Evaluations of Electrostatic Filtration Efficiency and Antibacterial Efficacy of Antibacterial Electret Polypropylene Filters: Effects of Using Low Molecular Antibacterial Agent as Additive

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Antibacterial Electret PP Filters

2.3. Surface Voltages and Surface Potential

2.4. Filtration Efficiency and Pressure Drop

2.5. Differential Scanning Calorimeters

2.6. Inhibition Zone

3. Results and Discussions

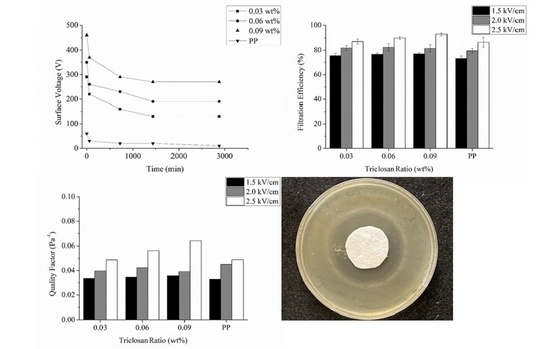

3.1. Surface Voltage and Surface Potential

3.2. Inhibition Zone (Electret PP Nonwoven Fabrics)

3.3. Filtration Efficiency, Pressure Drop and Quality Factor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hetland, R.B.; Cassee, F.R.; Refsnes, M.; Schwarze, P.E.; Lag, M.; Boere, A.J.F.; Dybing, E. Release of inflammatory cytokines, cell toxicity and apoptosis in epithelial lung cells after exposure to ambient air particles of different size fractions. Toxicol. In Vitro 2004, 18, 203–212. [Google Scholar] [CrossRef]

- Gualtieri, M.; Mantecca, P.; Corvaja, V.; Longhin, E.; Perrone, M.G.; Bolzacchini, E.; Camatini, M. Winter fine particulate matter from Milan induces morphological and functional alterations in human pulmonary epithelial cells (A549). Toxicol. Lett. 2009, 188, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Landrigan, P.J.; Fuller, R.; Acosta, N.J.R.; Adeyi, O.; Arnold, R.; Basu, N.; Balde, A.B.; Bertollini, R.; Bose-O’Reilly, S.; Boufford, J.I.; et al. The Lancet Commission on pollution and health. Lancet 2018, 391, 462–512. [Google Scholar] [CrossRef] [Green Version]

- Jeba, F.; Karim, T.T.; Khan, M.F.; Latif, M.T.; Quddus, K.F.; Salam, A. Receptor modelling and risk factors of polycyclic aromatic hydrocarbons (PAHs) in the atmospheric particulate matter at an IGP outflow location (island of the bay of Bengal-Bhola, Bangladesh). Air Qual. Atmos. Health 2021, 14, 1417–1431. [Google Scholar] [CrossRef]

- Wang, T.; Rovira, J.; Sierra, J.; Blanco, J.; Chen, S.J.; Mai, B.X.; Schuhmacher, M.; Domingo, J.L. Characterization of airborne particles and cytotoxicity to a human lung cancer cell line in Guangzhou, China. Environ. Res. 2021, 196, 9. [Google Scholar] [CrossRef]

- Wu, J.Y.; Tou, F.Y.; Yang, Y.; Liu, C.; Hower, J.C.; Baalousha, M.; Wang, G.H.; Liu, M.; Hochella, M.F. Metal-Containing Nanoparticles in Low-Rank Coal-Derived Fly Ash from China: Characterization and Implications toward Human Lung Toxicity. Environ. Sci. Technol. 2021, 55, 6644–6654. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Dai, Z.J.; He, B.; Ke, Q.F. The Effect of Temperature and Humidity on the Filtration Performance of Electret Melt-Blown Nonwovens. Materials 2020, 13, 4774. [Google Scholar] [CrossRef]

- Kerner, M.; Schmidt, K.; Schumacher, S.; Asbach, C.; Antonyuk, S. Ageing of electret filter media due to deposition of submicron particles—Experimental and numerical investigations. Sep. Purif. Technol. 2020, 251, 10. [Google Scholar] [CrossRef]

- Cai, R.R.; Li, S.Z.; Zhang, L.Z.; Lei, Y. Fabrication and performance of a stable micro/nano composite electret filter for effective PM2.5 capture. Sci. Total Environ. 2020, 725, 10. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J. Material Properties Influencing the Charge Decay of Electret Filters and their Impact on Filtration Performance. Polymers 2020, 12, 721. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.F.; Liu, N.; Zeng, Q.R.; Liu, J.X.; Zhang, X.; Ge, M.Z.; Zhang, W.; Li, S.Y.; Fu, Y.J.; Zhang, Y. Design of Polypropylene Electret Melt Blown Nonwovens with Superior Filtration Efficiency Stability through Thermally Stimulated Charging. Polymers 2020, 12, 2341. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.X.; Zhang, H.F.; Hou, J.; Wang, Y.X.; Deng, C.; Huang, C.; Jin, X.Y. Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters. Polymers 2021, 13, 485. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.W.; Wang, P.J.; Chen, R.W.; Gu, G.W.; Hu, S.Q.; Tian, R.Y. Laminated polyacrylonitrile nanofiber membrane codoped with boehmite nanoparticles for efficient electrostatic capture of particulate matters. Nanotechnology 2021, 32, 8. [Google Scholar] [CrossRef]

