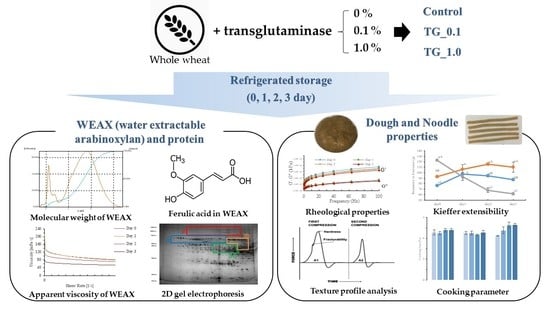

The Effects of Transglutaminase and Refrigerated Storage on the Physicochemical Properties of Whole Wheat Dough and Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Whole Wheat Dough (WWD) and Noodle (WWN) Preparation

2.3. Extraction of Water Extractable Arabinoxylans (WEAX) from WWD

2.4. Physicochemical Properties of WEAX from WWDs

2.4.1. Molecular Weight of WEAX

2.4.2. The Apparent Viscosity (AV) of WEAX Solutions

2.4.3. Ferulic Acid (FA) Content of WEAX

2.5. Two-Dimensional Gel Electrophoresis (2-DE) of WWDs

2.6. Resistance to Extension and Extensibility of WWDs

2.7. Dynamic Rheological Measurements of WWDs

2.8. Cooking Properties of WWN

2.9. Texture Profile Analysis (TPA) of Cooked Noodles

2.10. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties of Water Extractable Arabinoxylan in WWDs

3.2. Apparent Viscosity (AV) of WEAX Solutions

3.3. Two-Dimensional Electrophoresis of WWD Proteins

3.4. Resistance to Extension and Extensibility of WWD

3.5. Rheological Measurements of WWDs

3.6. Cooking Properties of Noodles

3.7. Texture Profile Analysis (TPA) of Cooked WWNs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hirawan, R.; Ser, W.Y.; Arntfield, S.D.; Beta, T. Antioxidant properties of commercial, regular-and whole-wheat spaghetti. Food Chem. 2010, 119, 258–264. [Google Scholar] [CrossRef]

- Marquart, L.; Jacobs, D.R., Jr.; McIntosh, G.H.; Poutanen, K.; Reicks, M. Whole Grains and Health; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Brouns, F.J.; van Buul, V.J.; Shewry, P.R. Does wheat make us fat and sick? J. Cereal Sci. 2013, 58, 209–215. [Google Scholar] [CrossRef]

- Bock, J.E.; Damodaran, S. Bran-induced changes in water structure and gluten conformation in model gluten dough studied by Fourier transform infrared spectroscopy. Food Hydrocoll. 2013, 31, 146–155. [Google Scholar] [CrossRef]

- Van Hung, P.; Maeda, T.; Fujita, M.; Morita, N. Dough properties and breadmaking qualities of whole waxy wheat flour and effects of additional enzymes. J. Sci. Food Agric. 2007, 87, 2538–2543. [Google Scholar] [CrossRef]

- Liu, L.; Yang, W.; Cui, S.W.; Jiang, Z.; Chen, Q.; Qian, H.; Wang, L.; Zhou, S. Effects of pentosanase and glucose oxidase on the composition, rheology and microstructure of whole wheat dough. Food Hydrocoll. 2018, 84, 545–551. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Kindelspire, J.; Krishnan, P.; Zhao, S. Microstructural, textural, and sensory properties of whole-wheat noodle modified by enzymes and emulsifiers. Food Chem. 2017, 223, 16–24. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.R.; Shah, R.; Madamwar, D. Improvement of the quality of whole wheat bread by supplementation of xylanase from Aspergillus foetidus. Bioresour. Technol. 2006, 97, 2047–2053. [Google Scholar] [CrossRef]

- Niu, M.; Li, X.D.; Wang, L.; Chen, Z.X.; Hou, G.G. Effects of Inorganic Phosphates on the Thermodynamic, Pasting, and Asian Noodle-Making Properties of Whole Wheat Flour. Cereal Chem. 2014, 91, 1–7. [Google Scholar] [CrossRef]

- Larré, C.; Denery-Papini, S.; Popineau, Y.; Deshayes, G.; Desserme, C.; Lefebvre, J. Biochemical analysis and rheological properties of gluten modified by transglutaminase. Cereal Chem. 2000, 77, 121–127. [Google Scholar] [CrossRef]

- Zhu, Y.; Rinzema, A.; Tramper, J.; Bol, J. Microbial transglutaminase—A review of its production and application in food processing. Appl. Microbiol. Biotechnol. 1995, 44, 277–282. [Google Scholar] [CrossRef]

- Ortolan, F.; Steel, C.J. Protein characteristics that affect the quality of vital wheat gluten to be used in baking: A review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 369–381. [Google Scholar] [CrossRef] [Green Version]

