Dual-Input Photovoltaic System Based on Parallel Z-Source Inverters

Abstract

:1. Introduction

- (1)

- Less time and cost are needed for developing the high-power PV system; also, it is more flexible.

- (2)

- It is more reliable because if the DC/AC converter is interrupted in the centralized structure, the whole system will interrupt.

- -

- Using parallel ZSIs as single-stage power conversion system for multi-string PV systems.

- -

- Proposing an effective control to perform MPPT and to inject high-quality current to the grid.

- -

- Suggesting enhanced dual-string maximum power point tracking (eDS-MPPT) to reduce computational burden and to remove the need for using PV strings voltage sensors.

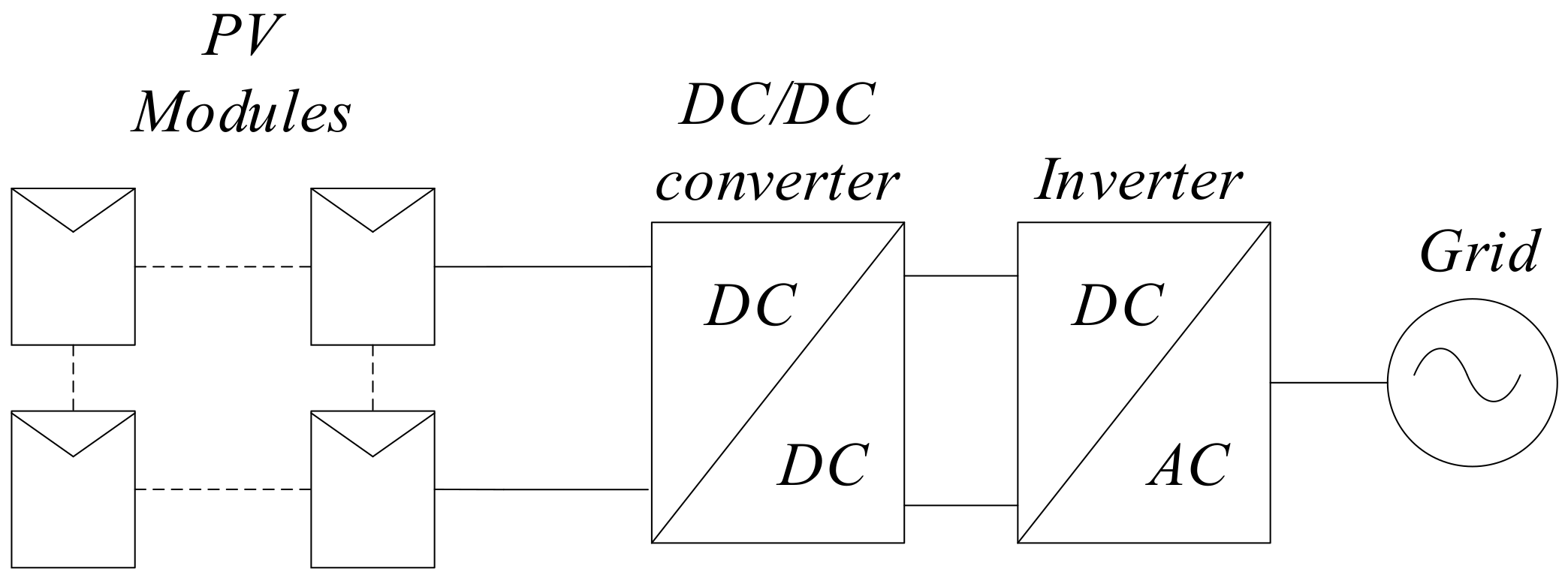

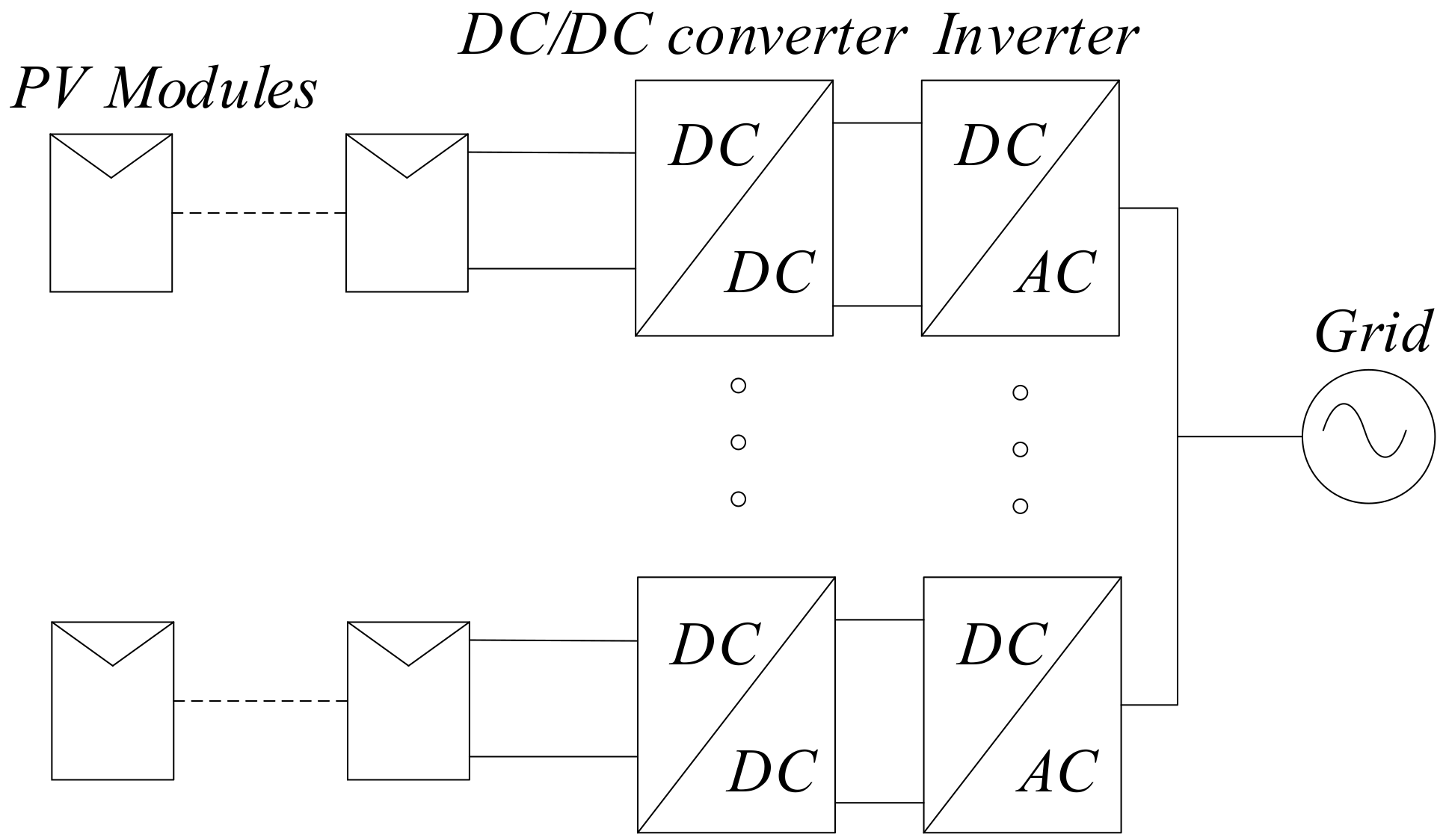

2. Proposed Topology

3. Proposed Control Method

3.1. Controlling Power Delivered to the Grid

3.1.1. Inner Current Control Loop

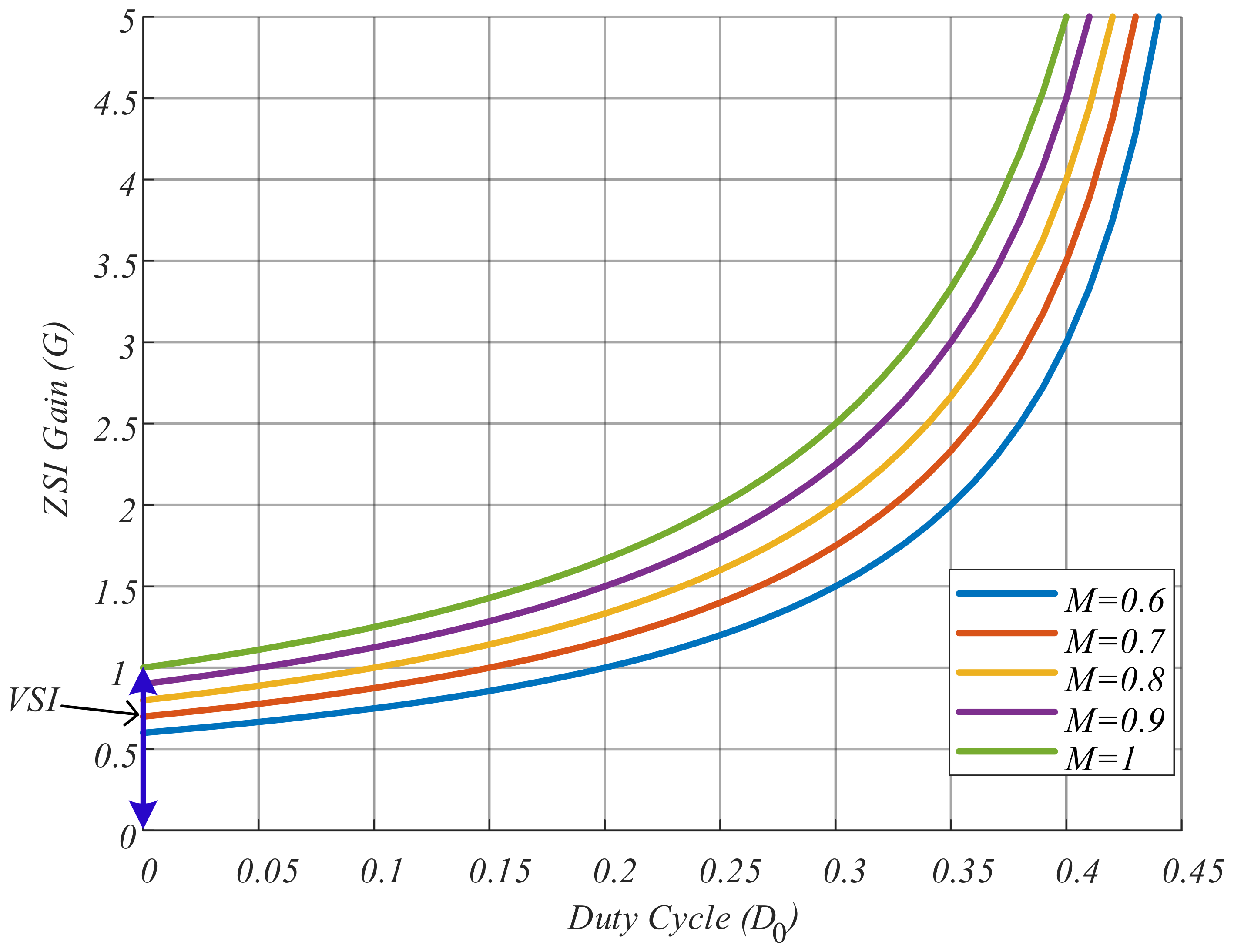

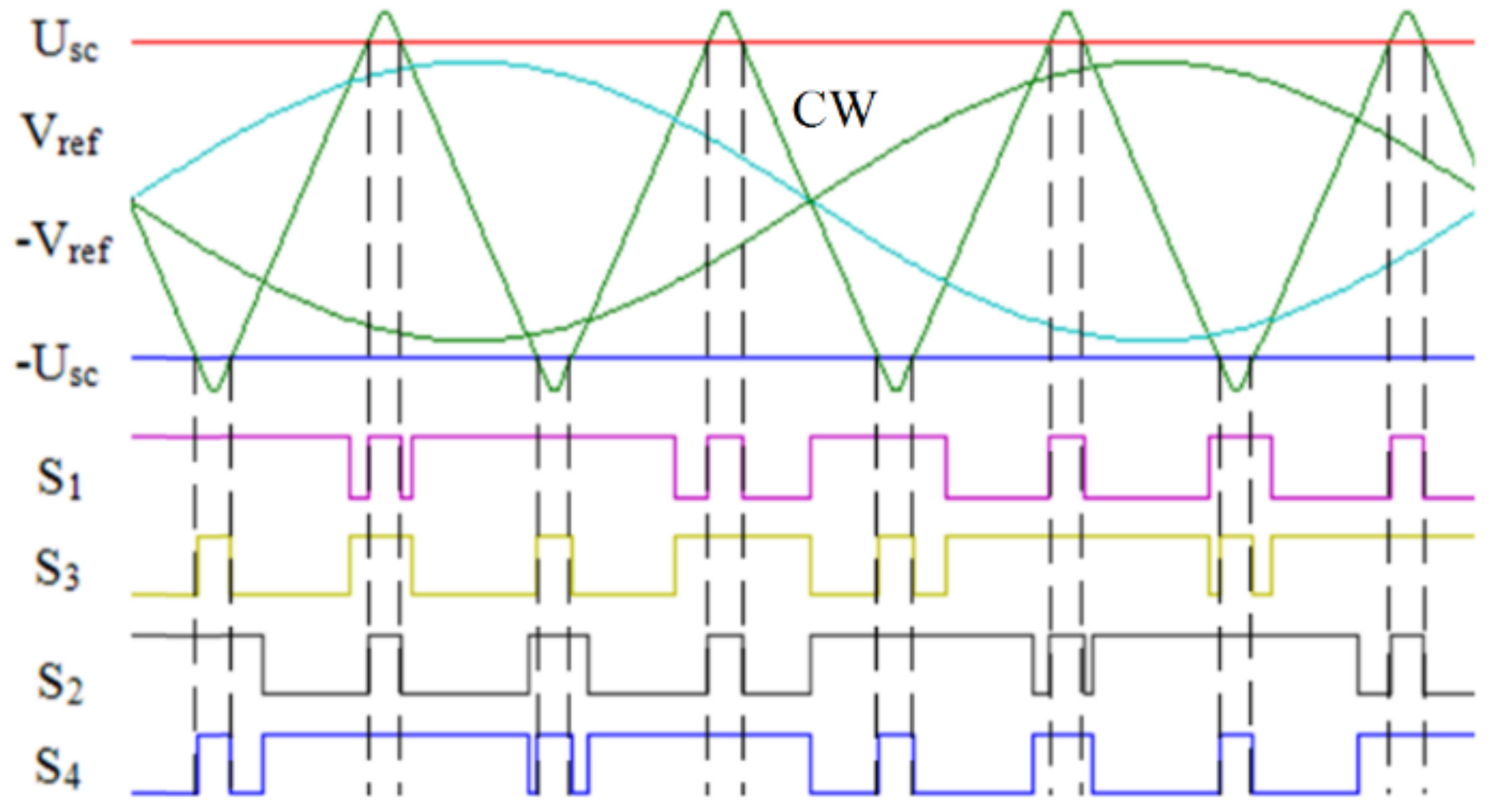

3.1.2. Voltage Controller of the ZSI Capacitor

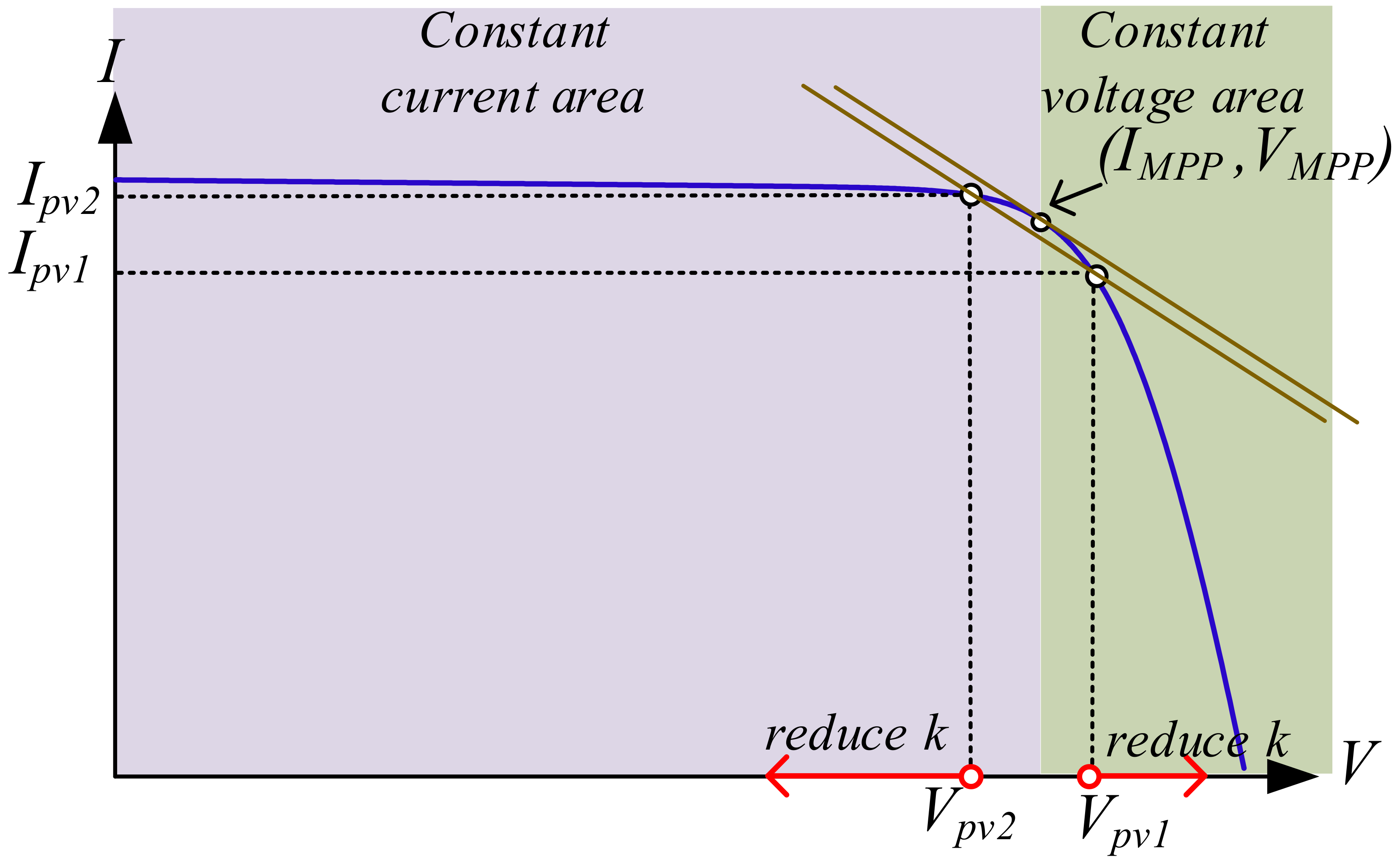

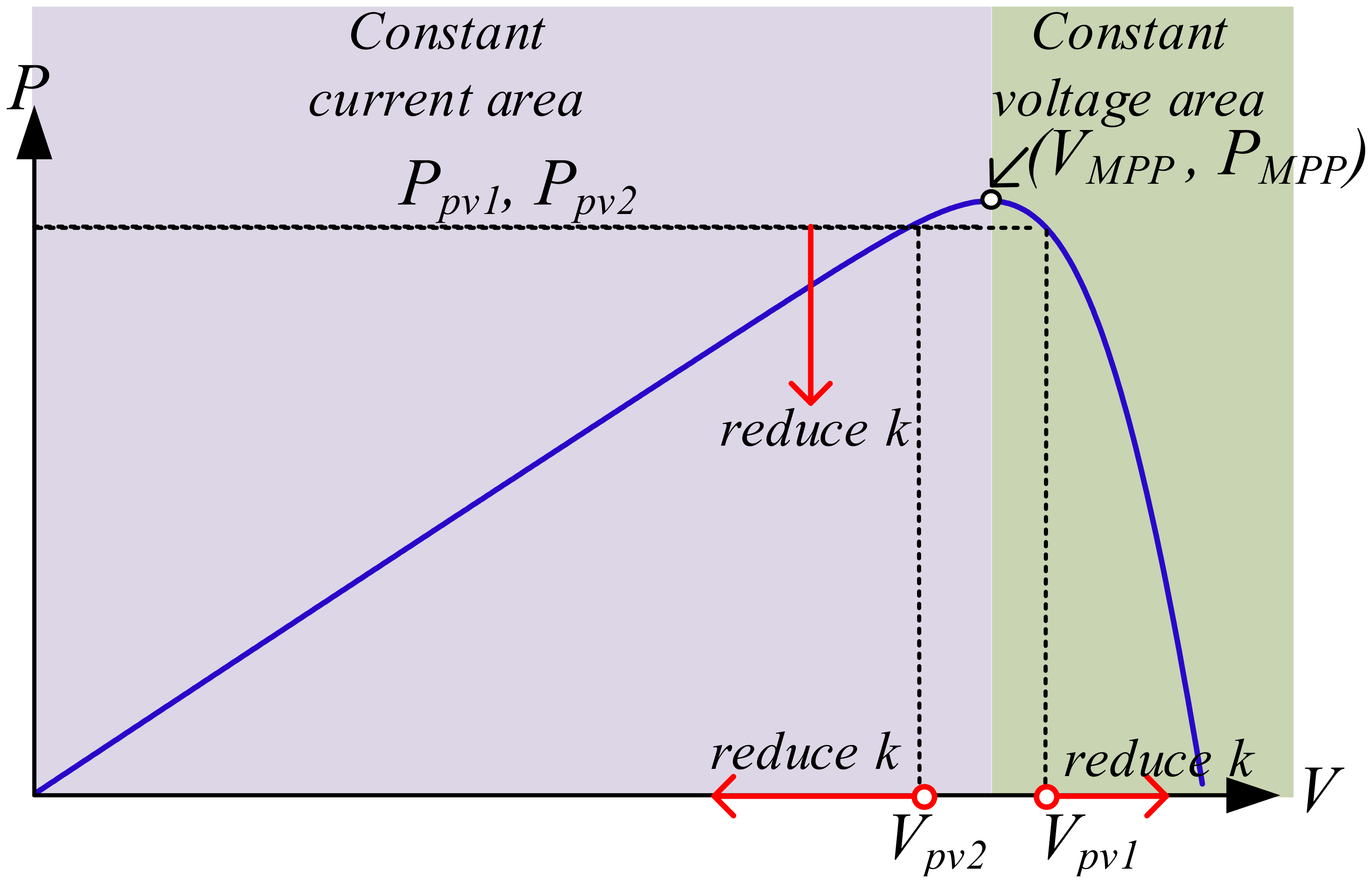

3.2. Proposed MPPT Method

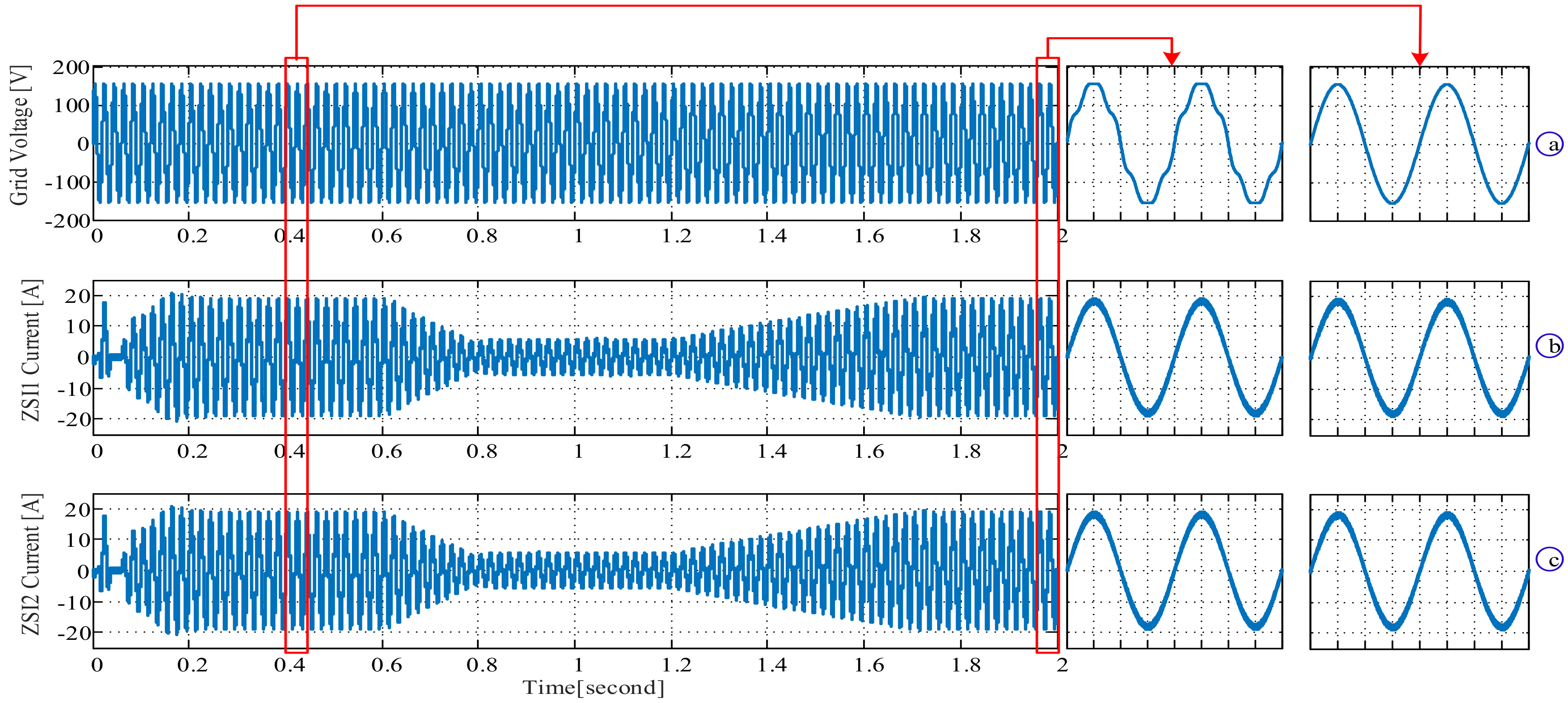

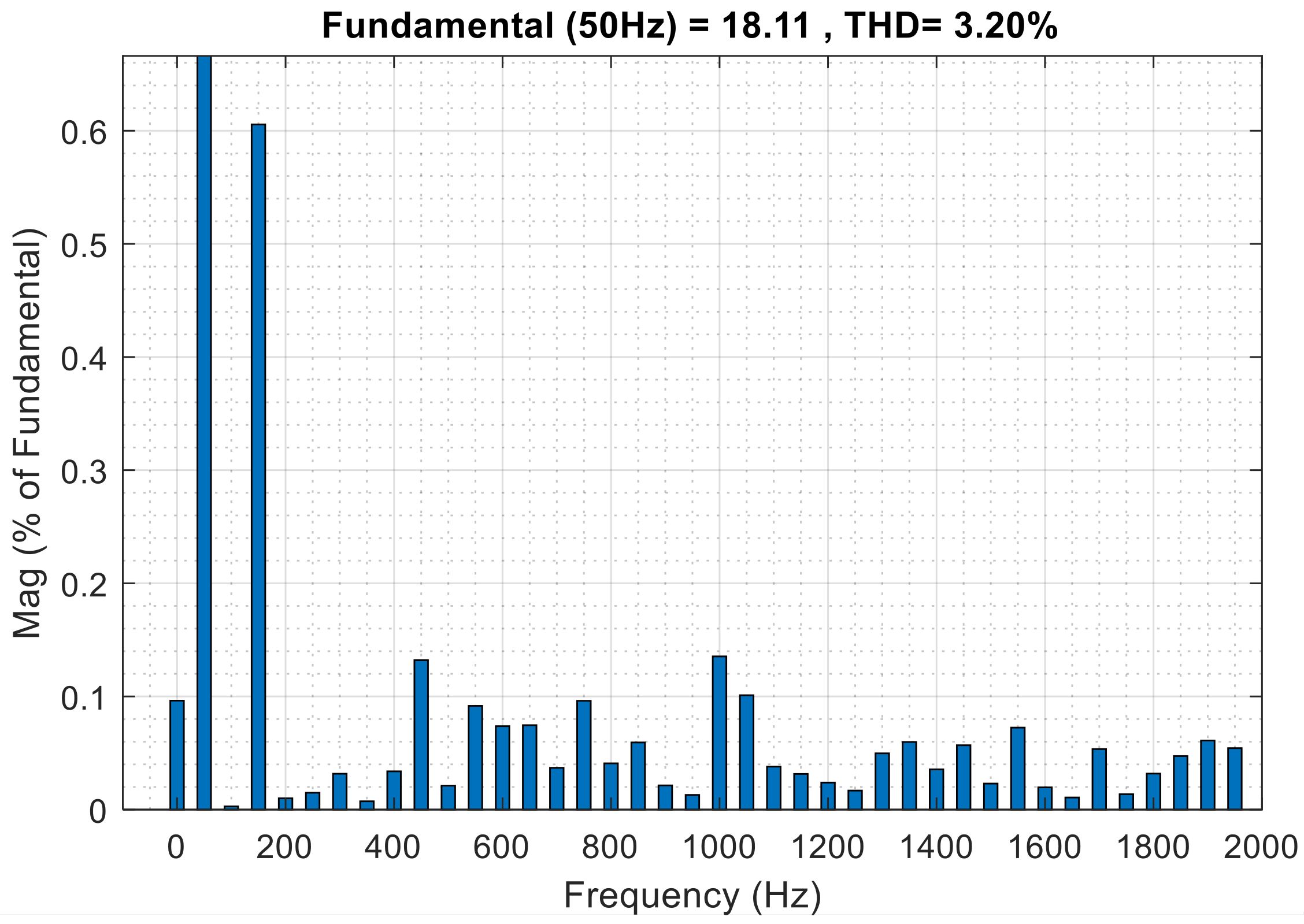

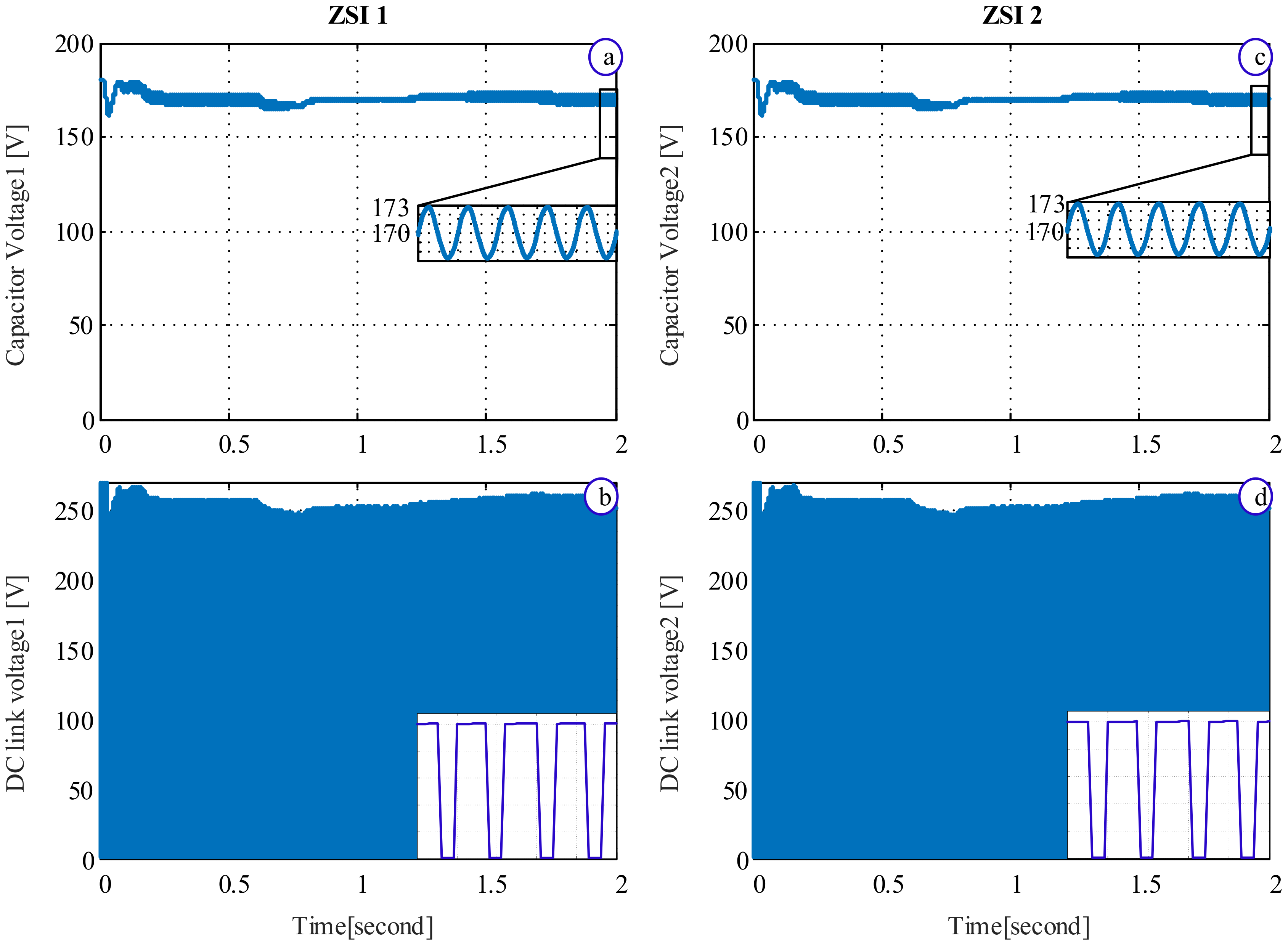

