Glasses and Ceramics for Luminescence Applications (2nd Edition)

A special issue of Materials (ISSN 1996-1944). This special issue belongs to the section "Advanced and Functional Ceramics and Glasses".

Deadline for manuscript submissions: 20 May 2024 | Viewed by 1794

Special Issue Editor

Interests: transparent ceramics; luminescent glass; PiG; nano-phosphor; crystal structure determination; material calculation and simulation

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

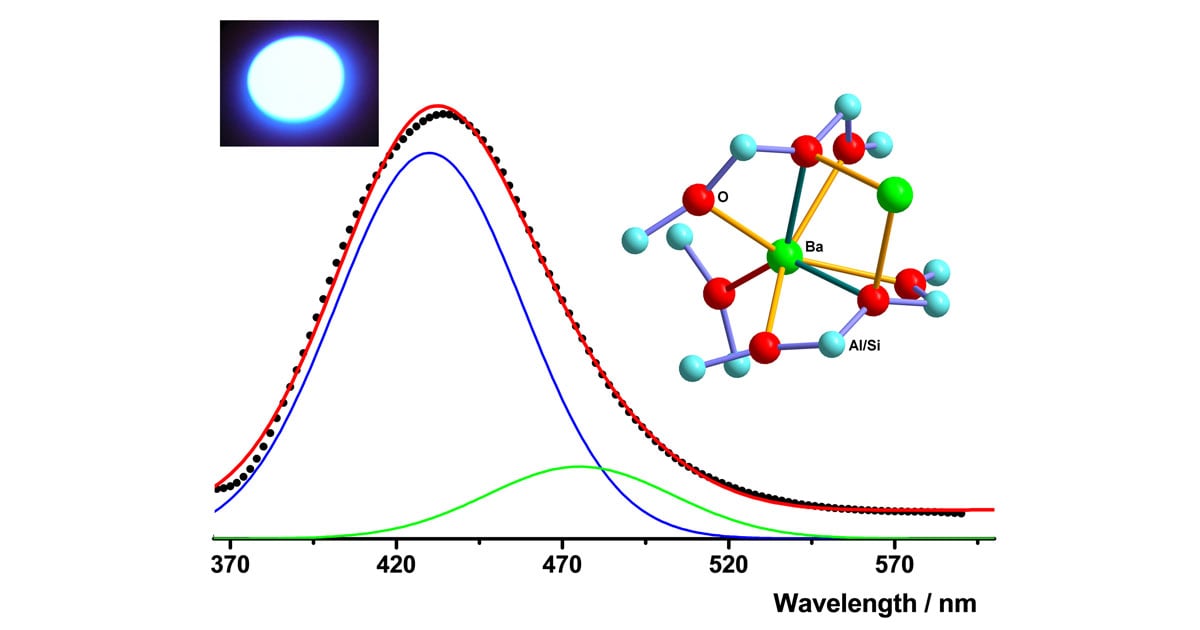

Luminescent glasses and ceramics are used in many applications, such as illumination, display, telecommunication, medical diagnosis, security checks, lasers, nuclear fusion, and other fields, playing many roles in our daily life, culture and development.

Different from phosphor also called as (opaque or normal) ceramics sometimes in terms of their polycrystalline character, luminescent blocks like glasses, transparent ceramics, and single crystals have excellent transparence and fewer defects, which is important for applications beyond illumination and display. Additionally glasses and ceramics are better than single crystals in terms of time and cost of fabrication as well as uniformity, variety, and high concentration.

The aim of this Special Issue is to focus on the latest developments in luminescent glasses and ceramics including novel structures, luminescent centers and mechanisms, architectures or frameworks of packaged devices (e.g., LD/LED and detectors), techniques, methods, and applications. We are mainly interested in advanced materials with excellent luminescent properties, but others that are useful for material developments such as novel designs for measurement, calculation, and unconventional application are also welcome.

We believe that this collection will present recent interesting and important results that could be useful for young investigators and leading experts in the field. It will also be helpful for people with an interest in novel luminescent materials with advanced properties and potential applications in their projects.

We would like to thank the authors for their contributions to the 1st edition. The 1st edition and the attached papers can be found here: https://0-www-mdpi-com.brum.beds.ac.uk/journal/materials/special_issues/glass_ceramic_lumi.

Dr. Haohong Chen

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- luminescent glass and ceramics

- process–structure–property relationships

- calculation and simulation

- advanced manufacturing or measurement technology

- innovative luminescent applications

Related Special Issue

- Glasses and Ceramics for Luminescence Applications in Materials (10 articles)