- Niu, M.; Hou, G.G. Whole wheat noodle: Processing, quality improvement, and nutritional and health benefits. Cereal Chem. 2019, 96, 23–33. [Google Scholar] [CrossRef]

- Bellido, G.; Hatcher, D. Effects of a cross-linking enzyme on the protein composition, mechanical properties, and microstructure of Chinese-style noodles. Food Chem. 2011, 125, 813–822. [Google Scholar] [CrossRef]

- Simsek, S.; Whitney, K.; Ohm, J.B.; Mergoum, M. Refrigerated dough quality of hard red spring wheat: Effect of genotype and environment on dough syruping and arabinoxylan production. Cereal Chem. 2011, 88, 445–450. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Simsek, S.; Campanella, O.H.; Ohm, J.B.; Chang, H.; Reuhs, B.L.; Mergoum, M. Rheological changes in refrigerated dough during storage in relation to proteins. J. Food Process. Eng. 2011, 34, 639–656. [Google Scholar] [CrossRef]

- Whitney, K.; Ohm, J.B.; Simsek, S. Addition of glucose oxidase for the improvement of refrigerated dough quality. Cereal Chem. 2014, 91, 548–553. [Google Scholar] [CrossRef]

- Mendez-Encinas, M.A.; Carvajal-Millan, E.; Rascon-Chu, A.; Astiazaran-Garcia, H.F.; Valencia-Rivera, D.E. Ferulated arabinoxylans and their gels: Functional properties and potential application as antioxidant and anticancer agent. Oxidative Med. Cell. Longev. 2018, 2018, 2314759. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kiszonas, A.M.; Fuerst, E.P.; Morris, C.F. Wheat arabinoxylan structure provides insight into function. Cereal Chem. 2013, 90, 387–395. [Google Scholar] [CrossRef] [Green Version]

- Rosicka-Kaczmarek, J.; Tkaczyk, M.; Makowski, B.; Komisarczyk, A.; Nebesny, E. The influence of non-starch polysaccharide on thermodynamic properties of starches from facultative wheat varieties. Eur. Food Res. Technol. 2017, 243, 2243–2253. [Google Scholar] [CrossRef] [Green Version]

- Simsek, S.; Zhang, Y.; Campanella, O.H. Physicochemical properties of arabinoxlans in refrigerated dough. Food Res. Int. 2010, 43, 2119–2125. [Google Scholar] [CrossRef]

- Wang, P.; Hou, C.; Zhao, X.; Tian, M.; Gu, Z.; Yang, R. Molecular characterization of water-extractable arabinoxylan from wheat bran and its effect on the heat-induced polymerization of gluten and steamed bread quality. Food Hydrocoll. 2019, 87, 570–581. [Google Scholar] [CrossRef]

- Ma, F.; Dang, Y.; Xu, S. Interaction between gluten proteins and their mixtures with water-extractable arabinoxylan of wheat by rheological, molecular anisotropy and CP/MAS 13C NMR measurements. Eur. Food Res. Technol. 2016, 242, 1177–1185. [Google Scholar] [CrossRef]

- Tao, H.; Xiao, Y.; Wu, F.; Xu, X. Optimization of additives and their combination to improve the quality of refrigerated dough. LWT Food Sci. Technol. 2018, 89, 482–488. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.; Lee, B.; Chen, Z.X. Effects of fine grinding of millfeeds on the quality attributes of reconstituted whole-wheat flour and its raw noodle products. LWT Food Sci. Technol. 2014, 57, 58–64. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Wang, L.; Chen, Z.X. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014, 60, 382–388. [Google Scholar] [CrossRef]

- Cao, X.L.; Zhou, S.M.; Yi, C.P.; Wang, L.; Qian, H.F.; Zhang, H.; Qi, X.G. Effect of whole wheat flour on the quality, texture profile, and oxidation stability of instant fried noodles. J. Texture Stud. 2017, 48, 607–615. [Google Scholar] [CrossRef] [PubMed]

- American Association of Cereal Chemists (AACC). AACC Method 66-60.01. Available online: http://methods.aaccnet.org/summaries/66-60.01.aspx (accessed on 13 January 2020).

