droplet transport in liquid sprays. Infrared Phys. Technol. 2010, 53, 218–226. [Google Scholar] [CrossRef]

- Akafuah, N.K. Visualization and Characterization of Ultrasonic Cavitating Atomizer and Other Automotive Paint Sprayers Using Infrared Thermography. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2009. [Google Scholar]

- Ogasawara, S.; Daikoku, M.; Shirota, M.; Inamura, T.; Saito, Y.; Yasumura, K.; Shoji, M.; Aoki, H.; Miura, T. Liquid Atomization Using a Rotary Bell Cup Atomizer. J. Fluid Sci. Technol. 2010, 5, 464–474. [Google Scholar] [CrossRef]

| Horizontal Distance from Cup Edge (Streamwise Direction, Z) (Non-Dimensionalized with Cup Radius, R) | 0.31R | 0.92R | 1.54R | 3.08R | 6.15R |

|---|---|---|---|---|---|

| Vertical Distance below Cup Center (Radial Direction, r) (non-dimeasionalized with cup radius, R) | 0 | 0 | 0 | 0 | 0 |

| 0.5R | ----- | 0.5R | ----- | 0.5R | |

| R | ----- | R | ----- | R | |

| 1.5R | ----- | 1.5R | ----- | 1.5R | |

| 2R | ----- | 2R | ----- | 2R |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darwish Ahmad, A.; Singh, B.B.; Doerre, M.; Abubaker, A.M.; Arabghahestani, M.; Salaimeh, A.A.; Akafuah, N.K. Spatial Positioning and Operating Parameters of a Rotary Bell Sprayer: 3D Mapping of Droplet Size Distributions. Fluids 2019, 4, 165. https://0-doi-org.brum.beds.ac.uk/10.3390/fluids4030165

Darwish Ahmad A, Singh BB, Doerre M, Abubaker AM, Arabghahestani M, Salaimeh AA, Akafuah NK. Spatial Positioning and Operating Parameters of a Rotary Bell Sprayer: 3D Mapping of Droplet Size Distributions. Fluids. 2019; 4(3):165. https://0-doi-org.brum.beds.ac.uk/10.3390/fluids4030165

Chicago/Turabian StyleDarwish Ahmad, Adnan, Binit B. Singh, Mark Doerre, Ahmad M. Abubaker, Masoud Arabghahestani, Ahmad A. Salaimeh, and Nelson K. Akafuah. 2019. "Spatial Positioning and Operating Parameters of a Rotary Bell Sprayer: 3D Mapping of Droplet Size Distributions" Fluids 4, no. 3: 165. https://0-doi-org.brum.beds.ac.uk/10.3390/fluids4030165