Digital Drill Core Models: Structure-from-Motion as a Tool for the Characterisation, Orientation, and Digital Archiving of Drill Core Samples

Abstract

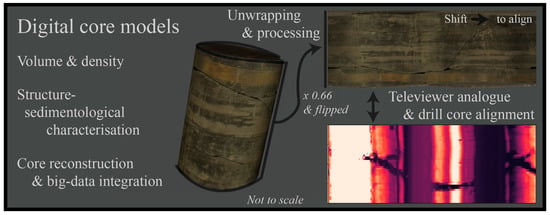

:1. Introduction

2. Materials and Methods

2.1. The Longyearbyen CO2 Lab Data Sets and Sample Collection

2.2. Digital Image Acquisition

2.3. SfM Processing

- (1)

- automatically detect (ArUco) GCPs and assign their x,y-pixel coordinates;

- (2)

- create frame-encompassing masks isolating the GCPs, calibration aids, and the sample, effectively filtering out the white background; and,

- (3)

- apply real-world distances between markers derived from a marker-layout file.

- (1)

- First, the individual images were populated with marker positions and masked with the pre-generated masks.

- (2)

- Secondly, the internal coordinate system was updated with real-world marker distances, providing real-world coordinates to the project.

- (3)

- Thirdly, a batch process was initiated to subsequently align the photos (with masks applied to their key points; ‘highest’), improve camera alignment, build a dense point cloud (‘medium’ or ‘high’; ‘mild filtering’), and generate a mesh (‘based on dense point cloud’) and texture (4 or 8k).

- (4)

- Finally, the resulting meshes were trimmed to remove extraneous points and meshes.

2.4. DCM Characterisation

2.4.1. Volumetric Calculations and Bulk Densities

2.4.2. Characterisation and Alignment

3. Results

3.1. Volume and Structure Assessment

3.2. Core Characterisation and Alignment

4. Discussion

4.1. Feature Alignment during SfM

4.2. Volume Assessment and Error-Contributing Factors

4.3. 3D Image Analysis and Characterisation

4.4. Future Applications

- All scientific digitisation projects must result in a secure, stable, ordered, and accessible archive, featuring digital backup strategies and updated, (semi-)permanent storage solutions.

- Standards and procedures for the creation, selection, management, compilation and transfer of the archive must be agreed upon in the design stage, and each procedure must be fully documented.

- The entire archive must be compiled in such a way to ensure the preservation of relationships between elements and to facilitate access to all parts in the future. This also includes the linked storage of such related and derived data as interpretations and subsequent processing.

- Where possible, physical and digital sample storage should be in the same place, or at least stored through association, to prevent red tape from being in the way of access.

- Finally, a digitisation project is only completed after the archive has been transferred to a recognised repository, and is fully accessible for consultation.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CC(U)S | carbon capture, (use) and storage |

| DCM | digital (drill) core model |

| GCP | ground control point |

| MD | measured depth |

| RMSE | root mean square error |

| SfM | structure-from-motion |

| VOM | virtual outcrop model |

References

- Westoby, M.J.; Brasington, J.; Glasser, N.F.; Hambrey, M.J.; Reynolds, J.M. ’Structure-from-Motion’ photogrammetry: A low-cost, effective tool for geoscience applications. Geomorphology 2012, 179, 300–314. [Google Scholar] [CrossRef] [Green Version]

- Carrivick, J.; Smith, M.; Quincey, D. Structure from Motion in the Geosciences; Wiley-Blackwell: Hoboken, NJ, USA, 2016; p. 197. [Google Scholar] [CrossRef]

- Pringle, J.K.; Howell, J.A.; Hodgetts, D.; Westerman, A.R.; Hodgson, D.M. Virtual outcrop models of petroleum reservoir analogues: A review of the current state-of-the-art. First Break 2006, 24, 33–42. [Google Scholar] [CrossRef]

- Yilmaz, H.M. Close range photogrammetry in volume computing. Exp. Tech. 2010, 34, 48–54. [Google Scholar] [CrossRef]