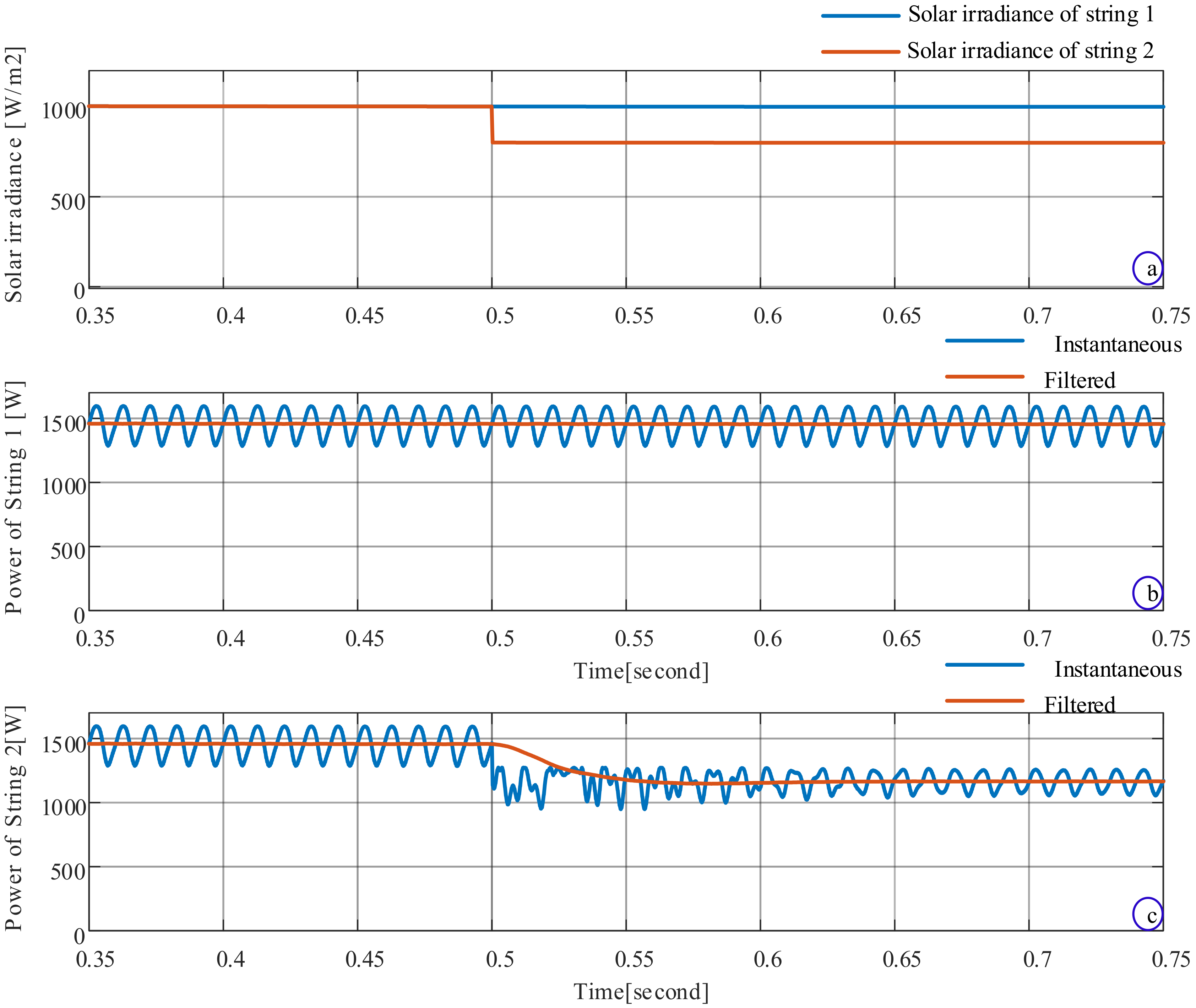

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AC | Alternating current |

| B | The boost coefficient |

| L | Inductor of Z-source network |

| C | Capacitor of Z-source network |

| CW | Carrier wave |

| D0 | Shoot-through duty cycle |

| DC | Direct Current |

| i | Current of the converter in AC side |

| irms | Current of the grid |

| Iin | Input current of inverter bridge |

| G | ZSI gain |

| k | MPPT tracking coefficient |

| kpdc | Integral gain of capacitor voltage controller |

| kp | Proportional gain of current controller |

| kpdc | Proportional gain of capacitor voltage controller |

