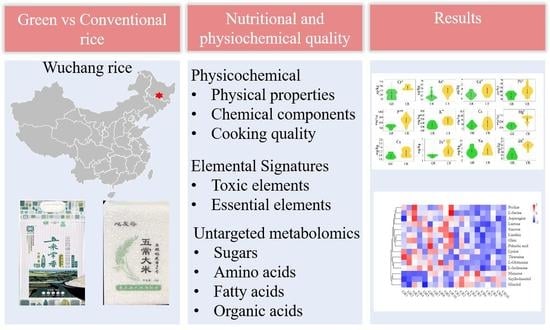

Green Labelled Rice Shows a Higher Nutritional and Physiochemical Quality Than Conventional Rice in China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Chemicals and Reagents

2.3. Physicochemical and Rheological Properties

2.4. Elemental Analysis

2.5. Non-Targeted Metabolomics Analysis

2.6. Data Processing and Multivariate Data Analysis

3. Results and Discussion

3.1. Physicochemical and Rheological Properties

3.1.1. Physical Properties

3.1.2. Main Chemical Components

3.1.3. Rheological Properties

3.2. Elemental Signatures of Green and Conventional Rice

3.2.1. Toxic Elements

3.2.2. Essential Elements

3.3. Untargeted Metabolomics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, X.H.; Gao, Z.F.; Zeng, Y.C. Willingness to pay for the “Green Food” in China. Food Policy 2014, 45, 80–87. [Google Scholar] [CrossRef]

- Qi, X.; Ploeger, A. Explaining consumers’ intentions towards purchasing green food in Qingdao, China: The amendment and extension of the theory of planned behavior. Appetite 2019, 133, 414–422. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Zhou, D.Y.; Ma, C.X. Green food industry in China: Development, problems and policies. Renew. Agric. Food Syst. 2010, 25, 69–80. [Google Scholar] [CrossRef]

- Xu, J.L.; Zhang, Z.H.; Zhang, X.; Ishfaq, M.; Zhong, J.H.; Li, W.; Zhang, F.S.; Li, X.X. Green Food Development in China: Experiences and Challenges. Agriculture 2020, 10, 614. [Google Scholar] [CrossRef]

- Peng, S.B.; Tang, Q.Y.; Zou, Y.B. Current Status and Challenges of Rice Production in China. Plant Prod. Sci. 2009, 12, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Hou, D.P.; Peng, X.L.; Ma, B.J.; Shao, S.M.; Jing, W.J.; Gu, J.F.; Liu, L.J.; Wang, Z.Q.; Liu, Y.Y.; et al. Optimizing integrative cultivation management improves grain quality while increasing yield and nitrogen use efficiency in rice. J. Integr. Agric. 2019, 18, 2716–2731. [Google Scholar] [CrossRef]

- Clark, C.M.; Tilman, D. Loss of plant species after chronic low-level nitrogen deposition to prairie grasslands. Nature 2008, 451, 712–715. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Liu, M.; Liu, J.; Li, W.T.; Jiang, C.Y.; Li, Z.P. Optimize nitrogen fertilization location in root-growing zone to increase grain yield and nitrogen use efficiency of transplanted rice in subtropical China. J. Integr. Agric. 2017, 16, 2073–2081. [Google Scholar] [CrossRef]

- Tang, S.; Zhang, H.X.; Liu, W.Z.; Dou, Z.; Zhou, Q.Y.; Chen, W.Z.; Wang, S.H.; Ding, Y.F. Nitrogen fertilizer at heading stage effectively compensates for the deterioration of rice quality by affecting the starch-related properties under elevated temperatures. Food Chem. 2019, 277, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Sano, O.; Ito, T.; Saigusa, M. Effects of co-situs application of controlled-availability fertilizer on fertilizer and soil nitrogen uptake by rice (Oryza sativa L.) in paddy soils with different available nitrogen. Soil Sci. Plant Nutr. 2008, 54, 769–776. [Google Scholar] [CrossRef]