- Hasiuk, F. Making things geological: 3-D printing in the geosciences. GSA Today 2014, 24, 28–29. [Google Scholar] [CrossRef] [Green Version]

- Wajs, J. Research on surveying technology applied for DTM modelling and volume computation in open pit mines. Min. Sci. 2015, 22, 75–83. [Google Scholar] [CrossRef]

- Banu, T.P.; Borlea, G.F.; Banu, C. The Use of Drones in Forestry. J. Environ. Sci. Eng. B 2016, 5, 557–562. [Google Scholar] [CrossRef] [Green Version]

- Vallet, J.; Gruber, U.; Dufour, F. Photogrammetric avalanche volume measurements at Vallée de la Sionne, Switzerland. Ann. Glaciol. 2001, 32, 141–146. [Google Scholar] [CrossRef] [Green Version]

- Cardenal, J.; Mata, E.; Perez-Garcia, J.; Delgado, J.; Andez, A.; Gonzalez, A.; Diaz-de Teran, J. Close range digital photogrammetry techniques applied to landslide monitoring. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2008, 37, 235–240. [Google Scholar]

- Grazioso, S.; Caporaso, T.; Selvaggio, M.; Panariello, D.; Ruggiero, R.; Di Gironimo, G. Using photogrammetric 3D body reconstruction for the design of patient–tailored assistive devices. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0 and IoT). Institute of Electrical and Electronics Engineers (IEEE), Naples, Italy, 4–6 June 2019; pp. 240–242. [Google Scholar] [CrossRef]

- Mitchell, J.; Chandrasekera, T.C.; Holland, D.J.; Gladden, L.F.; Fordham, E.J. Magnetic resonance imaging in laboratory petrophysical core analysis. Phys. Rep. 2013, 526, 165–225. [Google Scholar] [CrossRef]

- Van Stappen, J.F.; Meftah, R.; Boone, M.A.; Bultreys, T.; De Kock, T.; Blykers, B.K.; Senger, K.; Olaussen, S.; Cnudde, V. In Situ Triaxial Testing to Determine Fracture Permeability and Aperture Distribution for CO2 Sequestration in Svalbard, Norway. Environ. Sci. Technol. 2018, 52, 4546–4554. [Google Scholar] [CrossRef] [PubMed]

- Tangelder, J.W.; Ermes, P.; Vosselman, G.; van den Heuvel, F.A. CAD-based photogrammetry for reverse engineering of industrial installations. Comput.-Aided Civ. Infrastruct. Eng. 2003, 18, 264–274. [Google Scholar] [CrossRef]

- Remondino, F. Heritage recording and 3D modeling with photogrammetry and 3D scanning. Remote Sens. 2011, 3, 1104–1138. [Google Scholar] [CrossRef] [Green Version]

- Falkingham, P.L. Acquisition of high resolution three-dimensional models using free, open-source, photogrammetric software. Palaeontol. Electron. 2012, 15. [Google Scholar] [CrossRef]

- Eulitz, M.; Reiss, G. 3D reconstruction of SEM images by use of optical photogrammetry software. J. Struct. Biol. 2015, 191, 190–196. [Google Scholar] [CrossRef]

- Casini, G.; Hunt, D.W.; Monsen, E.; Bounaim, A. Fracture characterization and modeling from virtual outcrops. AAPG Bull. 2016, 100, 41–61. [Google Scholar] [CrossRef]

- Enge, H.D.; Buckley, S.J.; Rotevatn, A.; Howell, J.A. From outcrop to reservoir simulation model: Workflow and procedures. Geosphere 2007, 3, 469–490. [Google Scholar] [CrossRef] [Green Version]

- Eide, C.H.; Schofield, N.; Lecomte, I.; Buckley, S.J.; Howell, J.A. Seismic interpretation of sill complexes in sedimentary basins: Implications for the sub-sill imaging problem. J. Geol. Soc. 2018, 175, 193–209. [Google Scholar] [CrossRef] [Green Version]

