1. Introduction

In basic terms, animals require an adequate supply of carbohydrates, proteins, fats/oils, vitamins, minerals, and water. However, the composition of raw materials in animal feeds varies from formulation to formulation and between different species [

1]. In South Africa, the poultry industry is divided into two, i.e., the broiler industry, which supplies poultry meat, and the egg industry that is generally layer and breeder farm chickens for egg production [

2]. While poultry feeds are largely composed of cereal grains, protein, and vitamin supplements [

3], the most significant ingredients used in South African poultry feeds are maize, oilcake, soybeans and fishmeal [

1]. The poultry industry in the country remains the second largest consumer of maize often used as the main ingredient in poultry feed formulation [

2].

In most cases, feeds are produced and stored for a long period of time before distribution and this may endanger the quality for animal consumption. Poor composition of raw materials, high carbon, and moisture in feeds may very often lead to fungal and mycotoxin contamination [

4,

5,

6,

7]. Mycotoxins are well-known toxic secondary metabolites mainly produced by various filamentous fungal species of the

Aspergillus,

Fusarium,

Penicillium, and

Alternaria genera, which are commonly recognised as contaminants of food and feedstuffs [

7,

8]. Even though over 300 mycotoxins are known to occur under a wide range of climatic conditions, those that are significant due to health and economic significance in sub-Saharan Africa (SSA) are the aflatoxins (AFs), fumonisins (FUMs), in addition to ochratoxins (OTs) and trichothecenes (TH) [

8,

9]. The significance of these mycotoxins rests on their existence in food and feed above regulatory limits. Other than their presence in food and feed, emerging

Alternaria mycotoxins such as alternariol monomethyl ether (AME), alternariol (AOH) and tenuazonic acid (TeA) are frequently encountered as contaminants of feed ingredients [

10] that could occasionally find themselves in the final product. Although their contamination levels are generally low with limited toxicity data in chickens, their health risk cannot be completely excluded when noting their possible reproductive and immune system effects in both humans and animals [

11,

12,

13].

Most cases related to chronic conditions result from the consumption of mycotoxins regularly at low doses, which go unnoticed especially since they can co-occur throughout the animal’s developmental cycle, causing multiple diseases [

3,

14,

15,

16,

17]. In poultry, the consumption of ochratoxin A (OTA) contaminated feed can result in ochratoxicosis, a general term for OTs causing disease, characterised by low egg production and poor weight gain [

3,

5], whereas the consumption of AF contaminated feed or feedstuff results in the hepatic condition, aflatoxicosis, causing anorexia and affecting growth rates, decreasing egg production and increasing death rates [

3,

17]. Aflatoxins, which mostly flourish under tropical conditions, have the ability to cause extensive liver damage in poultry and other livestock [

5]. The co-occurrence of FUMs, deoxynivalenol (DON), and zearalenone (ZEN) in poultry feed can possibly lead to symptoms such as reduced villus height in broiler chicks [

14,

16].

Feed represents one of the main aspects in poultry production. Both broilers and layers are effective in converting feed to food products [

15,

18] and as such, there are high chances of the carry-over of mycotoxins into edible by-products from poultry bird fed with contaminated feeds. The situation of poultry feeds contaminated by mycotoxins is an eminent potential of carry-over affecting negatively poultry health and performance. Broiler and layer chickens in farms affected by mycotoxicosis have been seen to exhibit symptoms such as weight loss, reduced feed conversion competency, immunosuppression, failure to vaccination responses, low fertility, high chances of egg blood spots, kidney enlargement, pale fatty liver, gizzard erosions, increased incidence of leg malformations, visceral haemorrhages, inclusion body hepatitis and oral lesion [

7,

15,

18]. Such conditions may negatively and seriously affect the poultry industry.

In South Africa, few studies on mycotoxins in poultry feed are reported, meaning that limited studies in monitoring them exist. Recently, a study on the dairy cattle feeds from the Gauteng Province of South Africa established the occurrence of 15 mycotoxins [

19]. A study on compound feeds produced in South Africa reported FUMs as the most dominant mycotoxin that co-existed with ZEN and DON in 67% of all the samples analysed [

8]. The survey on South African feed samples revealed the occurrence of 75% FUMs, 90% DON, 20% ZEN and 14% AFs [

20]. The nature and presence of mycotoxins in South African animal feeds should be an on-going matter since some of these mycotoxins are found in animal products from animals that consume feeds contaminated with mycotoxins [

21,

22]. Despite an increased interest in mycotoxins contamination and their health effects, only a few studies covered the scope of mycobiota and mycotoxins in poultry feed in the country [

8,

23,

24].