| ki | Resonant gain of current controller |

| M | Modulation index of inverter |

| MPP | Maximum power point |

| MPPT | Maximum power point tracking |

| Lf1, Lf2 | Inductor of L filters |

| P | Active power injected by the inverter to the grid |

| PR | Proportional-resonant controller |

| Q | Reactive power injected by the inverter to the grid |

| S1, S2, S3, S4 | Semiconductor switches |

| s | Laplace operator |

| SB-PWM | Simple Boost Pulse Width Modulation |

| T0 | Shoot-through vector interval |

| T | Switching period |

| u1, u2 | Inverter output voltage |

| uin1, uin2 | Inverter DC link voltage |

| Usc | Shoot-through signal |

| Vref | Reference of switching modulator |

| Vpv1, Vpv2 | PV strings voltages |

| Vg | Grid voltage |

| ωo | Fundamental resonant frequency in rad/s |

Subscripts and Superscripts

| 1, 2 | ZSI 1 and 2 |

| C | Capacitor of Z-source network |

| i | ZSI’s number indicator |

| L | Inductor of Z-source network |

| in | DC link of inverter |

| g | Grid |

| max | Maximum |

| MPP | Maximum power point |

| pv | PV string |

| rms | RMS |

| * | Reference |

| ^ | Calculated value |

References

- Shahparasti, M.; Mohamadian, M.; Parsa Moghaddam, M.; Teimourzadeh Baboli, P.; Haghifam, M.R. Energy management and operation modelling of hybrid AC–DC microgrid. IET Gener. Transm. Distrib. 2014, 8, 1700–1711. [Google Scholar] [CrossRef]

- Shahparasti, M.; Mohamadian, M.; Teimourzadeh Baboli, P.; Yazdian, A.; Member, S.; Mohamadian, M. Toward Power Quality Management in Hybrid AC—DC Microgrid Using LTC-L Utility Interactive Inverter: Load Voltage—Grid Current Tradeoff. IEEE Trans. Smart Grid 2015, 8, 1–11. [Google Scholar] [CrossRef]

- Ahmad, M.W.; Kumar, P.N.; Arya, A.; Anand, S. Noninvasive technique for DC-link capacitance estimation in single-phase inverters. IEEE Trans. Power Electron. 2018, 33, 3693–3696. [Google Scholar] [CrossRef]