- Bellian, J.; Kerans, C.; Jennette, D. Digital Outcrop Models: Applications of Terrestrial Scanning Lidar Technology in Stratigraphic Modeling. J. Sediment. Res. 2005, 75, 166–176. [Google Scholar] [CrossRef] [Green Version]

- Smith, H.; Bohloli, B.; Skurtveit, E.; Mondol, N.H. Engineering parameters of draupne shale—Fracture characterization and integration with mechanical data. In Proceedings of the 6th EAGE Shale Workshop, Bordeaux, France, 29 April–2 May 2019. [Google Scholar] [CrossRef]

- McGinnis, M.J.; Pessiki, S.; Turker, H. Application of three-dimensional digital image correlation to the core-drilling method. Exp. Mech. 2005, 45, 359–367. [Google Scholar] [CrossRef]

- Ren, W.; Kou, X.; Ling, H. Application of digital close-range photogrammetry in deformation measurement of model test. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2004, 23, 436–440. [Google Scholar]

- Maas, H.G.; Hampel, U. Programmetric techniques in civil engineering material testing and structure monitoring. Photogramm. Eng. Remote Sens. 2006, 72, 39–45. [Google Scholar] [CrossRef]

- Benton, D.J.; Iverson, S.R.; Martin, L.A.; Johnson, J.C.; Raffaldi, M.J. Volumetric measurement of rock movement using photogrammetry. Int. J. Min. Sci. Technol. 2016, 26, 123–130. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Paor, D.G. Virtual Rocks. GSA Today 2016, 26, 4–11. [Google Scholar] [CrossRef]

- Mallison, H.; Wings, O. Photogrammetry in paleontology—A practical guide. J. Paleontol. Tech. 2014, 12, 1–31. [Google Scholar]

- Dombroski, C.E.; Balsdon, M.E.; Froats, A. The use of a low cost 3D scanning and printing tool in the manufacture of custom-made foot orthoses: A preliminary study. BMC Res. Notes 2014, 7, 443. [Google Scholar] [CrossRef] [Green Version]

- Olaussen, S.; Senger, K.; Braathen, A.; Grundvåg, S.A.; Mørk, A. You learn as long as you drill; research synthetis from the Longyearbyen CO2 Laboratory, Svalbard, Norway. Nor. J. Geol. 2019. [Google Scholar] [CrossRef] [Green Version]

- Braathen, A.; Bælum, K.; Christiansen, H.; Dahl, T.; Eiken, O.; Elvebakk, H.; Hansen, F.; Hanssen, T.; Jochmann, M.; Johansen, T.; et al. The Longyearbyen CO2 Lab of Svalbard, Norway—Initial assessment of the geological conditions for CO2 sequestration. Nor. J. Geol. 2012, 92, 353–376. [Google Scholar]

- Larsen, L. Analyses of Sept. 2011 Upper Zone Injection and Falloff Data from DH6 and Interference Data from DH5; Technical Report; UNIS CO2 Lab: Longyearbyen, Svalbard, 2012. [Google Scholar]

- Magnabosco, C.; Braathen, A.; Ogata, K. Permeability model of tight reservoir sandstones combining core-plug and Miniperm analysis of drillcore; Longyearbyen CO2 Lab, Svalbard. Nor. J. Geol. 2014, 94, 189–200. [Google Scholar]

- Ogata, K.; Senger, K.; Braathen, A.; Tveranger, J.; Olaussen, S. Fracture systems and mesoscale structural patterns in the siliciclastic Mesozoic reservoir-caprock succession of the Longyearbyen CO2 Lab project: Implications for geological CO2 sequestration in Central Spitsbergen, Svalbard. Nor. J. Geol. 2014, 94, 121–154. [Google Scholar]

- Bohloli, B.; Skurtveit, E.; Grande, L.; Titlestad, G.O.; Børresen, M.H.; Johnsen, Ø.; Braathen, A.; Braathen, A. Evaluation of reservoir and cap-rock integrity for the longyearbyen CO2 storage pilot based on laboratory experiments and injection tests. Nor. J. Geol. 2014, 94, 171–187. [Google Scholar]