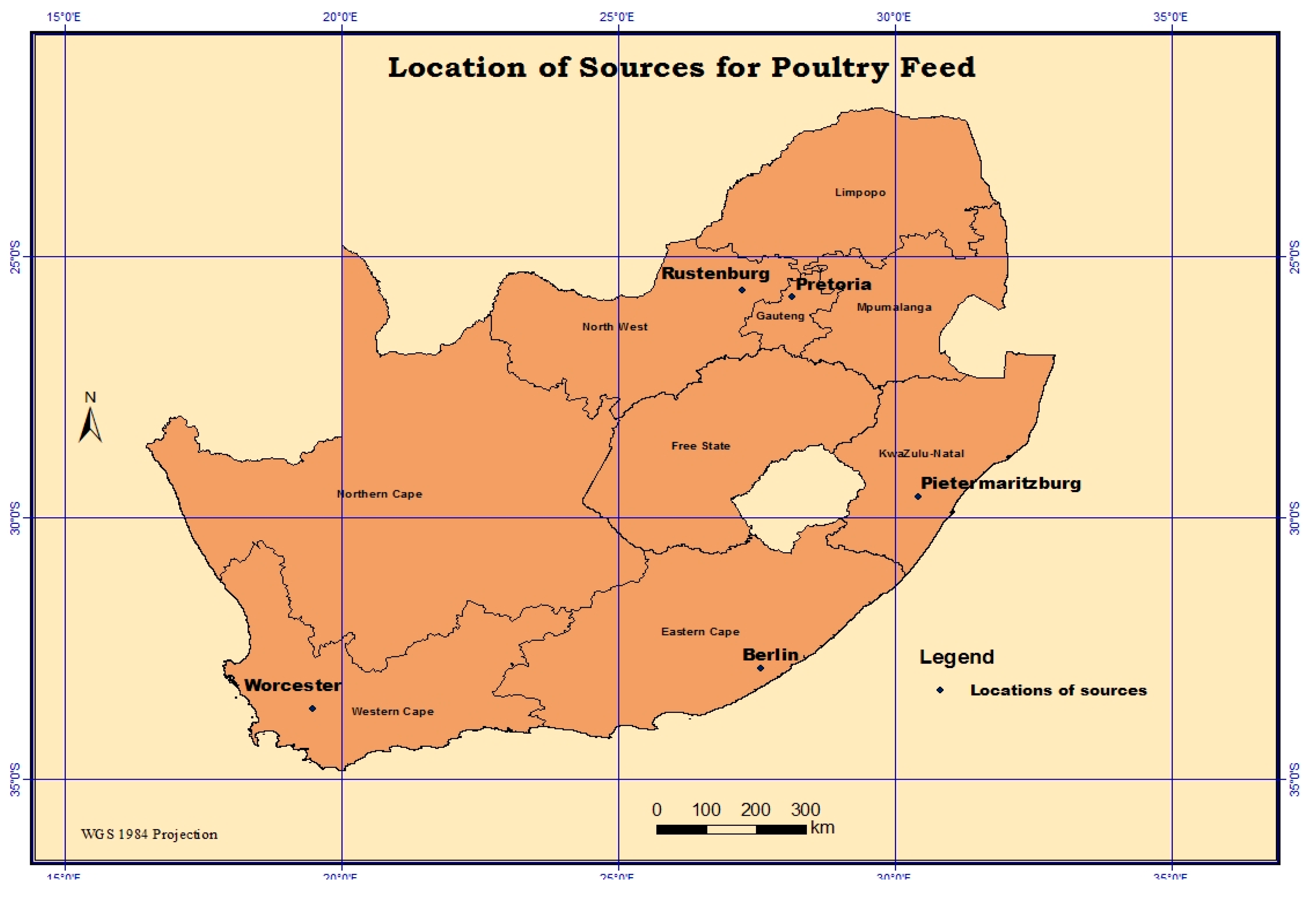

Hence in this study, the most commonly encountered mycotoxins (AFs, FUMs, DON, ZEN, T-2 toxin and HT-2 toxin) including the

Alternaria toxin, AME and derivatives of ZEN i.e., α-ZEL and β-ZEL, and derivatives of DON i.e., 3-ADON and 15-ADON in poultry feed manufactured in South Africa were screened for multiple contamination using UHPLC-MS/MS. This was particularly important since the co-occurrence of these mycotoxins could synergistically act with one another to potentiate additional or at best synergistic toxic effects in animals, as reported elsewhere [

5,

14].