- Perez, C.M.; Juliano, B.O.; Liboon, S.P.; Alcantara, J.M.; Cassman, K.G. Effects of late nitrogen fertilizer application on head rice yield, protein content, and grain quality of rice. Cereal Chem. 1996, 73, 556–560. [Google Scholar]

- Peng, S.B.; Buresh, R.J.; Huang, J.L.; Zhong, X.H.; Zou, Y.B.; Yang, J.C.; Wang, G.H.; Liu, Y.Y.; Hu, R.F.; Tang, Q.Y.; et al. Improving nitrogen fertilization in rice by site-specific N management. A review. Agron. Sustain. Dev. 2010, 30, 649–656. [Google Scholar] [CrossRef]

- Peng, S.B.; Buresh, R.J.; Huang, J.L.; Zhong, X.H.; Zou, Y.B.; Yang, J.C.; Wang, G.H.; Liu, Y.Y.; Hu, R.F.; Tang, Q.Y.; et al. Improving nitrogen fertilization in rice by site-specific N management. Sustain. Agric. 2011, 2, 943–952. [Google Scholar]

- Ding, W.C.; Xu, X.P.; He, P.; Ullah, S.; Zhang, J.J.; Cui, Z.L.; Zhou, W. Improving yield and nitrogen use efficiency through alternative fertilization options for rice in China: A meta-analysis. Field Crop. Res. 2018, 227, 11–18. [Google Scholar] [CrossRef]

- Xu, M.-G.; Li, D.-C.; Li, J.-M.; Qin, D.Z.; Kazuyuki, Y.; Hosen, Y. Effects of organic manure application with chemical fertilizers on nutrient absorption and yield of rice in Hunan of Southern China. Agric. Sci. China 2008, 7, 1245–1252. [Google Scholar] [CrossRef]

- Naher, U.A.; Panhwar, Q.A.; Othman, R.; Ismail, M.R.; Berahim, Z. Biofertilizer as a supplement of chemical fertilizer for yield maximization of rice. J. Agric. Food Devel. 2016, 2, 16–22. [Google Scholar] [CrossRef]

- Custodio, M.C.; Cuevas, R.P.; Ynion, J.; Laborte, A.G.; Velasco, M.L.; Demont, M. Rice quality: How is it defined by consumers, industry, food scientists, and geneticists? Trends Food Sci. Technol. 2019, 92, 122–137. [Google Scholar] [CrossRef]

- Liu, R.F.; Gao, Z.F.; Yan, G.A.; Ma, H.Y. Why should we protect the interests of “Green Food” certified product growers? Evidence from kiwifruit production in China. Sustainability 2018, 10, 4797. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Liu, Y.X.; Ouyang, X.H.; Hao, J.Q.; Yang, X.S. Comparative environmental impact assessments of green food certified cucumber and conventional cucumber cultivation in China. Renew. Agric. Food Syst. 2018, 33, 432–442. [Google Scholar] [CrossRef]

- Tong, Q.; Anders, S.; Zhang, J.; Zhang, L. The roles of pollution concerns and environmental knowledge in making green food choices: Evidence from Chinese consumers. Food Res. Int. 2020, 130, 108881. [Google Scholar] [CrossRef]

- Song, H.; Lu, B.; Ye, C.; Li, J.; Zhu, Z.; Zheng, L. Fraud vulnerability quantitative assessment of Wuchang rice industrial chain in China based on AHP-EWM and ANN methods. Food Res. Int. 2020, 140, 109805. [Google Scholar] [CrossRef] [PubMed]

- Reddy, C.K.; Luan, F.; Xu, B.J. Morphology, crystallinity, pasting, thermal and quality characteristics of starches from adzuki bean (Vigna angularis L.) and edible kudzu (Pueraria thomsonii Benth). Int. J. Biol. Macromol. 2017, 105, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Zhou, Q.; Liu, J.; Liu, W.; Wang, T.; Zhang, Q.; Jiang, G. High levels of heavy metals in rice (Oryzasativa L.) from a typical E-waste recycling area in southeast China and its potential risk to human health. Chemosphere 2008, 71, 1269–1275. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.L.; Wu, L.Q.; Tong, B.X.; Yin, J.X.; Huang, Z.C.; Li, W.; Li, X.X. Magnesium supplementation alters leaf metabolic pathways for higher flavor quality of Oolong tea. Agriculture 2021, 11, 120. [Google Scholar] [CrossRef]