- Elvebakk, H. Results of borehole logging in well LYB CO2, Dh4 of 2009, Longyearbyen, Svalbard. Technical Report; NGU: Trondheim, Norway, 2010. [Google Scholar]

- Lubrano-Lavadera, P.; Senger, K.; Lecomte, I.; Mulrooney, M.J.; Kühn, D. Seismic modelling of metre-scale normal faults at a reservoir-cap rock interface in Central Spitsbergen, Svalbard: Implications for CO2 storage. Nor. J. Geol. 2019. [Google Scholar] [CrossRef]

- Koevoets, M.J.; Hammer, Ø.; Olaussen, S.; Senger, K.; Smelror, M.I. Integrating subsurface and outcrop data of the middle jurassic to lower cretaceous agardhfjellet formation in central spitsbergen. Nor. J. Geol. 2018, 98, 1–34. [Google Scholar] [CrossRef] [Green Version]

- Rismyhr, B.; Bjærke, T.; Olaussen, S.; Mulrooney, M.J.; Senger, K. Facies, palynostratigraphy and sequence stratigraphy of the Wilhelmøya Subgroup (Upper Triassic–Middle Jurassic) in western central Spitsbergen, Svalbard. Nor. J. Geol. 2019. [Google Scholar] [CrossRef]

- Mulrooney, M.J.; Larsen, L.; Van Stappen, J.; Rismyhr, B.; Senger, K.; Braathen, A.; Olaussen, S.; Mørk, M.B.E.; Ogata, K.; Cnudde, V. Fluid flow properties of the Wilhelmøya Subgroup, a potential unconventional CO2 storage unit in central Spitsbergen. Nor. J. Geol. 2018. [Google Scholar] [CrossRef]

- Agisoft. Agisoft Metashape User Manual Professional Edition, version 1.5; Agisoft LLC: St. Petersburg, Russia, 2018; p. 130. [Google Scholar]

- Garrido-Jurado, S.; Muñoz-Salinas, R.; Madrid-Cuevas, F.J.; Marín-Jiménez, M.J. Automatic generation and detection of highly reliable fiducial markers under occlusion. Pattern Recognit. 2014, 47, 2280–2292. [Google Scholar] [CrossRef]

- Bradski, G. The OpenCV Library. Dr. Dobbs J. Softw. Tools 2000, 25, 120–125. [Google Scholar] [CrossRef]

- Agisoft. Metashape Python Reference; Release 1.5.0; Agisoft LLC: St. Petersburg, Russia, 2018. [Google Scholar]

- Blender Foundation. Blender—A 3D Modelling and Rendering Package; Blender Foundation: Amsterdam, The Netherlands, 2019. [Google Scholar]

- ISO/TC 182 Geotechnics. ISO 17892-2:2014—Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 2: Determination of Bulk Density; Technical report; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- Agüera-Vega, F.; Carvajal-Ramírez, F.; Martínez-Carricondo, P. Assessment of photogrammetric mapping accuracy based on variation ground control points number using unmanned aerial vehicle. Meas. J. Int. Meas. Confed. 2017, 98, 221–227. [Google Scholar] [CrossRef]

- Tonkin, T.N.; Midgley, N.G. Ground-control networks for image based surface reconstruction: An investigation of optimum survey designs using UAV derived imagery and structure-from-motion photogrammetry. Remote Sens. 2016, 8, 786. [Google Scholar] [CrossRef] [Green Version]

- Bauer, T.; Strauss, P.; Murer, E. A photogrammetric method for calculating soil bulk density§. J. Plant Nutr. Soil Sci. 2014, 177, 496–499. [Google Scholar] [CrossRef]