3. Discussion

Poultry feed was analysed for mycotoxin contamination. The overall results of the reported mycotoxins in poultry feeds analysed herein are fairly in line with those of compound feeds previously analysed by Njobeh and colleagues [

8], suggesting that AFs, FUMs, DON, and ZEN are the most common contaminants of poultry and other livestock feeds produced in South Africa; furthermore, reporting FB

1 with higher concentration than other mycotoxins. Although the

Fusarium toxins as such are predominately found as common contaminants of foods and feedstuffs mostly in maize-based products [

8,

9], the study on compound feeds established the high levels of FUMs in the cattle feeds and suggested that the concentration was not linked to the levels of maize as poultry feed remains the biggest consumer of maize [

8]. In this study, FB

1, FB

2, and FB

3 were recovered in all poultry feed samples. Fumonisin B

1 was recovered from feeds at a maximum value of 7125.3 µg/kg as compared to FB

2 and FB

3 with maximum values of 125.1 and 115.1 µg/kg, respectively. These values are comparably higher than those previously reported in other animal feed studies conducted in the country [

8,

19]. The much higher levels of FUMs established in this study are most likely to be due to the increased inclusion of increased levels of fibre and of protein content which may be indicators of certain ingredients in different poultry feed groups (

Appendix A Table A1).

Higher concentrations of FB

1 compared to FB

2 and FB

3 are very often reported [

8,

10]. The natural occurrence of FUMs in maize and maize-based products in several African countries including South Africa is reported with these products as principal substrates [

9,

25]. Whereas this study established that the high contamination levels of FUMs are attributable to increased FB

1 contamination (being at least 40 times higher than other analysed FUMs analogue), however, all the observed levels were below that regulated by the South African Department of Agriculture, Forestry and Fisheries (DAFF) set at 50,000 µg/kg in poultry feed [

26]. Furthermore, the FUMs levels investigated herein were demonstrated to be well within the European Commission (EC) guidance values set at 20,000 µg/kg for combined maximum levels of FB

1 and FB

2 in complementary and complete feeds for poultry [

27]. The FUMs levels were also found to be well within the US Food and Drug Administration (USFDA) guidance levels for the sum of FB

1, FB

2 and FB

3 at 30,000 µg/kg for breeding poultry and 100,000 µg/kg in feed for poultry being raised for slaughter [

27].

Zearalenone and its derivatives strongly interfere with animal reproductive systems and decreased fertility [

16]. Whereas currently both DAFF and USFDA do not have regulatory limits for ZEN in poultry feeds [

26,

27], this mycotoxin is gradually being recognized as a significant contaminant of cereal crops [

16,

20] and it is regulated by the EC with guidance values of 2000 µg/kg for cereal and cereal-based products and 3000 µg/kg for maize products [

28]. The occurrence of ZEN and its derivatives have been reported in maize and maize-products but at low concentrations [

22]. Lower levels of mycotoxin derivatives are common due to possible biotransformation of the conjugated mycotoxin from the parent mycotoxin [

5]. In South African studies, ZEN is reported in lower concentrations, which makes it less problematic and probably why it is not regulated in South African poultry feed [

8,

20]. In a recent South African study on multi-mycotoxins occurrence in Gauteng cattle feeds, ZEN was established in 60% samples at a mean concentration of 2.8 µg/kg [

19], whereas Njobeh et al. [

8] reported ZEN in chicken feeds with an incidence rate level of close to 52% at a maximum value of 610 µg/kg; the levels of this toxin in our study were found in 100% tested samples to be as high as 429 µg/kg. The derivatives of ZEN were also detected in 100% of the samples but much lower concentrations were recovered (maximum values of 22.1 µg/kg for β-ZEL and 20 µg/kg for α-ZEL). Although they are within the EC guidance values for both cereal and maize-based products, such high levels of ZEN and its derivatives are not common in SSA. However, the world mycotoxins survey showed ZEN as the third major contaminant following DON and FUM in animal feed samples from African countries including South Africa [

25].

Trichothecenes (THs) are

Fusarium-derived toxins with a high potency that are commonly associated with

Fusarium head blight in cereal grains [

16]. Those of significance in this study were the type A TH, i.e., T-2 and HT-2 and commonly occurring type B TH DON along with its acetylated derivatives, i.e., 15-ADON and 3-ADON. This group of mycotoxins is very common and problematic in European countries, thus considered as significant contaminants in colder European climates [

9]. Hence, the EC recently placed recommended levels of 500 µg/kg for the sum of T-2 and HT-2 in cereal-based products and 250 µg/kg in compound feeds [

29]. There is inadequate data on TH toxins in South Africa. None of the South African feed samples analysed previously contained either T-2, HT-2, or both, hence, there is no room for comparison on the occurrence of TH toxins in South Africa. Thus, to the best of our knowledge within the EC guidance values, this study reports for the first time, T-2 with a range of 0.1–15.3 µg/kg and for the second time following a recent study on dairy cattle feed contamination [

19], our study reports HT-2 (range of 0.2–5.9 µg/kg) in 100% of the poultry feed samples analysed.