- Liu, J.X.; Zhang, H.F.; Gong, H.; Zhang, X.; Wang, Y.X.; Jin, X.Y. Polyethylene/Polypropylene Bicomponent Spunbond Air Filtration Materials Containing Magnesium Stearate for Efficient Fine Particle Capture. ACS Appl. Mater. Interfaces 2019, 11, 40592–40601. [Google Scholar] [CrossRef]

- He, W.D.; Guo, Y.H.; Shen, R.Q.; Liu, Q.T.; Liu, J.X. Enhancement of filtration performance of polyester (PET) filters by compositing with schorl powder. Powder Technol. 2019, 342, 321–327. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, Y.R.; Wen, W.; Wang, C.Y.; Ni, J.; Jiang, J.J.; Fu, X.Y.; Zhou, M.Y.; Ye, L.; Ge, Z.J.; et al. The Dilemma of Masks During the COVID-19 Outbreak. Risk Manag. Healthc. Policy 2021, 14, 2369–2375. [Google Scholar] [CrossRef]

- Xiao, Y.X.; Wang, Y.; Zhu, W.N.; Yao, J.M.; Sun, C.L.; Militky, J.; Venkataraman, M.; Zhu, G.C. Development of tree-like nanofibrous air filter with durable antibacterial property. Sep. Purif. Technol. 2021, 259, 8. [Google Scholar] [CrossRef]

- Ungur, G.; Hruza, J. Modified Nanofibrous Filters with Durable Antibacterial Properties. Molecules 2021, 26, 1255. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.X.; Yue, Y.; He, W.D.; Jiang, F.Z.; Lin, C.H.; Pui, D.Y.H.; Liang, Y.; Wang, J. The antibacterial performance of positively charged and chitosan dipped air filter media. Build. Environ. 2020, 180, 107020. [Google Scholar] [CrossRef]

- Zhong, Z.X.; Xu, Z.; Sheng, T.; Yao, J.F.; Xing, W.H.; Wang, Y. Unusual Air Filters with Ultrahigh Efficiency and Antibacterial Functionality Enabled by ZnO Nanorods. ACS Appl. Mater. Interfaces 2015, 7, 21538–21544. [Google Scholar] [CrossRef]

- Juuti, P.; Nikka, M.; Gunell, M.; Eerola, E.; Saarinen, J.J.; Omori, Y.; Seto, T.; Makela, J.M. Fabrication of Fiber Filters with Antibacterial Properties for VOC and Particle Removal. Aerosol Air Qual. Res. 2019, 19, 1892–1899. [Google Scholar] [CrossRef]

- Zhao, H.F.; Li, Y.; Sha, L.Z. Preparation of Functional Air Filter Material Based on Biodegradable Fibers and Nano Titanium Dioxide. Dig. J. Nanomater. Biostruct. 2018, 13, 391–397. [Google Scholar]

- Kamalipour, J.; Masoomi, M.; Khonakdar, H.A.; Razavi, S.M.R. Preparation and release study of Triclosan in polyethylene/Triclosan anti-bacterial blend. Colloid Surf. B Biointerfaces 2016, 145, 891–898. [Google Scholar] [CrossRef]

- Mustafa, M.; Wondimu, B.; Hultenby, K.; Yucel-Lindberg, T.; Modeer, T. Uptake, distribution and release of C-14-triclosan in human gingival fibroblasts. J. Pharm. Sci. 2003, 92, 1648–1653. [Google Scholar] [CrossRef]

- Schena, D.; Papagrigoraki, A.; Girolomoni, G. Sensitizing potential of triclosan and triclosan-based skin care products in patients with chronic eczema. Dermatol. Ther. 2008, 21, S35–S38. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.Z.; Wang, S.X.; Yang, W.; Chen, S.W.; Xu, Z.S.; Mo, X.W.; Zhou, H.; Duan, J.J.; Hu, B.; Huang, L. Trap-Induced Dense Monocharged Perfluorinated Electret Nanofibers for Recyclable Multifunctional Healthcare Mask. ACS Nano 2021, 15, 5486–5494. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.F.; Chen, G.J.; Bhat, G.S.; Azari, H.; Pen, H.L. Electret characteristics of melt-blown polylactic acid fabrics for air filtration application. J. Appl. Polym. Sci. 2020, 137, 48309. [Google Scholar] [CrossRef]