- Tavani, S.; Granado, P.; Corradetti, A.; Girundo, M.; Iannace, A.; Arbués, P.; Muñoz, J.A.; Mazzoli, S. Building a virtual outcrop, extracting geological information from it, and sharing the results in Google Earth via OpenPlot and Photoscan: An example from the Khaviz Anticline (Iran). Comput. Geosci. 2014, 63, 44–53. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, W.; Manhein, M.; Waggenspack, W.; Li, X. 3D fragment reassembly using integrated template guidance and fracture-region matching. In Proceedings of the 2015 IEEE International Conference on Computer Vision (ICCV), Santiago, Chile, 7–13 December 2015. Technical Report. [Google Scholar] [CrossRef]

- Winkelbach, S.; Wahl, F.M. Pairwise matching of 3D fragments using cluster trees. Int. J. Comput. Vis. 2008, 78, 1–13. [Google Scholar] [CrossRef]

- Gwynn, X.; Brown, M.; Mohr, P. Combined use of traditional core logging and televiewer imaging for practical geotechnical data collection. In Proceedings of the 2013 International Symposium on Slope Stability in Open Pit Mining and Civil Engineering, Brisbane, QLD, Australia, 25–27 September 2013. [Google Scholar]

- Shigematsu, N.; Otsubo, M.; Fujimoto, K.; Tanaka, N. Orienting drill core using borehole-wall image correlation analysis. J. Struct. Geol. 2014, 67, 293–299. [Google Scholar] [CrossRef]

- Paulsen, T.S.; Jarrard, R.D.; Wilson, T.J. A simple method for orienting drill core by correlating features in whole-core scans and oriented borehole-wall imagery. J. Struct. Geol. 2002, 24, 1233–1238. [Google Scholar] [CrossRef]

- Perrin, K.; Brown, D.H.; Lange, G.; Bibby, D.; Carlsson, A.; Degraeve, A.; Kuna, M.; Larsson, Y.; Pàlsdottir, S.U.; Stoll-Tucker, B.; et al. A Standard and Guide To Best Practice for Archaeological Archiving in Europe; Europae Archaeologiae Consilium: Namur, Belgium, 2014; p. 66. [Google Scholar]

- Koch, P.H.; Lund, C.; Rosenkranz, J. Automated drill core mineralogical characterization method for texture classification and modal mineralogy estimation for geometallurgy. Miner. Eng. 2019, 136, 99–109. [Google Scholar] [CrossRef]

- Pérez-Barnuevo, L.; Lévesque, S.; Bazin, C. Automated recognition of drill core textures: A geometallurgical tool for mineral processing prediction. Miner. Eng. 2018, 118, 87–96. [Google Scholar] [CrossRef]

- Senger, K. Svalbox: A Geoscientific Database for High Arctic Teaching and Research. In Proceedings of the AAPG Annual Convention and Exhibition, San Antonio, TX, USA, 19–22 May 2019. [Google Scholar]

- Naumann, N.; Howell, J.A.; Buckley, S.J.; Ringdal, K.; Dolva, B.; Maxwell, G.; Chmielewska, M. New ways of sharing outcrop data: The SAFARI database and 3D web viewer. In Proceedings of the 3rd Virtual Geoscience Conference, Kingston, ON, Canada, 22–24 August 2018. [Google Scholar]

- Cawood, A.; Bond, C. eRock: An Open-Access Repository of Virtual Outcrops for Geoscience Education. GSA Today 2019, 29, 36–37. [Google Scholar] [CrossRef] [Green Version]

Sample Availability: Raw and processed resources (i.e., photos, marker pages, marker distances, Metashape projects, and models) are available through the Svalbox repository (svalbox.no) upon request, following the UNIS CO2 Lab guidelines on data accessibility. |

| Sample ID | Well | Top (MD, m) | (Largest) Height (cm) | (Smallest) Height (cm) | Width (cm) | Total # Aligned Photos | Ground Control Points (GCPs) | Marker Set | Mean Control Point Error (RMSE, cm) | Maximum Control Point Error (cm) | Points (in Dense Cloud) | Faces (in Mesh) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DH4-466 | DH4 | 466.09 | 2.9 | 2.6 | 4.7 | 97 | 6 | AM | 0.013 | 0.018 | 1,792,213 | 998,378 |