The incidence of DON has consistently been reported in South African crop-based products and for that reason, the mycotoxin has been of great interest in the country [

8]. Department of Agriculture, Forestry and Fisheries of South Africa regulates this mycotoxin in poultry feed limiting the level to 4000 µg/kg [

26]. In South African feedstuffs, Njobeh et al. [

8] found DON in chicken feeds with mean levels of 620 ± 386 µg/kg at a maximum level of 1980 µg/kg while Changwa et al. [

19] reported lower levels of DON with a maximum value of 81.6 µg/kg in dairy feeds. Our study reports DON incidence of 99% but at comparatively much lower concentrations (max: 154 µg/kg) than those previously reported [

8,

19]. In this study, derivatives of DON, i.e., 3-ADON and 15-ADON (max: 12.9 and 44.9 µg/kg, respectively) were simultaneously analysed in combination, taking into consideration their isometric and co-eluting nature. The incidence levels of DON and its derivatives in this study remained well within the DAFF’s maximum regulatory limits of 4000 µg/kg for poultry feeds [

26].

Once more, this study established the natural occurrence of AME (max: 155.5 µg/kg) in 100% of analysed poultry feed samples, the

Alternaria toxin. There are no regulations currently available for this toxin in food or feed, however, studies have focused on establishing its profile along with alternariol (AOH), both being the main toxins produced by

Alternaria alternata most commonly encountered in fruit products, sunflower seeds, wheat and other agricultural products [

10,

11,

12]. The presence of

Alternaria toxins has been reported in maize samples [

10,

11] and in sunflower seeds ranging between 1 and 103 µg/kg [

12]. There is scarce data concerning levels of this toxin in toxicological studies, hence, no regulations are set currently.

Results on AFs revealed unusual occurrence patterns wherein higher concentrations of the less potent AFG

1 and AFG

2 (mean: 0.7 and 0.5 µg/kg, respectively) than those of AFB

1 and AFB

2 (mean: 0.2 and 0.4 µg/kg, respectively) and moreover, the G-types occurred more frequently than the B-types as observed. In animal feed, similar findings were reported [

30,

31,

32], whereas, in raw maize and groundnut samples from Malawi lower mean concentrations of AFB

1 than that of AFG

2 were also reported [

31]. The proportion of B-types and G-types AF are highly influenced by an ecological niche of the parent fungus [

30,

31].

Aflatoxin flavus is known to be an AFB

1 and AFB

2 producer, while

A. parasiticus produces all four AFs (AFG

1, AFG

2, AFB

1, and AFB

2) [

17,

30,

31]. Such unusual changes in AFs pattern may be related to climate change and global warming that could impact and compromise the behaviour of fungal plant pathogens [

33]. None of the feed samples analysed was found at higher contamination level above the South African regulatory limit of 20 µg/kg, the USFDA limit range of 10–30 µg/kg, and the EU regulatory limit of 2 µg/kg for AFs in poultry feeds [

26,

27].

The data demonstrated the co-occurrence of analysed metabolites at various concentrations. Mycotoxins such as DON and ZEN are both produced by

Fusarium species found under cool and wet conditions [

9]. Mycotoxins such as FUMs, DON and ZEN, produced by

Fusarium spp. are most frequently encountered in feeds and feedstuffs [

4,

8,

34,

35,

36]. In this study, the overall data revealed mycotoxins co-contamination of poultry feed samples (

Figure 1). Based on the results of this study, exposure of individual poultry feed samples to multiple mycotoxins simultaneously is highly likely as a result of AFs, FUMs, ZENs, and DONs, as we observed co-contamination of these mycotoxins with the a higher frequency of 51%. Mycotoxins can co-occur even at levels above regulatory limits very often in food and feed commodities causing negative health effects in human and animals.

A systematic review of over a hundred papers between 1987–2016, revealed 127 mycotoxin combinations, of which AFs + FBs, AFs + OTA, DON + ZEA, and FBs + ZEA were amongst the most frequently co-occurring combinations in cereal crop [

27]. It has been reported that ZEA usually co-occurs with one or more of the THs, because of the ability of its producing fungi to synthesize more than one mycotoxin [

16]. Mngadi et al. [

23] provided some data in which several mycotoxins co-occur in feeds within the country. In our study, the co-existence of mycotoxins within the same sample was very common and data revealed that 91 samples contained multiple mycotoxins, with 67% that with 3 mycotoxins (FB + DON + ZEA), 26% with 4 mycotoxins (FB + DON + ZEA + AF).

Even though in this study, levels of the tested mycotoxins in individual samples were either below regulatory limits or at levels that could not elicit any toxic effect in poultry, a number of mycotoxins were found to co-occur with one another. Such co-occurrences of multiple mycotoxins may provoke some synergistic actions or additive effects thus, inducing various toxic effects in poultry [

8]. The data reported in this study established that 51% of the samples were contaminated with multiple mycotoxins.