- Mansberger, A.; D’Amico, S.; Novalin, S.; Schmidt, J.; Tömösközi, S.; Berghofer, E.; Schoenlechner, R. Pentosan extraction from rye bran on pilot scale for application in gluten-free products. Food Hydrocoll. 2014, 35, 606–612. [Google Scholar] [CrossRef]

- Kim, M.J.; Kwak, H.S.; Kim, S.S. Effects of germination on protein, γ-aminobutyric acid, phenolic acids, and antioxidant capacity in wheat. Molecules 2018, 23, 2244. [Google Scholar] [CrossRef] [Green Version]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Oakley, B.R.; Kirsch, D.R.; Morris, N.R. A simplified ultrasensitive silver stain for detecting proteins in polyacrylamide gels. Anal. Biochem. 1980, 105, 361–363. [Google Scholar] [CrossRef]

- Barros, F.; Alviola, J.; Tilley, M.; Chen, Y.; Pierucci, V.; Rooney, L.W. Predicting hot-press wheat tortilla quality using flour, dough and gluten properties. J. Cereal Sci. 2010, 52, 288–294. [Google Scholar] [CrossRef]

- Kaur, A.; Singh, N.; Ahlawat, A.K.; Kaur, S.; Singh, A.M.; Chauhan, H.; Singh, G.P. Diversity in grain, flour, dough and gluten properties amongst Indian wheat cultivars varying in high molecular weight subunits (HMW-GS). Food Res. Int. 2013, 53, 63–72. [Google Scholar] [CrossRef]

- Tudorica, C.; Kuri, V.; Brennan, C. Nutritional and physicochemical characteristics of dietary fiber enriched pasta. J. Agric. Food Chem. 2002, 50, 347–356. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, G.; Piber, M.; Koehler, P. Isolation and chemical characterisation of water-extractable arabinoxylans from wheat and rye during breadmaking. Eur. Food Res. Technol. 2005, 221, 487–492. [Google Scholar] [CrossRef]

- Wilkes, G.L. An Overview of the Basic Rheological Behavior of Polymer Fluids with an Emphasis on Polymer Melts. J. Chem. Education. 1981, 58, 880–892. [Google Scholar] [CrossRef] [Green Version]

- Izydorczyk, M.; Biliaderis, C. Structural and functional aspects of cereal arabinoxylans and β-glucans. In Developments in Food Science; Elsevier: Amsterdam, The Netherlands, 2000; Volume 41, pp. 361–384. [Google Scholar]

- Vensel, W.H.; Tanaka, C.K.; Altenbach, S.B. Protein composition of wheat gluten polymer fractions determined by quantitative two-dimensional gel electrophoresis and tandem mass spectrometry. Proteome Sci. 2014, 12, 8. [Google Scholar] [CrossRef] [Green Version]

- Steffolani, M.E.; Ribotta, P.D.; Perez, G.T.; Leon, A.E. Effect of glucose oxidase, transglutaminase, and pentosanase on wheat proteins: Relationship with dough properties and bread-making quality. J. Cereal Sci. 2010, 51, 366–373. [Google Scholar] [CrossRef]

- Nash, D.; Lanning, S.; Fox, P.; Martin, J.; Blake, N.; Souza, E.; Graybosch, R.; Giroux, M.; Talbert, L.E. Relationship of dough extensibility to dough strength in a spring wheat cross. Cereal Chem. 2006, 83, 255–258. [Google Scholar] [CrossRef]

- Aguirre, J.F.; Osella, C.A.; Carrara, C.R.; Sánchez, H.D.; Buera, M.D.P. Effect of storage temperature on starch retrogradation of bread staling. Starch-Stärke 2011, 63, 587–593. [Google Scholar] [CrossRef]

- Murtini, E.S. The Effect of TG on Dough and Bread Containing Wheat-Soybean Tempe Flour. Ph.D. Thesis, Oklahoma State University, Stillwater, OK, USA, July 2014. Available online: http://hdl.handle.net/11244/15034 (accessed on 31 May 2021).

- Tan, H.-Z.; Li, Z.-G.; Tan, B. Starch noodles: History, classification, materials, processing, structure, nutrition, quality evaluating and improving. Food Res. Int. 2009, 42, 551–576. [Google Scholar] [CrossRef]

- Chen, Z.; Sagis, L.; Legger, A.; Linssen, J.; Schols, H.; Voragen, A.G.J. Evaluation of starch noodles made from three typical Chinese sweet-potato starches. J. Food Sci. 2002, 67, 3342–3347. [Google Scholar] [CrossRef]