- Jittanit, W.; Angkaew, K. Effect of superheated-steam drying compared to conventional parboiling on chalkiness, head rice yield and quality of chalky rice kernels. J. Stored Prod. Res. 2020, 87, 1–16. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Y.Z.; Chen, T.T.; Zheng, J.L.; Sun, Y.D.; Chi, D.C. Soil nitrogen regulation using clinoptilolite for grain filling and grain quality improvements in rice. Soil Tillage Res. 2020, 199, 104547. [Google Scholar] [CrossRef]

- Gu, J.F.; Chen, J.; Chen, L.; Wang, Z.Q.; Zhang, H.; Yang, J.C. Grain quality changes and responses to nitrogen fertilizer of japonica rice cultivars released in the Yangtze River Basin from the 1950s to 2000s. Crop J. 2015, 3, 285–297. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.J.; Liang, S.S.; Ponce, K.; Marundon, S.; Ye, G.Y.; Zhao, X.Q. Factors affecting head rice yield and chalkiness in indica rice. Field Crop. Res. 2015, 172, 1–10. [Google Scholar] [CrossRef]

- Balindong, J.L.; Ward, R.M.; Liu, L.; Rose, T.J.; Pallas, L.A.; Ovenden, B.W.; Snell, P.J.; Waters, D.L.E. Rice grain protein composition influences instrumental measures of rice cooking and eating quality. J. Cereal Sci. 2018, 79, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Martin, M.; Fitzgerald, M.A. Proteins in rice grains influence cooking properties. J. Cereal Sci. 2002, 36, 285–294. [Google Scholar] [CrossRef]

- Leesawatwong, M.; Jamjod, S.; Kuo, J.; Dell, B.; Rerkasem, B. Nitrogen fertilizer increases seed protein and milling quality of rice. Cereal Chem. 2005, 82, 588–593. [Google Scholar] [CrossRef] [Green Version]

- Baxter, G.; Blanchard, C.; Zhao, J. Effects of glutelin and globulin on the physicochemical properties of rice starch and flour. J. Cereal Sci. 2014, 60, 414–420. [Google Scholar] [CrossRef]

- Baxter, G.; Zhao, J.A.; Blanchard, C. Albumin significantly affects pasting and textural characteristics of rice flour. Cereal Chem. 2010, 87, 250–255. [Google Scholar] [CrossRef]

- Alves, G.H.; Paraginski, R.T.; Lamas, N.D.; Hoffmann, J.F.; Vanier, N.L.; de Oliveira, M. Effects of organic and conventional cropping systems on technological properties and phenolic compounds of freshly harvested and stored rice. J. Food Sci. 2017, 82, 2276–2285. [Google Scholar] [CrossRef] [PubMed]

- Kaur, M.; Kaur, N.; Kaur, M.; Sandhu, K.S. Some properties of rice grains, flour and starches: A comparison of organic and conventional modes of farming. Lwt-Food Sci. Technol. 2015, 61, 152–157. [Google Scholar] [CrossRef]

- Gunaratne, A.; Sirisena, N.; Ratnayaka, U.K.; Ratnayaka, J.; Kong, X.L.; Arachchi, L.P.V.; Corke, H. Effect of fertiliser on functional properties of flour from four rice varieties grown in Sri Lanka. J. Sci. Food Agric. 2011, 91, 1271–1276. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.M. Effect of combined application of organic and mineral fertilizers on yield, quality and nitrogen uptake of rice. J. Plant Nutr. Fertil. 2012, 18, 234–240. [Google Scholar]