- Varaprasad, O.V.S.R.; Bharath Kumar, D.; Siva Sarma, D.V.S.S. Three level hysteresis current controlled vsi for power injection and conditioning in grid connected solar pv systems. In Proceedings of the 2014 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Mumbai, India, 16–19 December 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Chang, C.H.; Chang, E.C.; Cheng, H.L. A high-efficiency solar array simulator implemented by an LLC resonant DC-DC converter. IEEE Trans. Power Electron. 2013, 28, 3039–3046. [Google Scholar] [CrossRef]

- Yan, Y.; Xiang, L.; Dianfeng, W. Integrated Solutions for Photovoltaic Grid Connection: Increasing the Reliability of Solar Power. IEEE Power Energy Mag. 2014, 12, 84–91. [Google Scholar] [CrossRef]

- Romero-Cadaval, E.; Spagnuolo, G.; Franquelo, L.G.; Ramos-Paja, C.A.; Suntio, T.; Xiao, W.M. Grid-connected photovoltaic generation plants: Components and operation. IEEE Ind. Electron. Mag. 2013, 7, 6–20. [Google Scholar] [CrossRef] [Green Version]

- Jeon, Y.T.; Park, J.H. Unit-Minimum Least Power Point Tracking for the Optimization of Photovoltaic Differential Power Processing Systems. IEEE Trans. Power Electron. 2018, 34, 311–324. [Google Scholar] [CrossRef]

- De Freitas Takami, M.H.; Oliveira Da Silva, S.A.; Sampaio, L.P. Dynamic performance comparison involving grid-connected PV systems operating with active power-line conditioning and subjected to sudden solar irradiation changes. IET Renew. Power Gener. 2019, 13, 587–597. [Google Scholar] [CrossRef]

- Koran, A.; LaBella, T.; Lai, J.S. High Efficiency Photovoltaic Source Simulator with Fast Response Time for Solar Power Conditioning Systems Evaluation. IEEE Trans. Power Electron. 2014, 29, 1285–1297. [Google Scholar] [CrossRef]

- Kouro, S.; Leon, J.I.; Vinnikov, D.; Franquelo, L.G. Grid-connected photovoltaic systems: An overview of recent research and emerging PV converter technology. IEEE Ind. Electron. Mag. 2015, 9, 47–61. [Google Scholar] [CrossRef]

- Bacha, S.; Picault, D.; Burger, B.; Etxeberria-Otadui, I.; Martins, J. Photovoltaics in microgrids: An overview of grid integration and energy management aspects. IEEE Ind. Electron. Mag. 2015, 9, 33–46. [Google Scholar] [CrossRef]

- Shahparasti, M.; Sadeghi Larijani, A.; Fatemi, A.; Yazdian Varjani, A.; Mohammadian, M. Quasi Z-source inverter for photovoltaic system connected to single phase AC grid. In Proceedings of the 2010 1st Power Electronic & Drive Systems & Technologies Conference (PEDSTC), Tehran, Iran, 17–18 February 2010; pp. 456–460. [Google Scholar] [CrossRef]

- ABB Solar Inverters—ABB String Inverters—PVS-100/120-TL. 2017, pp. 98–101. Available online: https://new.abb.com/products/6AGC069647/pvs-120-tl-sx2-full-inverter (accessed on 29 September 2020).

- Baumann, C. 4-Level Inverter UPS. 2020. Available online: https://7x24exchangerm.org/images/downloads/2017_Presentations/3_7x24_presentation_carsten_revised_4_level_ups_7x24_colorado.pdf (accessed on 29 September 2020).

- Honarmand, S.; Rajaei, A.; Shahparasti, M.; Luna, A.; Pouresmaeil, E. A Modified Partial Power structure for Quasi Z-Source Converter to Improve Voltage Gain and Power Rating. Energies 2019, 12, 2139. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Yang, Y.; Wang, B.; Blaabjerg, F. Leakage Current Reduction of Three-Phase Z-Source Three-Level Four-Leg Inverter for Transformerless PV System. IEEE Trans. Power Electron. 2019, 34, 6299–6308. [Google Scholar] [CrossRef]

- Sajadian, S.; Ahmadi, R.; Zargarzadeh, H. Extremum Seeking-Based Model Predictive MPPT for Grid-Tied Z-Source Inverter for Photovoltaic Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 216–227. [Google Scholar] [CrossRef]

- Hanif, M.; Basu, M.; Gaughan, K. Understanding the operation of a Z-source inverter for photovoltaic application with a design example. IET Power Electron. 2011, 4, 278–287. [Google Scholar] [CrossRef]

- Zhang, J. Unified control of Z-source grid-connected photovoltaic system with reactive power compensation and harmonics restraint: Design and application. IET Renew. Power Gener. 2018, 12, 422–429. [Google Scholar] [CrossRef]

- Zhang, X.; Fu, Z.; Xiao, Y.; Wang, G.; Xu, D. Control of parallel three-phase PWM converters under generalized unbalanced operating conditions. IEEE Trans. Power Electron. 2017, 32, 3206–3215. [Google Scholar] [CrossRef]

- Chen, Y.; Tan, R.; Zheng, Y.; Zhou, Z. Sliding-mode control with multipower approaching law for dc-link voltage of z-source photovoltaic inverters. IEEE Access 2019, 7, 133812–133821. [Google Scholar] [CrossRef]

- Lashab, A.; Sera, D.; Guerrero, J.M.; Mathe, L.; Bouzid, A. Discrete Model-Predictive-Control-Based Maximum Power Point Tracking for PV Systems: Overview and Evaluation. IEEE Trans. Power Electron. 2018, 33, 7273–7287. [Google Scholar] [CrossRef]

- Vu, P.; Nguyen, Q.; Tran, M.; Todeschini, G.; Santoso, S. Adaptive backstepping approach for dc-side controllers of Z-source inverters in grid-tied PV system applications. IET Power Electron. 2018, 11, 2346–2354. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Wang, H.; Khajepour, A.; He, H.; Ji, J. Model predictive control power management strategies for HEVs: A review. J. Power Sources 2017, 341, 91–106. [Google Scholar] [CrossRef]

- Vilathgamuwa, D.M.; Gajanayake, C.J.; Loh, P.C. Modulation and control of three-phase paralleled Z-source inverters for distributed generation applications. IEEE Trans. Energy Convers. 2009, 24, 173–183. [Google Scholar] [CrossRef]

- Sonkar, S.P.; Lal, V.N.; Singh, R.K. Three-phase quasi-Z source inverters with regulated multiple AC outputs for microgrid applications and three-phase residential load. IET Power Electron. 2020, 13, 2222–2235. [Google Scholar] [CrossRef]

- Aleem, Z.; Shin, D.; Cha, H.; Lee, J.P.; Yoo, D.W.; Peng, F.Z. Parallel operation of inverter using trans-Zsource network. IET Power Electron. 2015, 8, 2176–2183. [Google Scholar] [CrossRef]

- Shahparasti, M.; Yazdian, A.; Mohamadian, M.; Larijani, A.S.S.; Fatemi, A. Parallel uninterruptible power supplies based on Z-source inverters. IET Power Electron. 2012, 5, 1359. [Google Scholar] [CrossRef]