| DH4-487.5 | DH4 | 487.45 | 7.5 | 6.8 | 4.7 | 101 | 6 | ArUco | 0.024 | 0.035 | 1,726,817 | 976,624 |

| DH4-487.5a | DH4 | - | 1.9 | 1.3 | 4.7 | 138 | 6 | ArUco | 0.009 | 0.011 | 1,114,180 | 1,000,000 |

| DH4-487.5b | DH4 | - | 1.5 | 0 | 4.7 | 99 | 6 | ArUco | 0.018 | 0.029 | 766,148 | 50,276 |

| DH4-487.5c | DH4 | - | 2.9 | 0 | 4.7 | 96 | 6 | ArUco | 0.014 | 0.024 | 961,799 | 39,222 |

| DH4-487.5d | DH4 | - | 2.4 | 0 | 4.7 | 78 | 6 | ArUco | 0.015 | 0.022 | 662,883 | 23,102 |

| DH4-487.5e | DH4 | - | 3.0 | 0 | 4.7 | 75 | 6 | ArUco | 0.010 | 0.018 | 807,965 | 606,904 |

| DH4-487.5f | DH4 | - | 2.0 | 1.1 | 4.7 | 74 | 6 | ArUco | 0.019 | 0.035 | 760,895 | 958,208 |

| DH4-487.5g | DH4 | - | - | - | - | 76 | 6 | ArUco | 0.007 | 0.011 | 941,987 | 38,006 |

| DH4-487.5h | DH4 | - | - | - | - | 113 | 6 | ArUco | 0.009 | 0.011 | 1,596,769 | 106,170 |

| DH4-487.5i | DH4 | - | - | - | - | 90 | 6 | ArUco | 0.018 | 0.031 | 1,164,574 | 1,164,574 |

| DH4-487.5j | DH4 | - | - | - | - | 123 | 6 | ArUco | 0.009 | 0.011 | 2,316,701 | 154,084 |

| DH4-489 | DH4 | 489.86 | 2.6 | 1.8 | 4.7 | 118 | 6 | AM | 0.010 | 0.014 | 1,618,295 | 687,730 |

| DH4-503 | DH4 | 503.9 | 5.7 | 1.0 | 4.7 | 93 | 6 | AM | 0.009 | 0.013 | 2,447,668 | 810,404 |

| DH4-519 | DH4 | 519.011 | 4.7 | 4.7 | 4.7 | 101 | 6 | AM | 0.008 | 0.010 | 2,309,478 | 1,000,000 |

| DH4-568 | DH4 | 567.945 | 5.2 | 4.7 | 4.7 | 63 | 6 | AM | 0.026 | 0.044 | 954,972 | 761,066 |

| DH4-568a | DH4 | - | - | - | - | 63 | 1 | AM | 9.603 | 9.603 | 957,044 | 845,448 |

| DH4-568b | DH4 | - | - | - | - | 63 | 2 (neighbouring) | AM | 11.901 | 13.757 | 949,973 | 867,018 |

| DH4-568c | DH4 | - | - | - | - | 63 | 3 (triangle) | AM | 0.001 | 0.001 | 989,048 | 770,252 |

| DH4-568d | DH4 | - | - | - | - | 63 | 3 (neighbouring) | AM | 0.003 | 0.004 | 954,513 | 867,194 |

| DH4-568e | DH4 | - | - | - | - | 63 | 4 (square) | AM | 0.006 | 0.007 | 985,397 | 765,622 |

| DH4-591 | DH4 | 591 | 4.5 | 1.3 | 4.7 | 108 | 6 | AM | 0.009 | 0.012 | 1,944,754 | 998,882 |

| DH4-591w | DH4 | 591 | - | - | - | 96 | 6 | ArUco | 0.037 | 0.061 | 1,954,815 | 935,906 |