- Bagchi, T.B.; Ghosh, A.; Kumar, U.; Chattopadhyay, K.; Sanghamitra, P.; Ray, S.; Adak, T.; Sharma, S. Comparison of nutritional and physicochemical quality of rice under organic and standard production systems. Cereal Chem. 2016, 93, 435–443. [Google Scholar] [CrossRef]

- Iqbal, A.; Xie, H.; He, L.; Ahmad, S.; Hussain, I.; Raza, H.; Khan, A.; Wei, S.; Quan, Z.; Wu, K.; et al. Partial substitution of organic nitrogen with synthetic nitrogen enhances rice yield, grain starch metabolism and related genes expression under the dual cropping system. Saudi J. Biol. Sci. 2021, 28, 1283–1296. [Google Scholar] [CrossRef]

- Tong, C.; Chen, Y.L.; Tang, F.F.; Xu, F.F.; Huang, Y.; Chen, H.; Bao, J.S. Genetic diversity of amylose content and RVA pasting parameters in 20 rice accessions grown in Hainan, China. Food Chem. 2014, 161, 239–245. [Google Scholar] [CrossRef]

- Kesarwani, A.; Chiang, P.Y.; Chen, S.S. Rapid visco analyzer measurements of japonica rice cultivars to study interrelationship between pasting properties and farming system. Int. J. Agron. 2016, 2016, 3595326. [Google Scholar] [CrossRef] [Green Version]

- Yang, D.; Liu, J.C.; Wang, Q.; Hong, H.L.; Zhao, W.W.; Chen, S.; Yan, C.L.; Lu, H.L. Geochemical and probabilistic human health risk of chromium in mangrove sediments: A case study in Fujian, China. Chemosphere 2019, 233, 503–511. [Google Scholar] [CrossRef] [PubMed]

- Jitaru, P.; Millour, S.; Roman, M.; El Koulali, K.; Noel, L.; Guerin, T. Exposure assessment of arsenic speciation in different rice types depending on the cooking mode. J. Food Compos. Anal. 2016, 54, 37–47. [Google Scholar] [CrossRef]

- Londonio, A.; Morzan, E.; Smichowski, P. Determination of toxic and potentially toxic elements in rice and rice-based products by inductively coupled plasma-mass spectrometry. Food Chem. 2019, 284, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Fei, M.L.; Jin, Y.K.; Jin, L.; Su, J.; Ruan, Y.; Wang, F.; Liu, C.L.; Sun, C.X. Adaptation of rice to the nordic climate yields potential for rice cultivation at most northerly site and the organic production of low-arsenic and high-protein rice. Front Plant Sci. 2020, 11, 329. [Google Scholar] [CrossRef]

- Islam, S.; Rahman, M.M.; Rahman, M.A.; Naidu, R. Inorganic arsenic in rice and rice-based diets: Health risk assessment. Food Control 2017, 82, 196–202. [Google Scholar] [CrossRef]

- Ma, X.M.; Sharifan, H.; Dou, F.G.; Sun, W.J. Simultaneous reduction of arsenic (As) and cadmium (Cd) accumulation in rice by zinc oxide nanoparticles. Chem. Eng. J. 2020, 384, 123802. [Google Scholar] [CrossRef]

- Han, C.L.; Wu, L.H.; Tan, W.N.; Zhong, D.X.; Huang, Y.J.; Luo, Y.M.; Christie, P. Cadmium distribution in rice plants grown in three different soils after application of pig manure with added cadmium. Environ. Geochem. Hlth. 2012, 34, 481–492. [Google Scholar] [CrossRef] [PubMed]

- Gomez, D.; Nakazawa, T.; Furuta, N.; Smichowski, P. Multielemental chemical characterisation of fine urban aerosols collected in Buenos Aires and Tokyo by plasma-based techniques. Microchem. J. 2017, 133, 346–351. [Google Scholar] [CrossRef]

- Fang, Y.; Sun, X.Y.; Yang, W.J.; Ma, N.; Xin, Z.H.; Fu, J.; Liu, X.C.; Liu, M.; Mariga, A.M.; Zhu, X.F.; et al. Concentrations and health risks of lead, cadmium, arsenic, and mercury in rice and edible mushrooms in China. Food Chem. 2014, 151, 379. [Google Scholar] [CrossRef]