- Gajanayake, C.J.; Teodorescu, R.; Blaabjerg, F.; Vilathgamuwa, D.M.; Loh, P.C. Four-leg parallel Z-source inverter based DG systems to enhance the grid performance under unbalanced conditions. In Proceedings of the 2007 European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007. [Google Scholar] [CrossRef]

- Al Nabulsi, A.; Dhaouadi, R. Efficiency optimization of a dsp-based standalone PV system using fuzzy logic and dual-MPPT control. IEEE Trans. Ind. Inform. 2012, 8, 573–584. [Google Scholar] [CrossRef]

- Park, J.H.; Ahn, J.Y.; Cho, B.H.; Yu, G.J. Dual-module-based maximum power point tracking control of photovoltaic systems. IEEE Trans. Ind. Electron. 2006, 53, 1036–1047. [Google Scholar] [CrossRef]

- Kumar, N.; Hussain, I.; Singh, B.; Panigrahi, B.K. Framework of Maximum Power Extraction from Solar PV Panel Using Self Predictive Perturb and Observe Algorithm. IEEE Trans. Sustain. Energy 2018, 9, 895–903. [Google Scholar] [CrossRef]

- Killi, M.; Samanta, S. Modified perturb and observe MPPT algorithm for drift avoidance in photovoltaic systems. IEEE Trans. Ind. Electron. 2015, 62, 5549–5559. [Google Scholar] [CrossRef]

- Sera, D.; Mathe, L.; Kerekes, T.; Spataru, S.V.; Teodorescu, R. On the perturb-and-observe and incremental conductance mppt methods for PV systems. IEEE J. Photovolt. 2013, 3, 1070–1078. [Google Scholar] [CrossRef]

- Kumar, N.; Hussain, I.; Singh, B.; Panigrahi, B.K. Self-Adaptive Incremental Conductance Algorithm for Swift and Ripple-Free Maximum Power Harvesting from PV Array. IEEE Trans. Ind. Inform. 2018, 14, 2031–2041. [Google Scholar] [CrossRef]

- Wang, H.; Shen, J. An Improved Model Combining Evolutionary Algorithm and Neural Networks for PV Maximum Power Point Tracking. IEEE Access 2019, 7, 2823–2827. [Google Scholar] [CrossRef]

- Tang, S.; Sun, Y.; Chen, Y.; Zhao, Y.; Yang, Y.; Szeto, W. An Enhanced MPPT Method Combining Fractional-Order and Fuzzy Logic Control. IEEE J. Photovolt. 2017, 7, 640–650. [Google Scholar] [CrossRef]

- Kong, X.; Wong, C.K.; Lam, C.S. Effects of Parasitic Resistances on Magnetically Coupled Impedance-Source Networks. IEEE Trans. Power Electron. 2020, 35, 9171–9183. [Google Scholar] [CrossRef]

- Ding, X.; Qian, Z.; Xie, Y.; Lu, Z. Three-Phase Z-Source Rectifier. In Proceedings of the 2005 IEEE 36th Power Electronics Specialists Conference, Recife, Brazil, 16 June 2005; pp. 494–500. [Google Scholar]

- Fang Zheng, P.; Peng, F.Z.; Member, S. Z-Source Inverter. IEEE Trans. Ind. Appl. 2003, 39, 504–510. [Google Scholar] [CrossRef]

- Venkatramanan, D.; Adapa, A.K.; John, V. Design and comparative study of discrete and module-based IGBT power converters. Sadhana Acad. Proc. Eng. Sci. 2017, 42, 1401–1409. [Google Scholar] [CrossRef] [Green Version]

- Shahparasti, M.; Rocabert, J.; Muñoz, R.S.; Luna, A.; Rodríguez, P. Impedance Source Interlinking Converter for Microbial Electrosynthesis Energy Storage Applications. In Proceedings of the 2018 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018; pp. 1340–1345. [Google Scholar]

- Esram, T.; Chapman, P.L. Comparison of photovoltaic array maximum power point tracking techniques. IEEE Trans. Energy Convers. 2007, 22, 439–449. [Google Scholar] [CrossRef] [Green Version]

- Lopez-Santos, O.; Garcia, G.; Martinez-Salamero, L.; Giral, R.; Vidal-Idiarte, E.; Merchan-Riveros, M.C.; Moreno-Guzman, Y. Analysis, design, and implementation of a static conductance-based MPPT method. IEEE Trans. Power Electron. 2019, 34, 1960–1979. [Google Scholar] [CrossRef]

- Villalva, M.G.; Gazoli, J.R.; Filho, E.R. Comprehensive approach to modeling and simulation of photovoltaic arrays. IEEE Trans. Power Electron. 2009, 24, 1198–1208. [Google Scholar] [CrossRef]

- Siu, K.K.M.; Ho, C.N.M. System Model and Performance Evaluation of Single-Stage Buck-Boost Type Manitoba Inverter for PV Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 8, 3457–3466. [Google Scholar] [CrossRef]

- IEEE 1547-2003—IEEE Standard for Interconnecting Distributed Resources with Electric Power Systems. Available online: https://0-standards-ieee-org.brum.beds.ac.uk/standard/1547-2003.html (accessed on 20 April 2019).

| Parameter | Symbol | Value |

|---|---|---|

| Inductor of Z-source network | L | 2 mH |

| Capacitor of Z-source network | C | 2200 uF |

| Parameter | Symbol | Value |

|---|---|---|

| Current at maximum power | IMP | 15.22 A |

| Voltage at maximum power | VMP | 105.2 V |

| Maximum power | Pmax,e | 1600 W |

| Short circuit current | Isc | 16.42 A |

| Open circuit voltage | Voc | 131.6 V |

| Temperture coefficient of Voc | KV | −0.123 V/K |

| Temperture coefficient of Isc | KI | 0.0032 A/K |

| Parameters | Symbol | Value | |

|---|---|---|---|

| Capacitor voltage controller | Proportional parameter | kpdc | 0.7 |

| Integral parameters | kidc | 20 | |

| Current controller | Proportional parameter | kp | 0.08 |

| Resonant parameter | ki | 150 | |

| eDS-MPPT tracker gain | parameter k | k | 0.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahparasti, M.; Savaghebi, M.; Adabi, E.; Ebel, T. Dual-Input Photovoltaic System Based on Parallel Z-Source Inverters. Designs 2020, 4, 51. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4040051

Shahparasti M, Savaghebi M, Adabi E, Ebel T. Dual-Input Photovoltaic System Based on Parallel Z-Source Inverters. Designs. 2020; 4(4):51. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4040051

Chicago/Turabian StyleShahparasti, Mahdi, Mehdi Savaghebi, Ebrahim Adabi, and Thomas Ebel. 2020. "Dual-Input Photovoltaic System Based on Parallel Z-Source Inverters" Designs 4, no. 4: 51. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4040051