- Poortinga, A.T.; Bos, R.; Norde, W.; Busscher, H.J. Electric double layer interactions in bacterial adhesion to surfaces. Surf. Sci. Rep. 2002, 47, 3–32. [Google Scholar] [CrossRef]

- Yang, L.J.; Zhang, C.R.; Huang, F.; Liu, J.J.; Zhang, Y.M.; Yang, C.H.; Ren, C.H.; Chu, L.P.; Liu, B.; Liu, J.F. Triclosan-based supramolecular hydrogels as nanoantibiotics for enhanced antibacterial activity. J. Control. Release 2020, 324, 354–365. [Google Scholar] [CrossRef]

- Howse, G.L.; Bovill, R.A.; Stephens, P.J.; Osborn, H.M.I. Synthesis and antibacterial profiles of targeted triclosan derivatives. Eur. J. Med. Chem. 2019, 162, 51–58. [Google Scholar] [CrossRef] [Green Version]

| Triclosan Ratio (wt%) | Tc (°C) | Tm (°C) | Crystallinity (%) |

|---|---|---|---|

| 0 (Pure PP) | 121.04 | 146.57 | 6.87 |

| 0.03 | 121.38 | 150.43 | 13.80 |

| 0.06 | 119.95 | 150.77 | 17.42 |

| 0.09 | 116.82 | 145.08 | 20.63 |

| Triclosan Ratio (wt%) | Electric Field Intensity (kV/cm) | E. coli Inhibition Zone (mm) | S. aureus Inhibition Zone (mm) |

|---|---|---|---|

| 0 (Pure PP) | 0 | 0 | 0 |

| 1.5 | 0 | 0.7 ± 0.14 | |

| 2.0 | 0 | 0.8 ± 0.13 | |

| 2.5 | 0 | 0.9 ± 0.13 | |

| 0.03 | 0 | 0.5 ± 0.10 | 2.0 ± 0.10 |

| 1.5 | 0.8 ± 0.15 | 2.1 ± 0.08 | |

| 2.0 | 0.8 ± 0.09 | 2.1 ± 0.15 | |

| 2.5 | 1 ± 0.07 | 2.5 ± 0.31 | |

| 0.06 | 0 | 1.2 ± 0.19 | 6.0 ± 0.54 |

| 1.5 | 1.2 ± 0.35 | 6.8 ± 0.37 | |

| 2.0 | 1.4 ± 0.18 | 7.0 ± 0.03 | |

| 2.5 | 1.7 ± 0.39 | 7.7 ± 0.40 | |

| 0.09 | 0 | 1.9 ± 0.34 | 8.6 ± 0.41 |

| 1.5 | 2.0 ± 0.35 | 8.9 ± 0.38 | |

| 2.0 | 2.2 ± 0.29 | 9.2 ± 0.92 | |

| 2.5 | 2.5 ± 0.42 | 9.3 ± 0.50 |

| Triclosan Ratio (wt%) | Basis Weight (g/m2) | Thickness (mm) | Fiber Diameter (μm) | Air Permeability (cm3/s/cm2) |

|---|---|---|---|---|

| 0 (control group) | 70.3 ± 4.1 | 0.65 ± 0.02 | 6.14 ± 3.88 | 63.65 ± 4.17 |

| 0.03 | 65.4 ± 3.8 | 0.63 ± 0.04 | 6.50 ± 2.11 | 62.14 ± 4.09 |

| 0.06 | 59.1 ± 5.7 | 0.66 ± 0.01 | 6.31 ± 3.58 | 61.06 ± 4.61 |

| 0.09 | 61.8 ± 2.4 | 0.65 ± 0.02 | 6.46 ± 3.58 | 67.56 ± 4.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.-H.; Shih, Y.-H.; Huang, C.-H.; Lai, M.-F.; Lee, S.-A.; Shiu, B.-C.; Lou, C.-W. Evaluations of Electrostatic Filtration Efficiency and Antibacterial Efficacy of Antibacterial Electret Polypropylene Filters: Effects of Using Low Molecular Antibacterial Agent as Additive. Polymers 2021, 13, 3303. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193303

Lin J-H, Shih Y-H, Huang C-H, Lai M-F, Lee S-A, Shiu B-C, Lou C-W. Evaluations of Electrostatic Filtration Efficiency and Antibacterial Efficacy of Antibacterial Electret Polypropylene Filters: Effects of Using Low Molecular Antibacterial Agent as Additive. Polymers. 2021; 13(19):3303. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193303

Chicago/Turabian StyleLin, Jia-Horng, Ying-Huei Shih, Chen-Hung Huang, Mei-Feng Lai, Shu-An Lee, Bing-Chiuan Shiu, and Ching-Wen Lou. 2021. "Evaluations of Electrostatic Filtration Efficiency and Antibacterial Efficacy of Antibacterial Electret Polypropylene Filters: Effects of Using Low Molecular Antibacterial Agent as Additive" Polymers 13, no. 19: 3303. https://0-doi-org.brum.beds.ac.uk/10.3390/polym13193303