| DH4-643 | DH4 | 643 | 4.7 | 3.7 | 4.1 | 96 | 6 | AM | 0.013 | 0.016 | 1,553,969 | 1,000,000 |

| DH4-673 | DH4 | 673.03 | 8.0 | 6.7 | 4.1 | 93 | 6 | AM | 0.011 | 0.015 | 2,144,729 | 1,000,000 |

| Sample ID | V (p; cm) | M (p; g) | Density (p; g/cm3) | V (I; cm) | M (I; g) | Density (I; g/cm3) |

|---|---|---|---|---|---|---|

| DH4-466 | 49.00 | 124.78 | 2.55 | 49.27 | 124.47 | 2.53 |

| DH4-487.5 | 125.00 | 308.62 | 2.47 | - | - | - |

| DH4-487.5a | 30.08 | 75.14 | 2.50 | - | - | - |

| DH4-487.5b | 19.70 | 49.40 | 2.51 | - | - | - |

| DH4-487.5c | 29.62 | 74.34 | 2.51 | - | - | - |

| DH4-487.5d | 4.39 | 10.35 | 2.36 | - | - | - |

| DH4-487.5e | 11.91 | 29.11 | 2.45 | - | - | - |

| DH4-487.5f | 29.19 | 70.28 | 2.41 | - | - | - |

| DH4-487.5g | 16.02 | 39.46 | - | - | - | - |

| DH4-487.5h | 49.88 | 124.54 | - | - | - | - |

| DH4-487.5i | 44.99 | 109.74 | - | - | - | - |

| DH4-487.5j | 79.86 | 198.88 | - | - | - | - |

| DH4-489 | 46.22 | 115.88 | 2.51 | 46.47 | 115.68 | 2.49 |

| DH4-503 | 75.32 | 190.75 | 2.53 | 74.41 | 190.48 | 2.56 |

| DH4-519 | 75.88 | 197.05 | 2.60 | 75.57 | 195.66 | 2.59 |

| DH4-568 | 89.53 | 221.63 | 2.50 | 88.74 | 221.64 | 2.50 |

| DH4-568a | 125.74 | - | - | - | - | - |

| DH4-568b | 66.70 | - | - | - | - | - |

| DH4-568c | 88.49 | - | - | - | - | - |

| DH4-568d | 88.86 | - | - | - | - | - |

| DH4-568e | 88.81 | - | - | - | - | - |

| DH4-591 | 71.34 | 175.11 | 2.45 | 69.37 | 174.91 | 2.52 |

| DH4-591w | 73.18 | - | - | 74.35 | - | - |

| DH4-643 | 54.48 | 137.98 | 2.53 | 54.91 | 137.95 | 2.51 |

| DH4-673 | 50.02 | 154.52 | 3.09 | 50.59 | 153.54 | 3.04 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Betlem, P.; Birchall, T.; Ogata, K.; Park, J.; Skurtveit, E.; Senger, K. Digital Drill Core Models: Structure-from-Motion as a Tool for the Characterisation, Orientation, and Digital Archiving of Drill Core Samples. Remote Sens. 2020, 12, 330. https://0-doi-org.brum.beds.ac.uk/10.3390/rs12020330

Betlem P, Birchall T, Ogata K, Park J, Skurtveit E, Senger K. Digital Drill Core Models: Structure-from-Motion as a Tool for the Characterisation, Orientation, and Digital Archiving of Drill Core Samples. Remote Sensing. 2020; 12(2):330. https://0-doi-org.brum.beds.ac.uk/10.3390/rs12020330

Chicago/Turabian StyleBetlem, Peter, Thomas Birchall, Kei Ogata, Joonsang Park, Elin Skurtveit, and Kim Senger. 2020. "Digital Drill Core Models: Structure-from-Motion as a Tool for the Characterisation, Orientation, and Digital Archiving of Drill Core Samples" Remote Sensing 12, no. 2: 330. https://0-doi-org.brum.beds.ac.uk/10.3390/rs12020330