- Razzaque, M.S. Magnesium: Are we consuming enough? Nutrients 2018, 10, 1863. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- DiNicolantonio, J.J.; O’Keefe, J.H.; Wilson, W. Subclinical magnesium deficiency: A principal driver of cardiovascular disease and a public health crisis. Open Heart 2018, 5, e000668. [Google Scholar] [CrossRef]

- Jiang, S.L.; Wu, J.G.; Feng, Y.; Yang, X.E.; Shi, C.H. Correlation analysis of mineral element contents and quality traits in milled rice (Oryza stavia L.). J. Agric. Food Chem. 2007, 55, 9608–9613. [Google Scholar] [CrossRef] [PubMed]

- Shengzhe, E.; Jichao, Y.; Zhiyong, D.; Fengjuan, Y.; Xiaoping, Y.; Fuxiang, L. Effect of N, P, K, fertilizer on Fe, Zn, Cu, Mn, Ca, and Mg contents and yields in rice. Chin. J. Rice Sci. 2005, 19, 434–440, (In Chinese with English abstract). [Google Scholar]

- Antoine, J.M.R.; Fung, L.A.H.; Grant, C.N.; Dennis, H.T.; Lalor, G.C. Dietary intake of minerals and trace elements in rice on the Jamaican market. J. Food Compos. Anal. 2012, 26, 111–121. [Google Scholar] [CrossRef]

- Glahn, R.P.; Cheng, Z.; Welch, R.M.; Gregorio, G.B. Comparison of iron bioavailability from 15 rice genotypes: Studies using an in vitro digestion/Caco-2 cell culture model. J. Agric. Food Chem. 2002, 50, 3586–3591. [Google Scholar] [CrossRef]

- Swamy, B.P.M.; Rahman, M.A.; Inabangan-Asilo, M.A.; Amparado, A.; Manito, C.; Chadha-Mohanty, P.; Reinke, R.; Slamet-Loedin, I.H. Advances in breeding for high grain Zinc in Rice. Rice 2016, 9, 49. [Google Scholar] [CrossRef] [Green Version]

- Xiao, G.; Hu, Y.; Li, N.; Yang, D. Spatial autocorrelation analysis of monitoring data of heavy metals in rice in China. Food Control 2018, 89, 32–37. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, M.; Liu, X.; Wu, L.; Zhao, B.; Wu, C. Spatio-temporal index based on time series of leaf area index for identifying heavy metal stress in rice under complex stressors. Int. J. Environ. Res. Public Health 2020, 17, 2265. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.-H. The combined use of chemical and organic fertilizers and/or biofertilizer for crop growth and soil fertility. In Proceedings of the International Workshop on Sustained Management of the Soil-Rhizosphere System for Efficient Crop Production and Fertilizer Use, Land Development Department, Bangkok, Thailand, 16–20 October 2006; pp. 1–11. [Google Scholar]

- Wang, F.; Lin, C.; Li, Q.H.; He, C.M.; Li, Y.; Lin, X.J. Effects of long-term fertilization on rice grain qualities and soil fertility factors in yellow paddy fields of southern China. Plant Nutr. Fertil. Sci. 2011, 17, 283–290. [Google Scholar]

- Xiang, C.; Zhang, P.; Pan, G.; Qiu, D.; Chu, Q. Changes in diversity, protein content, and amino acid composition of earthworms from a paddy soil under different long-term fertilizations in the Tai Lake Region, China. Acta Ecologica Sinica 2006, 26, 1667–1673. [Google Scholar] [CrossRef]

- Park, J.-H.; Nam, S.-H.; Kim, Y.-O.; Kwon, O.-D.; An, K.-N. Comparison of quality, physiochemical and functional property between organic and conventional rice. J. Korean Soc. Food Sci. Nutr. 2010, 39, 725–730. [Google Scholar] [CrossRef]