| WEAX Samples | Refrigerated Storage Times | |

|---|---|---|

| Day 0 | Day 3 ** | |

| Control | 107,067 ± 4850 | 93,209 ± 1728 b |

| WWD + TG 0.1% * | 105,406 ± 2328 A | 96,516 ± 541 aB |

| WWD + TG 1% * | 109,692 ± 1179 A | 96,971 ± 834 aB |

| Cooking Loss (%) | Water Absorption (%) | Swelling Index | |

|---|---|---|---|

| Control | |||

| Day 0 | 6.84 ± 0.37 | 98.31 ± 1.52 aA | 2.46 ± 0.04 A |

| Day 1 | 6.75 ± 0.24 | 94.68 ± 1.54 bA | 2.41 ± 0.04 A |

| Day 2 | 7.16 ± 0.26 B | 94.03 ± 1.03 bA | 2.41 ± 0.02 A |

| Day 3 | 7.16 ± 0.23 B | 94.11 ± 1.92 bA | 2.48 ± 0.02 A |

| WWD + TG0.1% | |||

| Day 0 | 6.76 ± 0.19 | 98.08 ± 0.11 aA | 2.42 ± 0.02 aA |

| Day 1 | 6.75 ± 0.28 | 92.78 ± 0.90 bA | 2.33 ± 0.00 bB |

| Day 2 | 6.50 ± 0.10 C | 90.23 ± 0.80 cA | 2.29 ± 0.02 bB |

| Day 3 | 6.83 ± 0.34 B | 87.64 ± 1.85 dB | 2.27 ± 0.04 bB |

| WWD + TG1% | |||

| Day 0 | 6.37 ± 0.07 b | 87.28 ± 1.15 aB | 2.24 ± 0.02 B |

| Day 1 | 7.16 ± 0.50 a | 79.29 ± 2.16 bB | 2.16 ± 0.03 C |

| Day 2 | 7.90 ± 0.45 aA | 76.35 ± 3.11 bB | 2.17 ± 0.10 C |

| Day 3 | 7.96 ± 0.20 aA | 79.75 ± 0.21 bC | 2.24 ± 0.02 B |

| Hardness (g) | Adhesiveness | Springiness | Cohesiveness | Chewiness | Resilience | |

|---|---|---|---|---|---|---|

| Control | ||||||

| Day 0 | 4091 ± 49 aB | −44.62 ± 3.84 bB | 0.81 ± 0.04 | 0.53 ± 0.02 | 1748 ± 93 a | 0.23 ± 0.01 |

| Day 1 | 4224 ± 37 a | −37.20 ± 3.90 abB | 0.80 ± 0.03 | 0.52 ± 0.00 A | 1759 ± 60 a | 0.22 ± 0.00 |

| Day 2 | 3217 ± 634 bB | −32.08 ± 3.27 aB | 0.78 ± 0.05 | 0.54 ± 0.03 | 1336 ± 239 bB | 0.23 ± 0.02 |

| Day 3 | 3078 ± 542 bB | −35.32 ± 6.55 abAB | 0.84 ± 0.00 A | 0.52 ± 0.03 A | 1336 ± 151 bB | 0.24 ± 0.02 A |

| WWN + TG0.1% | ||||||

| Day 0 | 4015 ± 278 B | −40.18 ± 0.61 AB | 0.81 ± 0.01 a | 0.51 ± 0.00 | 1668 ± 117 | 0.23 ± 0.01 |

| Day 1 | 4311 ± 221 | −42.98 ± 0.79 C | 0.76 ± 0.03 b | 0.53 ± 0.03 A | 1715 ± 113 | 0.22 ± 0.01 |

| Day 2 | 4470 ± 150 A | −45.22 ± 0.65 C | 0.77 ± 0.01 b | 0.50 ± 0.03 | 1706 ± 77 A | 0.23 ± 0.00 |

| Day 3 | 4342 ± 244 A | −42.93 ± 9.76 B | 0.75 ± 0.01 bB | 0.51 ± 0.03 A | 1668 ± 13 A | 0.22 ± 0.00 AB |

| WWN + TG1% | ||||||

| Day 0 | 4899 ± 296 A | −34.96 ± 4.28 cA | 0.78 ± 0.01 | 0.51 ± 0.04 | 1734 ± 347 | 0.24 ± 0.00 a |

| Day 1 | 4837 ± 473 | −21.85 ± 0.80 aA | 0.81 ± 0.4 | 0.46 ± 0.01 B | 1793 ±136 | 0.22 ± 0.01 b |

| Day 2 | 5085 ± 32 A | −24.19 ± 0.30 abA | 0.77 ± 0.02 | 0.47 ± 0.02 | 1832 ± 77 A | 0.21 ± 0.01 bc |

| Day 3 | 4842 ± 103 A | −27.24 ± 1.13 bA | 0.77 ± 0.02 B | 0.45 ± 0.00 B | 1677 ± 85 A | 0.20 ± 0.00 cB |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, M.J.; Chung, S.-J.; Kim, S.S. The Effects of Transglutaminase and Refrigerated Storage on the Physicochemical Properties of Whole Wheat Dough and Noodles. Foods 2021, 10, 1675. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10071675

Kang MJ, Chung S-J, Kim SS. The Effects of Transglutaminase and Refrigerated Storage on the Physicochemical Properties of Whole Wheat Dough and Noodles. Foods. 2021; 10(7):1675. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10071675

Chicago/Turabian StyleKang, Min Jeong, Seo-Jin Chung, and Sang Sook Kim. 2021. "The Effects of Transglutaminase and Refrigerated Storage on the Physicochemical Properties of Whole Wheat Dough and Noodles" Foods 10, no. 7: 1675. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10071675