- Chung, I.M.; Kim, J.K.; An, Y.J.; Kwon, C.; Kim, S.Y.; Yang, Y.J.; Yarnes, C.T.; Chi, H.Y.; Kim, S.H. Compound-specific δ(13)C and δ(15)N analyses of fatty acids and amino acids for discrimination of organic, pesticide-free, and conventional rice (Oryza sativa L.). Food Chem. 2019, 283, 305–314. [Google Scholar] [CrossRef]

- Lu, C.Y.; Chen, H.H.; Teng, Z.Z.; Yuan, L.; Ma, J.; He, H.B.; Chen, X.; Zhang, X.D.; Shi, Y. Effects of N fertilization and maize straw on the dynamics of soil organic N and amino acid N derived from fertilizer N as indicated by N-15 labeling. Geoderma 2018, 321, 118–126. [Google Scholar] [CrossRef]

- Rashid, M.M.; Jahan, M.; Islam, K.S. Impact of nitrogen, phosphorus and potassium on brown planthopper and tolerance of its host rice plants. Rice Sci. 2016, 23, 119–131. [Google Scholar] [CrossRef] [Green Version]

- Kitta, K.; Ebihara, M.; Iizuka, T.; Yoshikawa, R.; Isshiki, K.; Kawamoto, S. Variations in lipid content and fatty acid composition of major non-glutinous rice cultivars in Japan. J. Food Compos. Anal. 2005, 18, 269–278. [Google Scholar] [CrossRef]

- Zhang, Q.C.; Shamsi, I.H.; Xu, D.T.; Wang, G.H.; Lin, X.Y.; Jilani, G.; Hussain, N.; Chaudhry, A.N. Chemical fertilizer and organic manure inputs in soil exhibit a vice versa pattern of microbial community structure. Appl. Soil Ecol. 2012, 57, 1–8. [Google Scholar] [CrossRef]

- Calder, P.C. Functional roles of fatty acids and their effects on human health. Jpen-Parenter Enter. 2015, 39, 18s–32s. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Green Rice | Conventional Rice |

|---|---|---|

| Thousand kernel weight (g) | 21.08 ± 3.23 a | 20.21 ± 3.11 b |

| Bulk density (g/mL) | 0.98 ± 0.12 a | 0.96 ± 0.09 a |

| Chalkiness (%) | 8.31 ± 1.47 b | 9.94 ± 2.26 a |

| Percentage of chalky kernels | 22.46 ± 5.06 b | 26.15 ± 3.43 a |

| Moisture content (g/100 g) | 11.65 ± 0.23 a | 11.53 ± 0.31 a |

| Protein (g/100 g) | 7.11 ± 0.56 b | 7.42 ± 0.71 a |

| Fat content (g/100 g) | 0.80 ± 0.12 a | 0.77 ± 0.13 a |

| Amylose content (g/100 g) | 17.2 ± 0.82 a | 16.3 ± 0.91 b |

| Parameters | GR | CR |

|---|---|---|

| Peak viscosity (cP) | 4250 ± 371 a | 4055 ± 411 b |

| Final viscosity (cP) | 4353 ± 324 a | 4132 ± 321 b |

| Breakdown viscosity (cP) | 1526 ± 142 a | 1478 ± 156 a |

| Setback viscosity (cP) | 1011 ± 179 b | 1231 ± 165 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Zhong, J.; Zhang, B.; Li, X. Green Labelled Rice Shows a Higher Nutritional and Physiochemical Quality Than Conventional Rice in China. Foods 2021, 10, 915. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10050915

Xu J, Zhong J, Zhang B, Li X. Green Labelled Rice Shows a Higher Nutritional and Physiochemical Quality Than Conventional Rice in China. Foods. 2021; 10(5):915. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10050915

Chicago/Turabian StyleXu, Jiuliang, Jiahui Zhong, Baozhen Zhang, and Xuexian Li. 2021. "Green Labelled Rice Shows a Higher Nutritional and Physiochemical Quality Than Conventional Rice in China" Foods 10, no. 5: 915. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10050915